Bolt with tensile stress and defect self-testing functions

A technology of self-testing and tensile stress, which is applied in the direction of specially improved connectors, screws, threaded fasteners, etc. for tensile load, can solve the problems of poor coupling conditions and low operating efficiency, and achieve simplified operation process, Effects of improving measurement efficiency and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiment of the present invention is described in detail below:

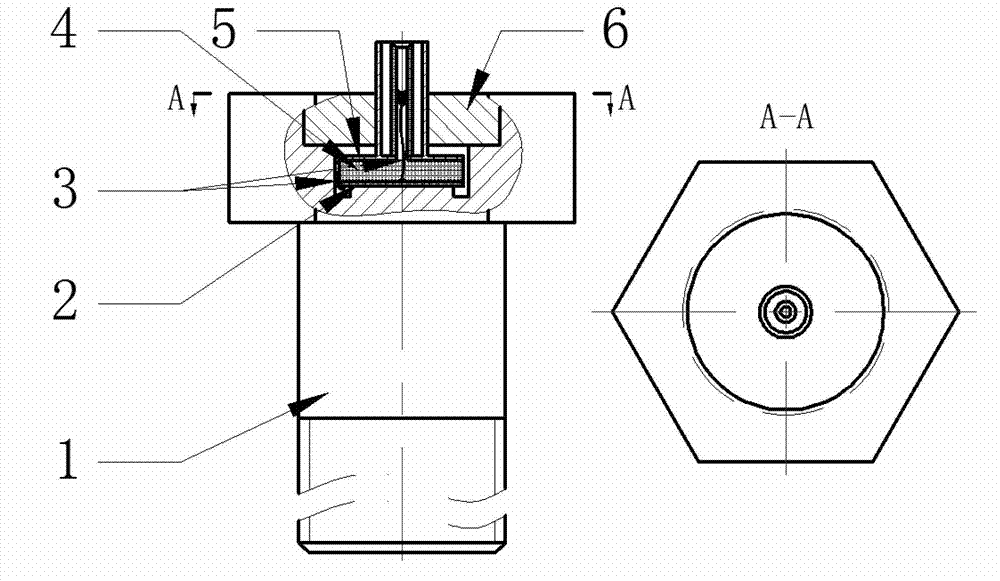

[0012] figure 1 Among them, a circular counterbore is opened on the head of the bolt 1, and the piezoelectric wafer 2 is bonded on the protrusion in the counterbore through conductive epoxy resin, and the back of the piezoelectric wafer 2 is attached with a backing 4, and the L5 joint 5 is pressed tightly on the Backing 4 on top. The lower surface of the piezoelectric wafer 2 is connected to the outer wall of the L5 joint 5 through the connecting wire 3 , and the upper surface of the piezoelectric wafer 2 is connected to the anode of the L5 joint 5 through the welding process with the connecting wire 3 . Finally, the compression end cover 6 is fastened to the round hole at the head of the bolt 1 to achieve the overall sealing effect. When in use, it is only necessary to connect the L5 joint 5 to the measurement system to achieve the purpose of measuring the axial stress of the bolt. Sinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com