Method for monitoring deformation of tunnel pipe-roof

A deformation monitoring and tunnel tube technology, applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of reducing the reliability of inclinometers, reading errors of inclinometers, monitoring interruptions, etc., and achieve simple and practical calculation methods, eliminating The effect of temperature influence and high monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with specific drawings.

[0054] For example Figure 4 The pipe shed shown is monitored, and three steel pipes (the steel pipe to be tested I1.1; the steel pipe to be tested II 1.2; the steel pipe to be tested III 1.3) are selected for monitoring.

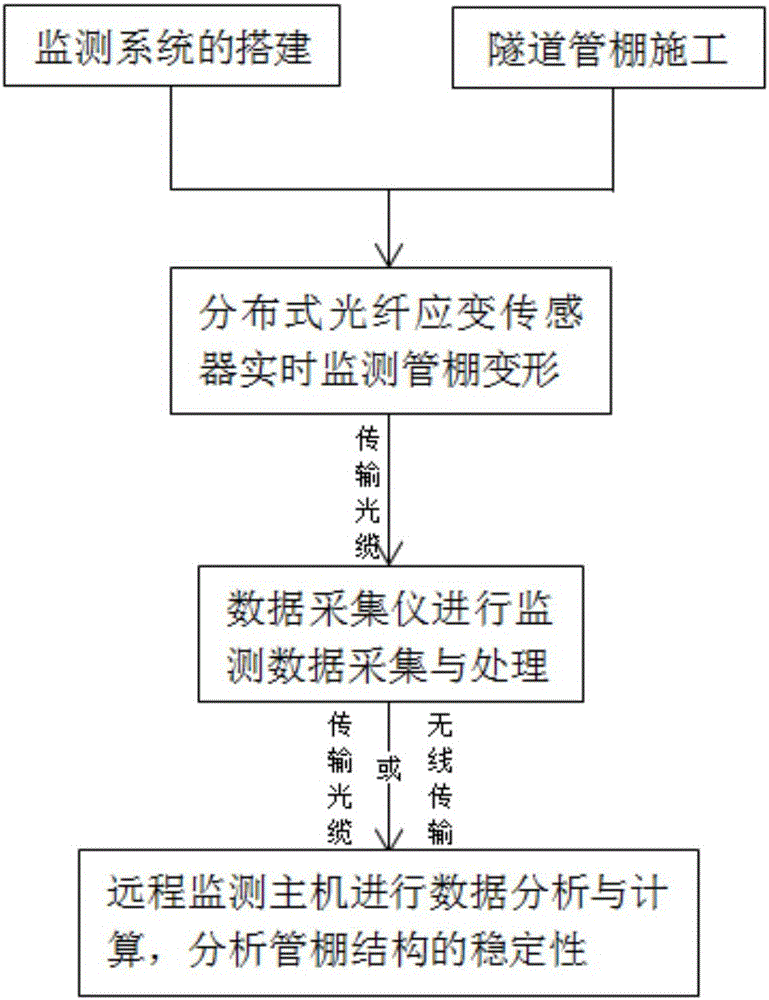

[0055] For each steel pipe to be tested according to the following figure 2 , 3 The arrangement scheme shown is to monitor the deformation of the tunnel pipe shed, including the following steps:

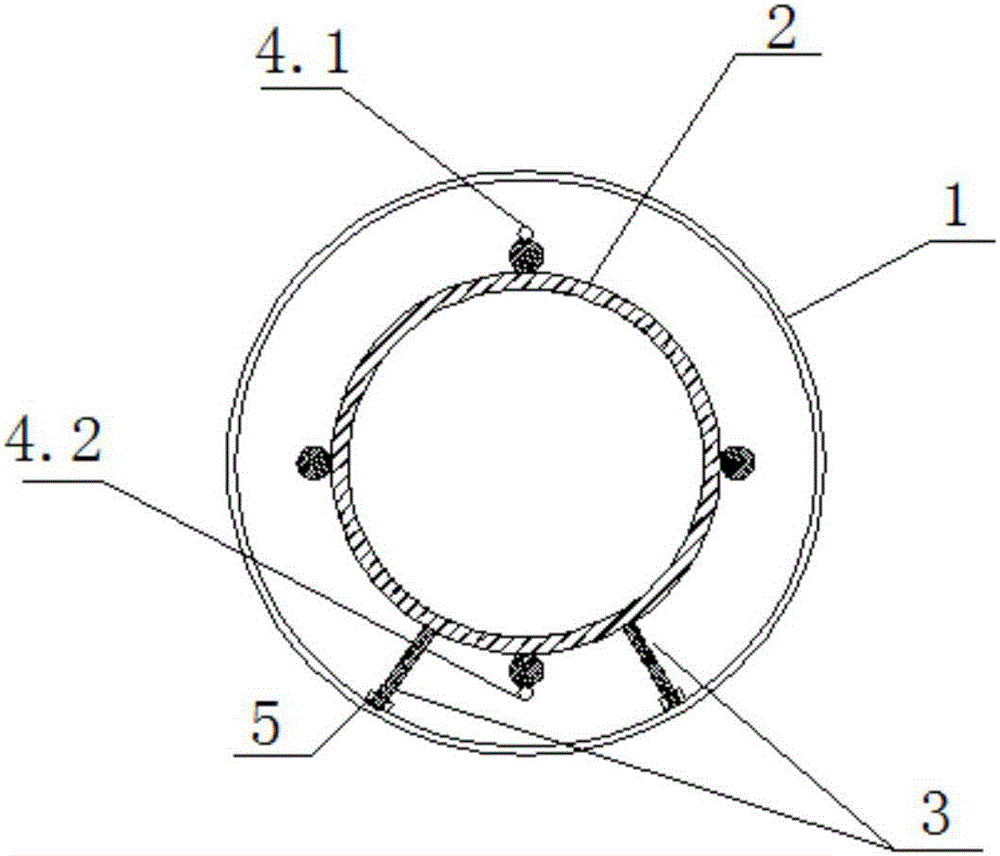

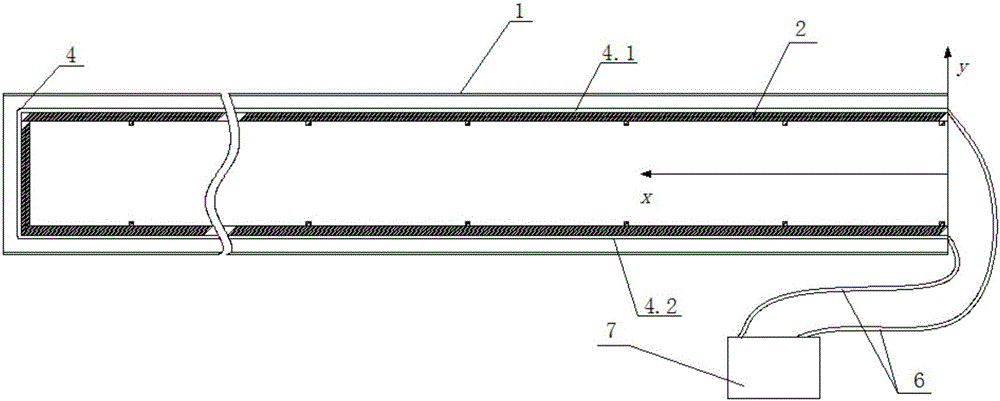

[0056] (1) Layout of the distributed optical fiber sensing circuit 4: After the pipe shed is drilled, the steel pipe 1 to be tested is selected at the tunnel vault and the arch waist position, and then a cylindrical steel cage 2 is prefabricated, and the steel bar The cage 2 is placed horizontally, and the reinforcement support 3 with the push roller 5 is welded below the reinforcement cage 2 . Take the axial cross-section perpendicular to the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com