Regenerating and recycling method for ferric trichloride etching liquid

A technology of ferric chloride etching and etching solution, which is applied in the field of regeneration and recycling of etching waste solution, can solve the problems of complicated process, increased regeneration cost and solid waste discharge, and is not suitable for large-scale industrial application, and achieves simplified operation. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

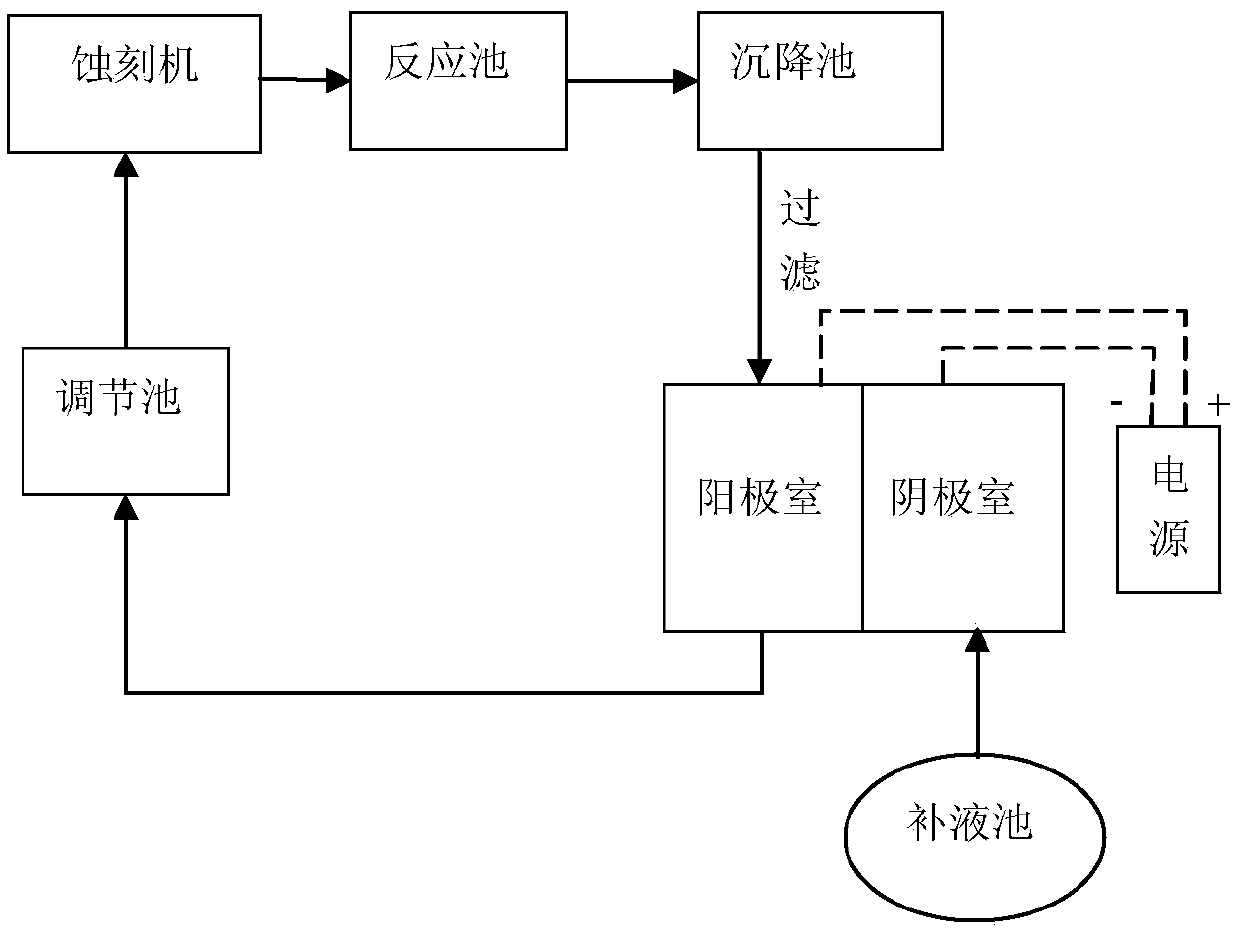

Method used

Image

Examples

Embodiment 1

[0024]Batch operation: Take a certain volume of ferric chloride etching waste solution, and use ICP-MS to detect that it contains 205g / L of total iron, 104mg / L of Cr, 1069mg / L of Mn, and 741mg / L of Cu. Adjust the pH of the waste liquid to 2-3, add a chemical precipitant to the reaction tank, and after filtering through the sedimentation tank, take the supernatant and introduce it into the anode chamber, using titanium plates as cathode and anode respectively, with a current density of 18A / dm 2 Add the pre-prepared electrolyte to the cathode chamber, monitor the concentration of the electrolyte in the cathode chamber according to the concentration detector, replenish the electrolyte consumed in the electrolysis process in time, and keep the temperature between 50-60°C; the Fe in the waste liquid of the anode chamber 2+ Oxidized to Fe 3+ , the etching ability gradually recovers, the waste etching solution is regenerated, and the Fe 2+ The concentration is 0.3g / L, and the conver...

Embodiment 2

[0026] On-line operation: random monitoring of ferric chloride etching waste liquid, with ICP-MS detection of total iron 178g / L, Cr 243mg / L, Mn 1927mg / L, Ni 5964mg / L in the waste liquid; regular precipitation removal Miscellaneous treatment, adjust the pH2-3 during treatment, add chemical precipitant to the reaction tank, filter through the sedimentation tank for use, and do not need precipitation treatment during online operation; the etching waste liquid is directly and continuously introduced into the lower inlet of the anode chamber, and flows out from the upper outlet anode chamber. The titanium plate is used as cathode and anode respectively, and the current density is 16A / dm 2 . The cathode chamber is filled with pre-prepared electrolyte, and the electrolyte consumed in the electrolysis process is replenished in time, and the temperature is kept between 50-60°C. Fe in anode chamber waste 2+ Oxidized to Fe 3+ , the etching ability gradually recovers, the waste etchin...

Embodiment 3

[0028] Take a certain volume of ferric chloride etching waste solution, and use ICP-MS to detect that the waste solution contains 193g / L of total iron, 89mg / L of Cr, 44mg / L of Ni, 1033mg / L of Mn, and 569mg / L of Cu. Adjust the pH of the waste liquid to 2-3, add a chemical precipitant to the reaction tank, and after filtering through the sedimentation tank, take the supernatant and introduce it into the anode chamber, and use the graphite plate as the cathode and anode respectively. Current density 20A / dm 2 . The cathode chamber is filled with pre-prepared electrolyte, and the electrolyte consumed in the electrolysis process is replenished in time, and the temperature is kept between 50-60°C. Fe in anode chamber waste 2+ Oxidized to Fe 3+ , the etching ability gradually recovers, the waste etching solution is regenerated, and the Fe 2+ The concentration is 0.5g / L, and the conversion rate reaches 95%. The regenerated anolyte enters the adjustment pool, and according to the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com