Method and apparatus for identifying polygonization of high speed train wheels

A high-speed EMU, polygonal technology, applied in signal pattern recognition, character and pattern recognition, instruments, etc., can solve the problem that the state monitoring technology of wheels and deformation parts lags behind market demand and affects the comfort, safety and environmental protection of high-speed railways , Restricting the service quality of the high-speed railway network, etc., to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

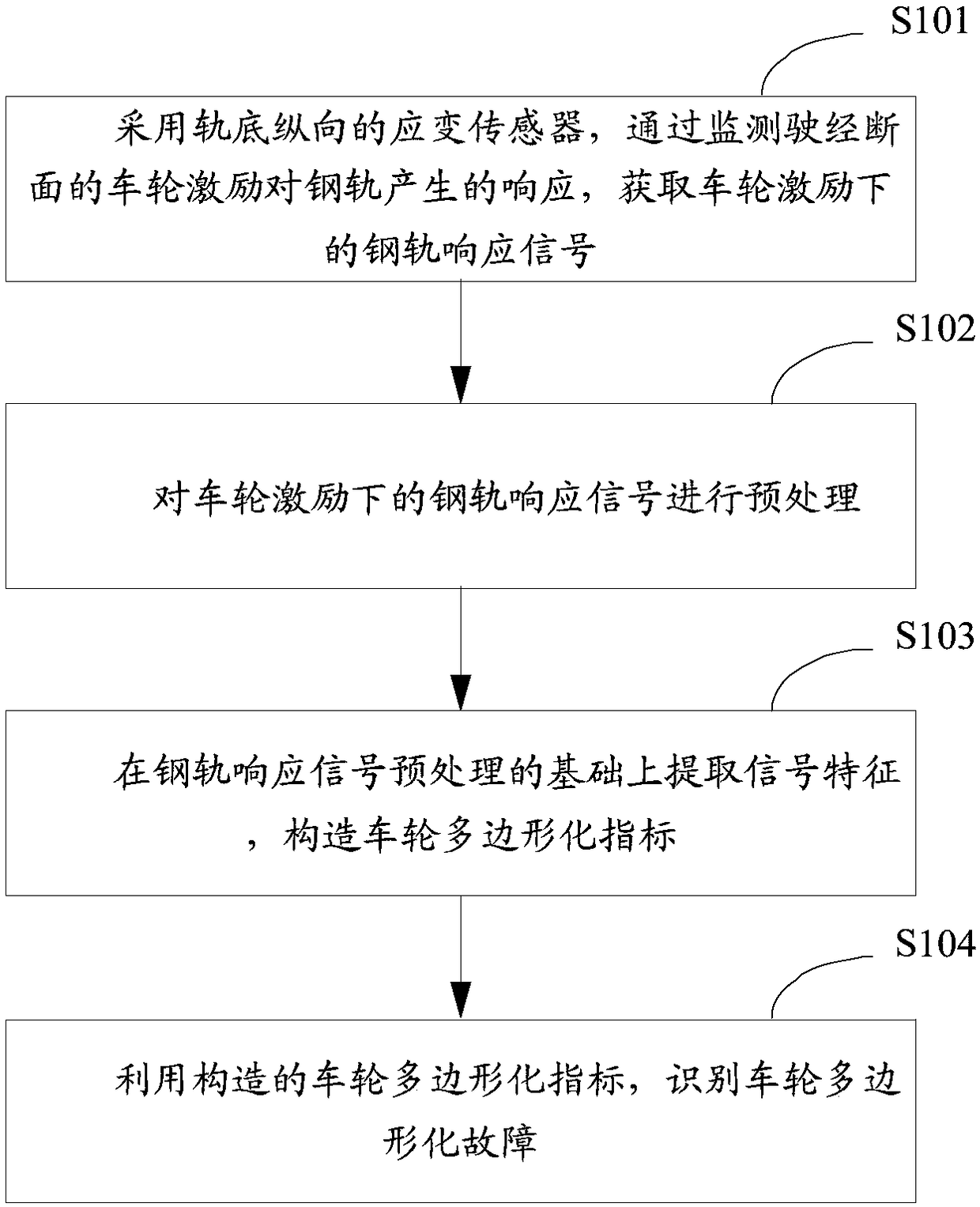

[0043] refer to figure 1 , figure 1It is a flow chart of the implementation of the high-speed EMU wheel polygon recognition method provided by the embodiment of the present invention. This method is applied to the terminal, such as figure 1 Shown, the recognition method of this high-speed EMU wheel polygonization can comprise the following steps:

[0044] S101, using a longitudinal strain sensor at the bottom of the rail to obtain the rail response signal under the wheel excitation by monitoring the response of the wheel excitation to the rail passing through the section;

[0045] When the wheel passes the bottom of the rail, execute S101.

[0046] Optionally, before S101, the identification method includes:

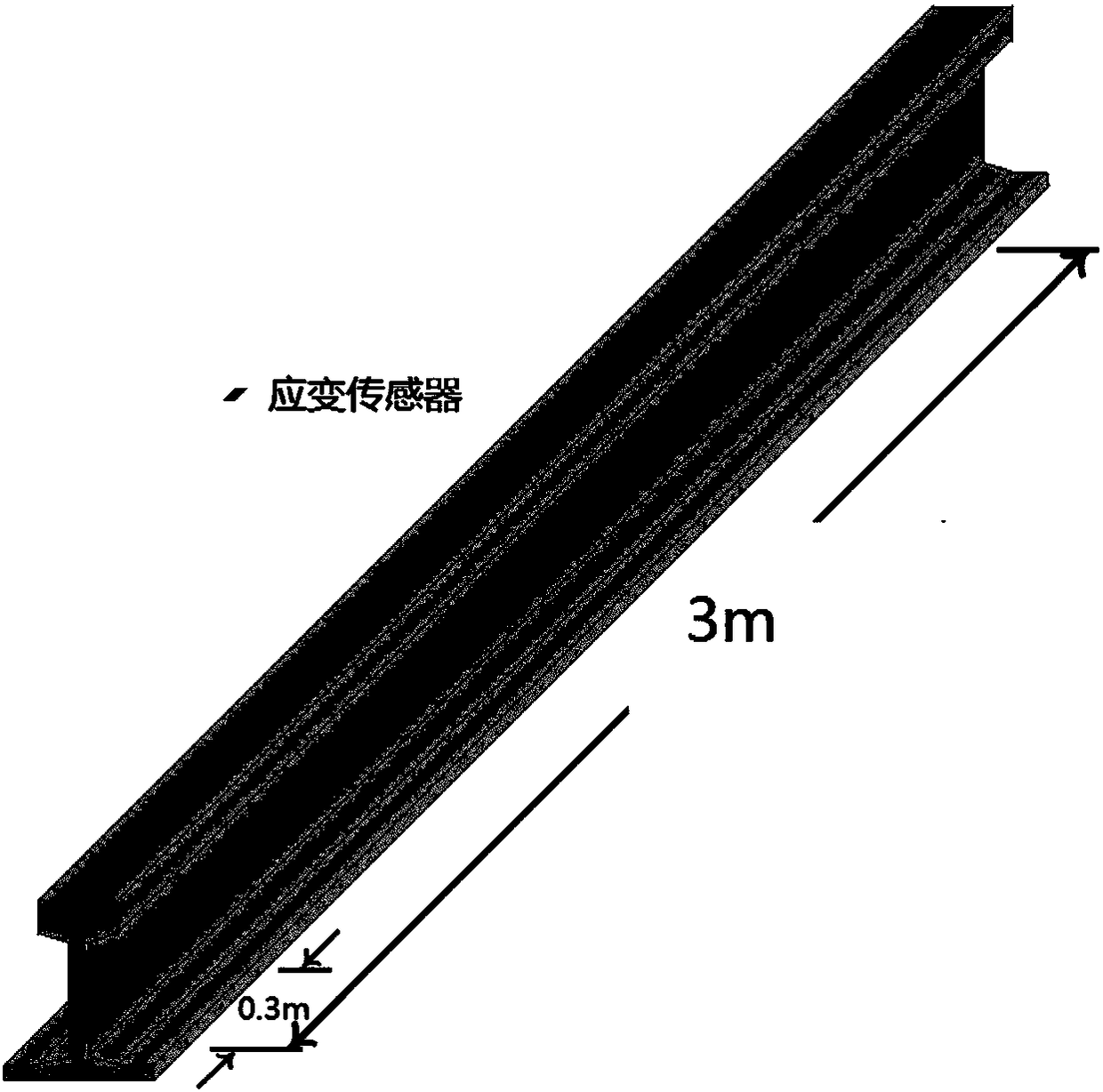

[0047] On the steel rail of the left rail or the right rail, strain sensors are arranged longitudinally to form a strain sensor array, so as to realize polygonal fault detection covering the entire wheel tread circumference.

[0048] Wherein, the strain sensors are a...

Embodiment 2

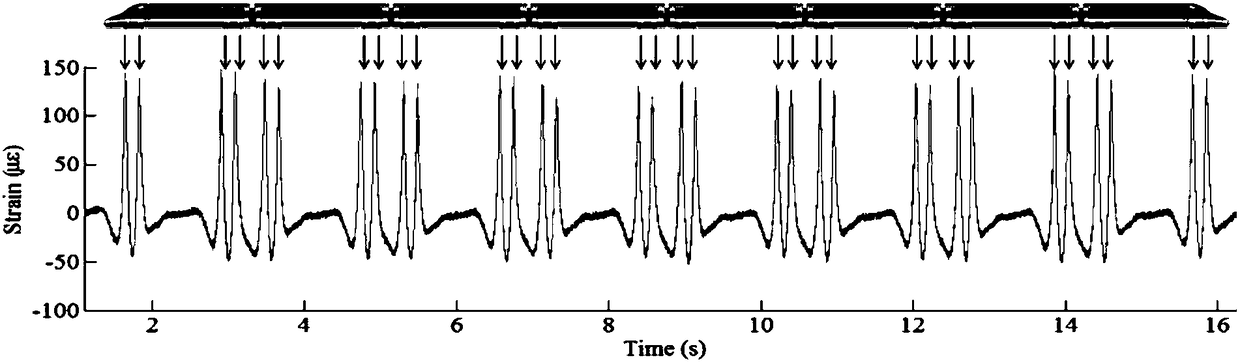

[0070] The embodiment of the present invention describes the implementation process of rail response signal extraction and vehicle speed calculation under the excitation of each wheel, which is described in detail as follows:

[0071] Identify the peak value Ps of the signal collected by a single strain sensor and the time Pt corresponding to the peak value, and take the number of points (N-1) / 2 on the left and right sides of each peak value to form an N×1 sequence si,j together with the peak value, which is the ith The track bottom strain response signal under the excitation of the jth wheel collected by a strain sensor;

[0072] Among them, i∈(1,M), M is the number of strain sensors in the single-side track bottom strain sensor array, j∈(1,L), Ps and Pt are both 1×L vectors, and L is the wheel set of the entire EMU Number, the sequence length N is an adjustable parameter. The sequence length N can be adjusted according to the sampling frequency and the relationship betwee...

Embodiment 3

[0094] The embodiment of the present invention describes the implementation process of wheel polygon fault feature extraction, which is described in detail as follows:

[0095] The feature extraction of wheel polygonal fault is based on the preprocessing of the rail response signal, and the signal feature extraction is performed on the rail response signal S' after the trend disappears.

[0096] Firstly, formula (1) is rewritten as a function of the frequency of the response signal as the order of the polygon:

[0097]

[0098] As mentioned above, a polygonized wheel of a certain order will excite a fixed-frequency rail response, and the response energy will be concentrated in a narrow-band frequency range. In order to identify the order of the polygon, the rail strain response signal can be decomposed according to different frequency bands. The center frequency of each frequency band is f(h), which is determined by a specific order h, and the upper and lower limit frequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com