Working roller bending device for double-roller rolling machine and roller bending force control method

A work roll bending and four-high rolling mill technology, applied in metal rolling, profile control, metal rolling, etc., can solve problems such as cylinder size and valve capacity waste, and achieve fewer cylinders, fewer maintenance points, and avoidance of Effects of Offset Loading Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

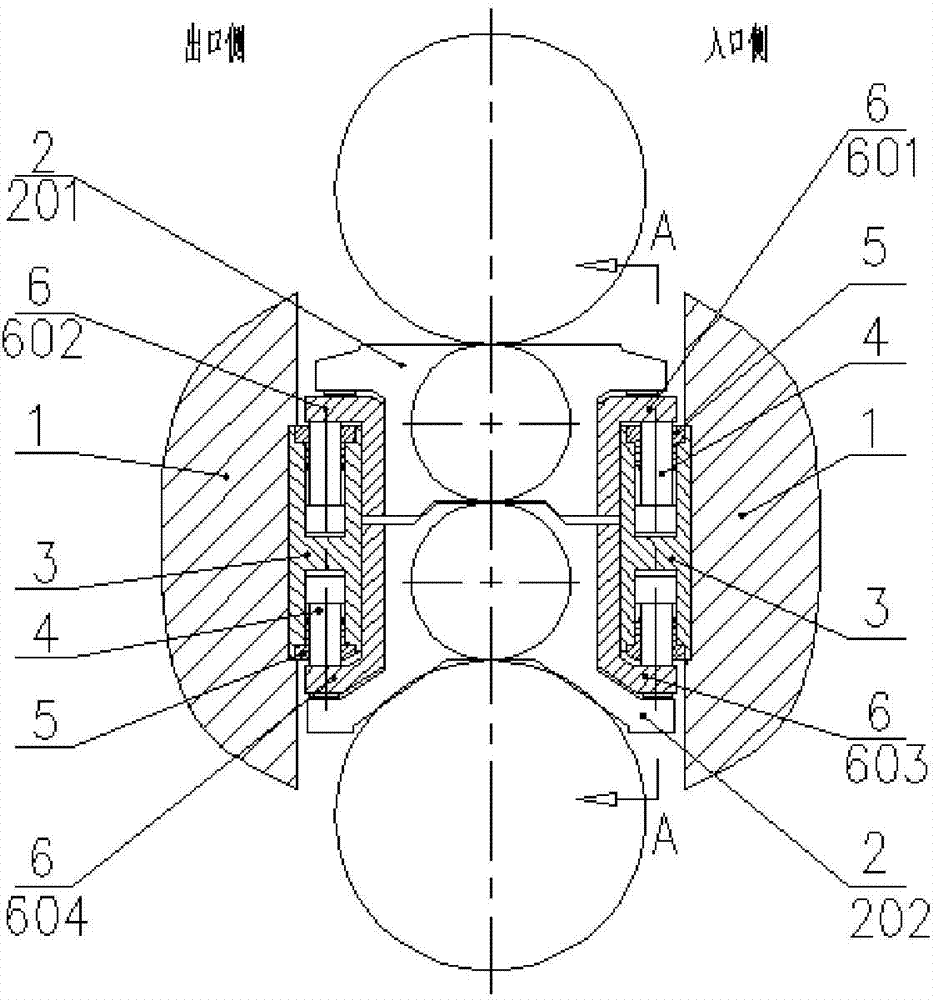

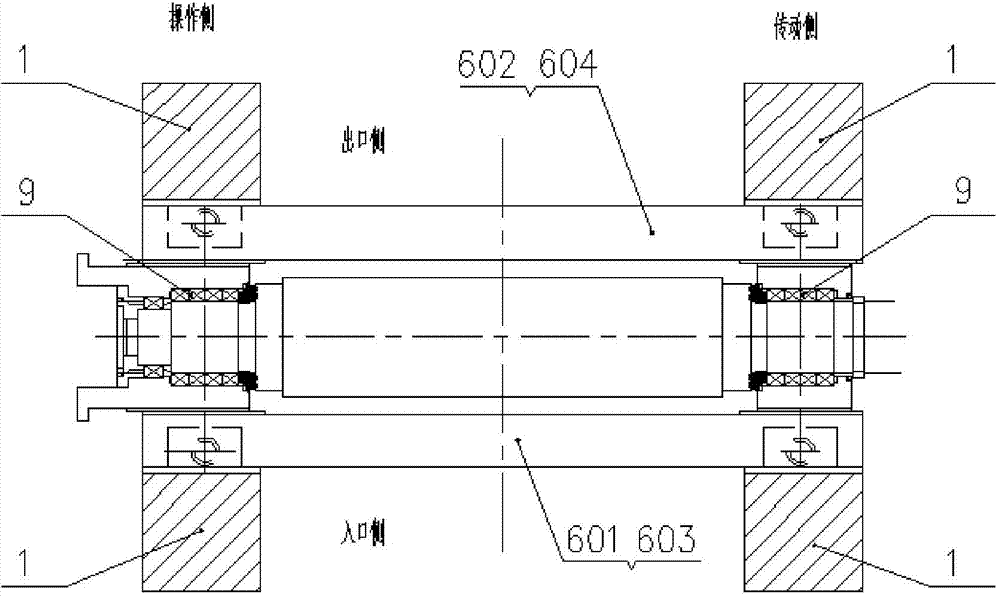

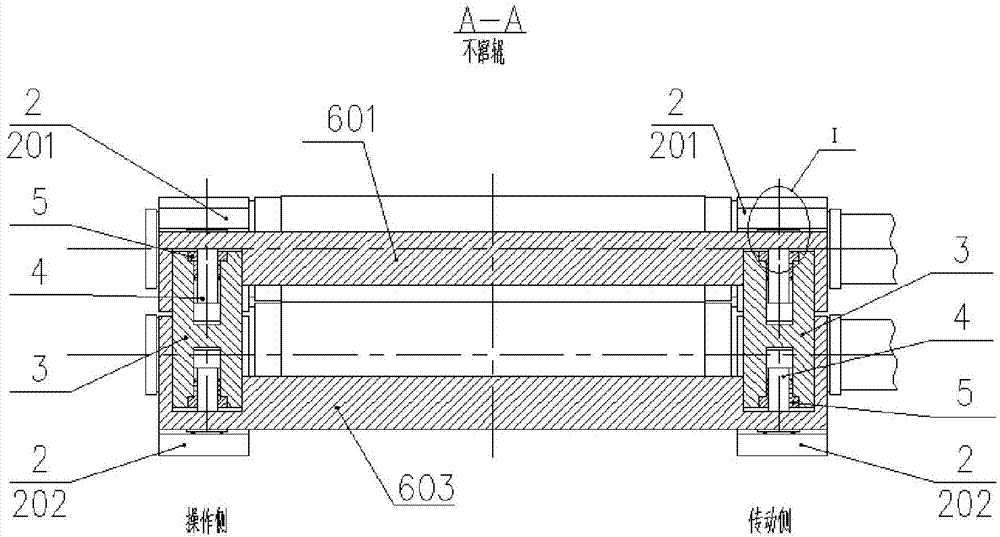

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown: a work roll bending device of a four-high rolling mill, the rolling mill includes an arch 1, work rolls and backup rolls, the arch 1 is provided with a transmission side and an operation side, and the two ends of the work roll are provided with bearings seat, the work roll bearing seat 2 is set in the window of the archway, and it is characterized in that: the roll bending device includes a roll bending mechanism for providing bending force to the work roll, and the roll bending mechanism is provided with a bending block 3 And the bending beam 6, the bending block 3 is fixedly installed in the window o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com