Monitoring system and monitoring method applied to industrial robot

An industrial robot and monitoring system technology, applied in the field of monitoring systems, can solve the problems of high misjudgment rate and low efficiency of real-time monitoring system, and achieve the effect of high monitoring efficiency, improving reliability and safety, and avoiding misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

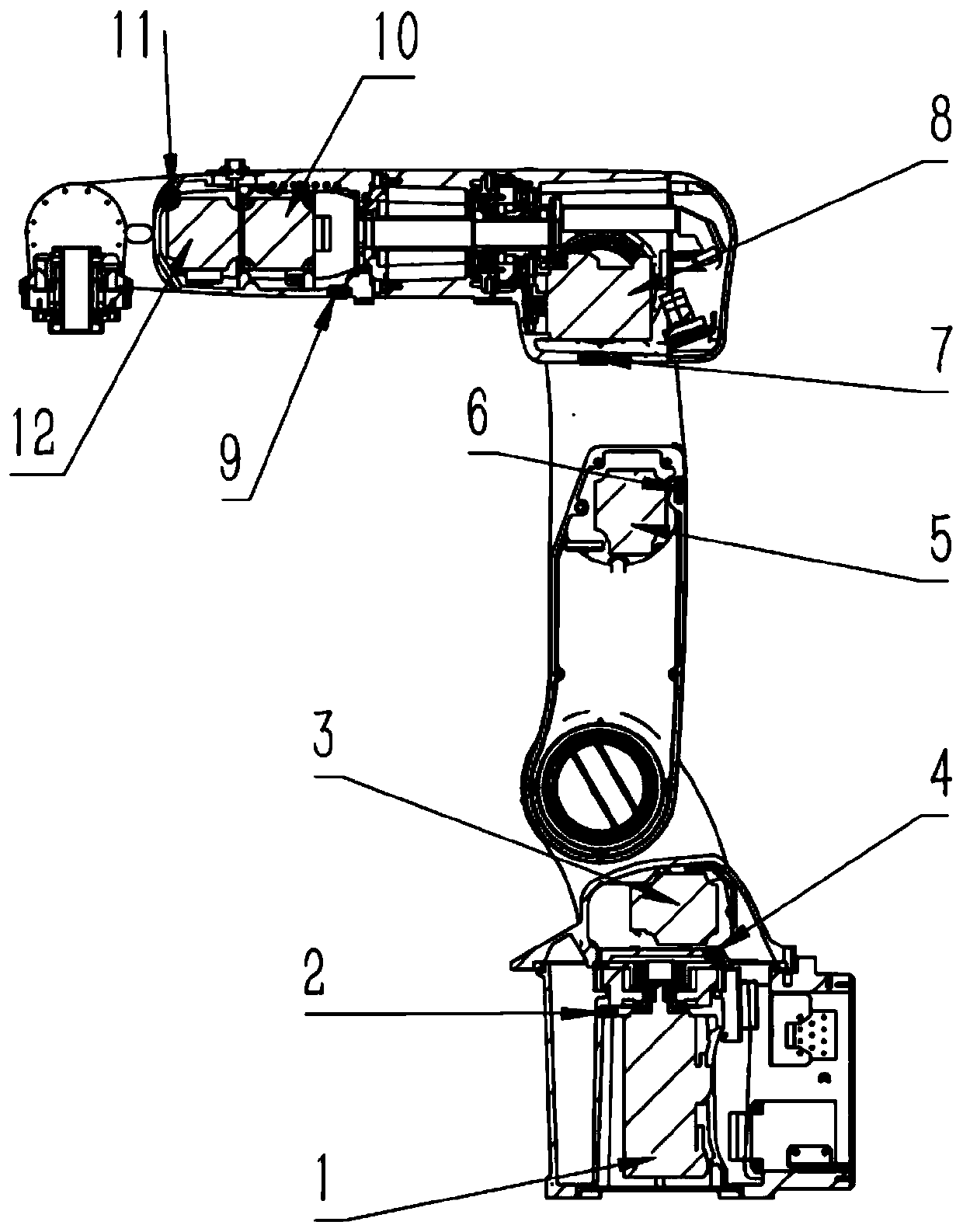

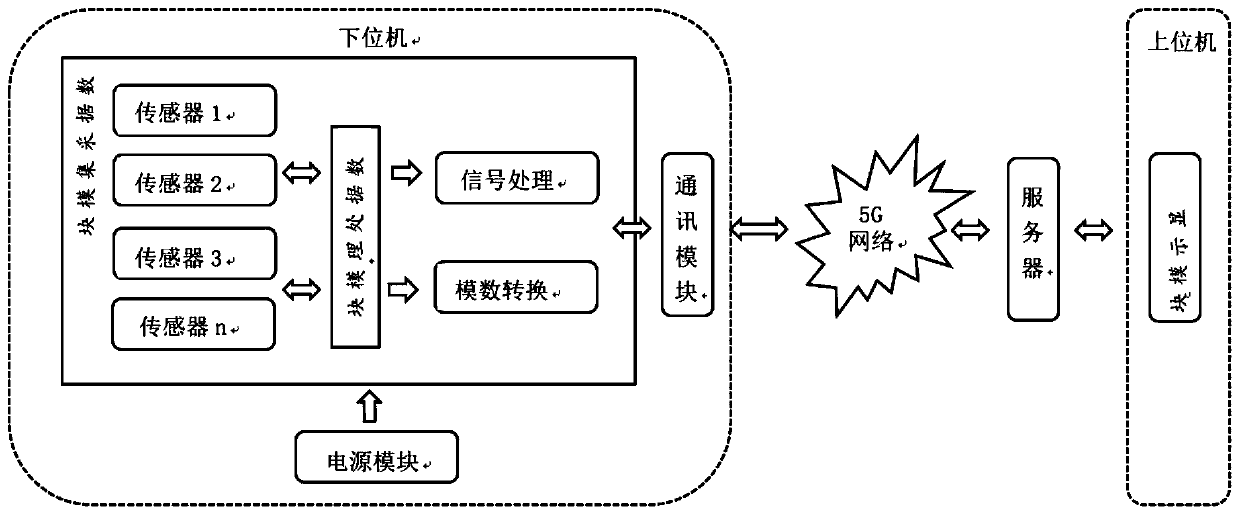

[0023] Such as figure 1 As shown, a monitoring system applied to industrial robots realizes on-demand monitoring and early warning of the robot's operating status by pre-embedding a variety of sensors at the casting stage of the six-axis robot.

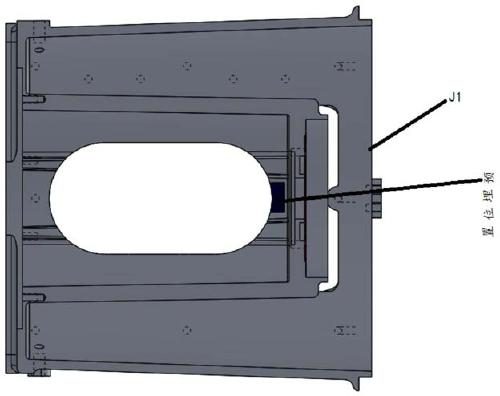

[0024] The industrial robot adopted in the present invention is a six-axis robot, and the joint axes from bottom to top are J1~J6. The first axis: the first axis is the position of the link chassis, and it is also the load-bearing and core position. It carries the weight of the entire robot and the robot. Large swings from side to side. The second axis: an important axis to control the robot's forward and backward swing, expansion and contraction. The third axis: The three-axis is also the one axis that controls the robot to swing back and forth, but the swing range is much smaller than that of the second axis, but this is also the basis for the arm span of the six-axis robot. The fourth axis: The four axis is an axis that controls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com