Connecting component test tooling for intelligent manufacturing of automobile lamps before leaving the factory

A technology for intelligent manufacturing and automotive lamps, which is applied in the direction of measuring devices, optical instrument testing, and optical performance testing. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

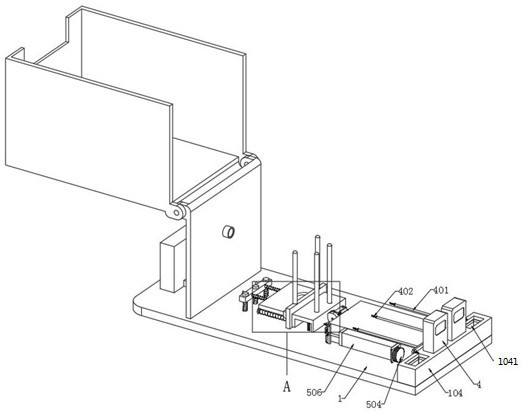

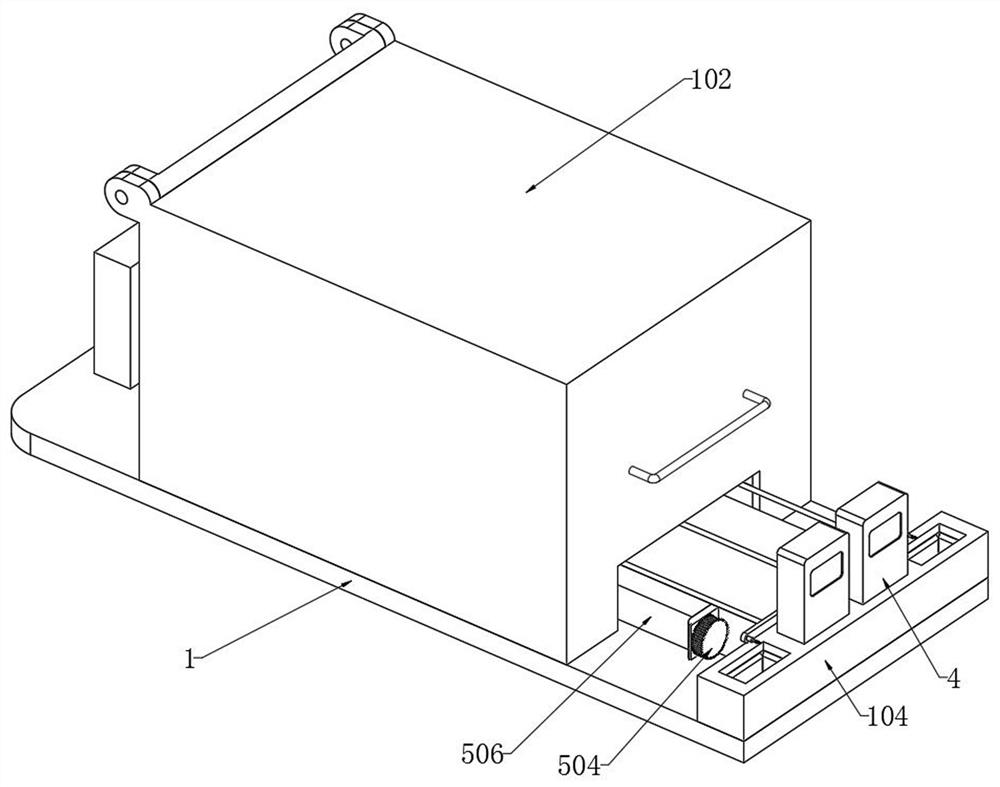

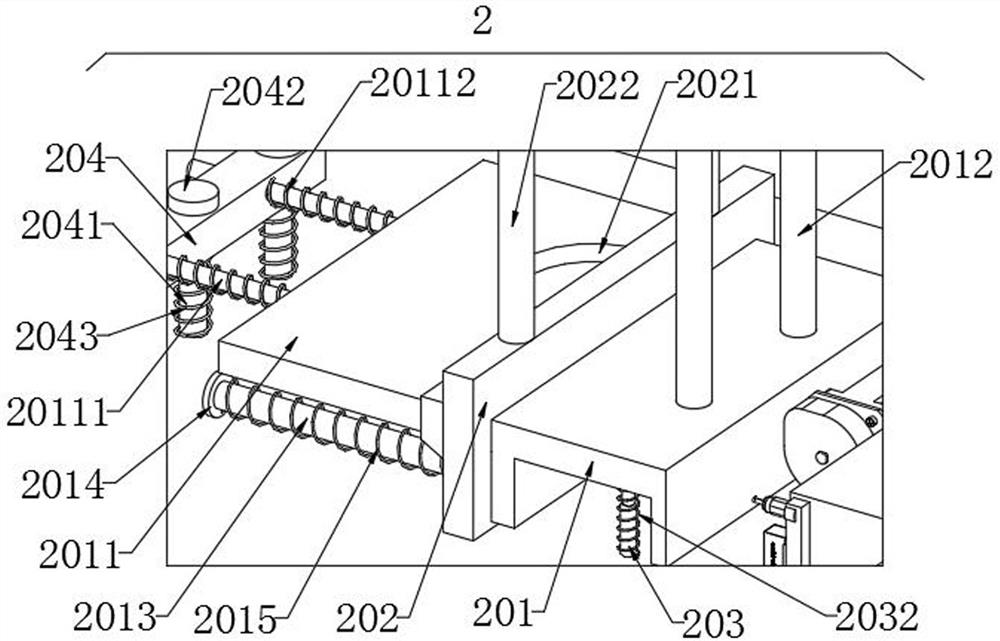

[0050] as attached figure 1 to attach Figure 8 Shown:

[0051] The present invention provides a connecting component testing tool for intelligent manufacturing of automobile lamps before leaving the factory, including a bottom plate 1; a vertical plate 101 and a control box 103 are connected to one end of the upper side of the bottom plate 1, and a rotating cover 102 is connected to the top of the vertical plate 101. The cover 102 is an opaque structure, and a photoelectric sensor 1011 is inlaid on the vertical plate 101, and the photoelectric sensor 1011 is electrically connected to the control box 103;

[0052] Among them, the photoelectric sensor 1011 is a device that converts optical signals into electrical signals, and its working principle is based on the photoelectric effect; Electric effect phenomenon; according to the different photoelectric effect phenomena, the photoelectric effect is divided into three categories: external photoelectric effect, internal photoelect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com