Patents

Literature

36results about How to "Test performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Control Groups for Network Testing

ActiveUS20150019713A1Test performanceDigital computer detailsHardware monitoringTest performanceNetwork connection

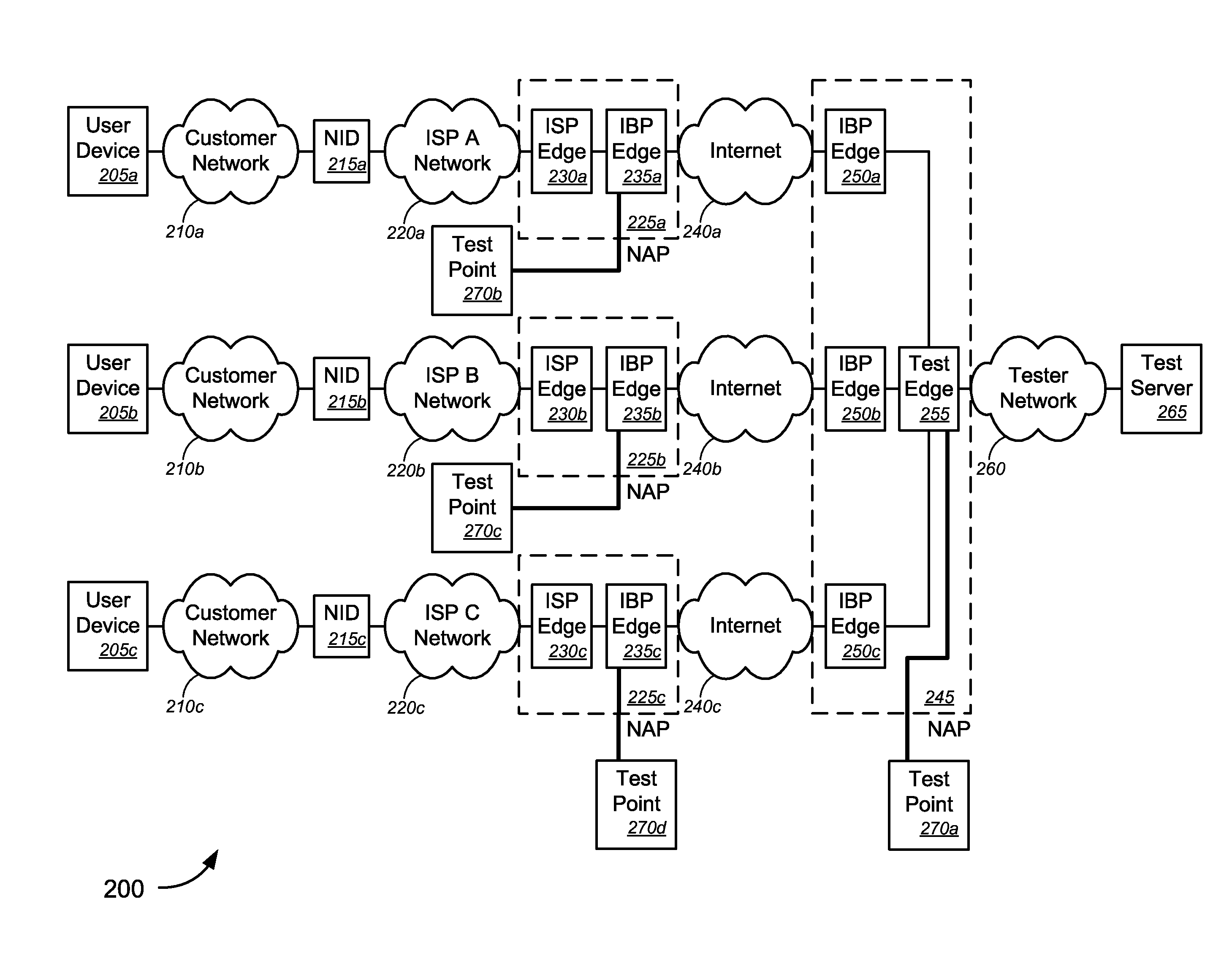

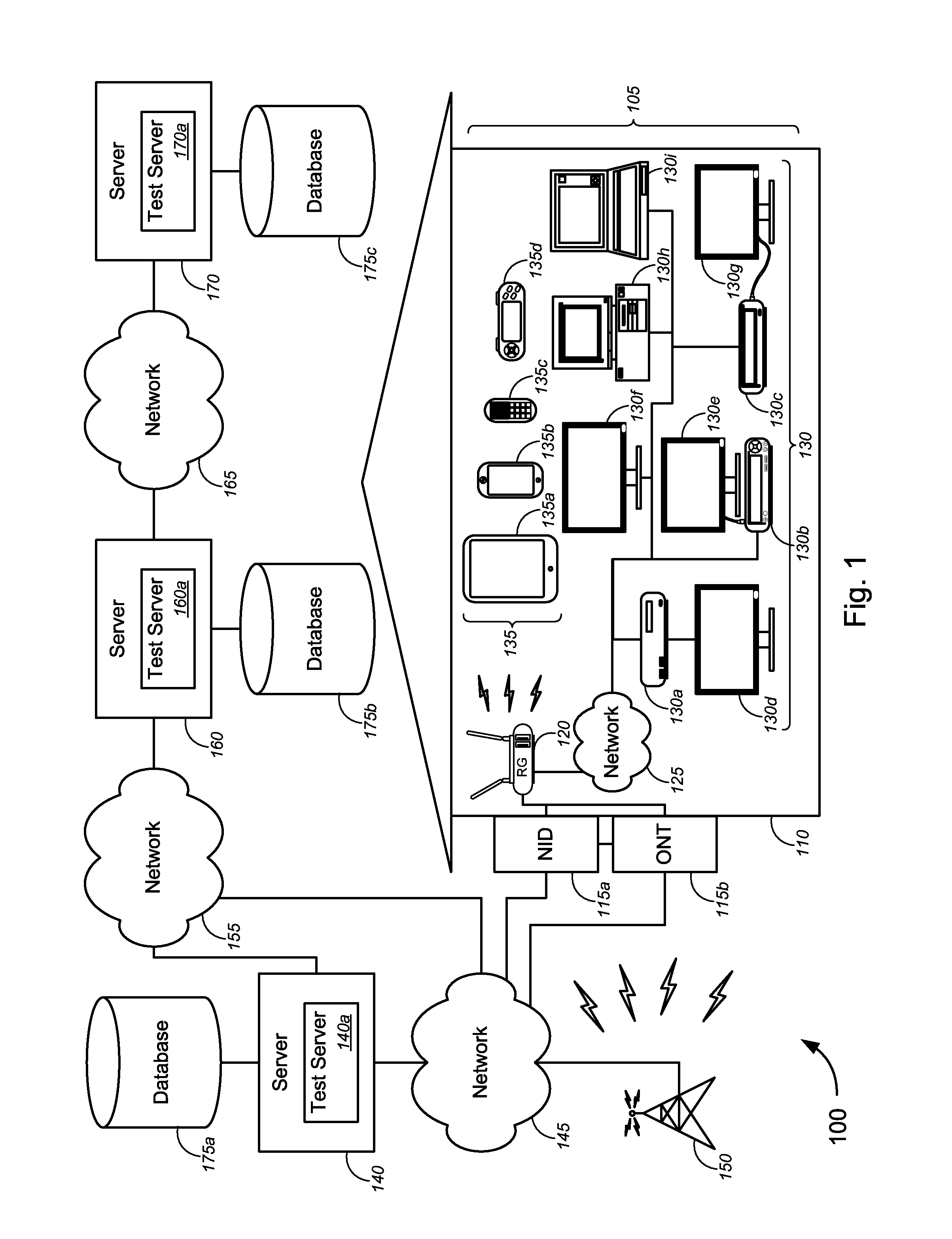

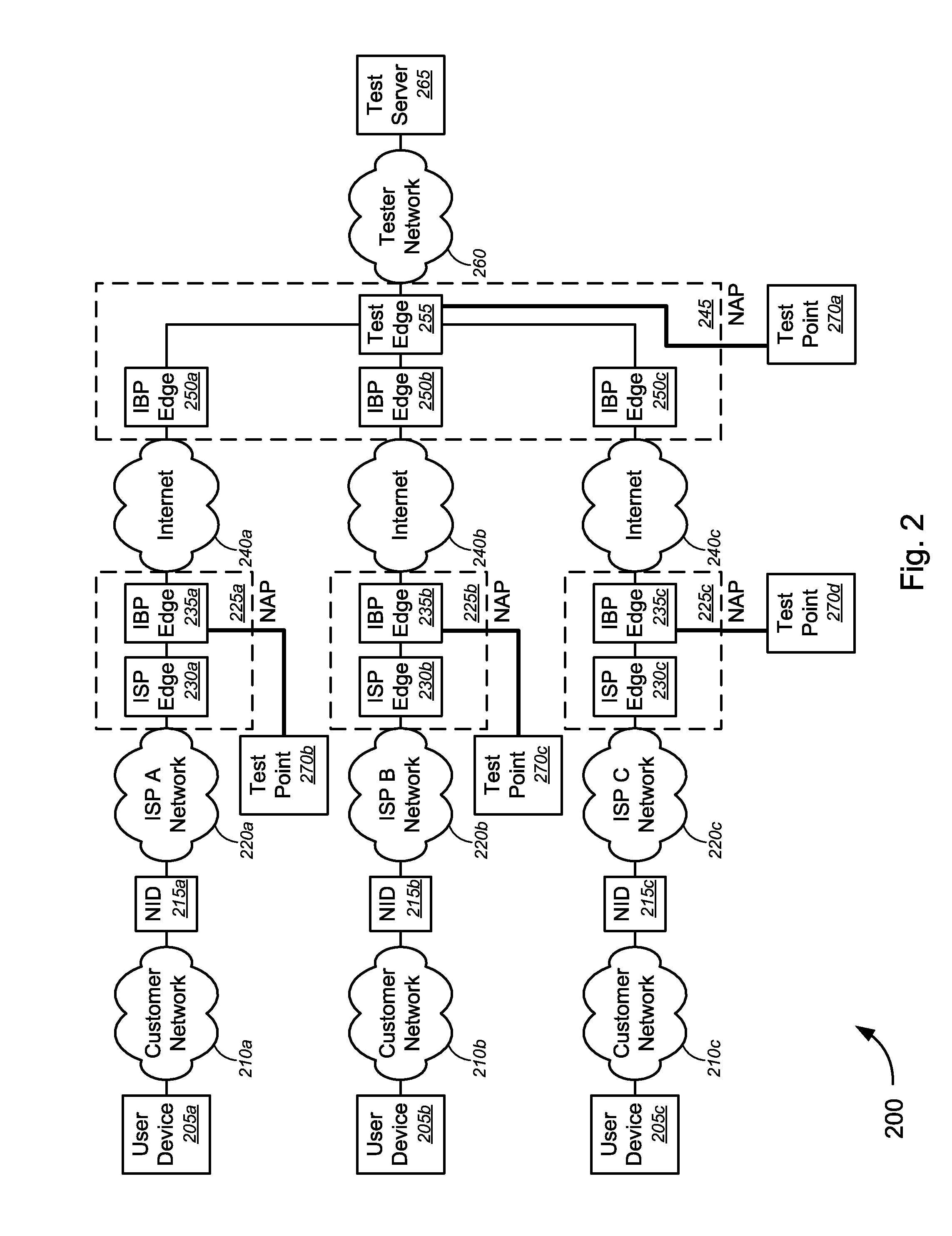

Novel tools and techniques are provided for testing performance of network connections. In some cases, a method for testing performance of a network connection might comprise establishing a plurality of test points within one or more segments in the network connection. With a computer, performance of a selected segment of the network connection at one or more first test points may be tested. The selected segment might have a first endpoint and a second endpoint. The performance of one or more sub-segments of the selected segment at one or more second test points may also be tested with the computer. The computer may also determine an isolated performance of a particular one of the sub-segments based on the testing. In some instances, the method might further comprise determining, with the computer, that performance of the one or more sub-segments has affected performance of the network connection.

Owner:CENTURYLINK INTPROP

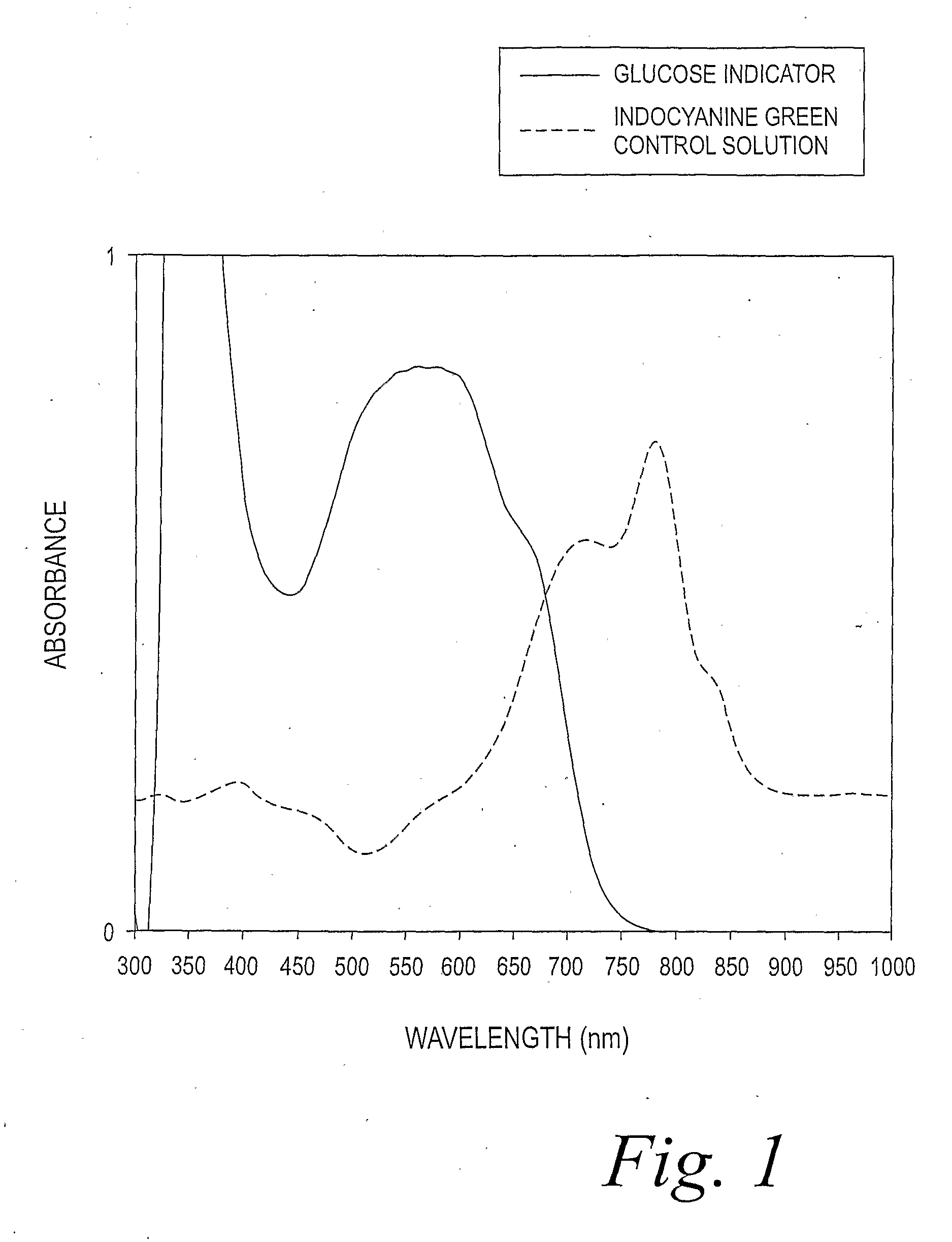

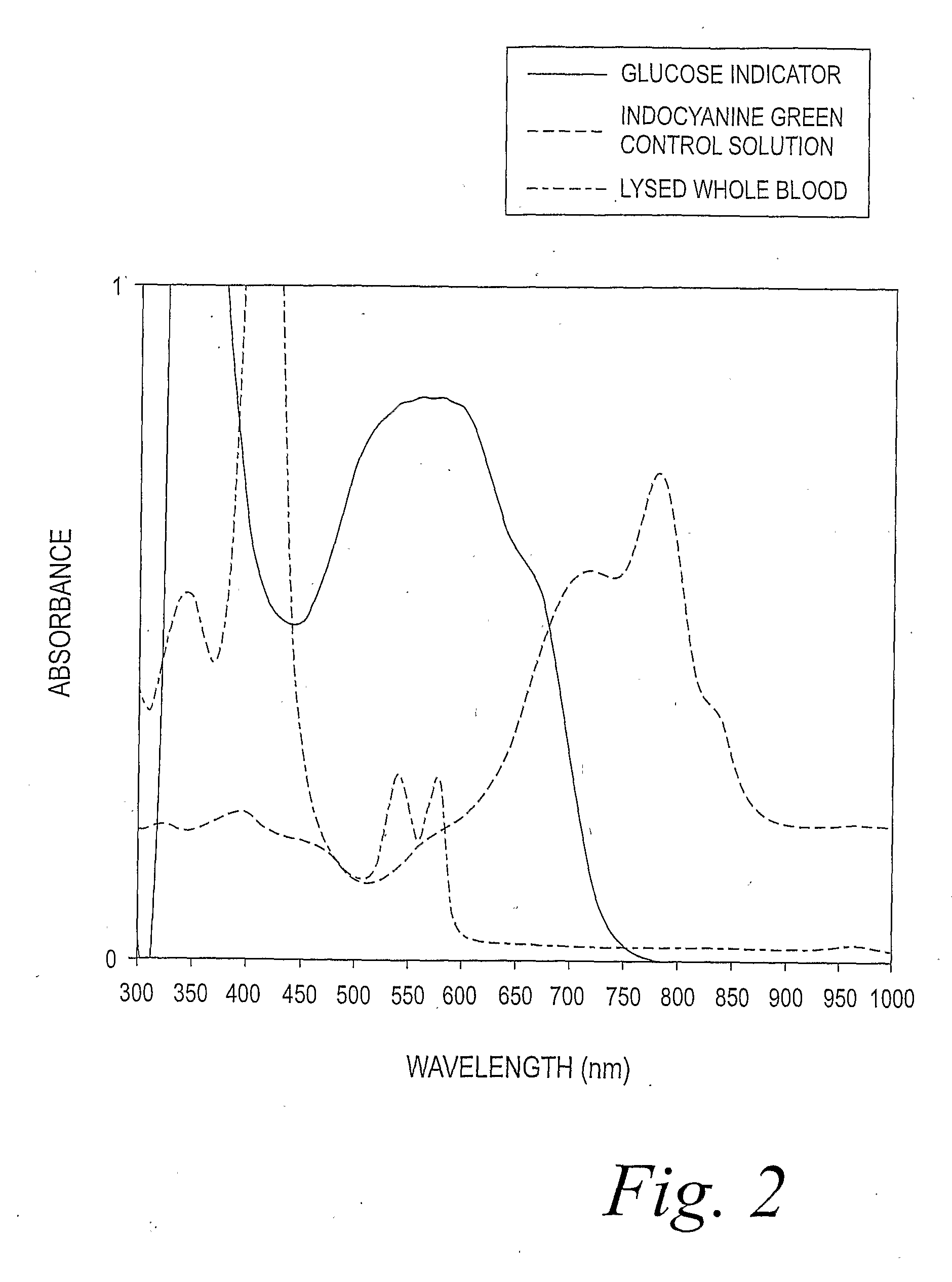

Method of Differentiating Between Blood and Control Solutions Containing a Common Analyte

ActiveUS20080145878A1Test performanceBioreactor/fermenter combinationsBiological substance pretreatmentsOptical instrumentAmount of substance

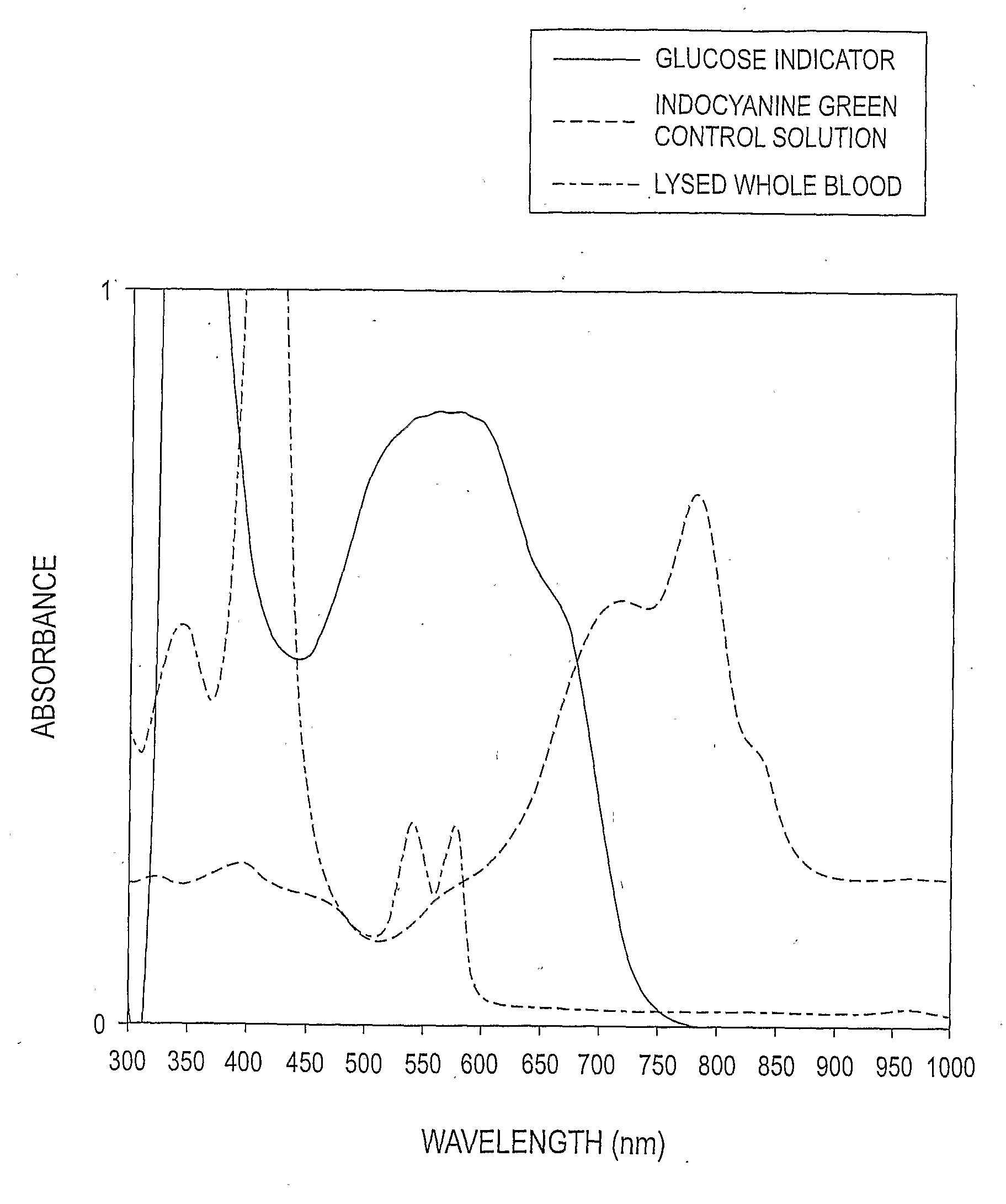

Glucose measured in blood samples is distinguished from glucose measured in the control solutions used to test the optical instruments which make such measurements. The control solutions contain a labeling substance recognized by the optical instrument to distinguish glucose measurements made of control solutions from those made of blood samples.

Owner:ASCENSIA DIABETES CARE HLDG AG

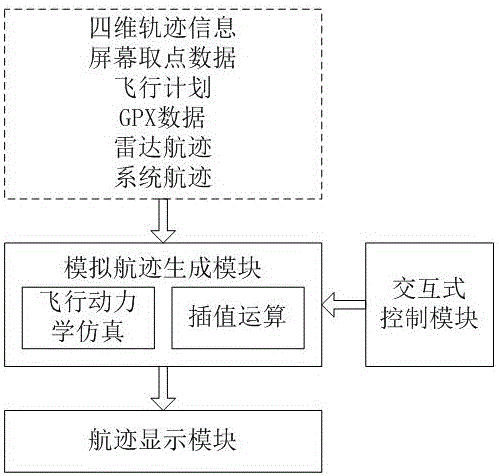

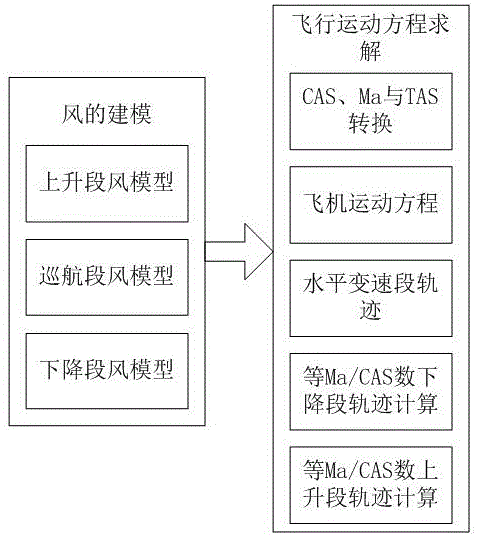

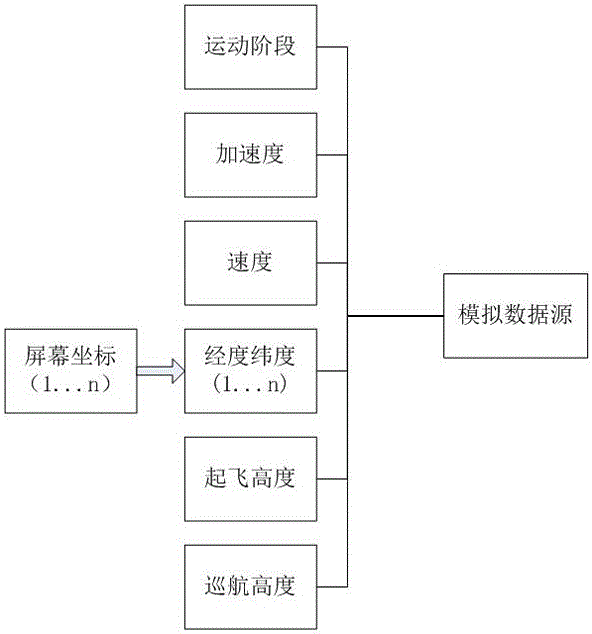

3D interactive simulated flight path generation method and 3D interactive simulated flight path generation system

InactiveCN106019987AEasy to storeGood immersionSimulator controlAircraft traffic controlSource dataAerospace engineering

The invention discloses a 3D interactive simulated flight path generation method and a 3D interactive simulated flight path generation system, relates to the technical field of air traffic management, and aims to provide a simulated flight path generation method of a variety of flight path data sources in view of the defects of the existing flight path generation process. The method comprises a simulated flight path generation step in which flight path source data is received and a real-time simulated flight path is generated according to the flight path source data, an interactive control step in which a simulation control instruction input by a user is received and the flight path simulation process is controlled according to the simulation control instruction, and a flight path display step in which the result of flight path simulation is displayed.

Owner:四川九洲空管科技有限责任公司

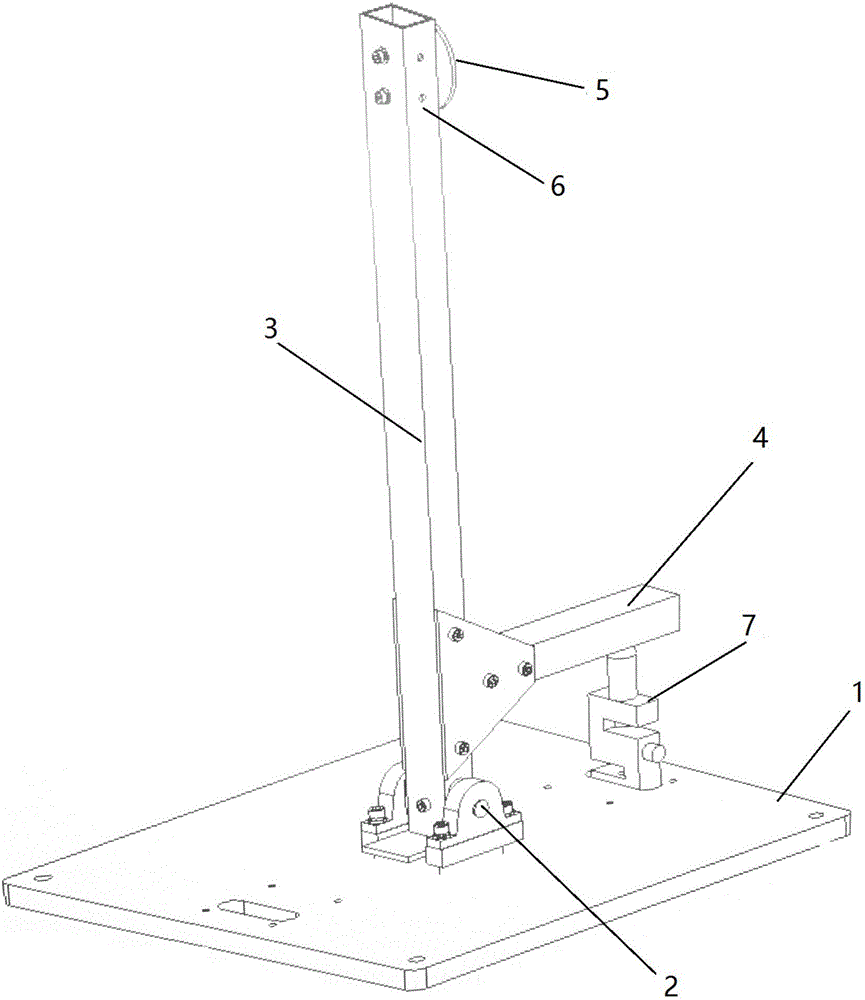

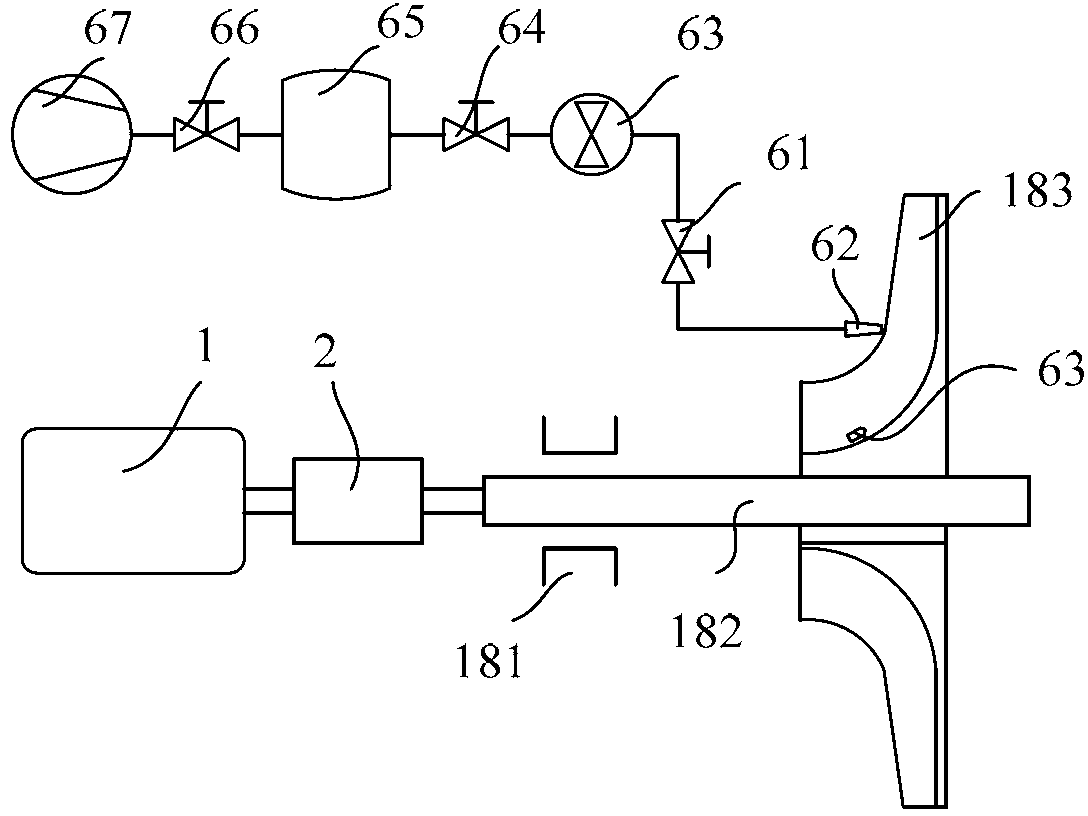

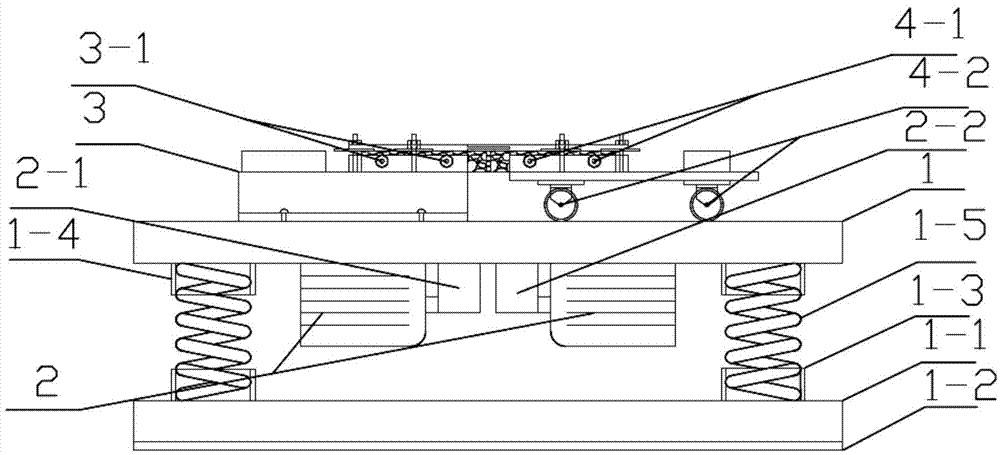

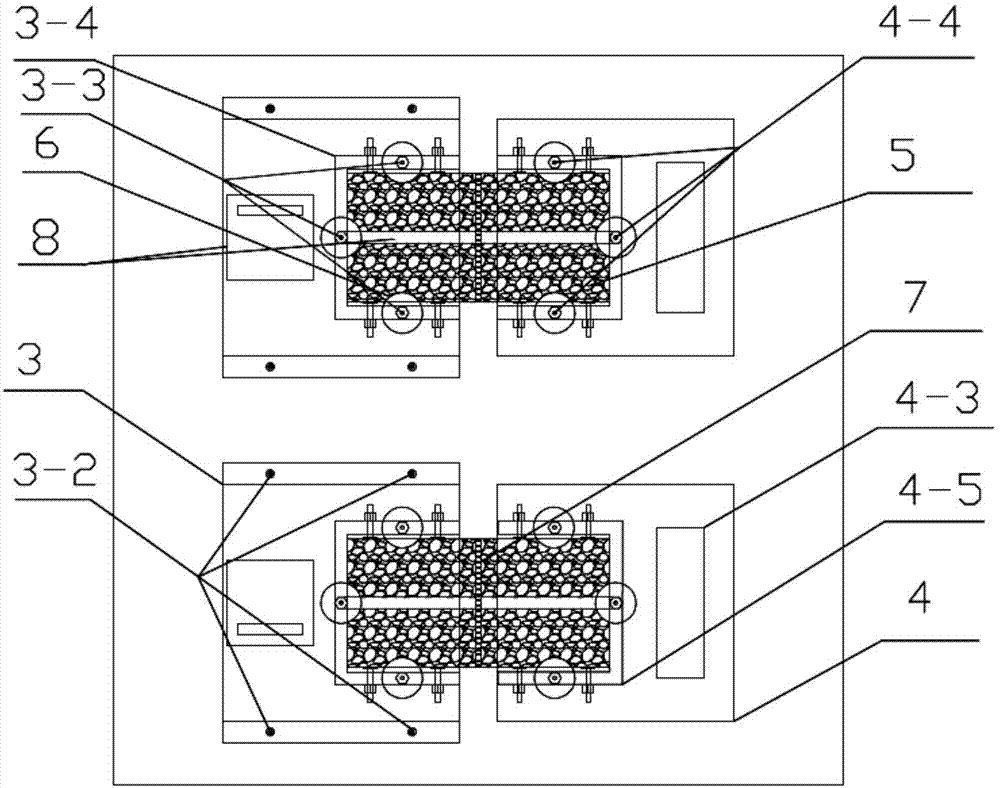

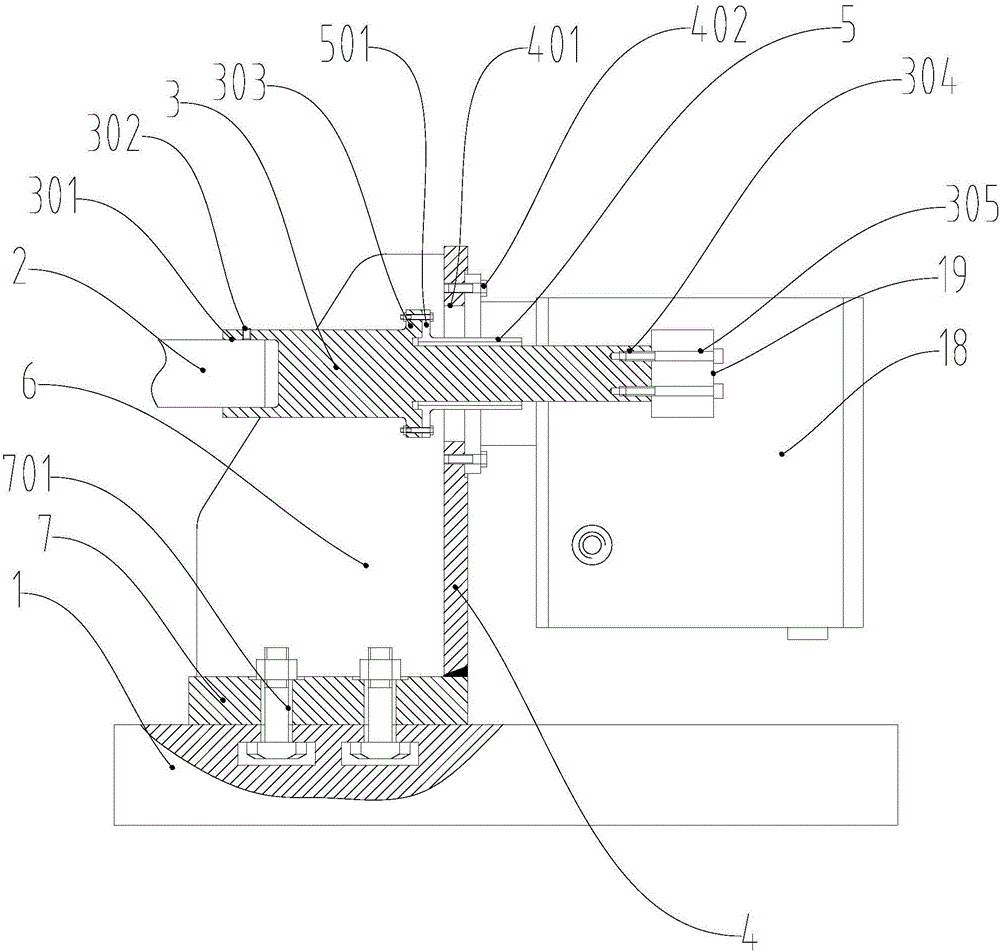

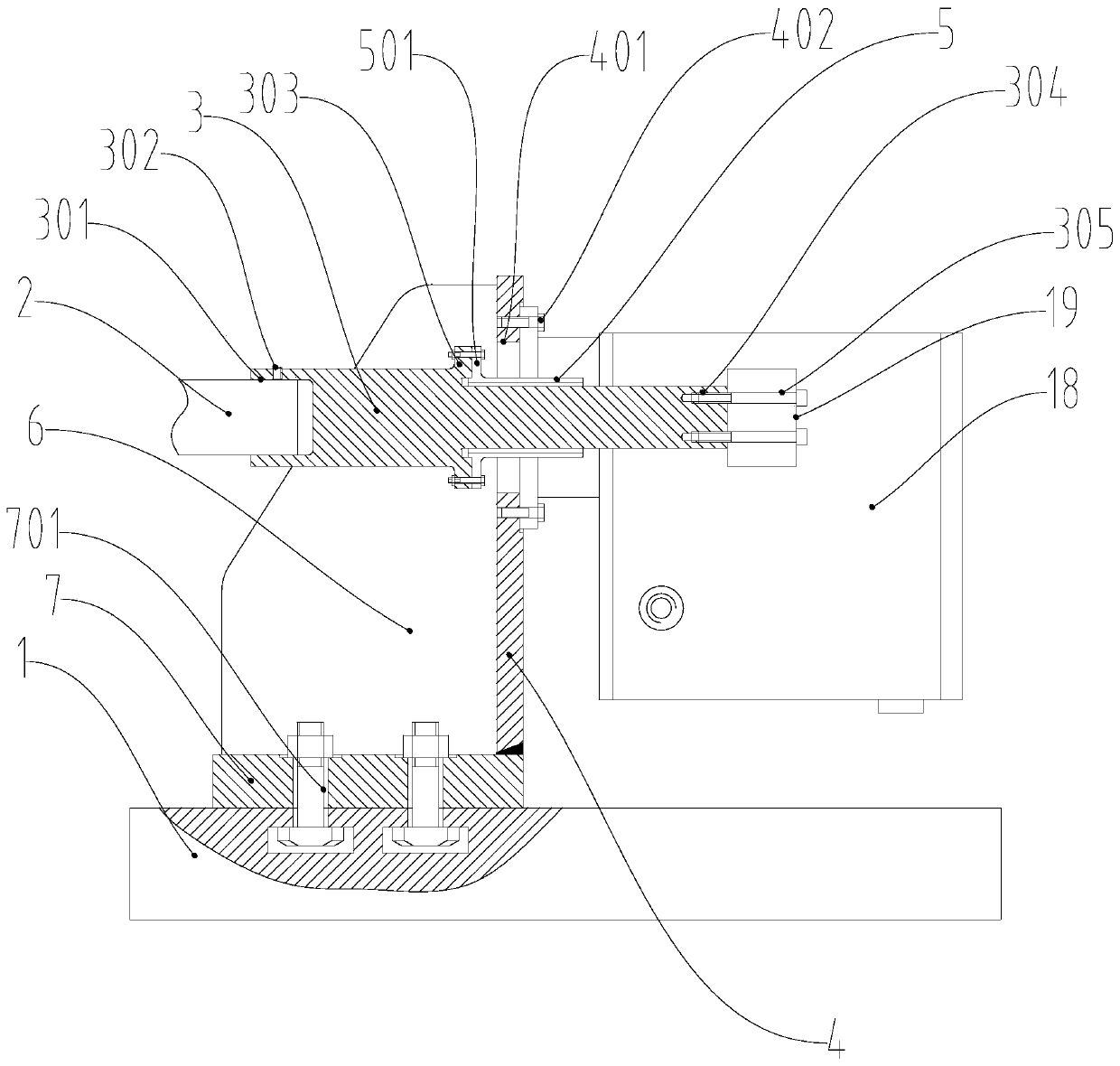

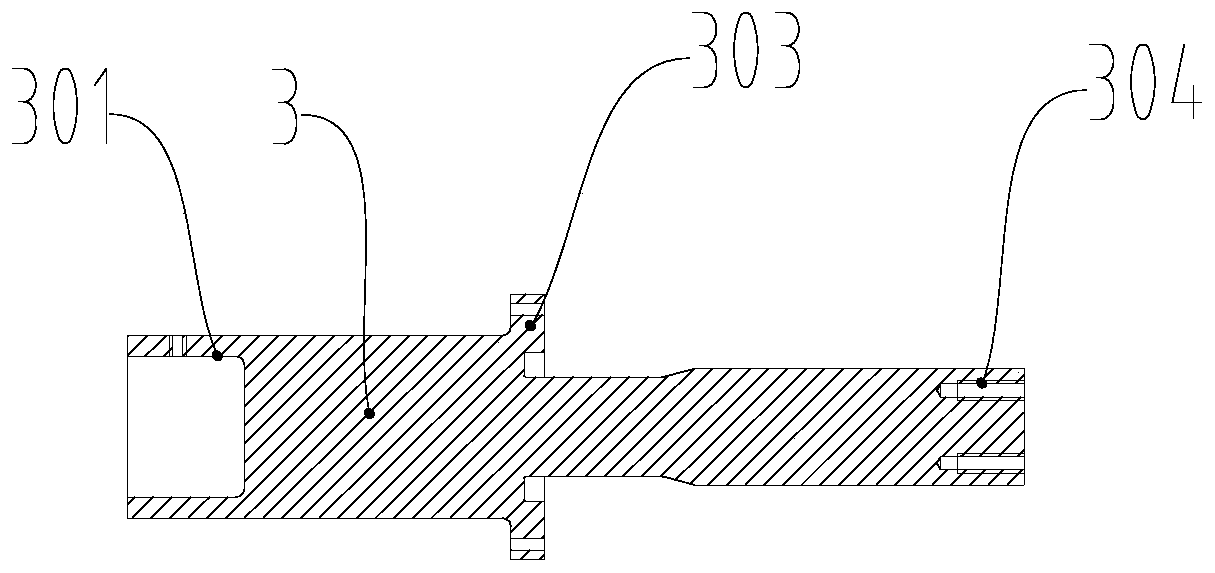

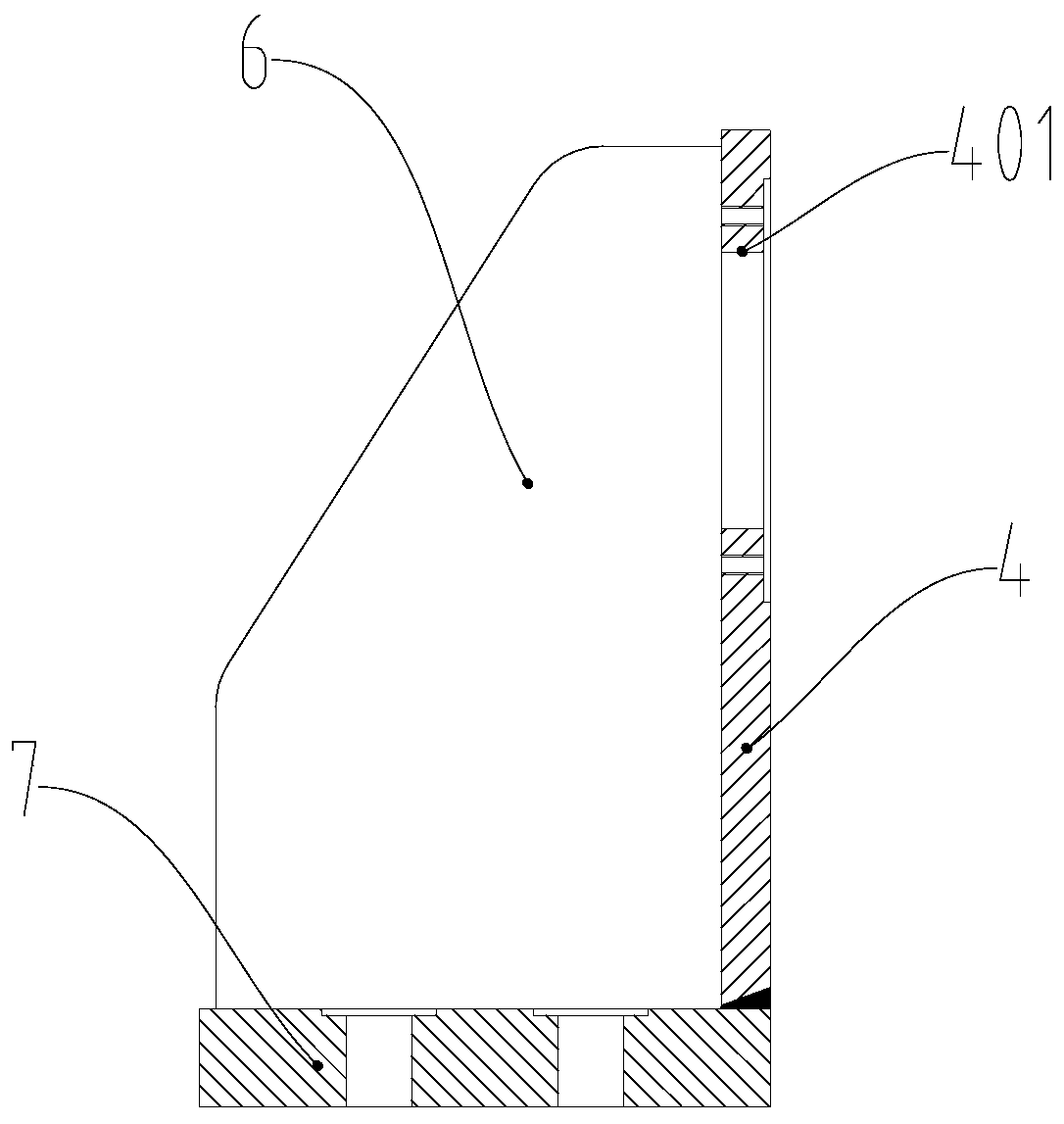

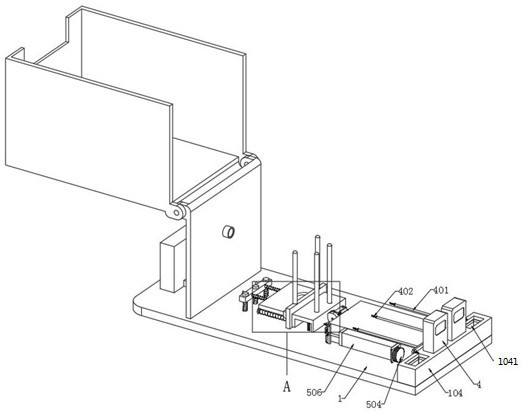

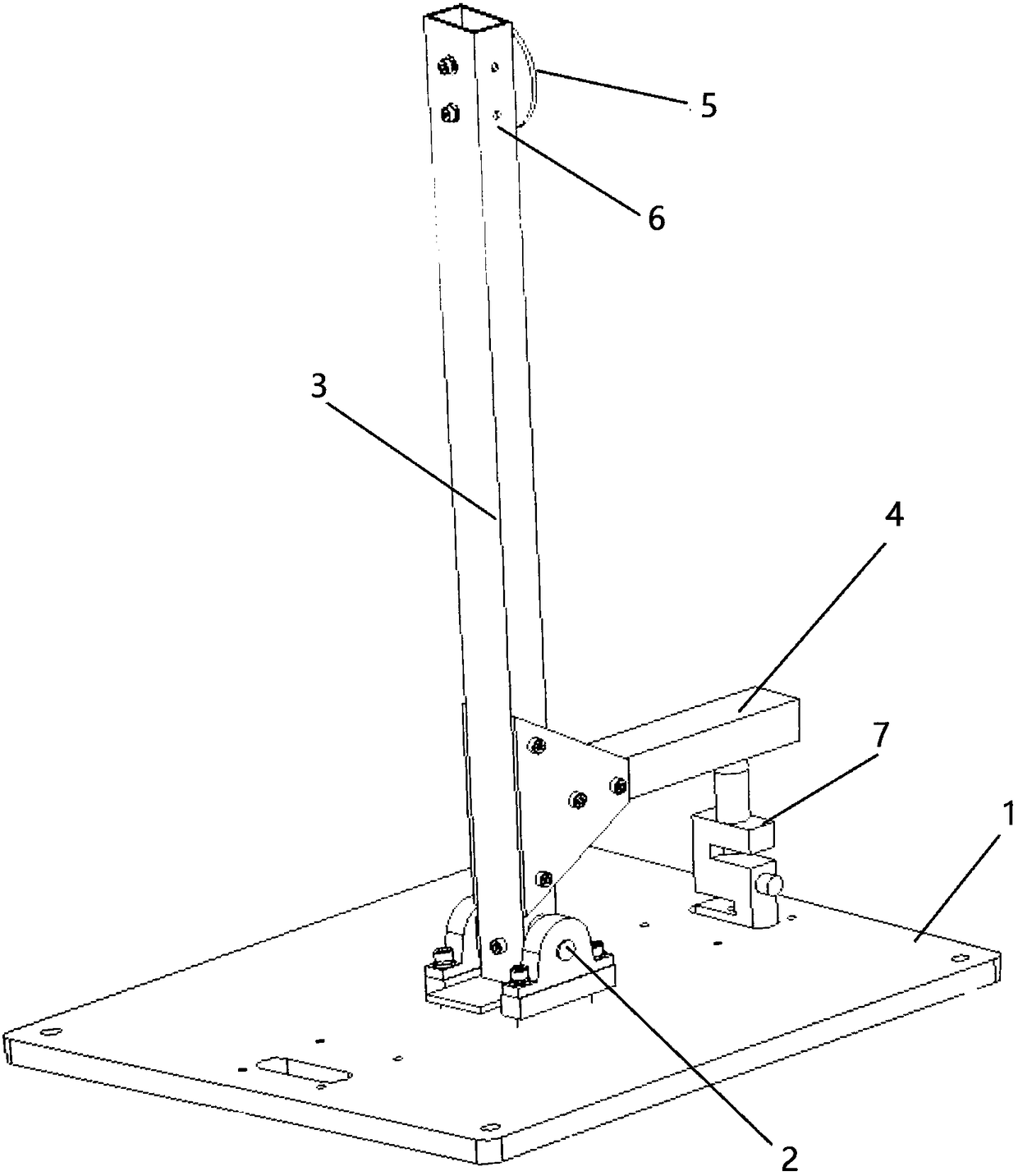

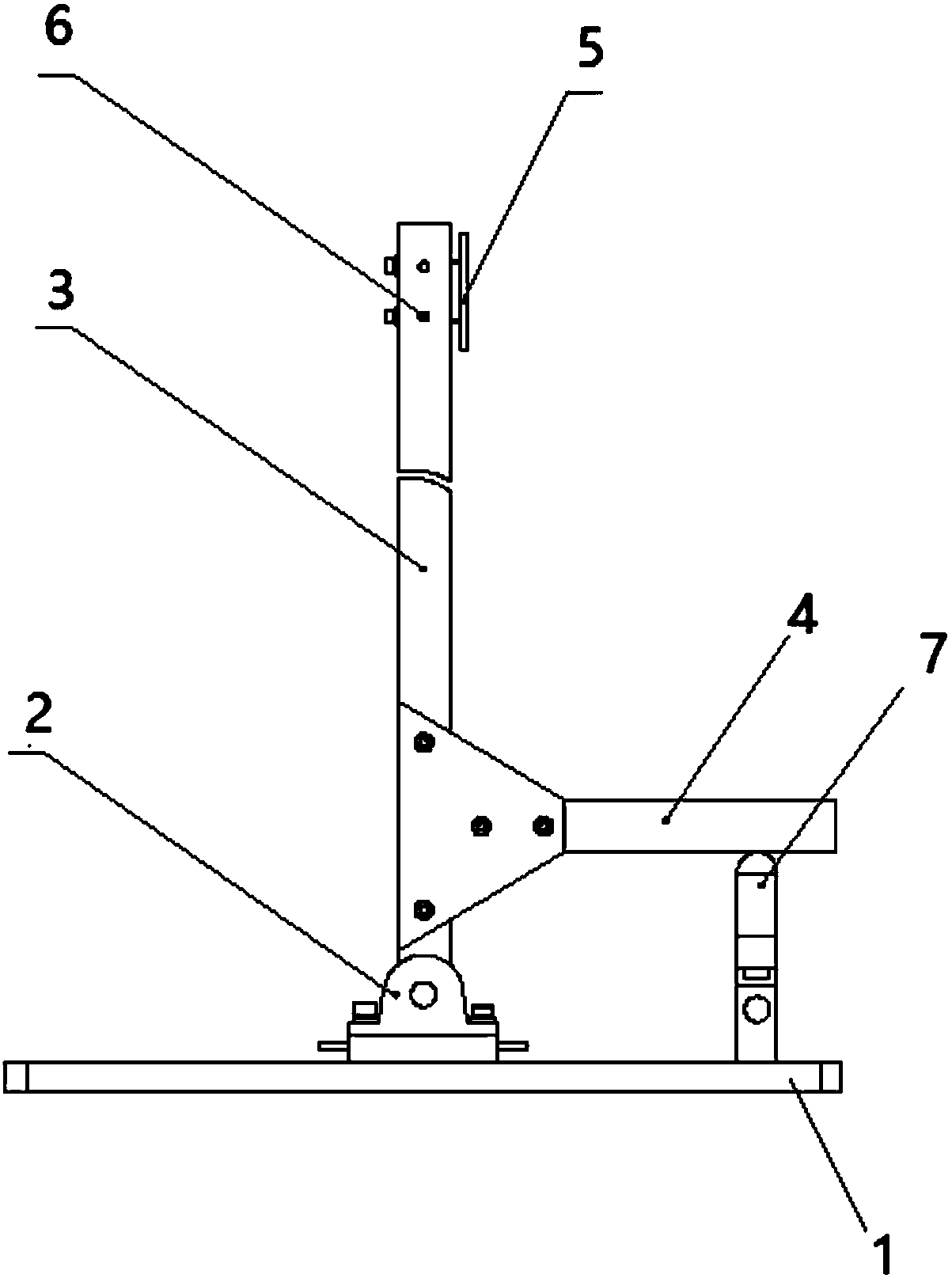

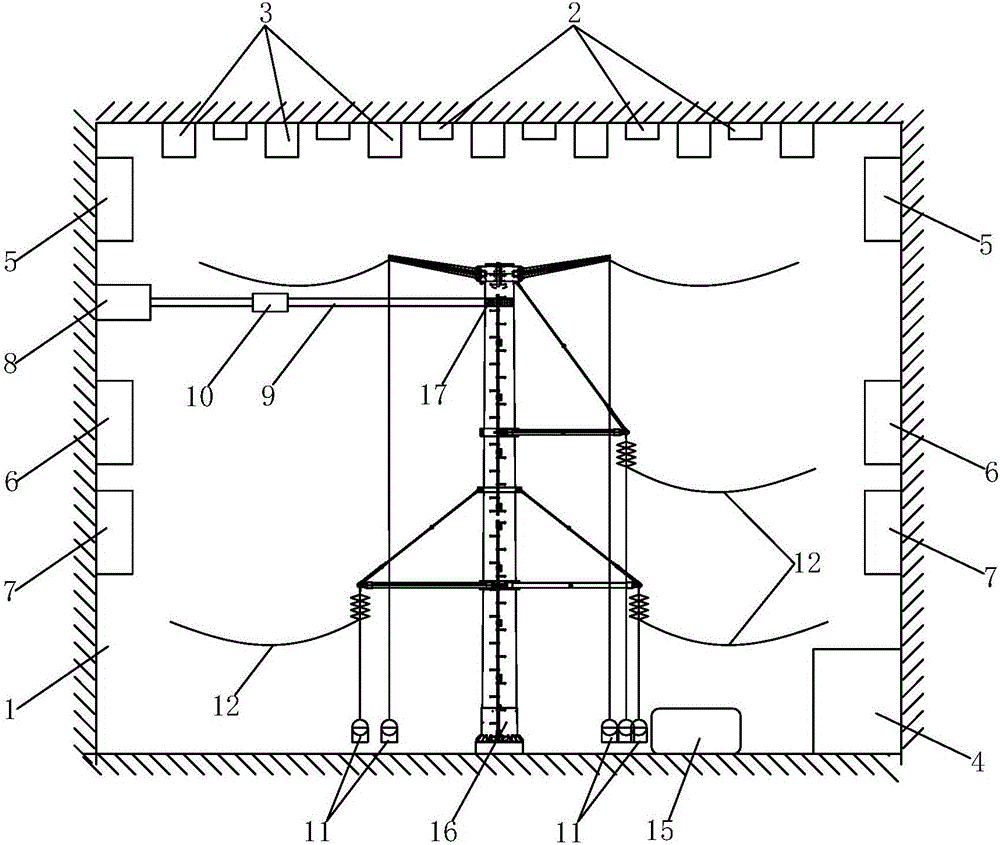

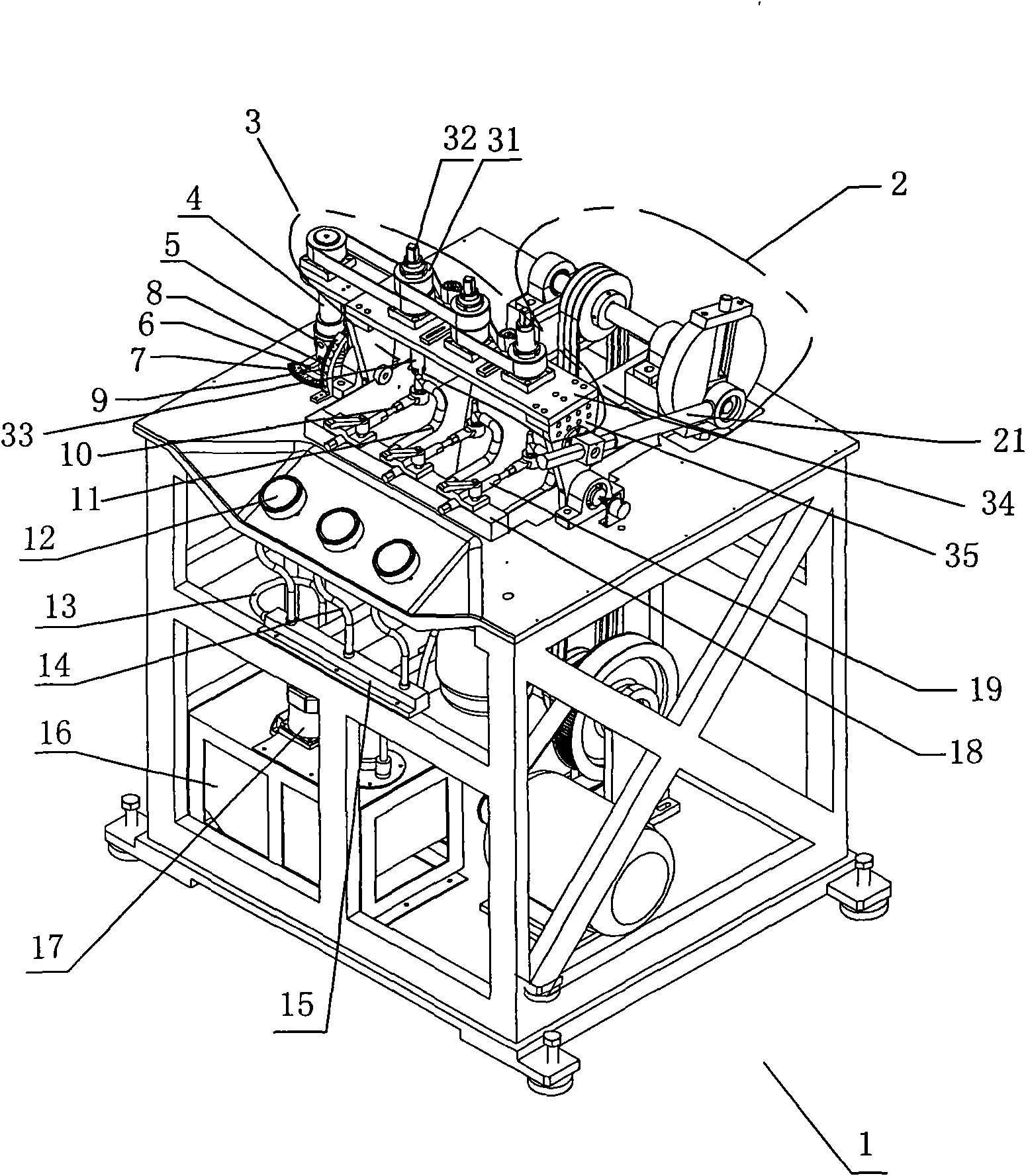

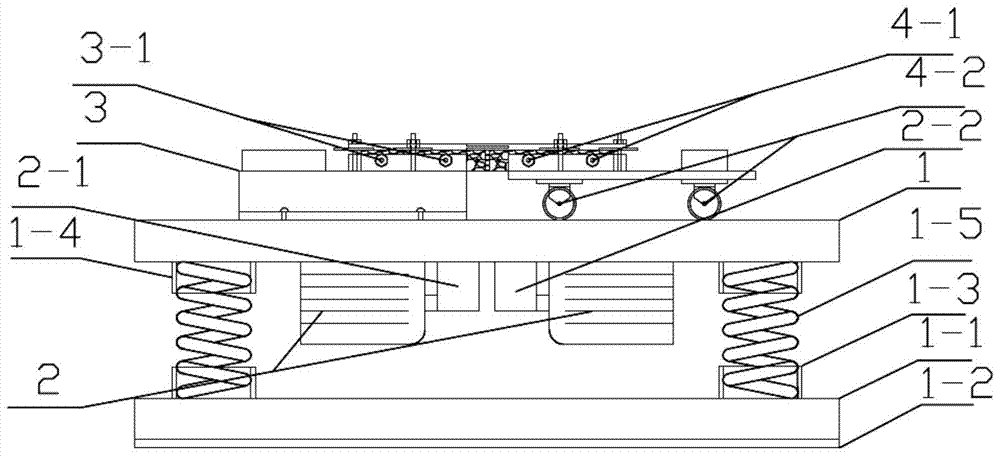

Multi-rotor power testing device and method

ActiveCN105947233AReduce the risk of lift-off testsValid Test PerformanceGround installationsPull forcePropeller

The invention provides a multi-rotor power testing device, comprising a testing base, a bearing, a vertical arm of force, a horizontal arm of force, and a pressure sensor, wherein the bearing is mounted on the testing base and used for changing directions of tensile and torque generated by a propeller under test during a test, the vertical arm of force is connected directly with the bearing, the horizontal arm of force is vertically mounted below the vertical arm of force, the vertical arm of force is rigidly connected with the horizontal arm of force, a push test mounting face and a torque test mounting face for the propeller are formed above the vertical arm of force, the push test mounting face is perpendicular to the torque test mounting face, and the pressure sensor is mounted below the horizontal arm of force, between the horizontal arm of force and the testing base. A testing system of the invention enables power performance and electrical performance of a multi-rotor unmanned aerial vehicle to be tested effectively and safely and may also meet testing requirements of rotor unmanned aerial vehicles with different arm numbers and driving units of different types.

Owner:NANJING NORTH OPTICAL ELECTRONICS

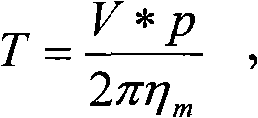

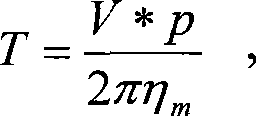

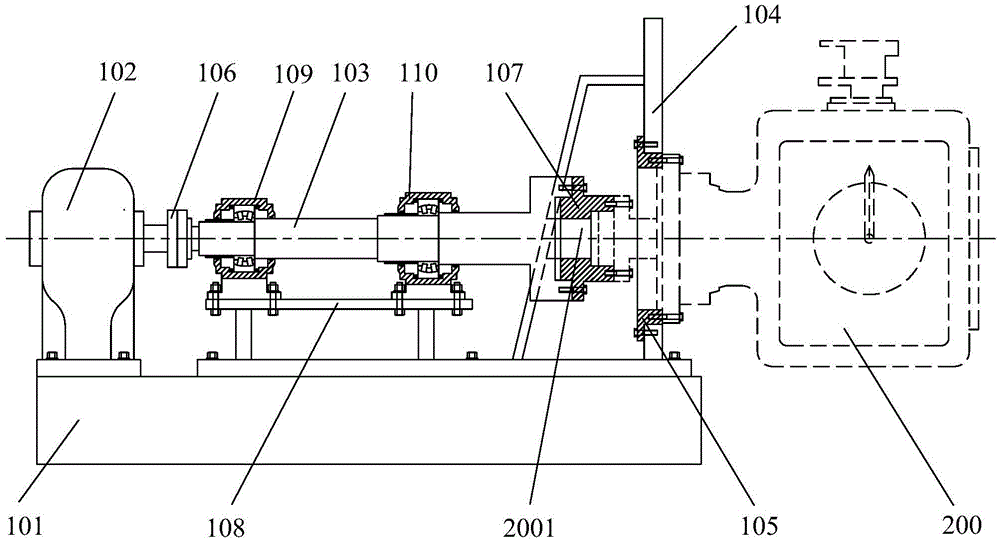

Turbine compressor test system

InactiveCN102937104AEnhanced airflow excitationReduce power consumptionPump controlNon-positive displacement fluid enginesTorque sensorAutomotive engineering

The invention discloses a turbine compressor test system. The turbine compressor test system is characterized in that rotation output of a motor is driven to a turbine compressor main shaft of a turbine compressor through a transmission case and a torque sensor so as to form a test main engine, an air inlet disturbance unit, an exhaust disturbance unit, an airflow actuating device and a measure and control unit are respectively arranged aiming at the test main engine. The turbine compressor test system provided by the invention can test properties of the turbine compressor under various working conditions such as different air inlet condition saltations, air inlet distortion and exhaust conditional mutation, simulate the excitation of airflow to blades under different work conditions through an experimental method, and measure the parameters including stress and vibration frequency of the blades under situations with different excitation of airflow.

Owner:HEFEI GENERAL MACHINERY RES INST

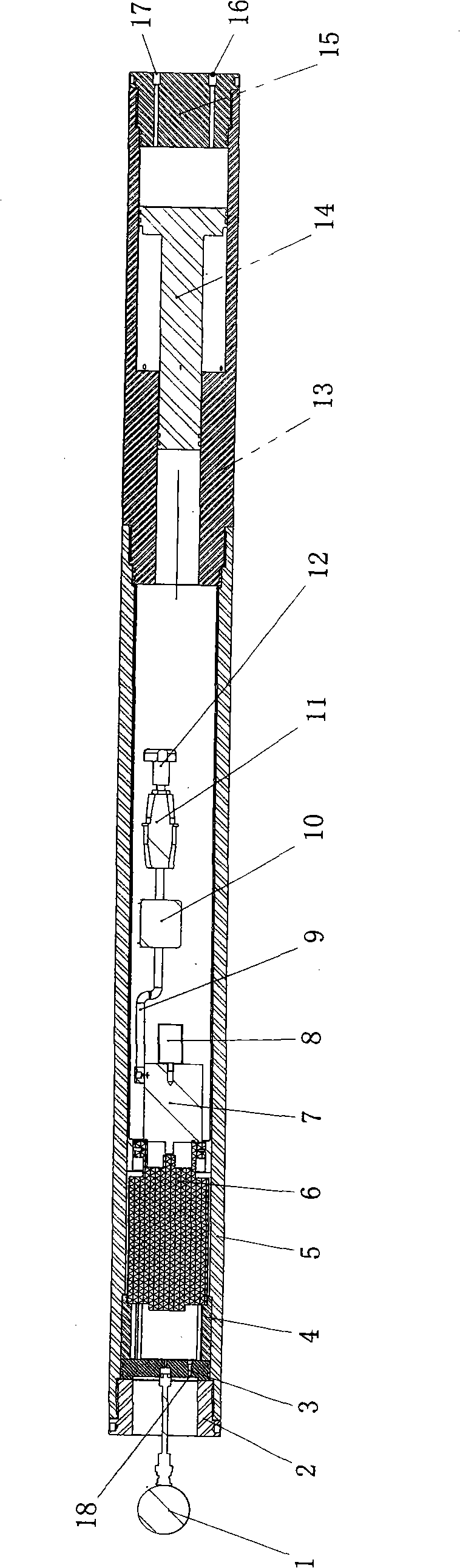

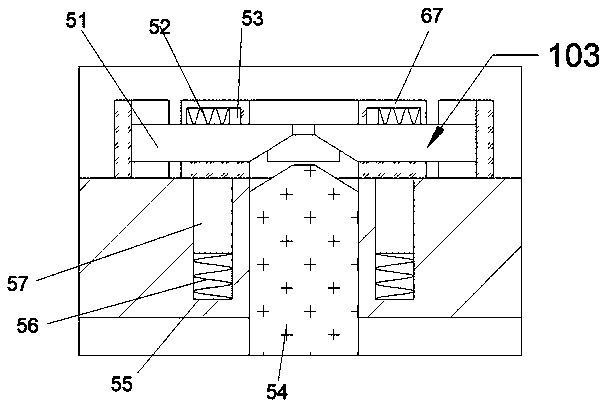

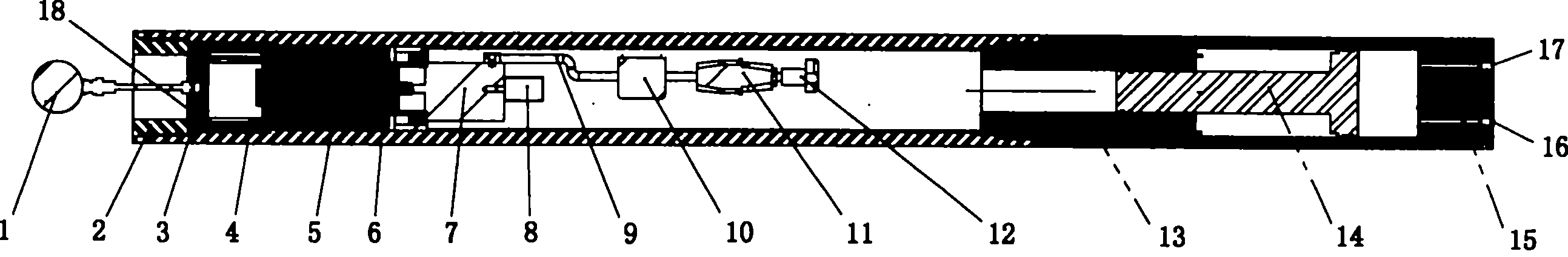

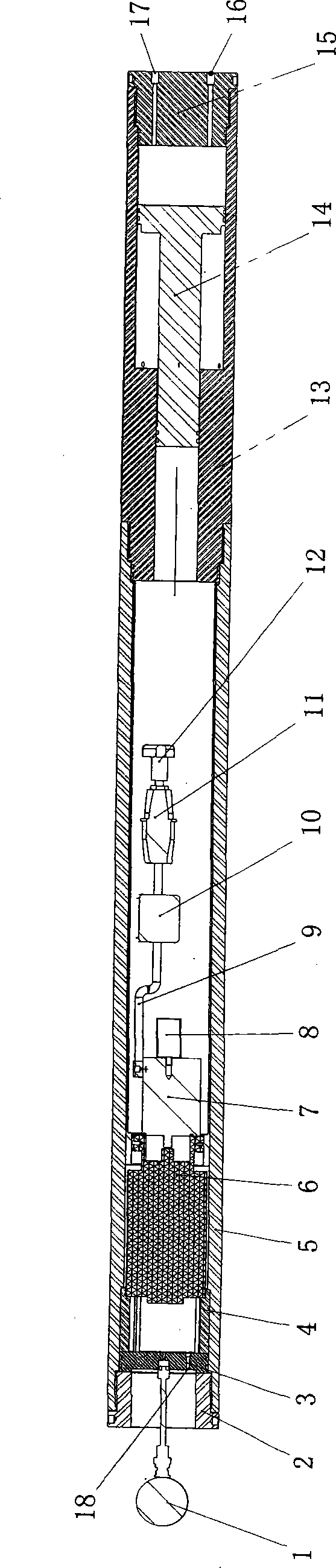

High temperature high voltage electric machine testing device

ActiveCN101281235AReal-time detection of working environment conditionsCalculate output powerDynamo-electric machine testingMotor testingElectric machine

The invention discloses a high temperature high-voltage motor testing device, which includes a cylindrical seal cavity shell, a pressure cylinder and a pressure piston thereof are provided in the cylindrical seal cavity shell, the pressure cylinder, the pressure piston and a bearing joint at the end of the seal cavity shell forms a high pressure seal cavity in the seal cavity shell, the inner of the high pressure seal cavity is filled with hydraulic oil, and a motor fixing sleeve for fixing the motor is mounted in the high pressure seal cavity. The apparatus can test operation situation and operating performance of the motor under and high voltage surroundings.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Quality measurement method of solar photovoltaic cable

InactiveCN102539247ATest air agingTest performanceWeather/light/corrosion resistanceResistance/reactance/impedenceCold testEngineering

The invention discloses a quality testing method of a solar photovoltaic cable. The quality testing method comprises the following testing steps of: 1, placing the solar photovoltaic cable in a place with the environment conditions that the temperature is 90 DEG C and the humidity is 85%, carrying out air thermal aging test for 1000h, and after the test is finished, when the maximal change rate of the strength / elongation of the solar photovoltaic cable does not exceed + / -30%, judging the solar photovoltaic cable to be qualified in the test and carrying out a next testing step; and 2, placing the solar photovoltaic cable in a low-temperature refrigerating cabinet at -40+ / -2 DEG C, carrying out a low-temperature test for 16 hours, and after the test is finished, when the solar photovoltaic cable has no cracks, judging the solar photovoltaic cable is qualified in the test and carrying a next testing step. The method disclosed by the invention is reasonable, the actual service environment of the solar photovoltaic cable is used during testing, so that the actual quality condition of the solar photovoltaic cable can be tested effectively, the actual service life of the solar photovoltaic cable can be measured, the quality problems are reduced, and the method has extensive popularization and application values.

Owner:广东优科检测认证有限公司

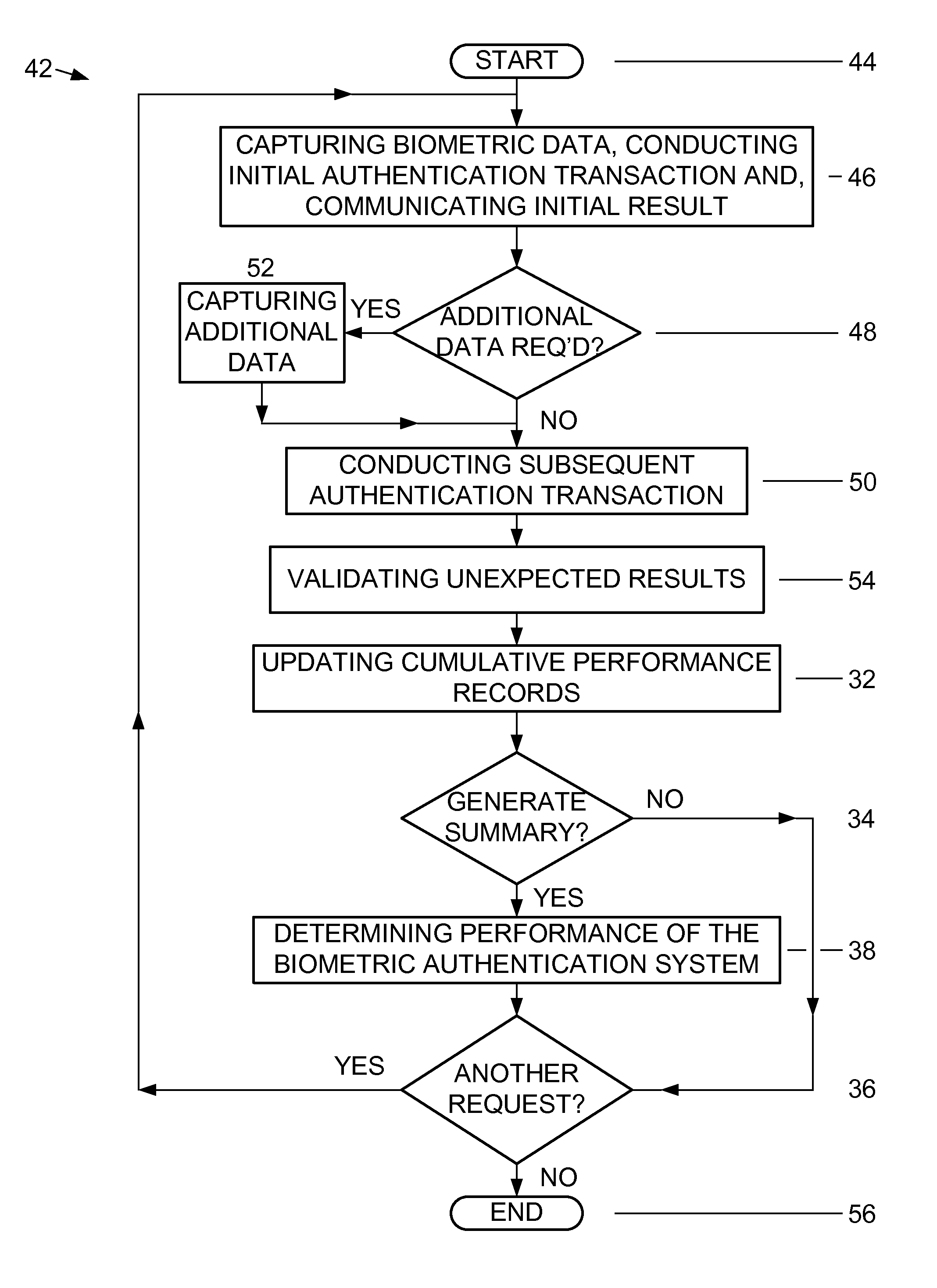

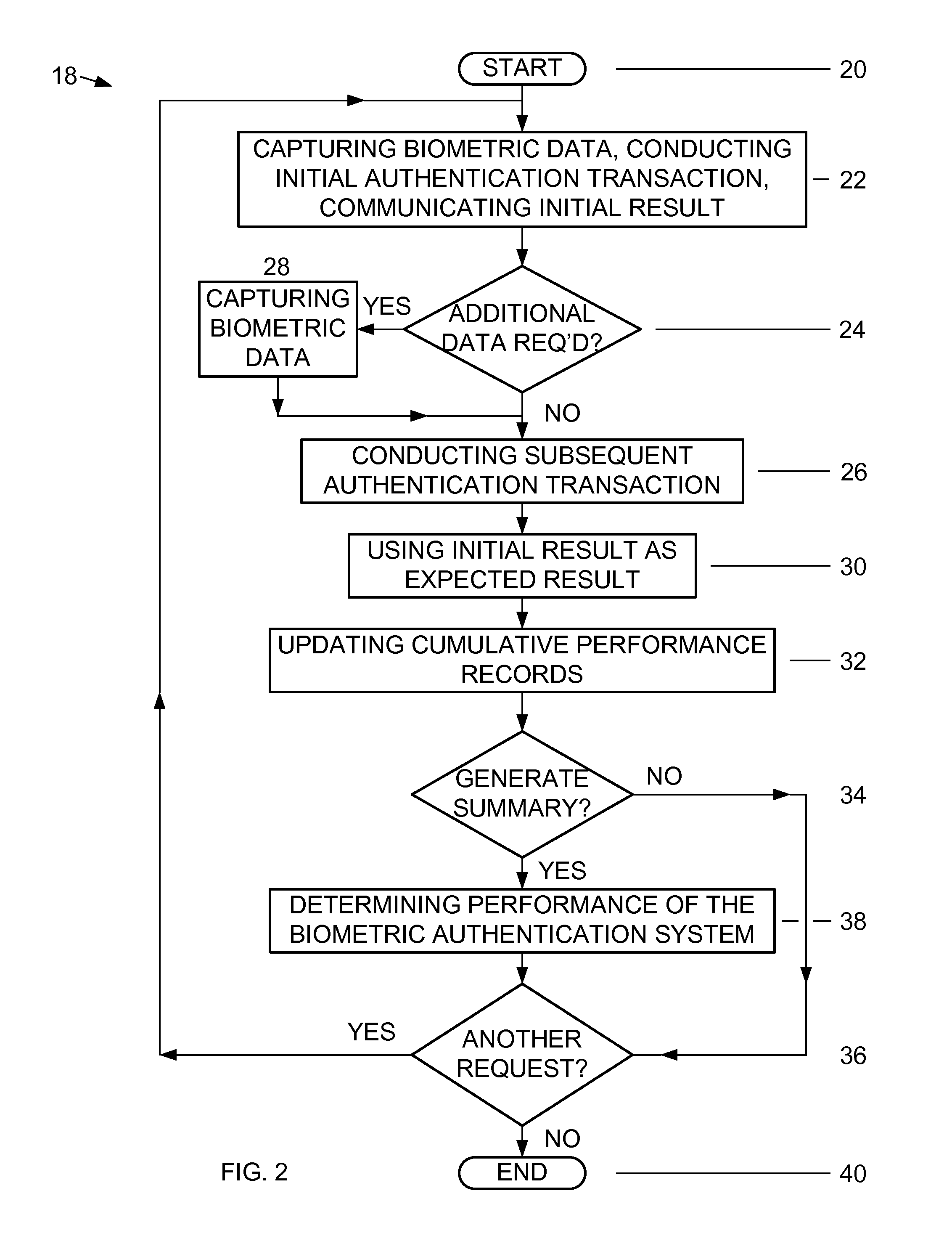

Methods and systems for testing performance of biometric authentication systems

ActiveUS20120167183A1Test performanceDigital data processing detailsUser identity/authority verificationComputer hardwareTest performance

A method of testing the performance of a biometric authentication system includes conducting an initial biometric authentication transaction for an individual using data associated with the individual, and generating an initial result for the initial transaction with the biometric authentication system. Moreover, the method includes obtaining additional data associated with the individual when the additional data is required for conducting a subsequent biometric authentication transaction or after randomly determining that the subsequent transaction is to be conducted. Furthermore, the method includes conducting the subsequent transaction, generating a subsequent result for the subsequent transaction with the biometric authentication system, and updating cumulative performance records based on the initial and subsequent results. The method also includes generating a summary on a temporal or quantifiable basis that includes the cumulative performance records, and determining the performance of the biometric authentication system using the cumulative performance records or the summary.

Owner:DAON TECH

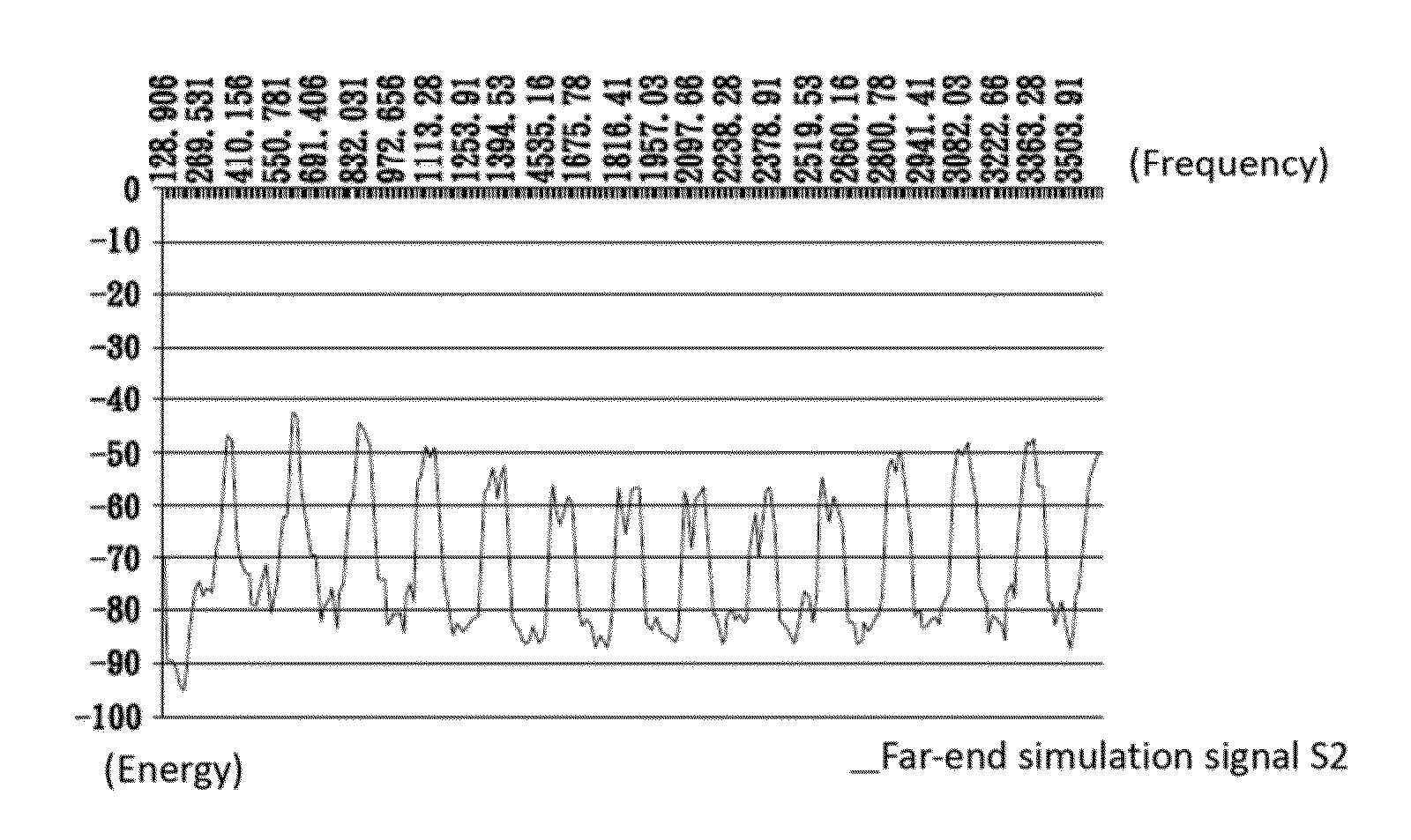

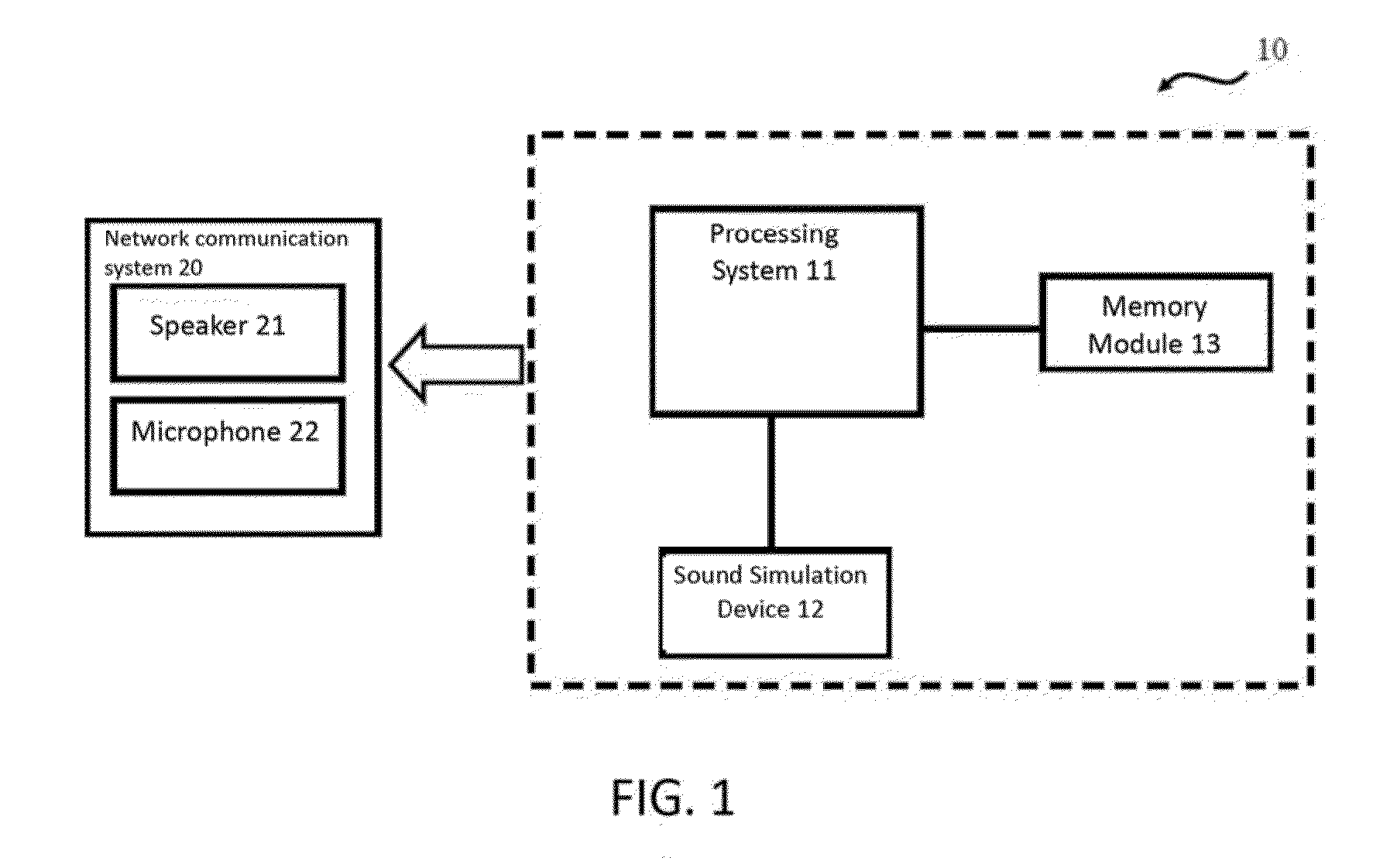

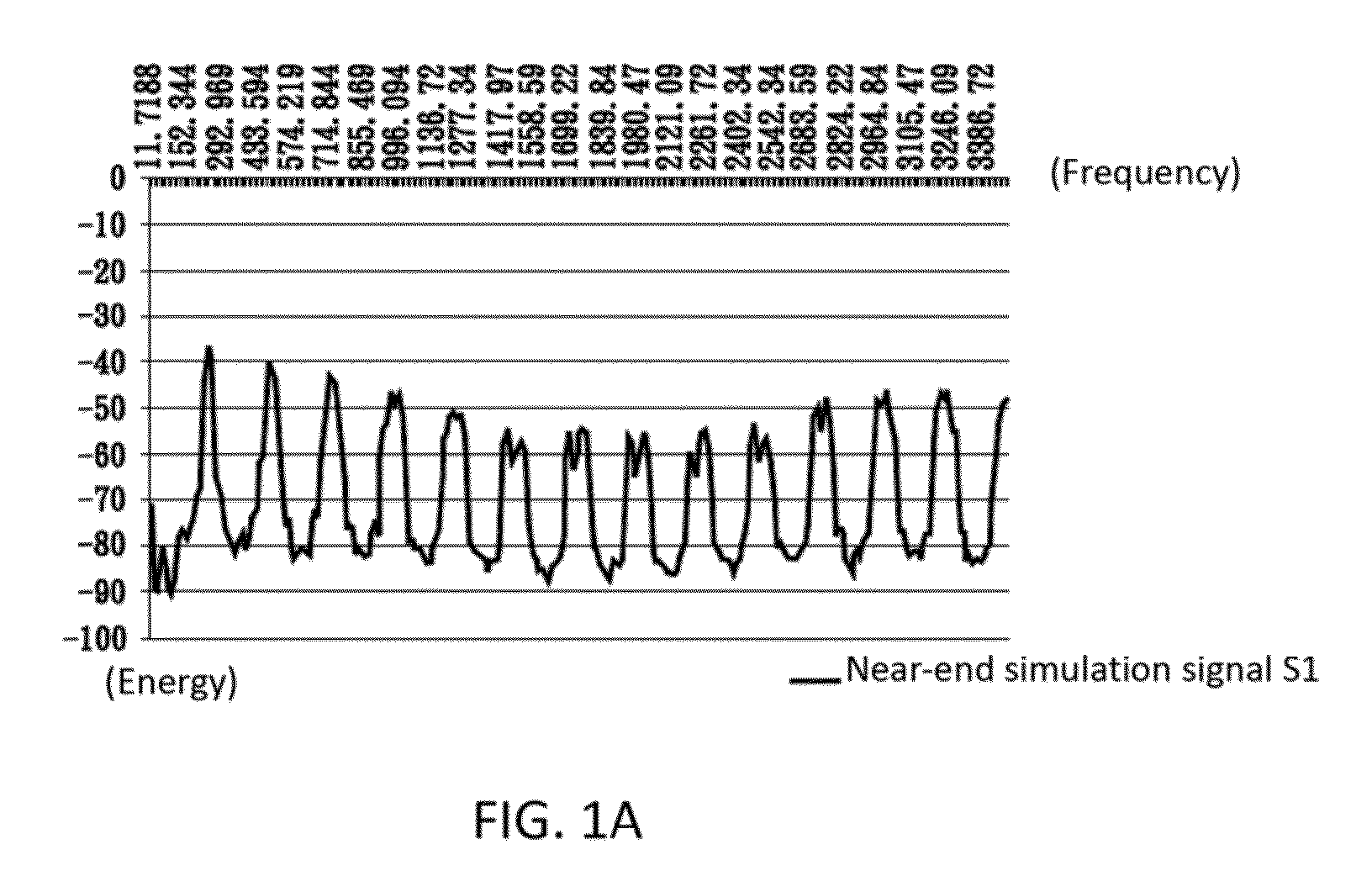

Network audio testing system and network audio testing method thereof

ActiveUS20140037073A1Test performanceSubstation speech amplifiersSupervisory/monitoring/testing arrangementsComputer hardwareUltrasound attenuation

A network audio testing system and a network audio testing method thereof for testing the performance of a network communication, system during communication are disclosed. The system includes a processing system and a sound simulation device. The processing system is for generating a near-end simulation signal and a far-end simulation signal. The sound simulation device is for receiving and making a near-end simulation sound. The near-end simulation sound is received by a microphone of the network communication system to generate a first test signal. The processing system further simultaneously makes the sound simulation device sounding the near-end simulation sound and a speaker sounding a far-end simulation sound to obtain a second test signal. The processing system compares the first and the second test signal to obtain an attenuation degree of the near-end simulation signal and a residual energy of the far-end simulation signal.

Owner:PEGATRON

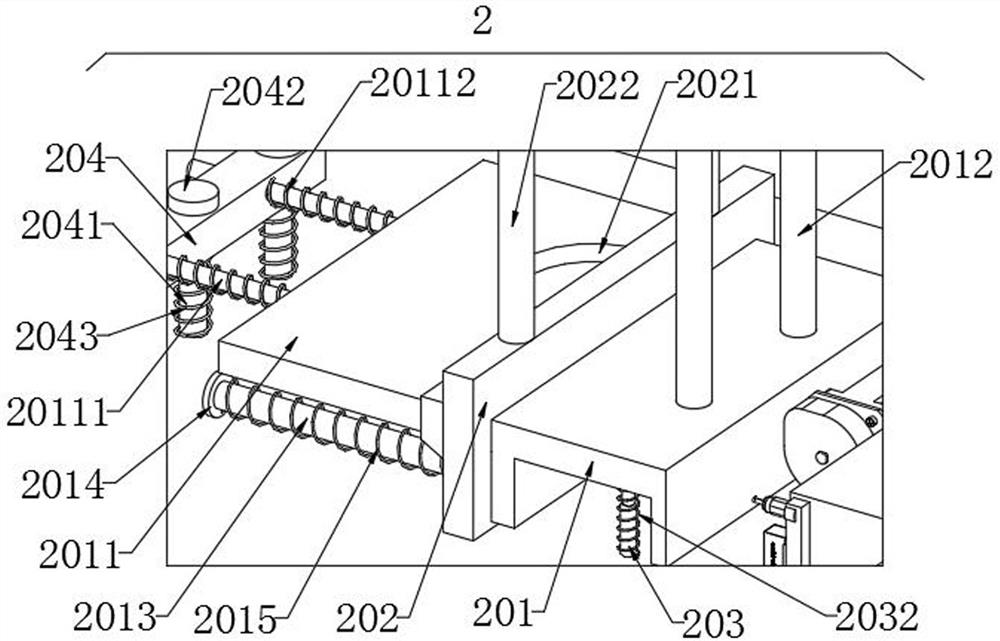

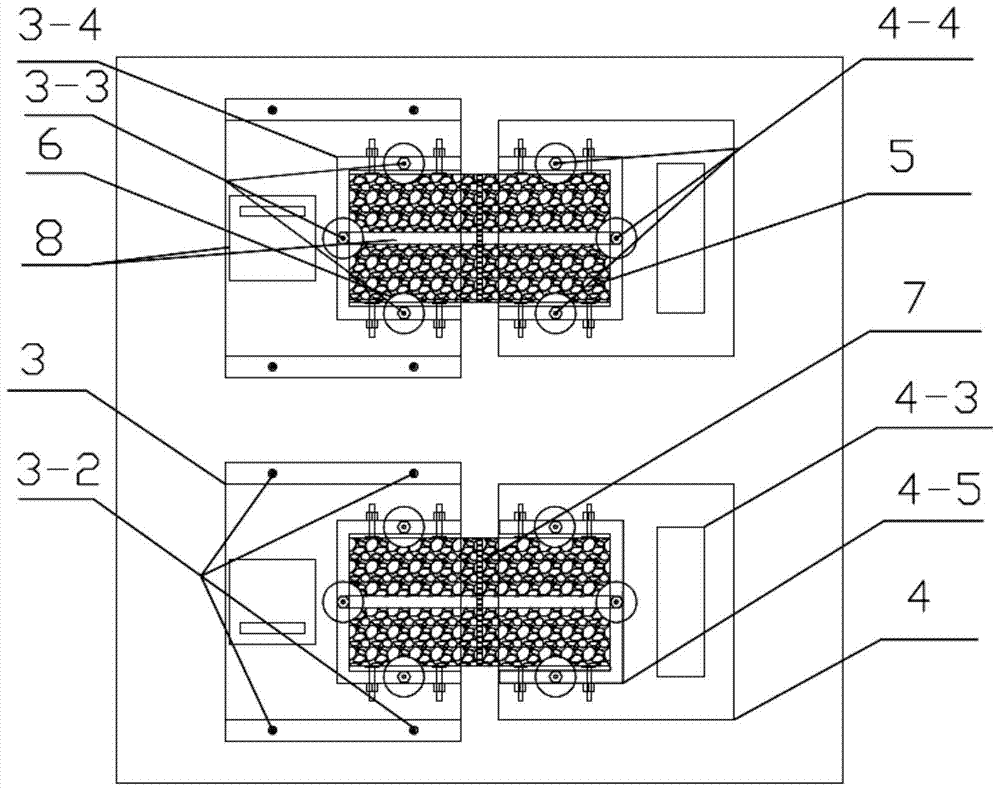

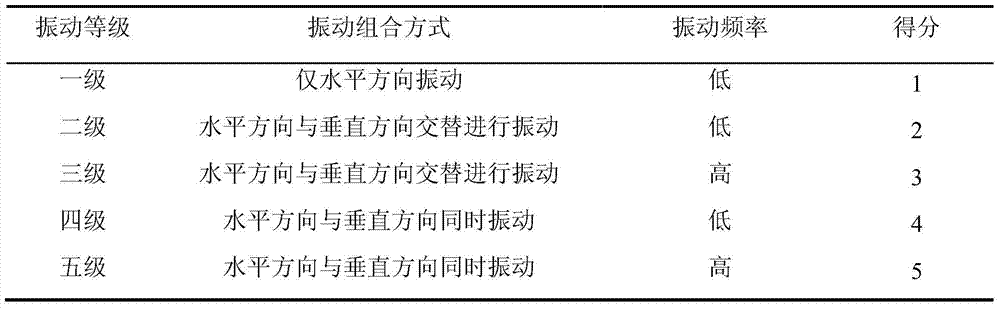

Equipment and method for testing bonding fatigue performance of pavement crack filling material

InactiveCN104777095AImplement performance testingGuaranteed accuracyUsing mechanical meansMaterial analysisElectric machineryRoad surface

Owner:CHANGAN UNIV

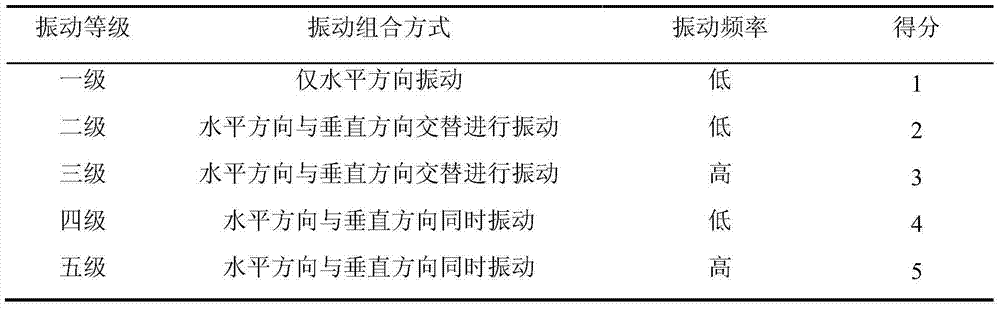

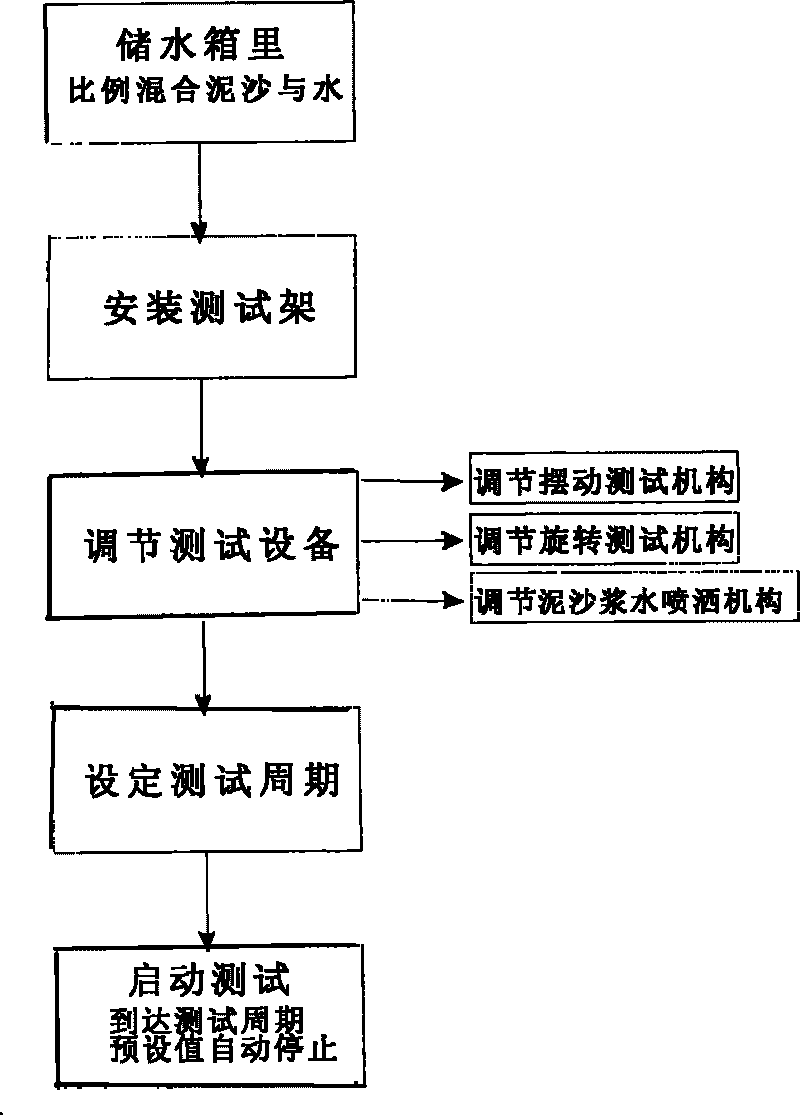

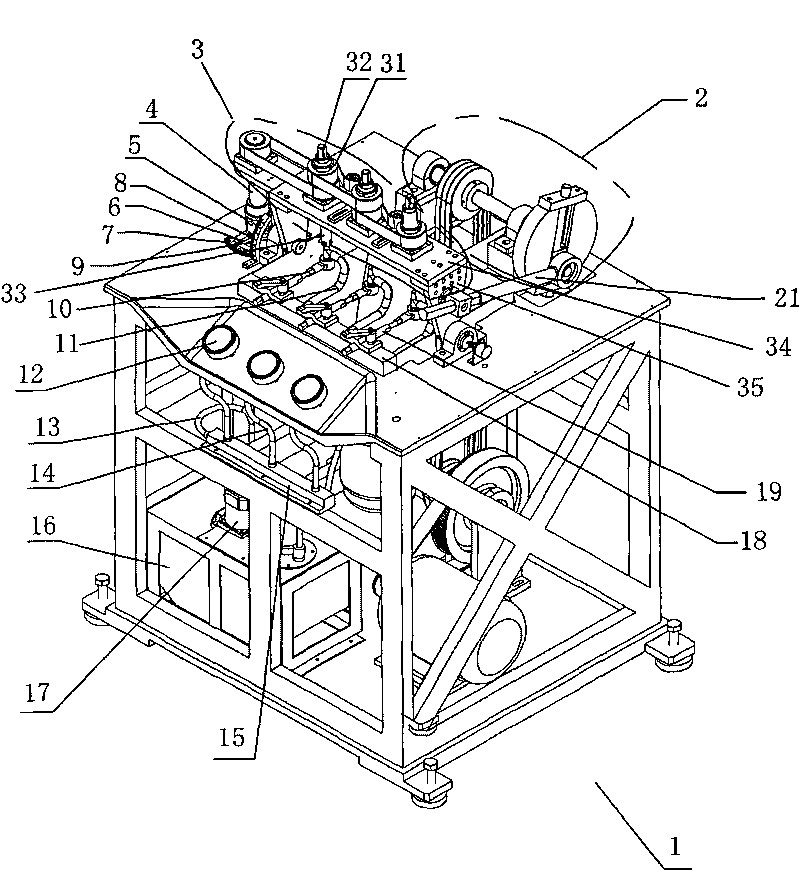

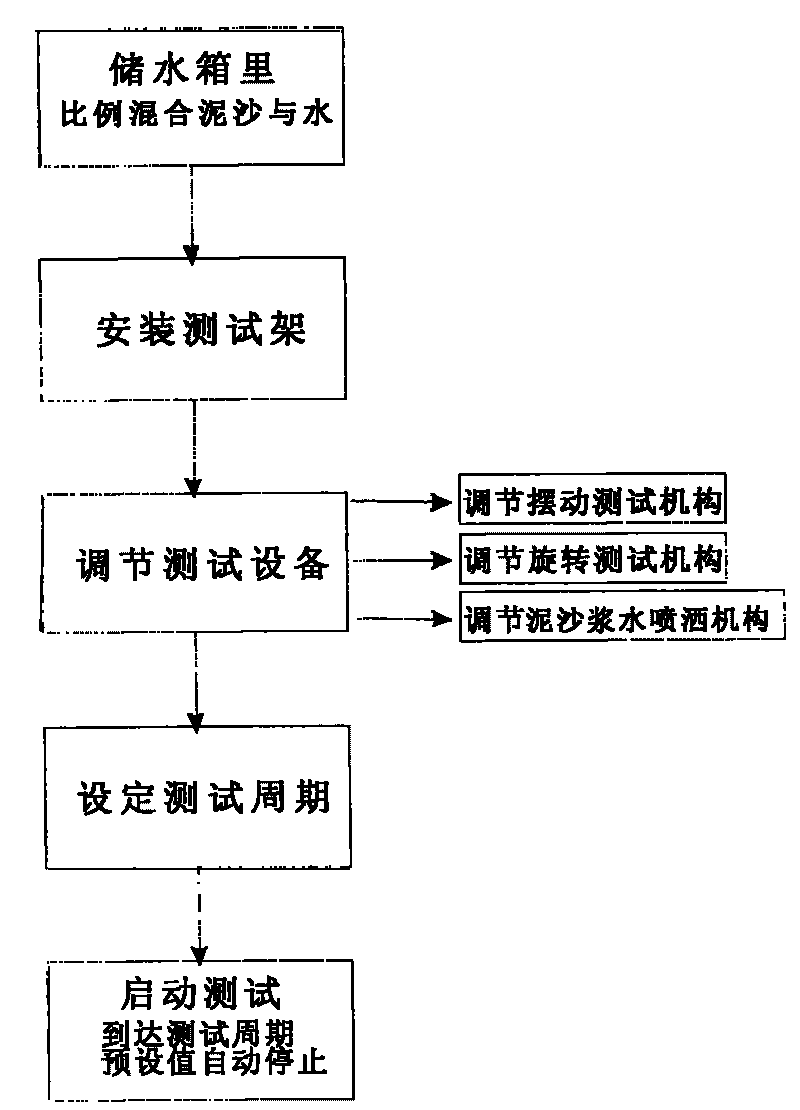

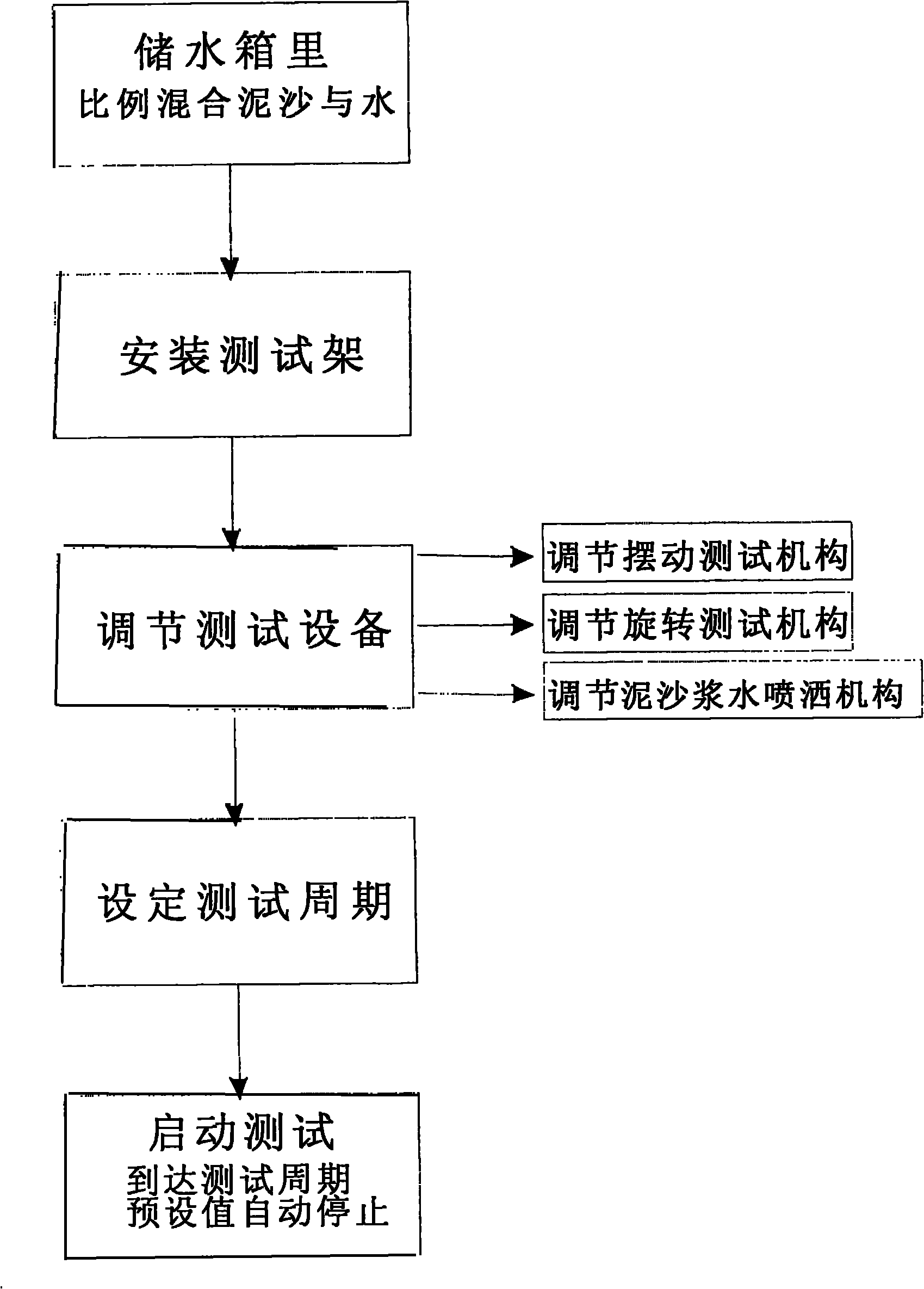

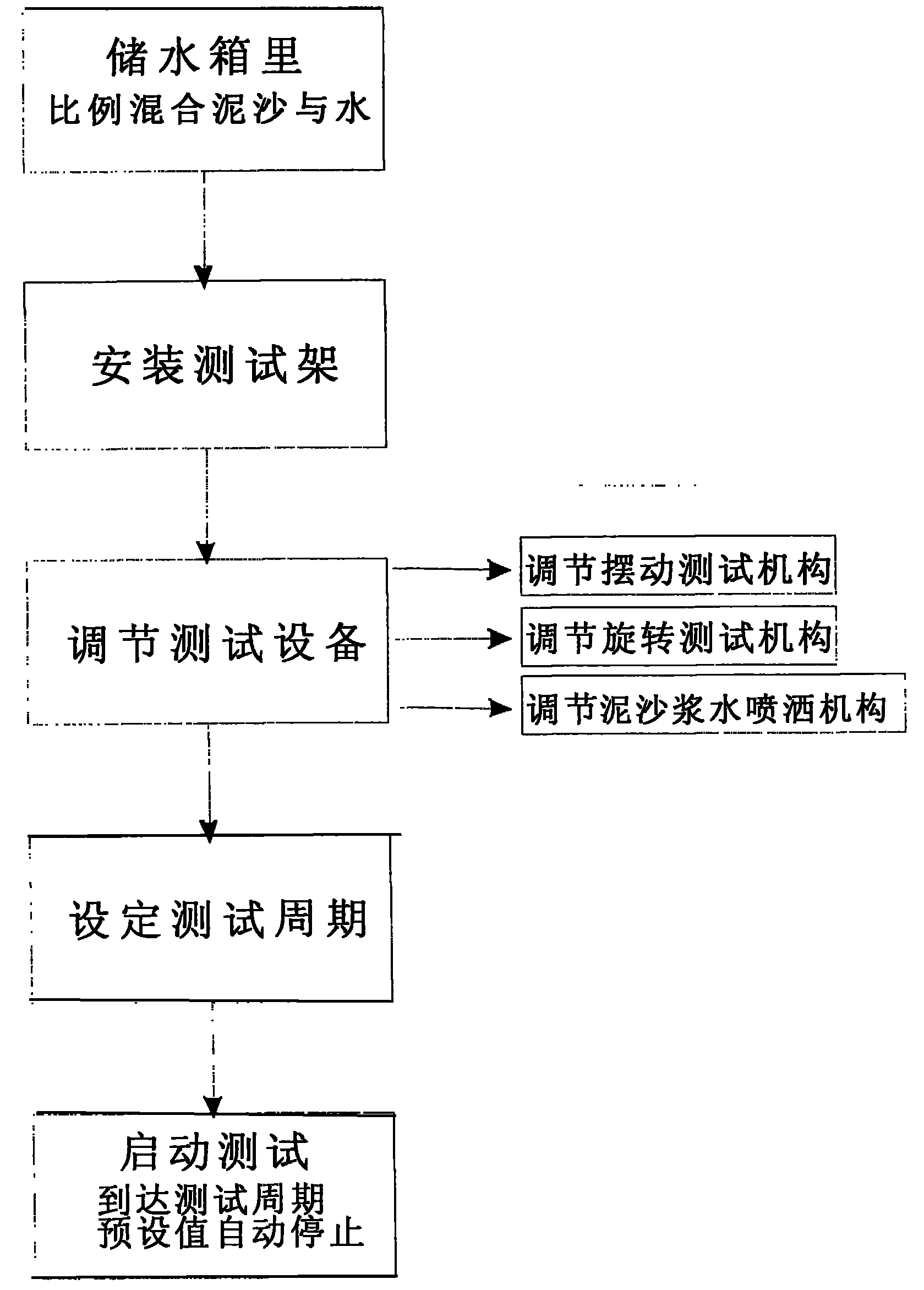

Automobile ball head durability test method

The invention relates to an automobile ball head durability test method and relates to a test method of automobile parts, comprising the following steps: 1. in a slit slurry water-spraying mechanism, slit and water are mixed in a water storage tank and are fully mixed according to the proportion of 50g / 1 liter of the slit and water; 2. a test piece, that is, an automobile ball head is arranged on a test frame of a machine; 3. test equipment is regulated; 4. the test period is set into from 1,000,000 times to 5,000,000 times; 5. the procedures of swinging test, rotating test and slit slurry water spraying are carried out simultaneously, when the test period reaches the setting value, the machine stops, and the test is finished. The method is used for the durability test of the automobile ball head under the condition that severe environment is simulated, so as to test the using performance of the automobile ball to the maximum extent.

Owner:GOTECH TESTING MACHINES DONGGUAN

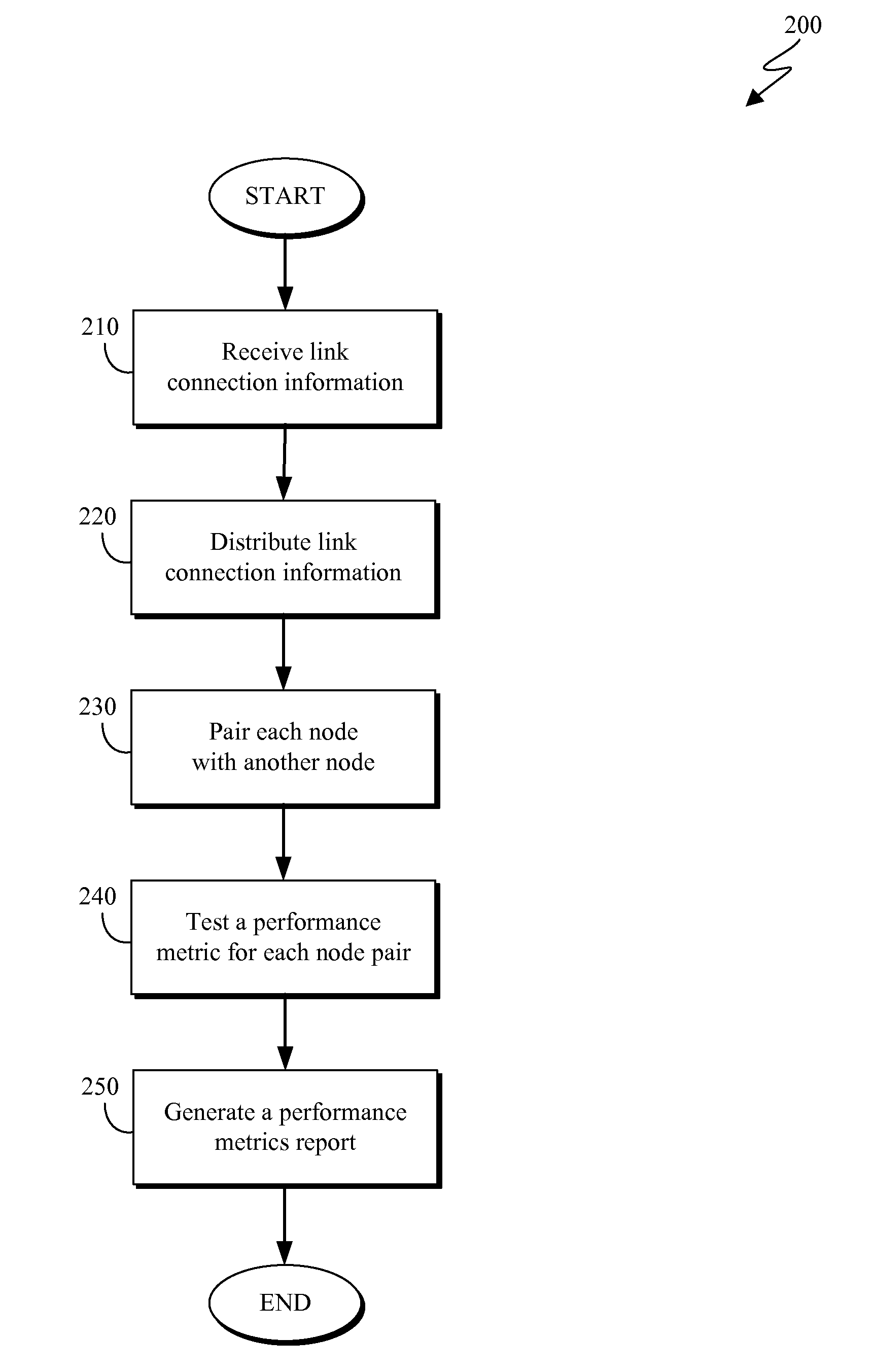

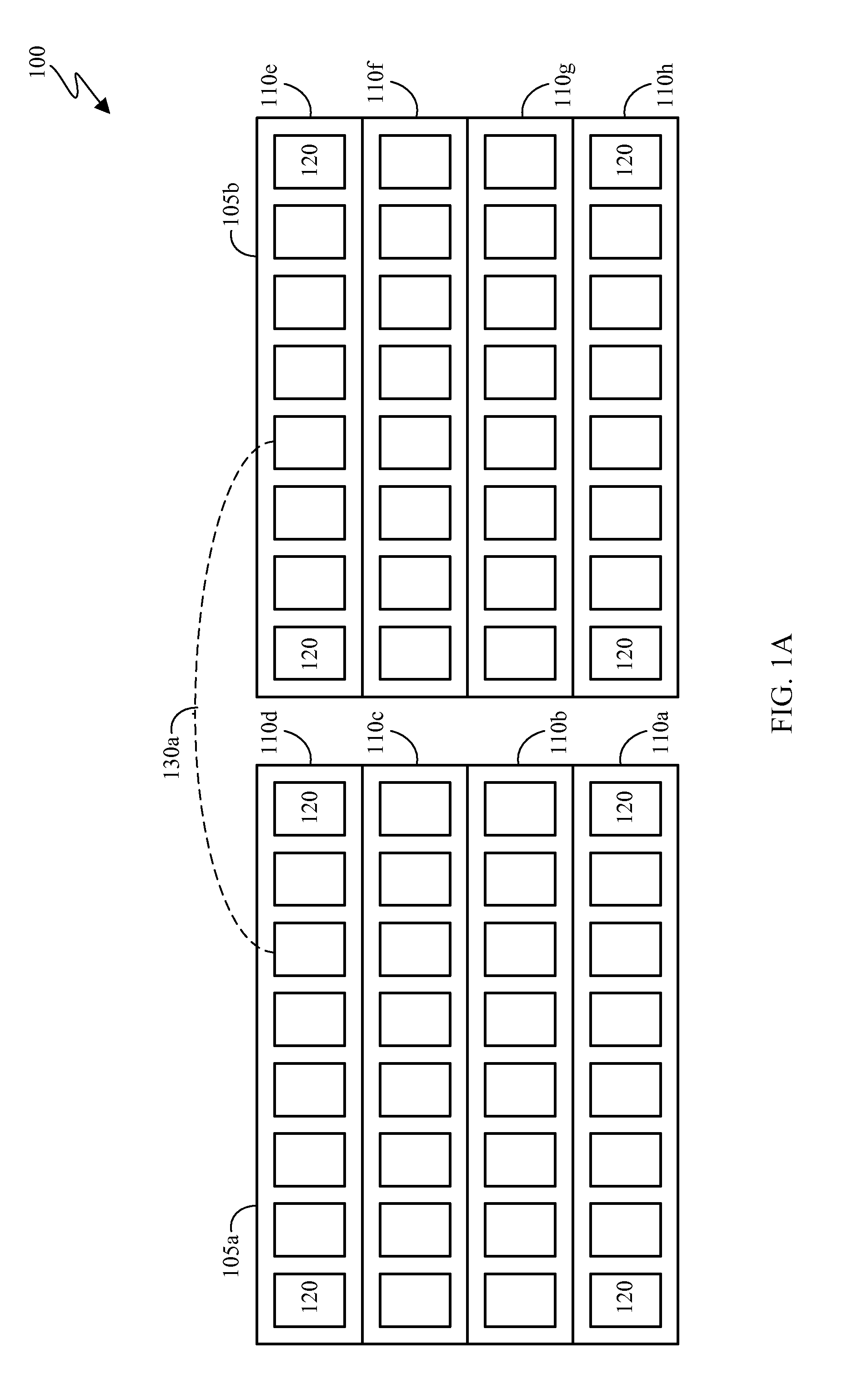

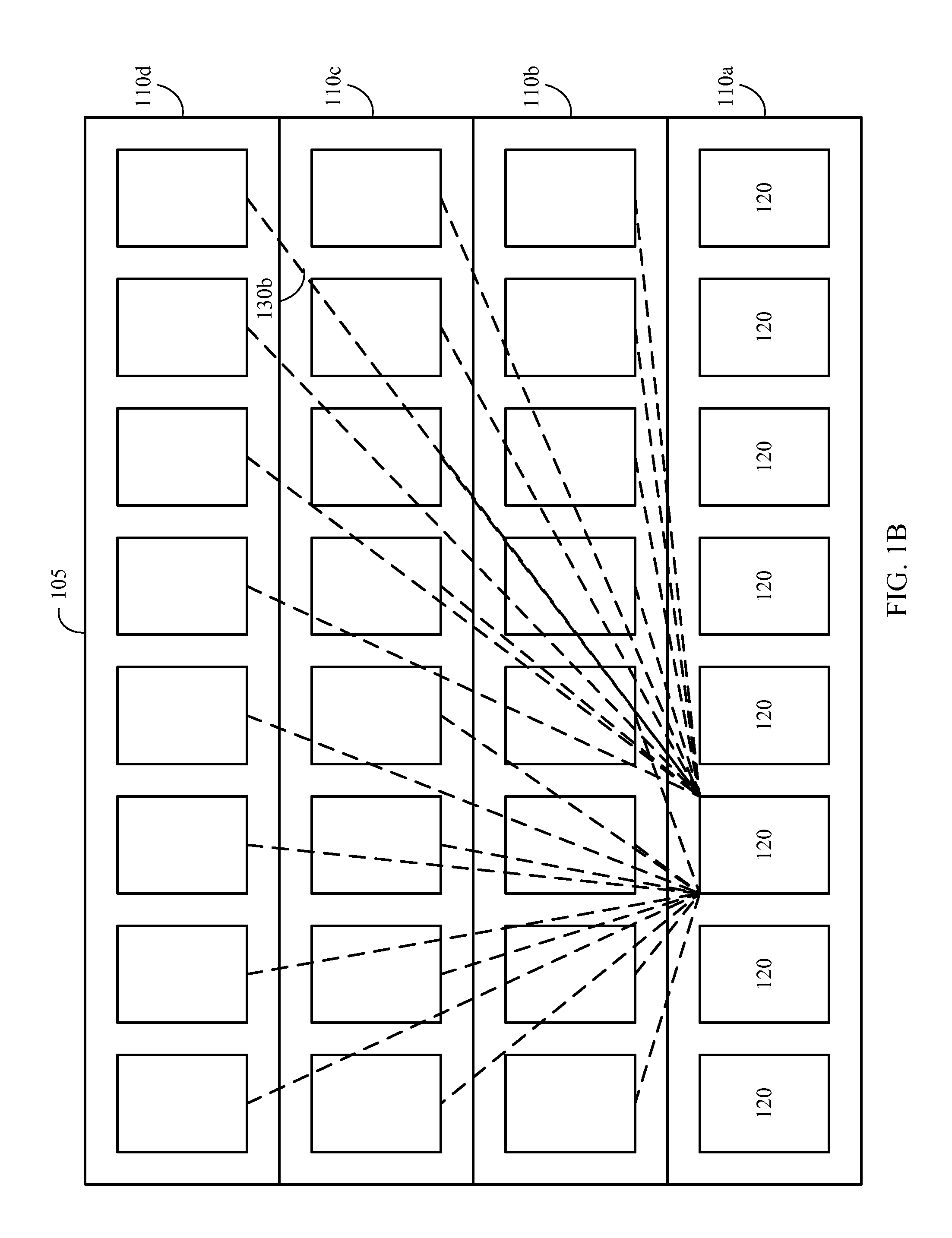

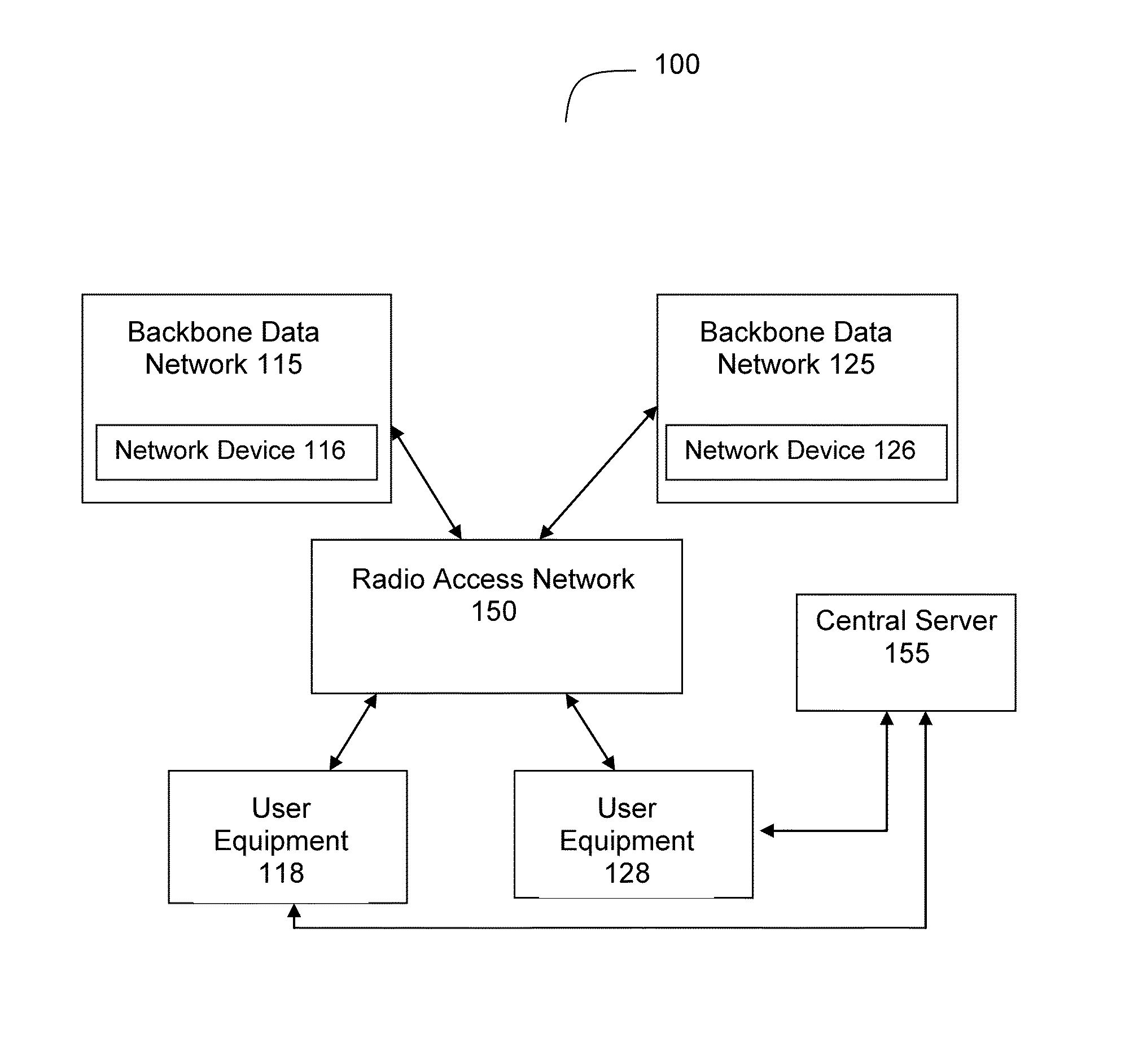

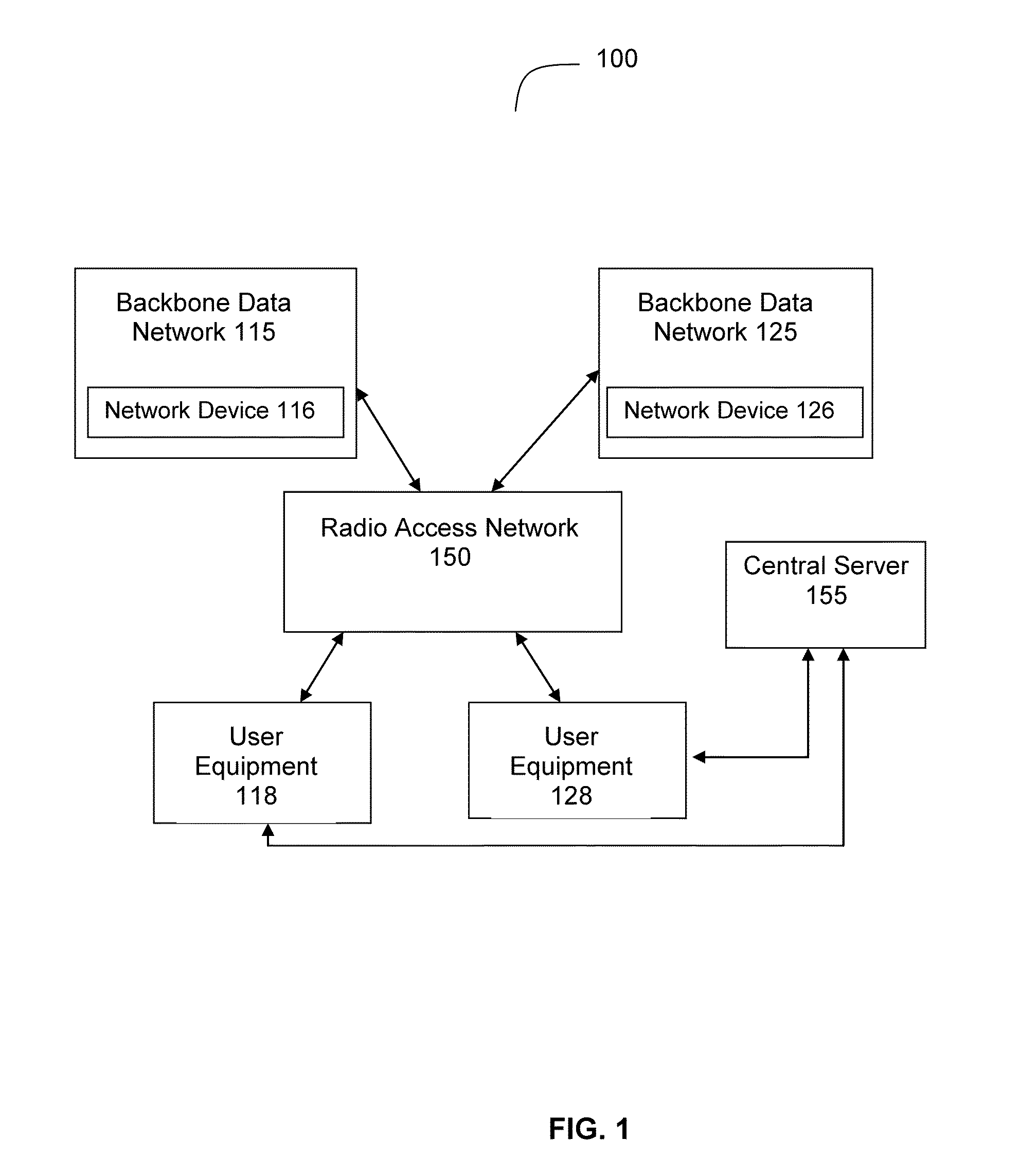

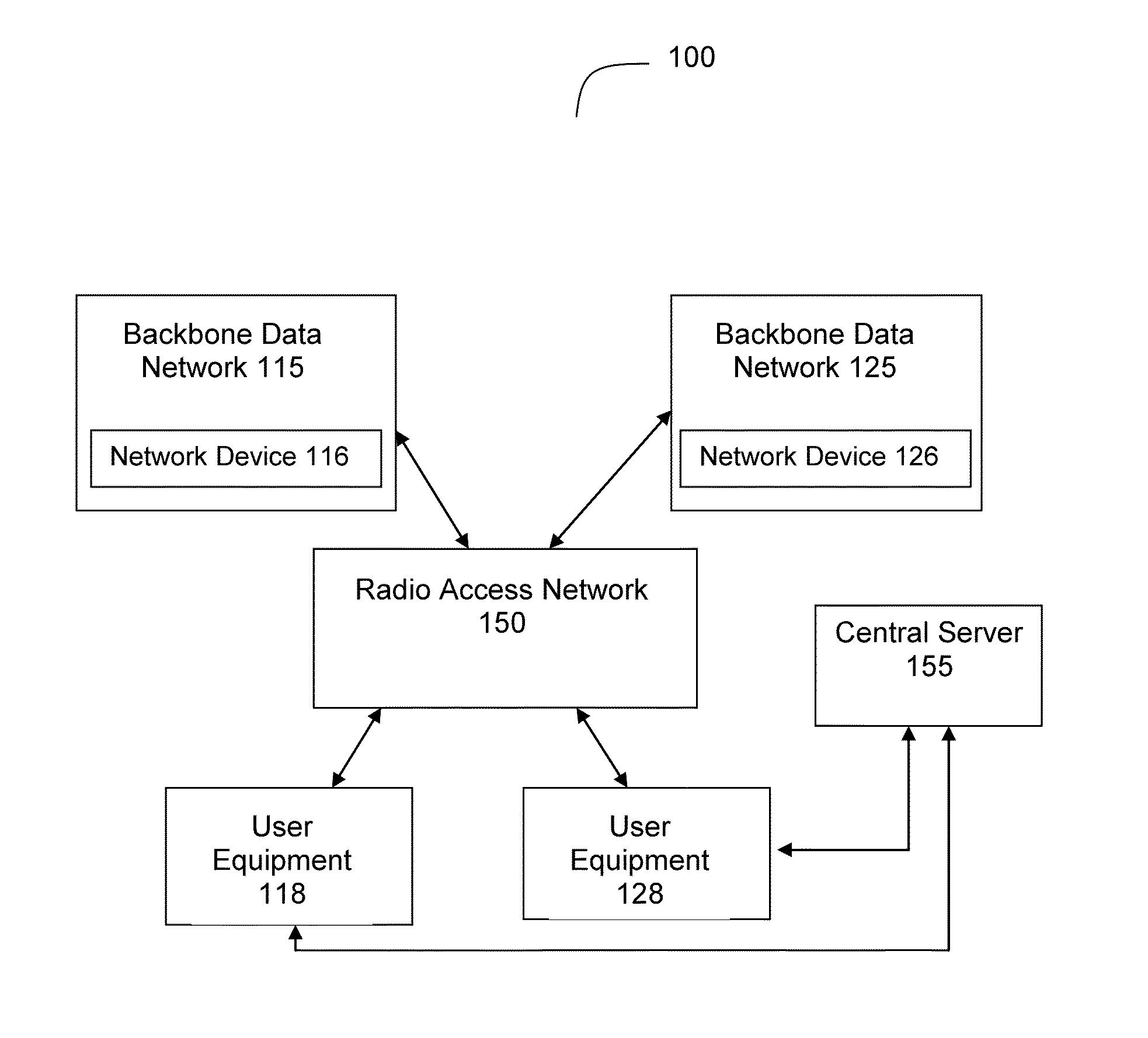

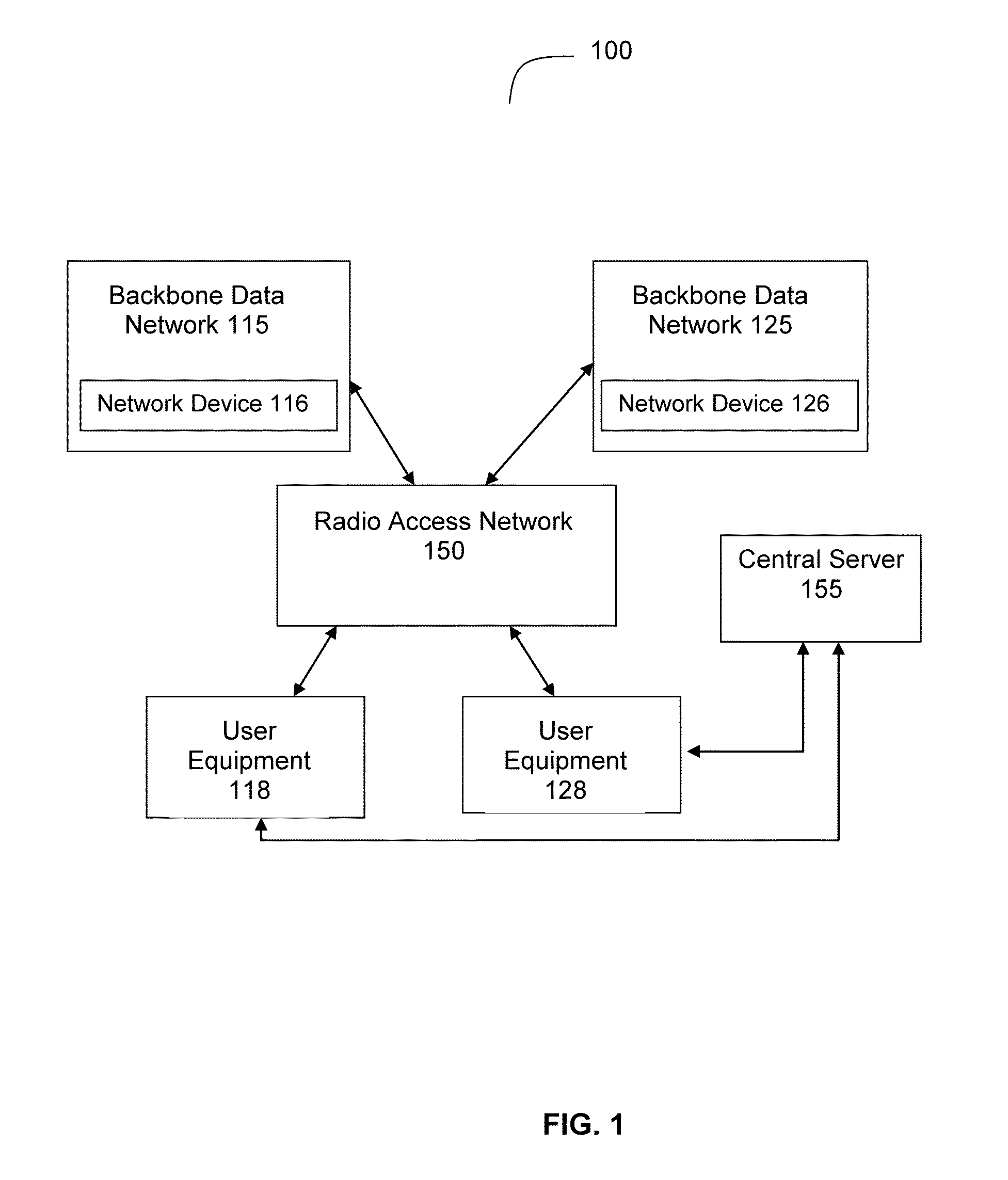

Network performance testing in non-homogeneous networks

InactiveUS20160183110A1Test performanceError preventionFrequency-division multiplex detailsNetwork generationComputerized system

As disclosed herein, a method, executed by a computer, for analyzing a performance metric includes distributing link connection information for a network to each node in the network, pairing each node with another node in the network to provide paired nodes, testing a performance metric for the paired nodes, and generating a performance report for the network. The method may further include receiving link connection information for the network. The method may further include constructing a connectivity graph based on the received link connection information. The method can be used to test link performance within non-homogeneous networks. A computer system product and a computer program product corresponding to the method are also disclosed herein.

Owner:IBM CORP

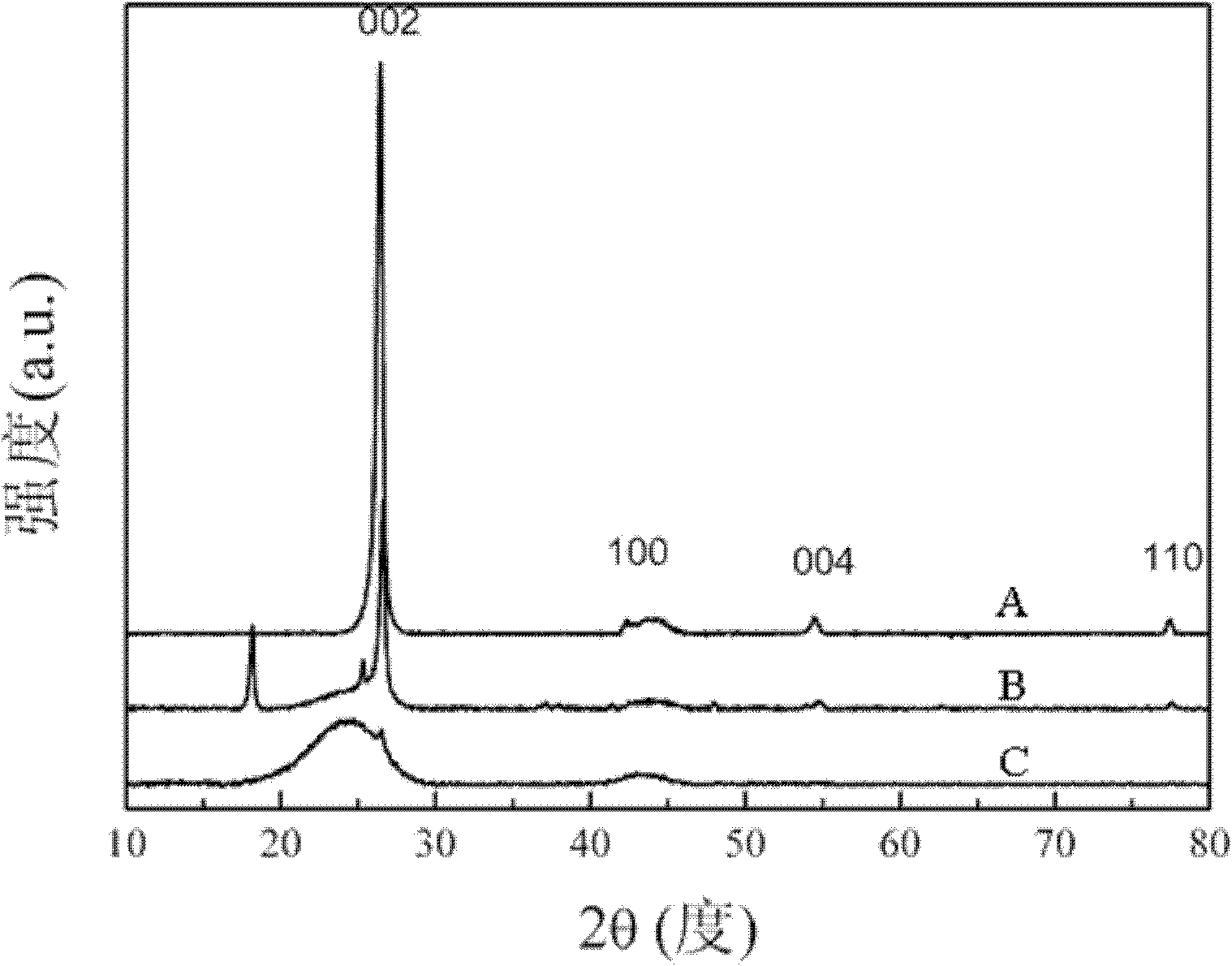

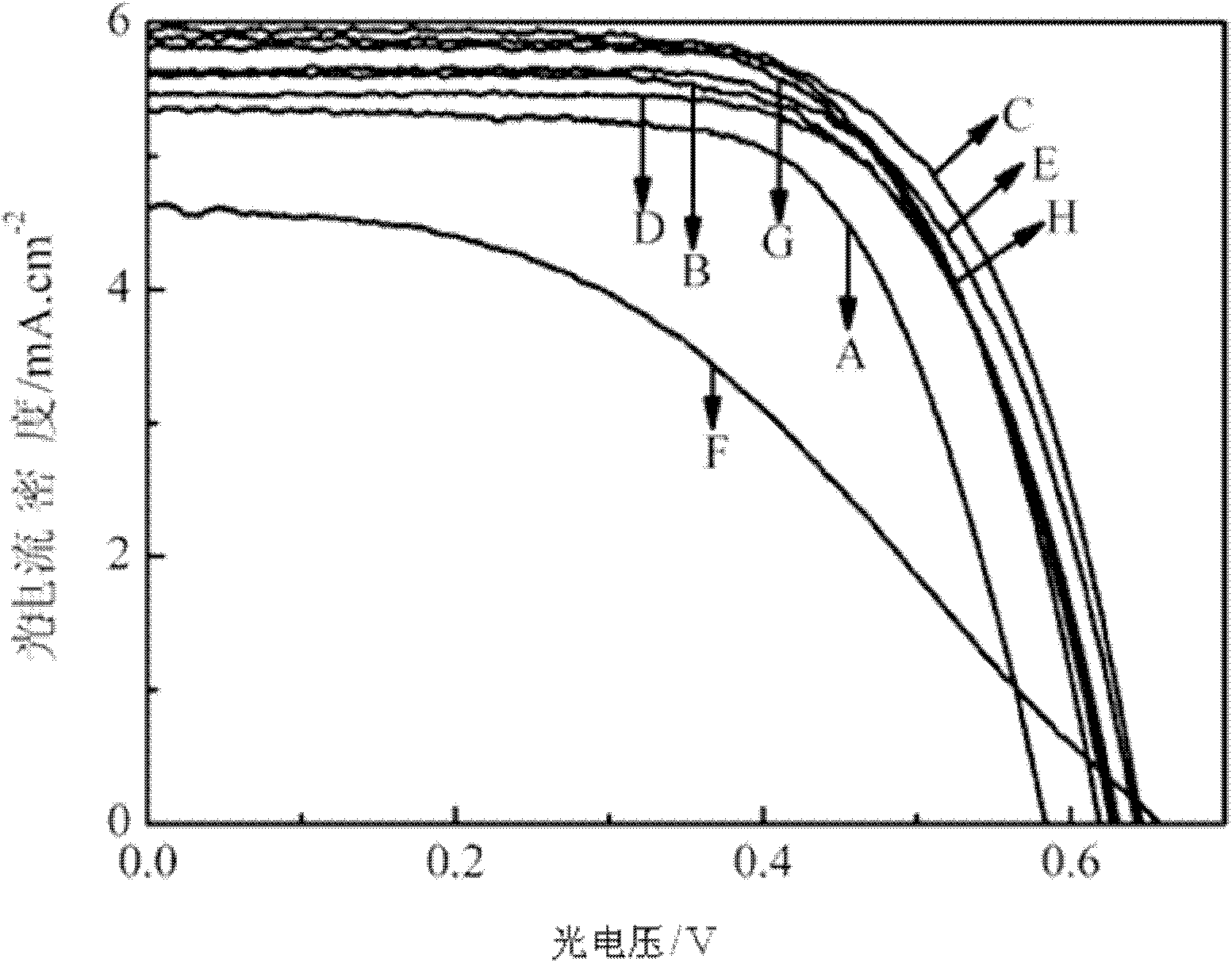

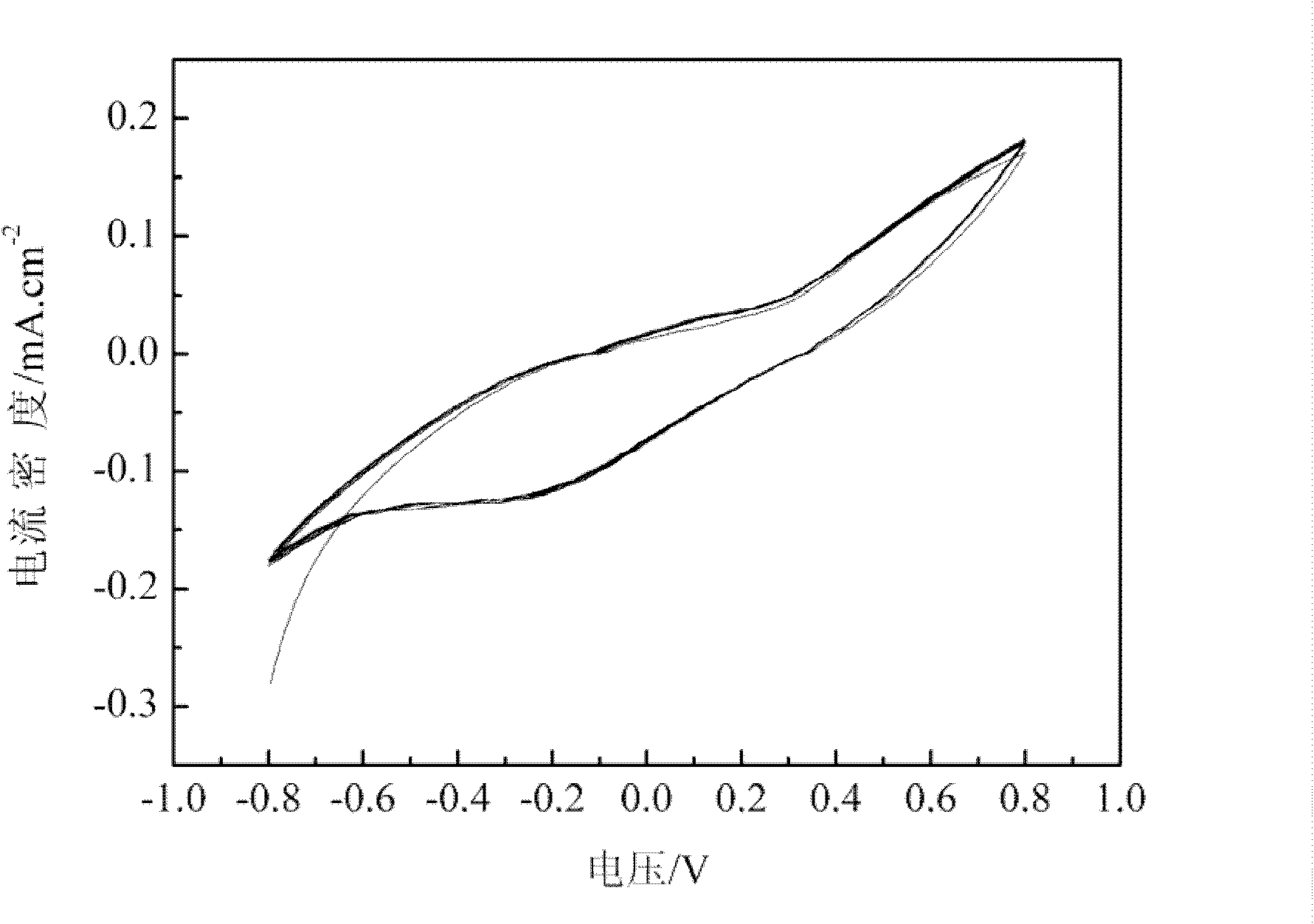

Preparation method of graphene and conductive carbon black composite material counter electrode

The invention provides a preparation method of a graphene and conductive carbon black composite material counter electrode and relates to a preparation method of a counter electrode. The invention aims to solve the problems that a traditional platinum counter electrode is high in price, is high in toxicity and does not facilitate large-scale use, and a graphene conductive film is complicated in preparation process, high in processing temperature and nonideal in electrical conductivity. The preparation method of the grapheme and conductive carbon black composite material counter electrode comprises the following steps of: step 1, weighing and uniformly mixing graphene with conductive carbon black to obtain a mixture; step 2, ball-milling the mixture obtained in the step 1 as well as polytetrafluoroethylene and N-methyl pyrrolidone to obtain slurry; and step 3, scrape-coating the slurry obtained in the step 2 on conductive glass and drying to obtain the graphene and conductive carbon black composite material counter electrode. The preparation method has the beneficial effects that the cost is low, and the process is simple; and when a counter electrode film is formed by 25 percent of grapheme, 70 percent of conductive carbon black and 5 percent of PTFE (Polytetrafluoroethylene), the photoelectric conversion efficiency of a system is the highest and exceeds that of the traditional platinum counter electrode. The preparation method is used for preparing the counter electrode.

Owner:HEILONGJIANG UNIV

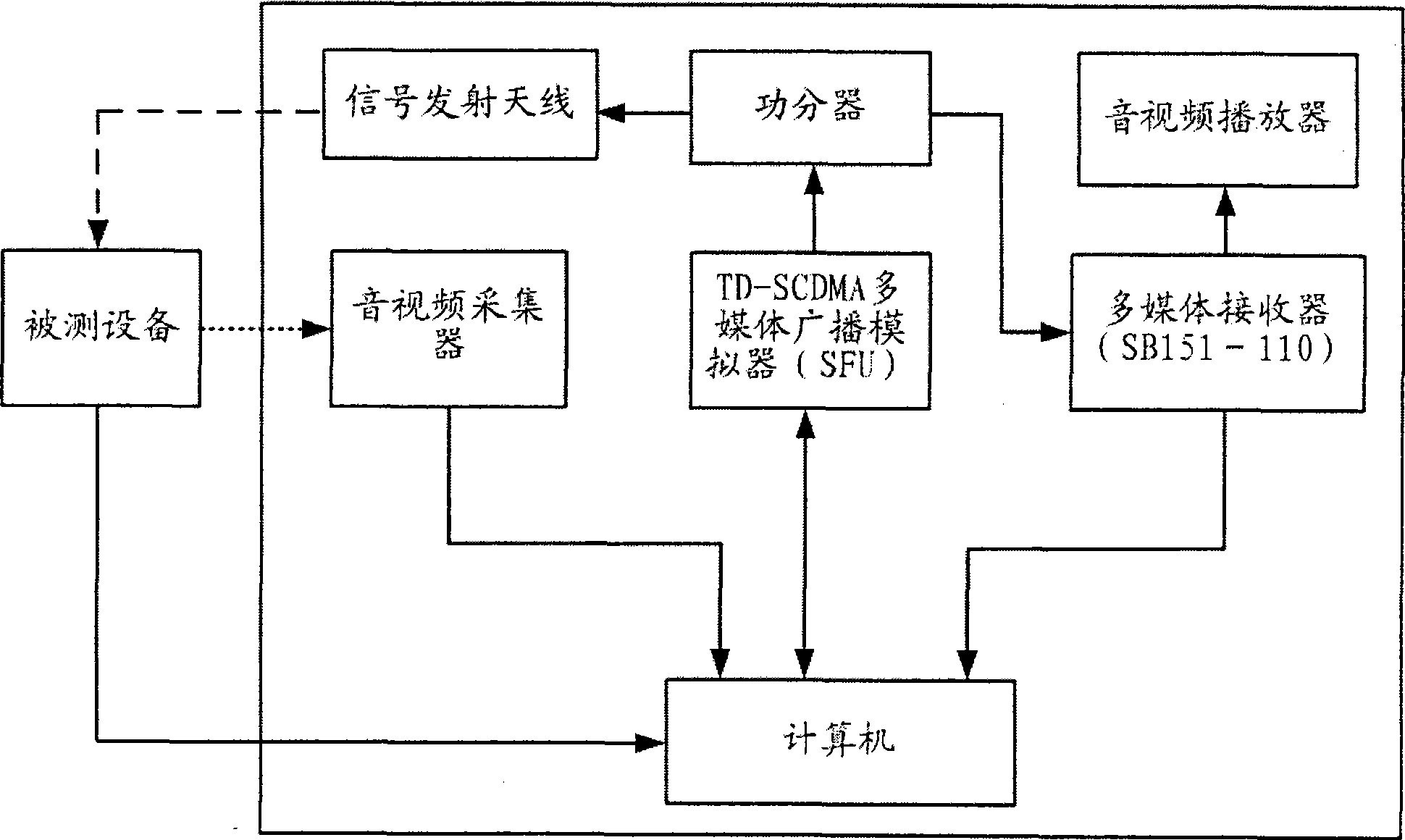

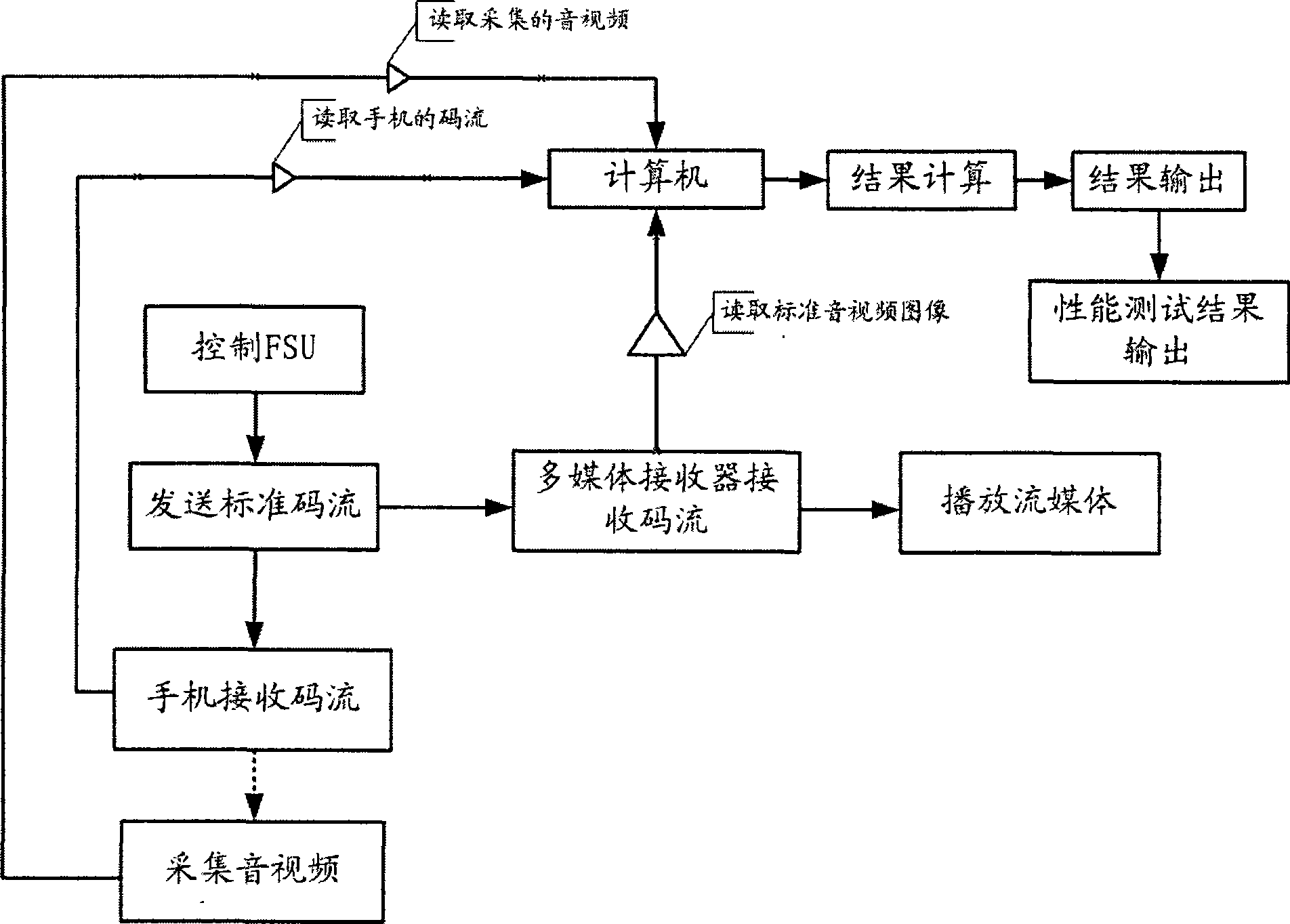

Performance test system for mobile phone stream media data service access by TD-SCDMA

ActiveCN101400078AImprove test accuracyHigh degree of automationBroadcast-related systemsWireless communicationComputer hardwareVideo player

The invention relates to a time-division synchronous code division multiple access handset flow medium data service performance testing system, belonging to the field of electromagnetic compatibility testing technology of the wireless communication products, the system comprises: a TD-SCDMA multimedia broadcast simulator, a multimedia receiver, an audio and video collector, a power distributor, an audio and video player, a signal transmitting antenna and a computer and control programs stored therein; the computer is connected with the TD-SCDMA multimedia broadcast simulator through GPIB cables, the TD-SCDMA multimedia broadcast simulator is connected with the power distributor through signal wires, the power distributor is respectively connected with the multimedia receiver and the signal transmitting antenna through the signal cables, the computer also is respectively connected with the multimedia receiver and the audio and video collector through the signal cables; the multimedia receiver is connected with the audio and video player. The system has the characteristics of high testing accuracy, convenient operation, high automaticity, low uncertainty.

Owner:CHINA ACADEMY OF INFORMATION & COMM

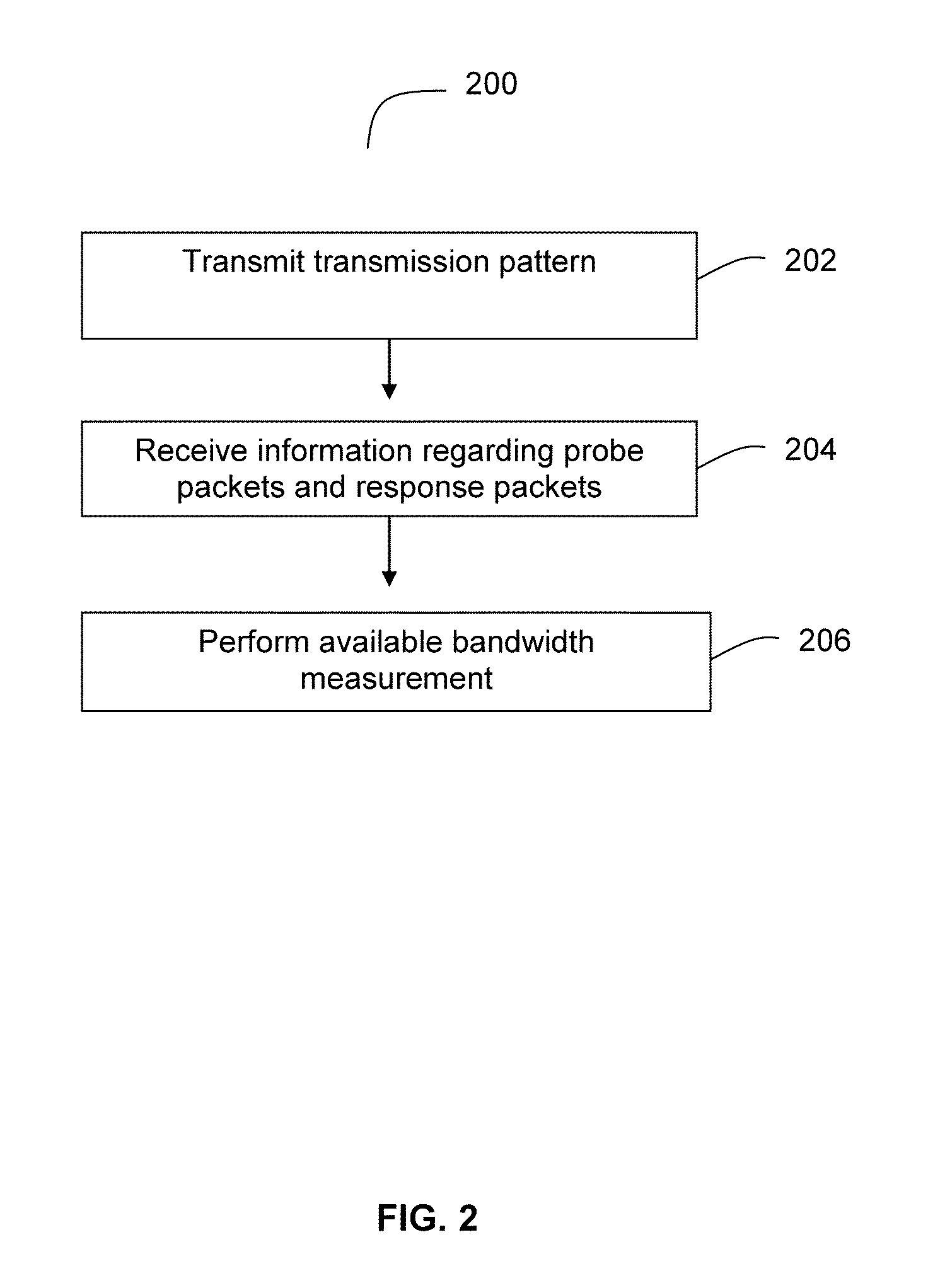

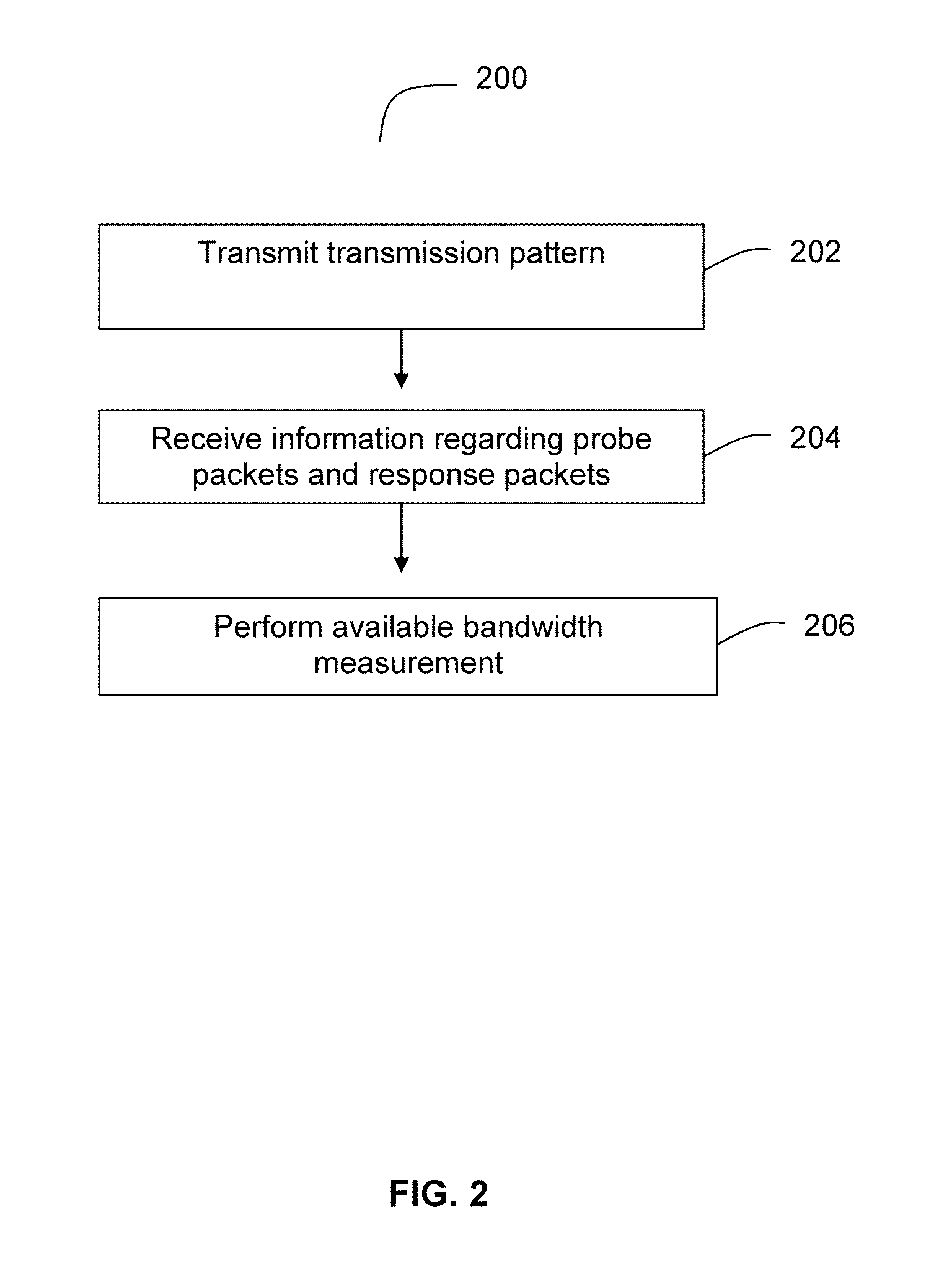

Systems and Methods for Measuring Available Bandwidth in Mobile Telecommunications Networks

ActiveUS20140056218A1Test performanceNetwork traffic/resource managementWireless commuication servicesTimestampBandwidth measurement

A network device receives probe packets communicated by a user equipment device. The network device communicates response packets back to the user equipment device, including timestamps, and / or other information. The user equipment device may be configured to test the performance of different portions of a wireless network (i.e., determine an available bandwidth measurement throughput (ABMT) of the wireless network) by accessing different network devices (or information associated with different network devices).

Owner:INFOVISTA

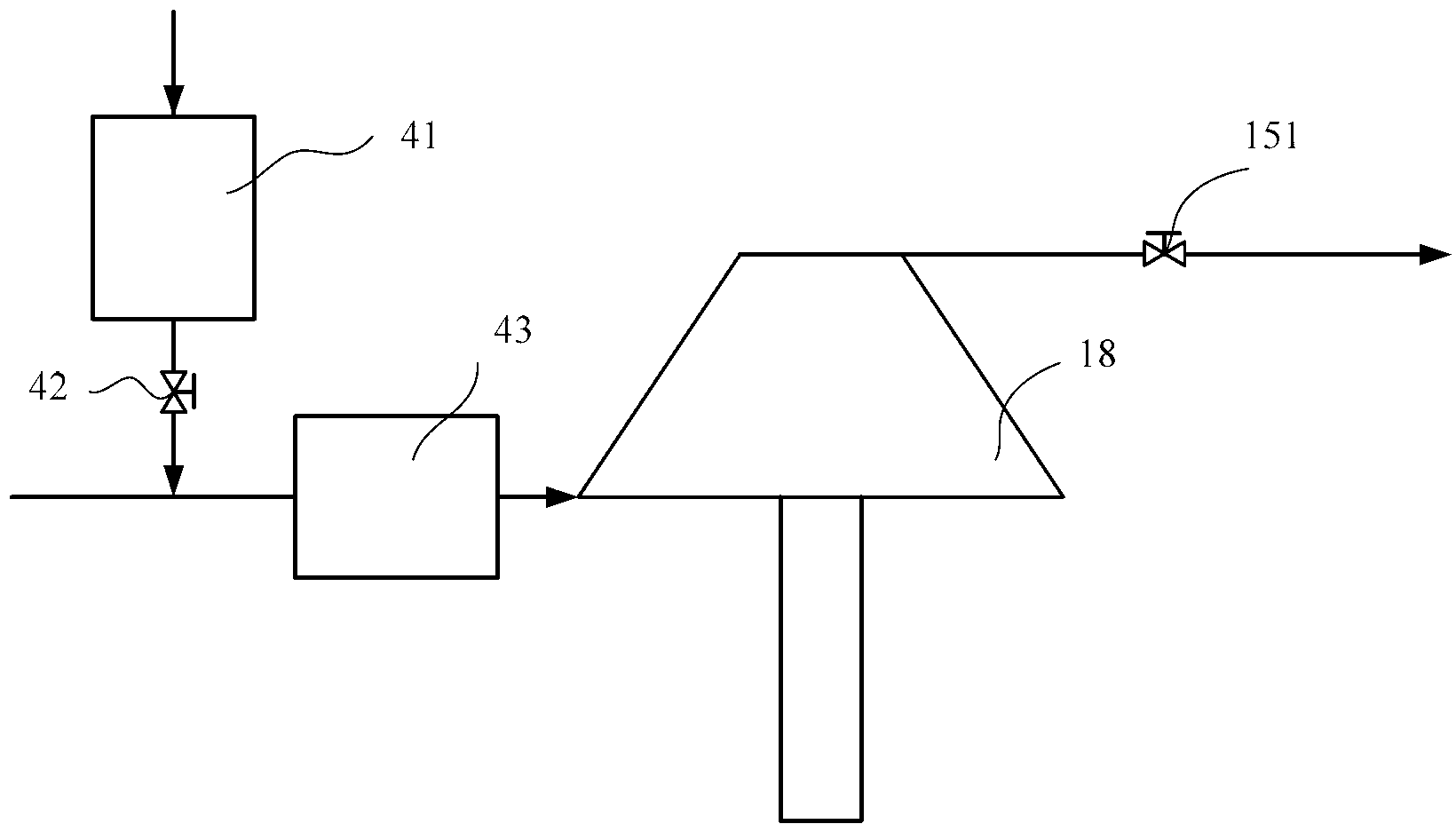

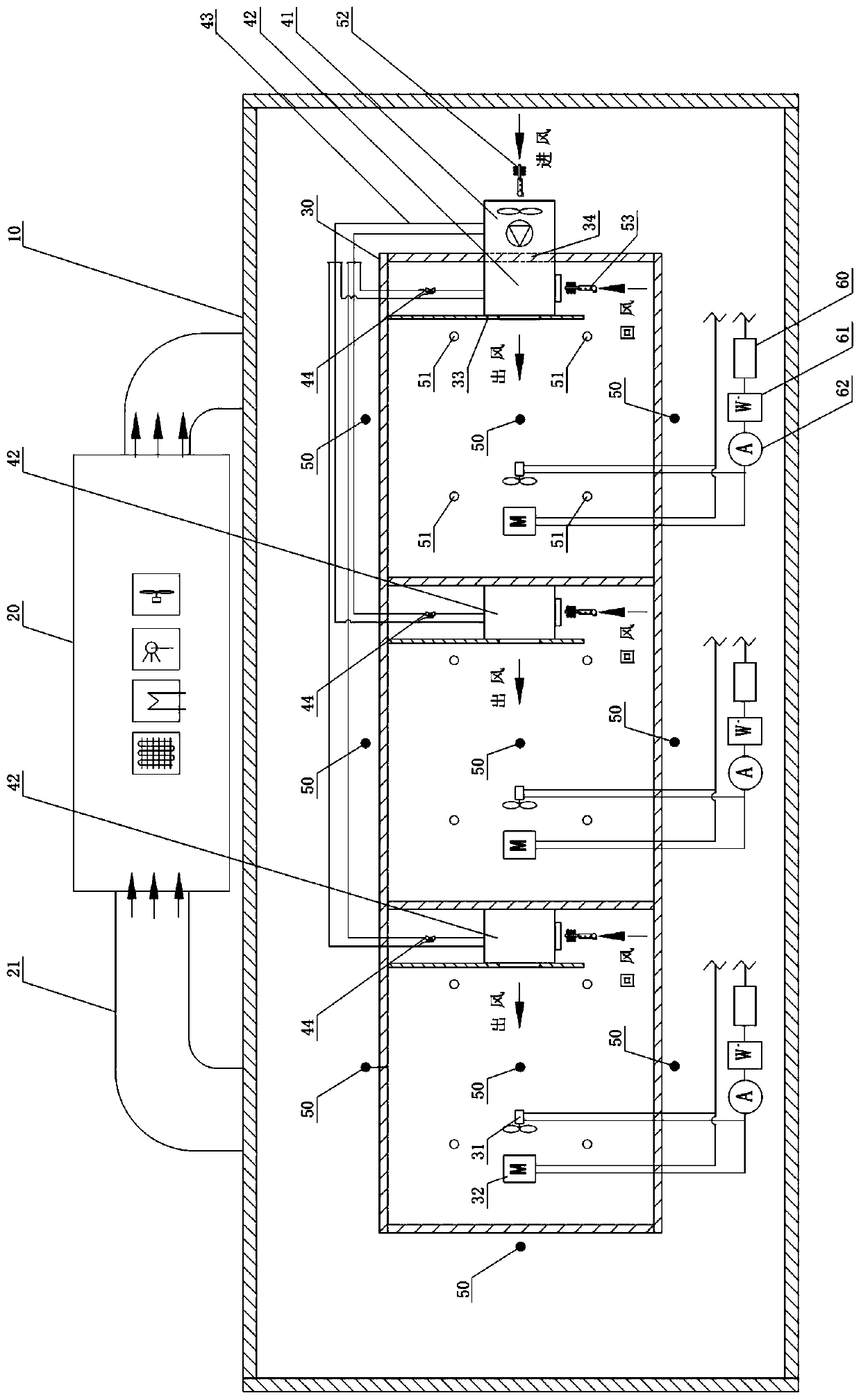

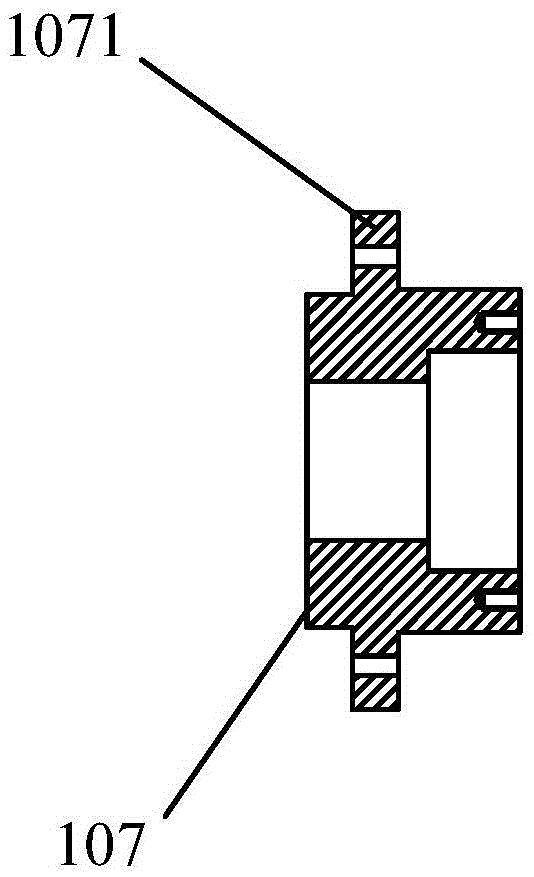

Box type oil distributor rotating test system

ActiveCN106323616ATest performanceMeet the requirementsMachine part testingHydraulic control unitOil distribution

The invention discloses a box type oil distributor rotating test system, and belongs to the field of marine machinery. The system comprises a driving unit which is used for driving the oil distribution shaft of a box type oil distributor to rotate and a hydraulic control unit which is used for testing the oil drainage amount between the oil distribution shaft and the oil distribution ring of the box type oil distributor. Comprehensive detection of the box type oil distributor before use can be realized through the driving unit and the hydraulic control unit so as to produce the box type oil distributor meeting the use requirements.

Owner:WUHAN MARINE MACHINERY PLANT

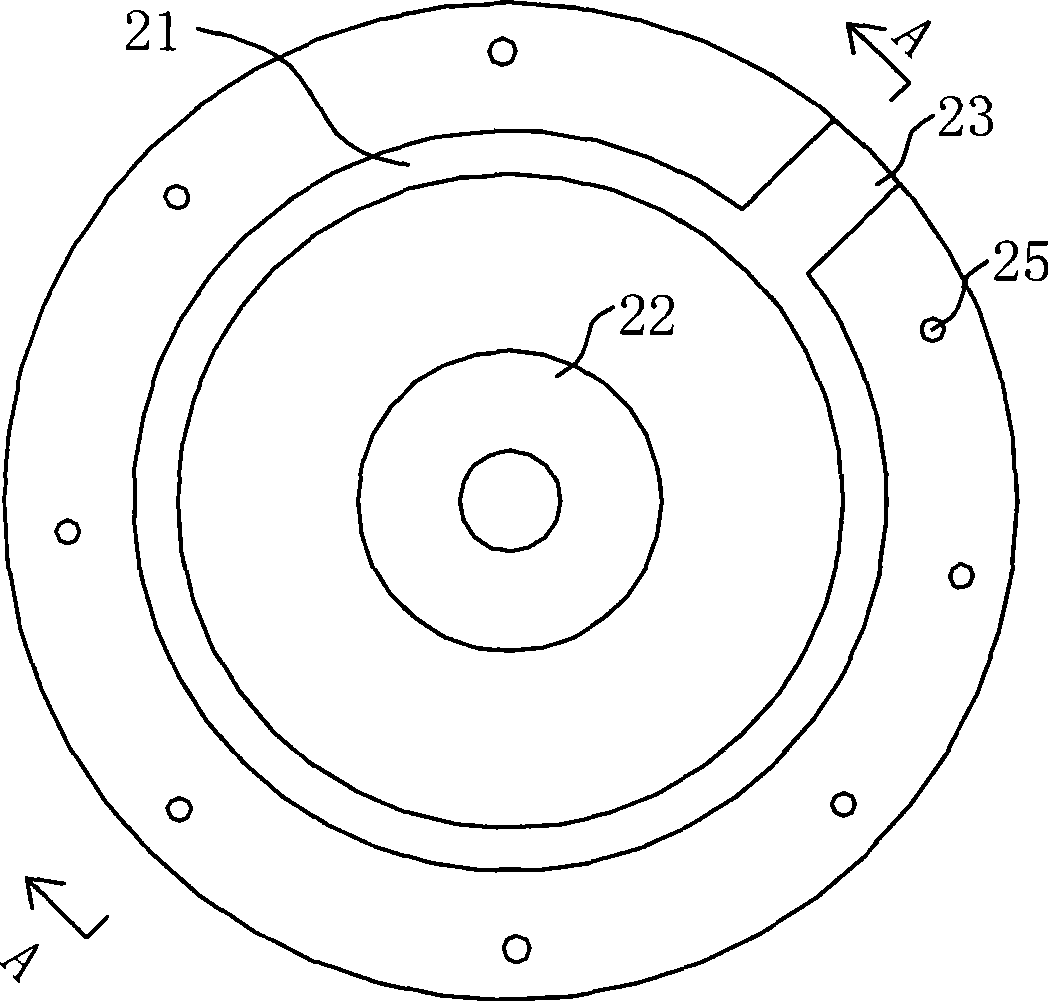

Revolving gear for spin-testing table for automobile gear box

Owner:WUHU WANLIYANG TRANSMISSION CO LTD

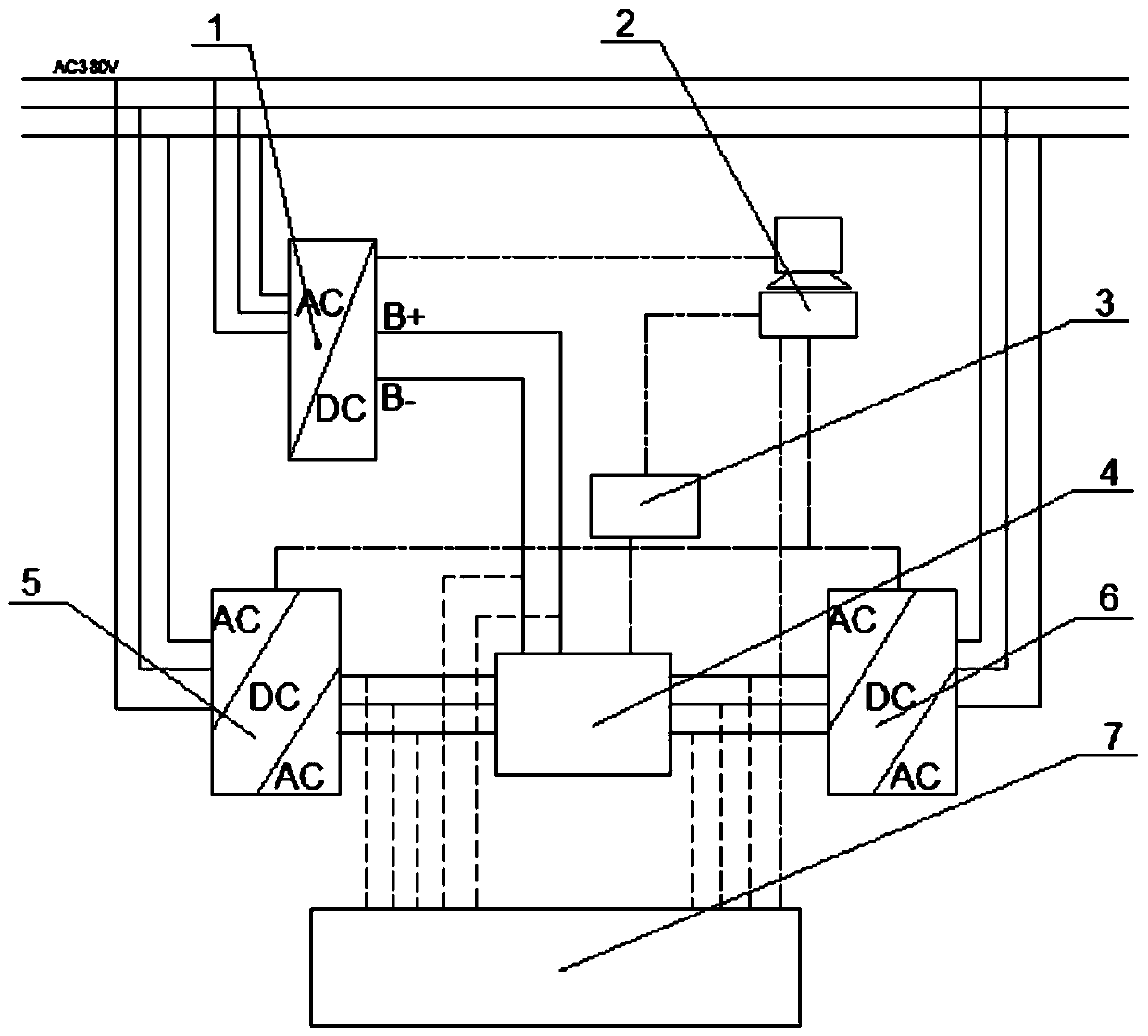

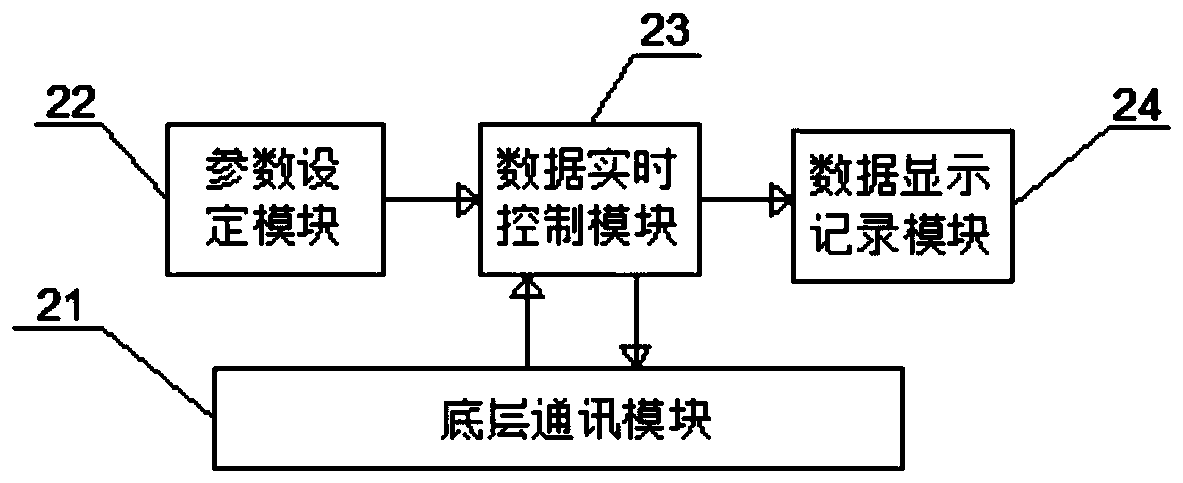

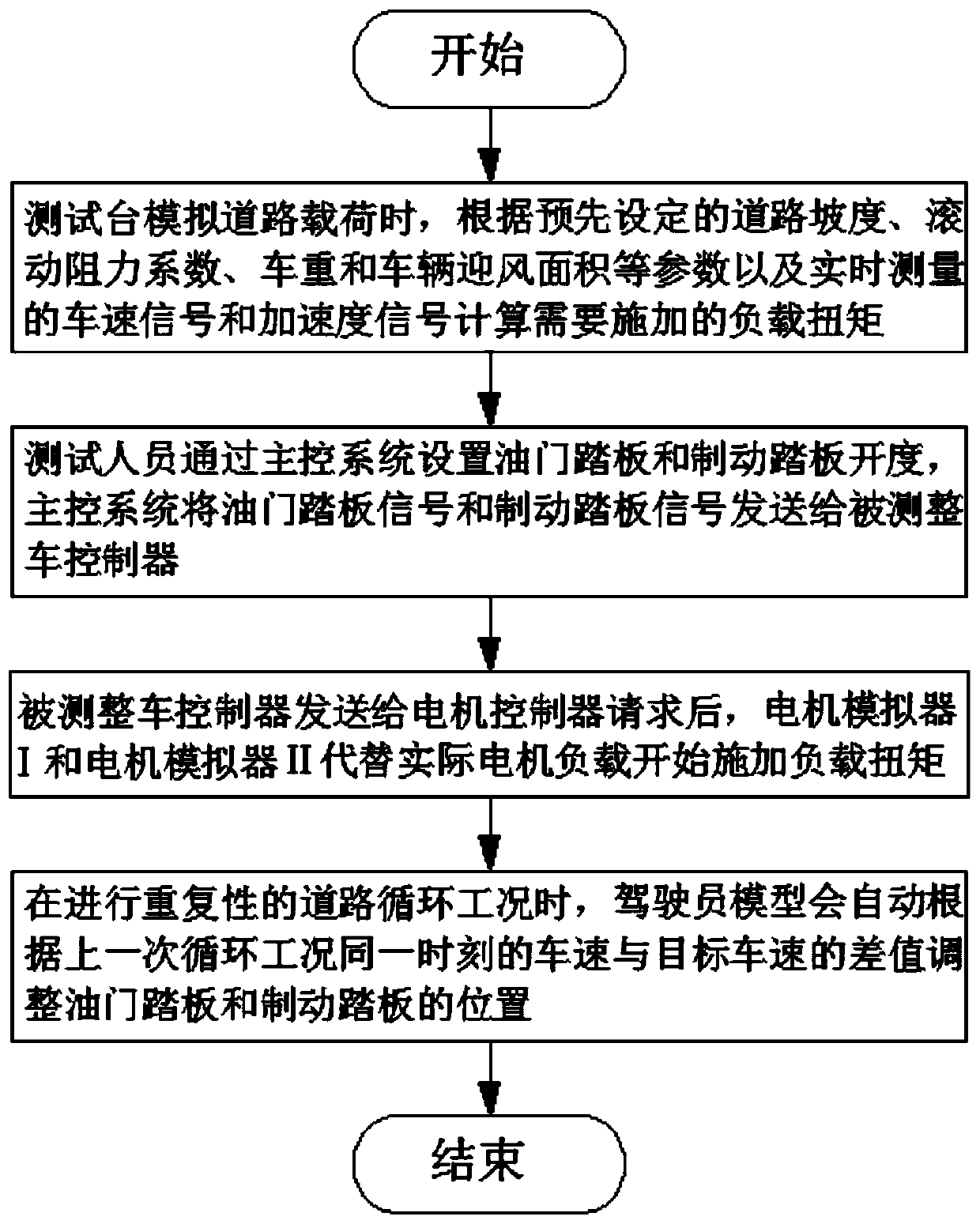

Distribution type driving control system testing platform

PendingCN109947085ASave spaceShorten the test cycleElectric testing/monitoringPower flowControl system

The invention discloses a distribution type driving control system testing platform which comprises a battery simulator, wherein the battery simulator is respectively and electrically connected with amain control system and a motor controller; the main control system is electrically connected with a tested overall controller; the tested overall controller is electrically connected with a motor controller; the motor controller is respectively and electrically connected with a motor simulator I and a motor simulator II ; input ends of the motor simulator I and the motor simulator II are electrically connected with a 380V voltage and used as actual motor loads to test voltage and current parameters output from a control system; a power analyzer is respectively and electrically connected withthe battery simulator, the main control system, the motor simulator I and the motor simulator II. By adopting the testing platform, actual motor loads are replaced by power grade motor simulators, testing can be carried out by using a power grade motor simulator matched with distribution type driving, motors, power testers, torque rotation speed sensors, and the like are avoided, and the space, cost and time are greatly reduced.

Owner:SUZHOU HUAYE DETECTION TECHNOLOGY SERVICE CO LTD

Quality inspection machine for bearing detection and repair

InactiveCN111036455AReduce use costTest performanceMachine bearings testingSpraying apparatusDrive wheelElectric machinery

The invention discloses a quality inspection machine for bearing detection and repair. The quality inspection machine comprises a machine body, wherein a working space with a forward opening is formedin the machine body, a detection device used for detecting the rotating speed of a bearing is arranged in the working space, and the detection device comprises an adjusting motor fixedly installed inthe working space. The quality inspection machine is advantaged in that the bearing can be completely fixed through a bottom fixing rod and a top fixing rod, then the bearing can be driven to reach arated rotating speed through rotation of a driving wheel, a light-emitting head and a photosensitive recording plate are used for measuring the internal loss degree of the bearing, a nozzle is for oiling repair, so some large bearings can be reused after being repaired, and performance of the bearing can be tested while use cost of the bearing is reduced.

Owner:SHENGZHOU NINGFENG BEARING CO LTD

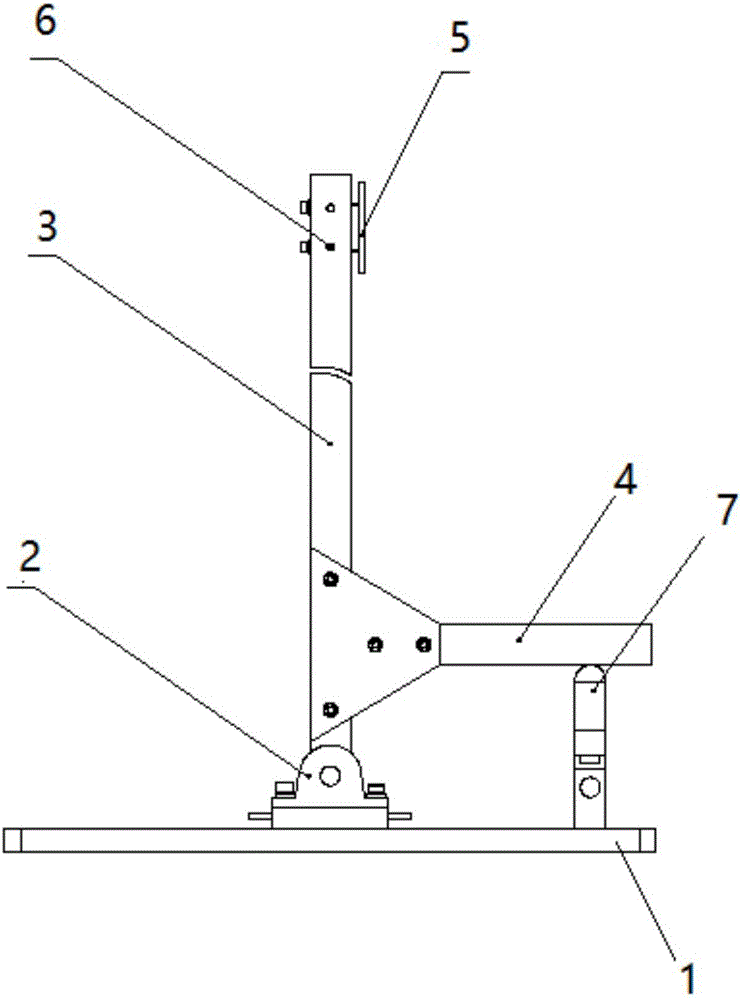

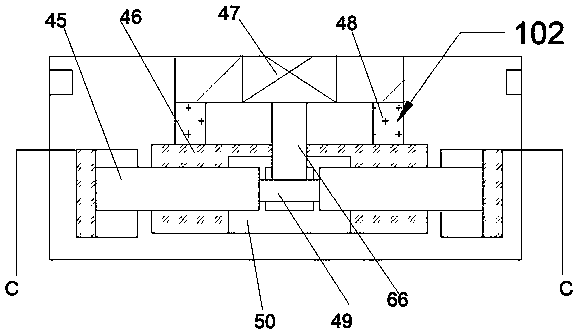

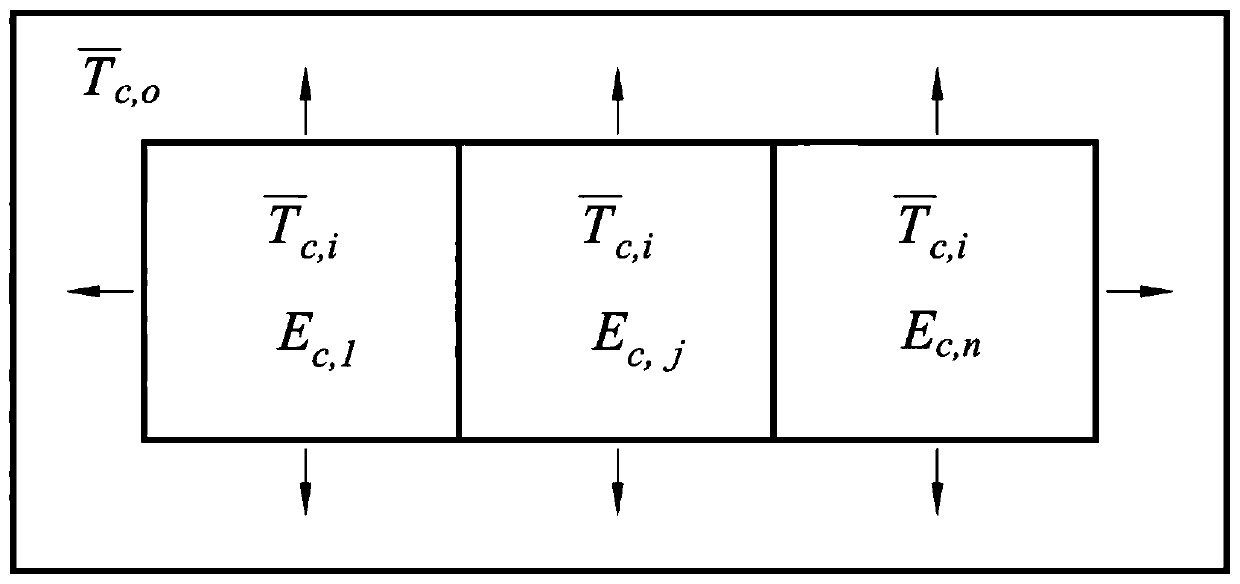

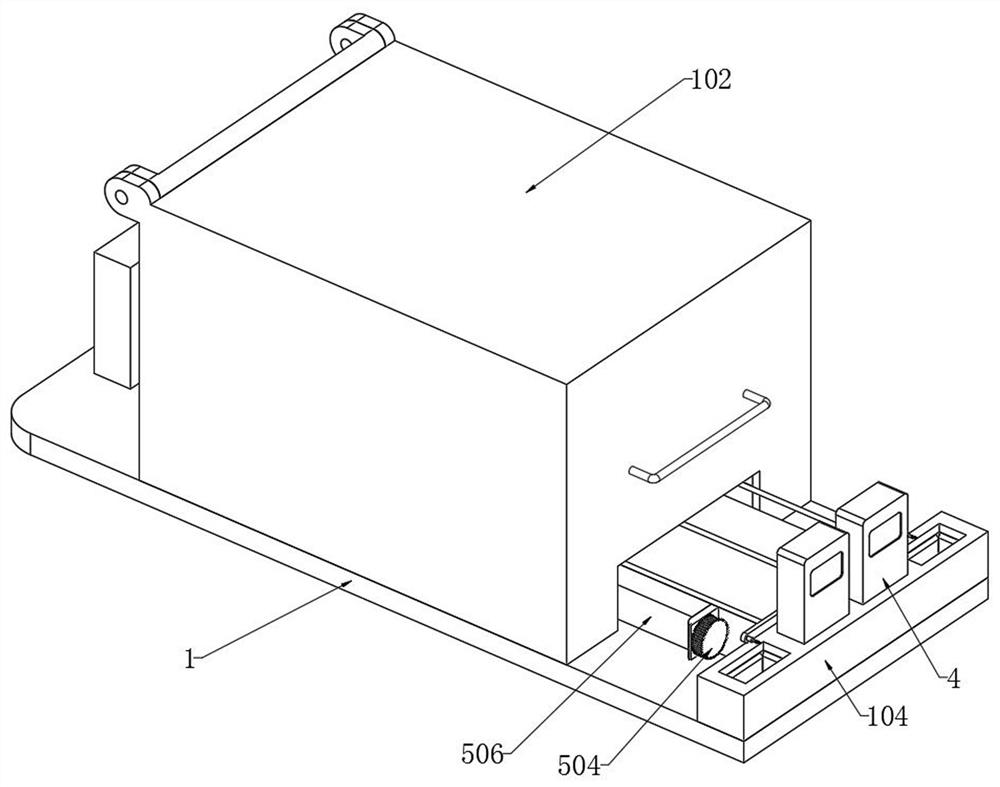

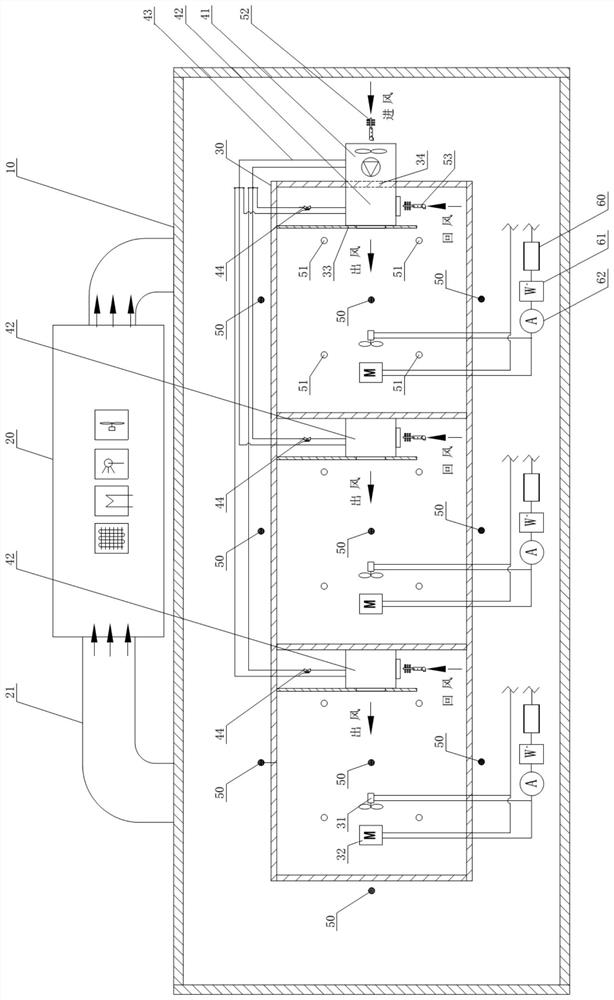

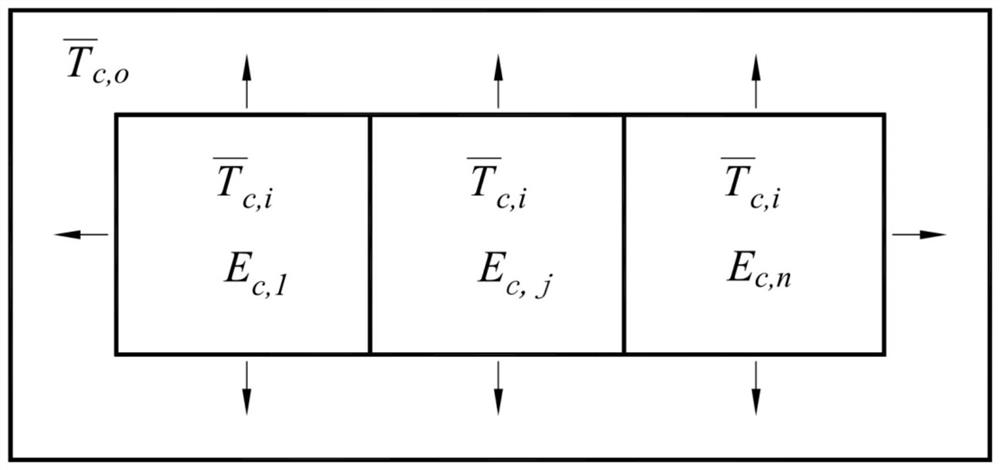

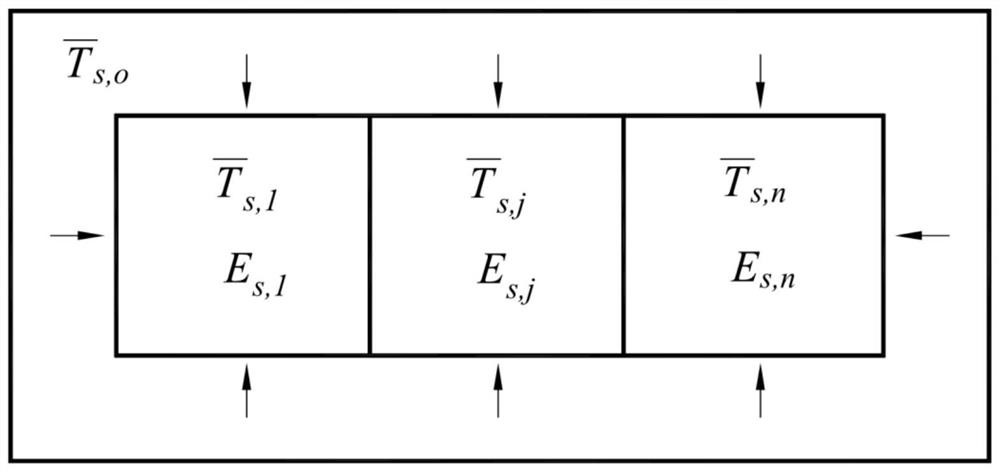

Multi-temperature-zone transportation refrigerating unit performance testing device and testing method

ActiveCN110779748ATest performanceAchieve performanceStructural/machines measurementThermodynamicsTest room

The invention belongs to the technical field of transportation refrigerating unit testing, and particularly relates to a multi-temperature-zone transportation refrigerating unit performance testing device and a multi-temperature-zone transportation refrigerating unit performance testing method. The multi-temperature-zone transportation refrigerating unit performance testing device comprises a plurality of test rooms, an external environment room, heating modules and first temperature testing modules, wherein the plurality of test rooms are closed and thermally insulated, and are sequentially and adjacently arranged; the external environment room surrounds all the test rooms and serves as a simulated environment; the heating modules are used for heating air in each test room, and the firsttemperature measurement modules are for measuring the temperature in each test room, an air processing module used for adjusting the air state in the outer environment chamber is arranged on the outerenvironment chamber, and a second temperature measuring module used for measuring the temperature in the outer environment chamber is arranged on the inner side of the outer environment chamber; anda to-be-detected multi-temperature-zone transportation refrigerating unit can cool the air in each test room. According to the multi-temperature-zone transportation refrigerating unit performance testing device and the multi-temperature-zone transportation refrigerating unit performance testing method, a mode that the plurality of test rooms are sleeved with the outer environment room, heat is transferred and heat balance is established by means of the wall surfaces of the plurality of test rooms, and therefore the purpose of testing the performance of the multi-temperature-zone transportationrefrigerating unit is achieved.

Owner:HEFEI GENERAL MACHINERY RES INST +1

Systems and Methods for Measuring Available Bandwidth in Mobile Telecommunications Networks

ActiveUS20140056158A1Test performanceError preventionTransmission systemsTelecommunications networkTimestamp

A network device receives probe packets communicated by a user equipment device. The network device communicates response packets back to the user equipment device, including timestamps, and / or other information. The user equipment device may be configured to test the performance of different portions of a wireless network (i.e., determine an available bandwidth measurement throughput (ABMT) of the wireless network) by accessing different network devices (or information associated with different network devices).

Owner:INFOVISTA

High temperature high voltage electric machine testing device

ActiveCN101281235BReal-time detection of working environment conditionsCalculate output powerDynamo-electric machine testingMotor testingControl signal

The invention discloses a high temperature high-voltage motor testing device, which includes a cylindrical seal cavity shell, a pressure cylinder and a pressure piston thereof are provided in the cylindrical seal cavity shell, the pressure cylinder, the pressure piston and a bearing joint at the end of the seal cavity shell forms a high pressure seal cavity in the seal cavity shell, the inner of the high pressure seal cavity is filled with hydraulic oil, and a motor fixing sleeve for fixing the motor is mounted in the high pressure seal cavity. The apparatus can test operation situation and operating performance of the motor under and high voltage surroundings.

Owner:CHINA NAT OFFSHORE OIL CORP +1

A Rotary Test System of Box Type Oil Distributor

ActiveCN106323616BTest performanceMeet the requirementsMachine part testingHydraulic control unitOil distribution

Owner:WUHAN MARINE MACHINERY PLANT

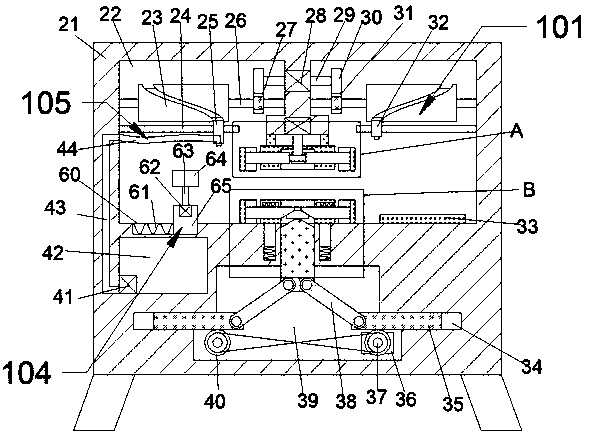

Connecting component test tooling for intelligent manufacturing of automobile lamps before leaving the factory

ActiveCN113295390BTest performanceAdjust the input currentCurrent/voltage measurementTesting optical propertiesElectric machineEngineering

The invention provides a connecting component testing tool for intelligent manufacturing of automobile lamps before leaving the factory, including a base plate; an upper end of the base plate is connected with a vertical plate and a control box, and the top end of the vertical plate is connected with a rotating cover, clamping the rotating testing part It is installed in the middle of the upper side of the bottom plate, and is arranged on the inner side of the rotating cover; the driving motor is fixedly installed on one side of the clamping and rotating test part. Clamp the test lamp between the clamping columns through the first clamping column and the second clamping column, and use the drive motor to drive the rotation of the cam to push the U-shaped frame to slide on the top of the telescopic support column, and the spring A Under the action of the car light, the car light can follow the slide, and at the same time, it can shake up and down under the action of the spring on the telescopic support column and the vertical guide post, thereby increasing the scene of the car light test, and adjusting the position of the adjustment block by turning the adjustment knob , change the resistance, and then adjust the input current of the lamp.

Owner:NANTONG SUHE LAMP PARTS

Multi-rotor dynamic testing device and method

ActiveCN105947233BReduce the risk of lift-off testsValid Test PerformanceAircraft components testingPropellerElectrical performance

The invention provides a multi-rotor power testing device, comprising a testing base, a bearing, a vertical arm of force, a horizontal arm of force, and a pressure sensor, wherein the bearing is mounted on the testing base and used for changing directions of tensile and torque generated by a propeller under test during a test, the vertical arm of force is connected directly with the bearing, the horizontal arm of force is vertically mounted below the vertical arm of force, the vertical arm of force is rigidly connected with the horizontal arm of force, a push test mounting face and a torque test mounting face for the propeller are formed above the vertical arm of force, the push test mounting face is perpendicular to the torque test mounting face, and the pressure sensor is mounted below the horizontal arm of force, between the horizontal arm of force and the testing base. A testing system of the invention enables power performance and electrical performance of a multi-rotor unmanned aerial vehicle to be tested effectively and safely and may also meet testing requirements of rotor unmanned aerial vehicles with different arm numbers and driving units of different types.

Owner:NANJING NORTH OPTICAL ELECTRONICS

Multi-temperature zone transport refrigeration unit performance test test device and test method

ActiveCN110779748BTest performanceAchieve performanceStructural/machines measurementTest roomAir treatment

The invention belongs to the technical field of testing transport refrigeration units, and in particular relates to a performance test device and a testing method for multi-temperature zone transport refrigeration units. The test device includes a plurality of closed and insulated test rooms arranged adjacently in sequence, and an external environment room that surrounds all test rooms as a simulated environment. The test device also includes a heating module for heating the air in each test room, and measures the temperature of each test room The first temperature measurement module of the internal temperature; the external environment room is provided with an air processing module for adjusting the air state in the external environment room, and the inner side is provided with a second temperature measurement module for measuring the temperature of the external environment room; multiple to be detected Zone transport refrigeration units cool the air in each test room. The invention adopts the mode between multiple test rooms and the external environment, conducts heat through the walls of multiple test rooms and establishes heat balance, so as to achieve the purpose of testing the performance of multi-temperature zone transport refrigeration units.

Owner:HEFEI GENERAL MACHINERY RES INST +1

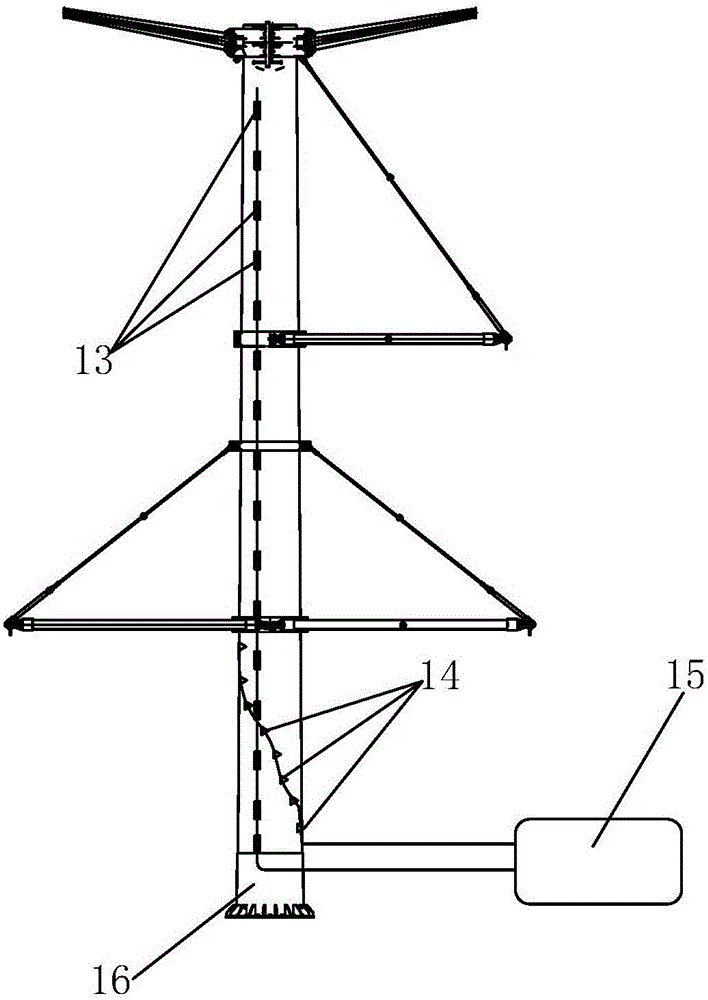

Multi-factor accelerated aging test device for composite poles

ActiveCN104198358BTest performanceSimple structureWeather/light/corrosion resistanceGratingUltraviolet

The invention discloses a multiple-factor accelerated aging test device for a composite material electric pole. The multiple-factor accelerated aging test device comprises an aging test room, wherein water nozzles and acid, alkali and salt atomizers are arranged on the roof surface of the aging test room; ozone generators, ultraviolet lamps, high-temperature and low-temperature humidity-heat devices, and a tensile machine are arranged on the side walls of the aging test room respectively; the action end of the tensile machine is connected with a traction rod which is provided with a force meter; corresponding to the composite material electric pole to be tested, weights, leads, longitudinal strain gratings, circumferential strain gratings, and a signal detection processor which is electrically connected with the force meter, the longitudinal strain gratings and the circumferential strain gratings respectively, are arranged inside the aging test room. By the cooperation of the water nozzles, the acid, alkali and salt atomizers, the ozone generators, the ultraviolet lamps, the high-temperature and low-temperature humidity-heat devices, the tensile machine, the weights and the leads, various natural environments can be simulated comprehensively, so that the performance of the composite material electric pole can be thoughtfully and correctly tested. The accelerated aging test device is applicable to testing of pole towers.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +1

Automobile ball head durability test method

The invention relates to an automobile ball head durability test method and relates to a test method of automobile parts, comprising the following steps: 1. in a slit slurry water-spraying mechanism, slit and water are mixed in a water storage tank and are fully mixed according to the proportion of 50g / 1 liter of the slit and water; 2. a test piece, that is, an automobile ball head is arranged on a test frame of a machine; 3. test equipment is regulated; 4. the test period is set into from 1,000,000 times to 5,000,000 times; 5. the procedures of swinging test, rotating test and slit slurry water spraying are carried out simultaneously, when the test period reaches the setting value, the machine stops, and the test is finished. The method is used for the durability test of the automobile ball head under the condition that severe environment is simulated, so as to test the using performance of the automobile ball to the maximum extent.

Owner:GOTECH TESTING MACHINES DONGGUAN

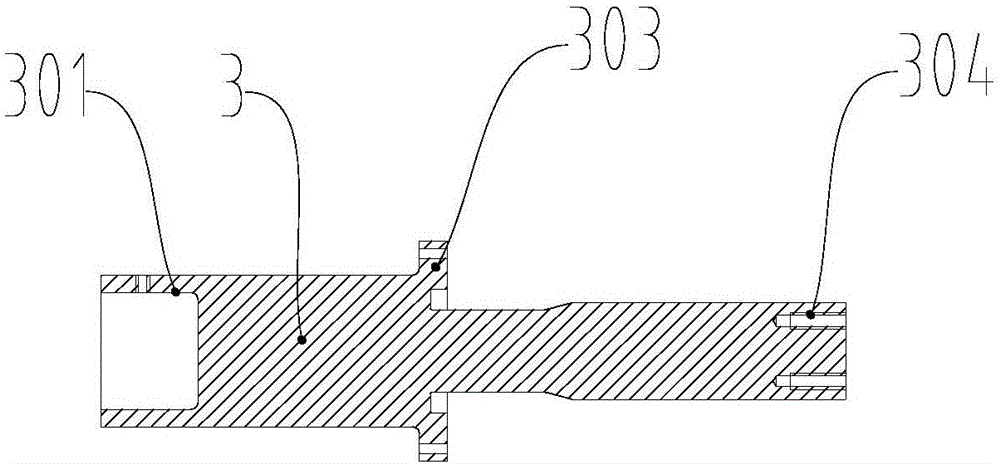

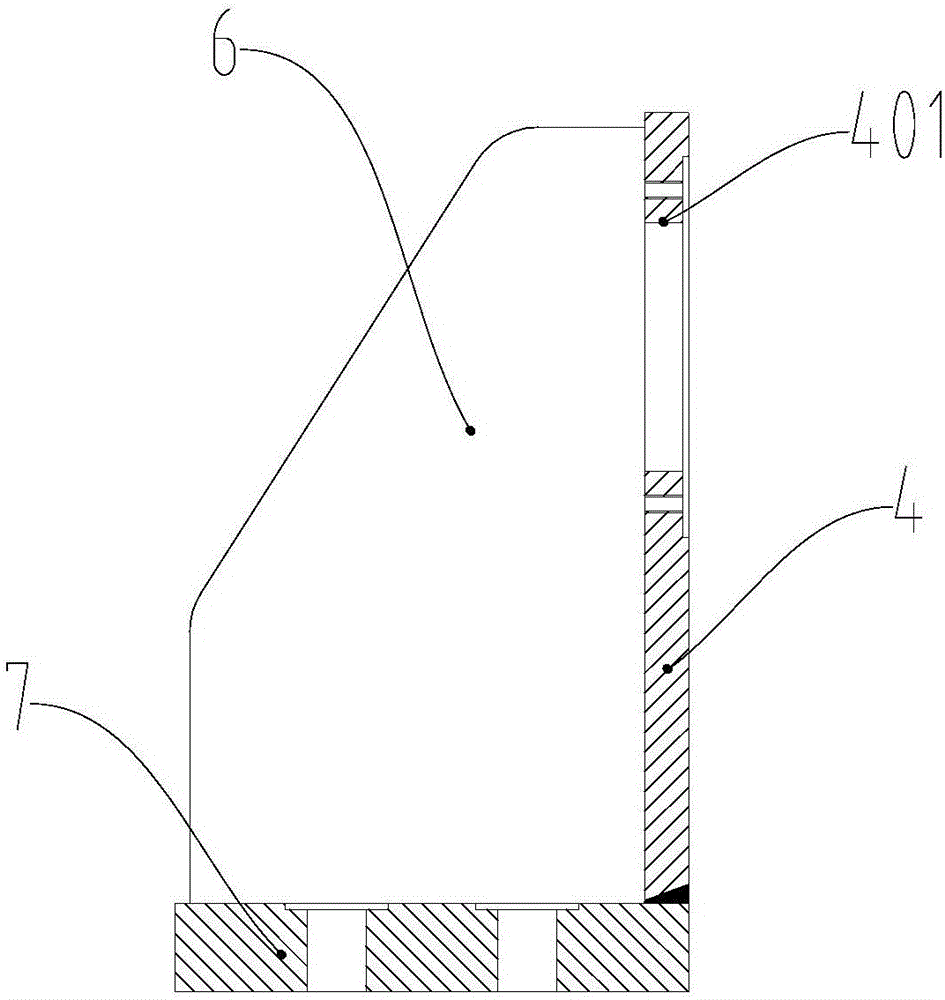

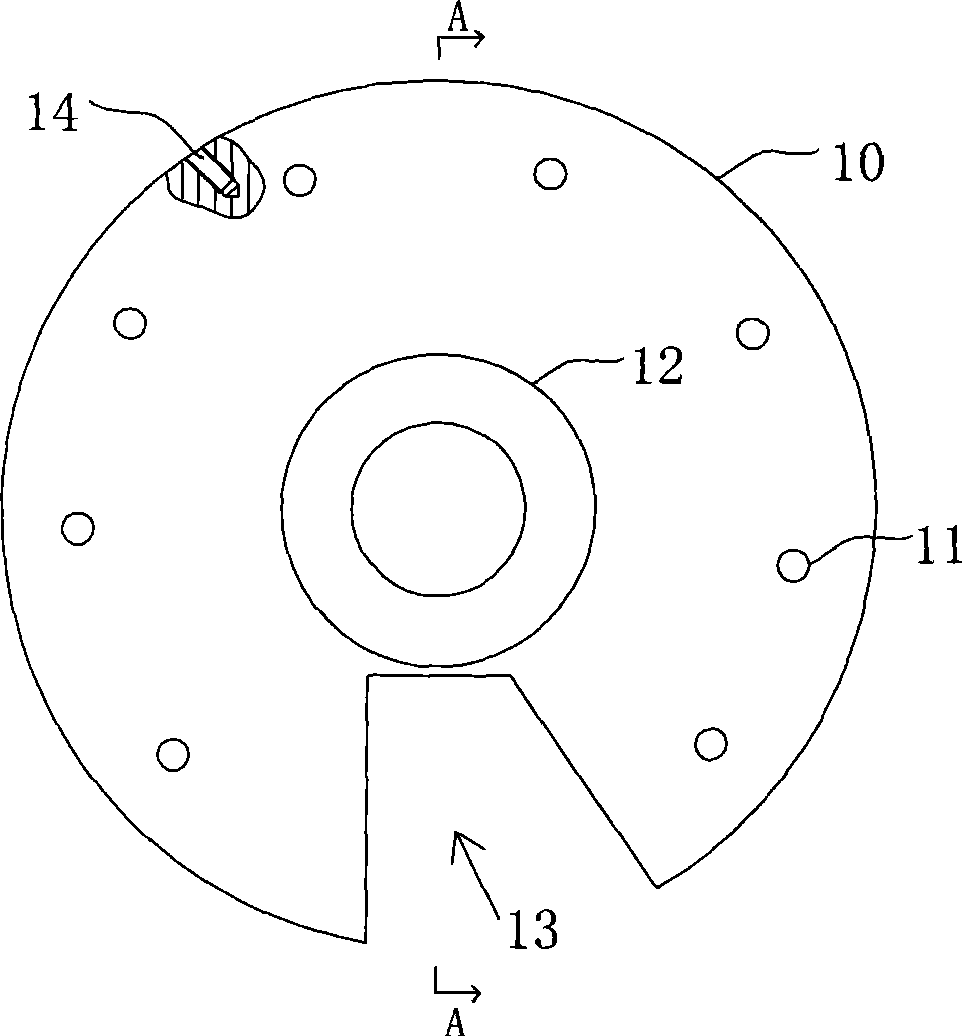

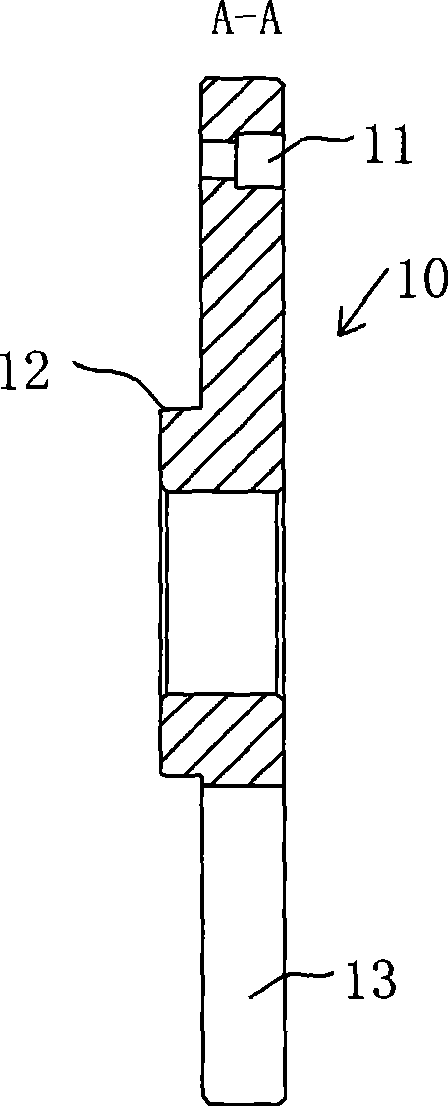

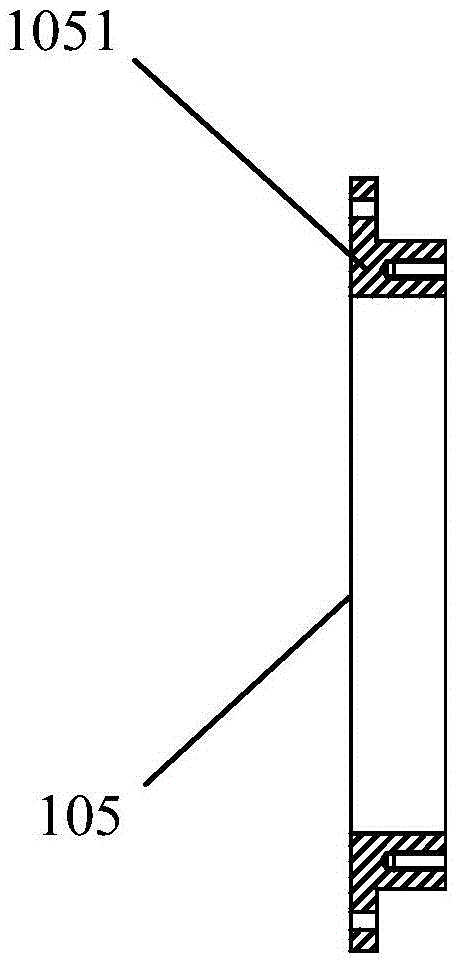

A rotary test device for a box-type oil distributor

The invention discloses a box-type oil distribution device rotation test device, and belongs to the field of machinery. The device comprises a pedestal, a power unit, a tooling false axis and a first support. The power unit and the first support are fixed on the pedestal. The tooling false axis is arranged between the power unit and the first support. An output shaft of the power unit is connected with one end of the tooling false axis, and the other end of the tooling false axis is provided with a connection interface used for connecting an oil distribution shaft of a box-type oil distribution device. The first support is provided with an installation hole used for installing the box-type oil distribution device. The tooling false axis is driven to rotate via the power unit, and the tooling false axis simulates a large gear shaft of a gear box of an adjustable pitch propeller to drive the oil distribution shaft of the oil distribution device to rotate in a high-speed way so that a rotation test is performed on the oil distribution device, and thus performance of the oil distribution device is tested when the oil distribution shaft rotates in the high-speed way.

Owner:WUHAN MARINE MACHINERY PLANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com