Method for controlling drilling hole sites of aircraft structural parts

A technology of aircraft structural parts and control methods, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of rigid structure hole drilling hole position deviation and high quality risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

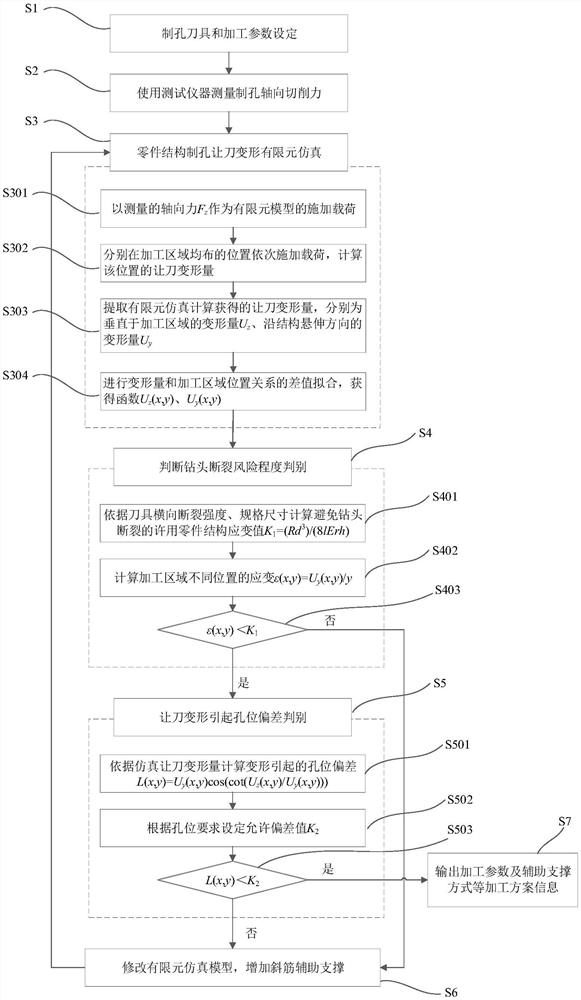

[0046] A method for controlling hole positions of aircraft structural parts, comprising the steps of:

[0047] The first step: setting of hole making tool and processing parameters;

[0048] Furthermore, the first step is specifically: facing the material characteristics of the processed parts, comprehensively considering factors such as hole diameter, surface quality, cutting force and vibration, selecting the hole-making tool and processing parameters for processing the part, and selecting the hole-making tool and processing parameters for the machining of the part. In this case, the hole making meets the processing quality requirements.

[0049] Step 2: Use a measuring instrument to measure the axial cutting force of the hole;

[0050] Furthermore, the second step is specifically: use cutting force testing equipment, design the test piece and conduct cutting tests according to the hole-making tool and processing parameters selected for part processing, collect cutting forc...

Embodiment 2

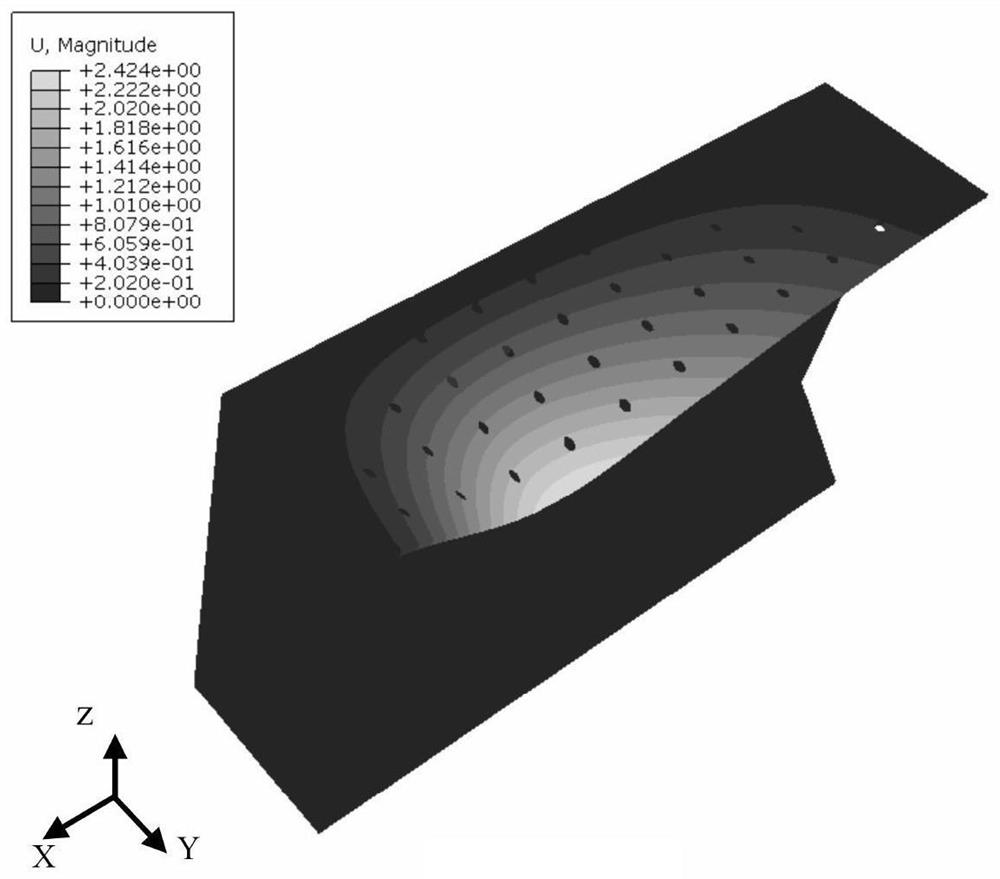

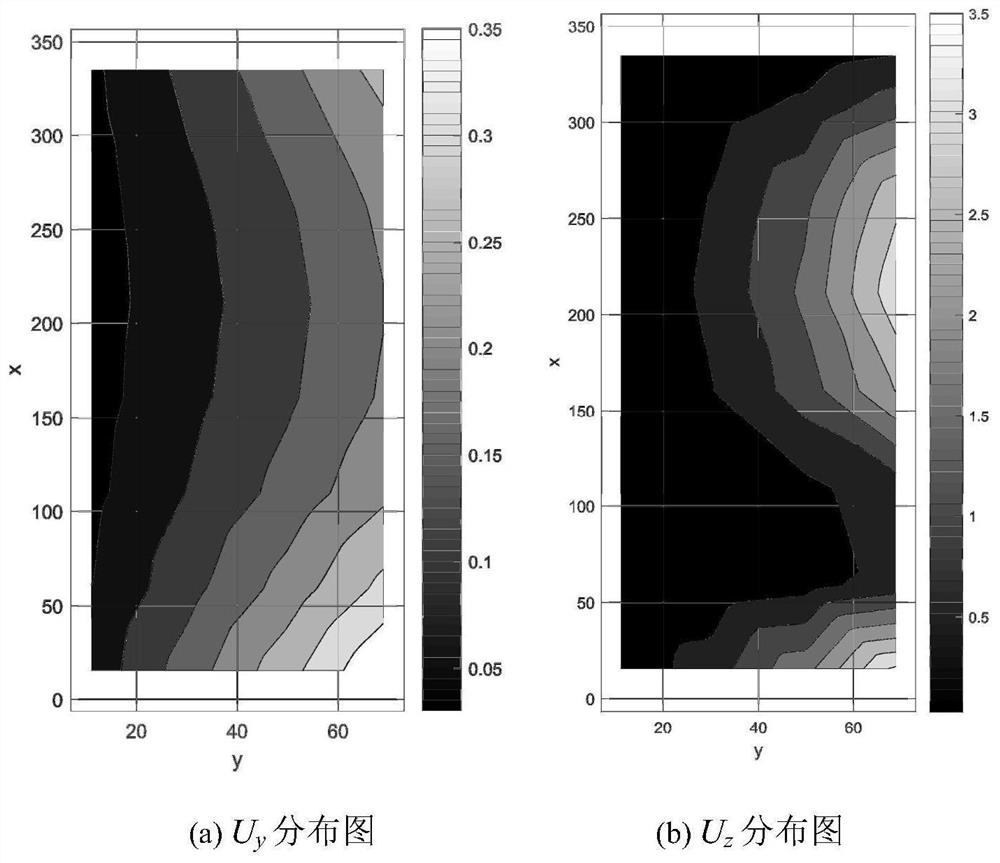

[0077] The present invention proposes a method for controlling the position of holes in aircraft structural parts, and the specific implementation contents are as follows:

[0078] S1: Hole making tool and processing parameter setting

[0079] Facing the material characteristics of the processed part 1, comprehensively considering the factors such as the hole diameter, surface quality, cutting force and vibration, the hole-making tool and processing parameters for the processing of the part 1 are selected, and the hole making under the working condition with good rigidity meets the processing quality Requirements, in this example, a twist drill with a diameter of 6mm is used, the cutting parameters are the speed of 1000mm / min, the feed rate of 100mm / r, the through hole 2 is made, and the cutting fluid is poured.

[0080] S2: Use measuring instruments to measure the axial cutting force of hole making

[0081] Use the cutting force testing instrument, use the hole-making tool a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com