Sleeve uninstalling device

A technology for unloading sleeves and hydraulic cylinders is applied in the field of unloading sleeve devices, which can solve the problems of sleeve inclination and cumbersomeness, and achieve the effects of balanced force, improved productivity, and saving time and human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention relates to the technical field of finishing equipment for metal strips, in particular to a sleeve unloading device.

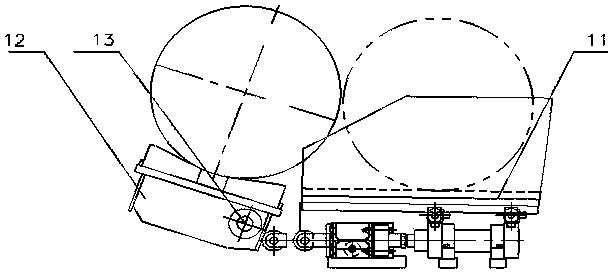

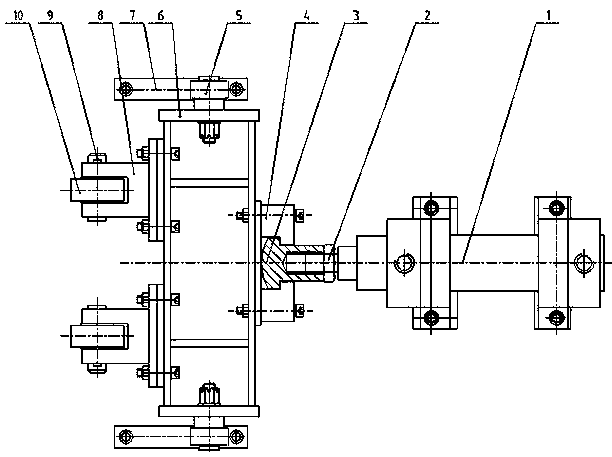

[0014] see figure 1 and figure 2 Shown, the concrete structure of a kind of unloading sleeve device that the present invention relates to is:

[0015] Including hydraulic cylinder 1, oil cylinder joint 3, clamping plate 4, first wheel 5, frame body 6, track 7, support 8, second wheel 10, collection basket 11 and trolley bracket 12; among them,

[0016] The hydraulic cylinder 1 is fixed, the hydraulic cylinder 1 is connected with the clamp 4 through the cylinder joint 3, the clamp 4 is further connected with the frame body 6, and the frame body 6 is connected with the support 8 again,

[0017] The first wheel 5 is arranged on both sides of the frame body 6, and the lower end of the first wheel 5 is provided with a track 7. During work, the first wheel 5 rolls on the track 7, and the second wheel 10 is installed on the support 8.

[0018]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com