Automobile ball head durability test method

A test method and durability technology, applied in vehicle testing, testing wear resistance, testing of mechanical parts, etc., can solve the problems of severe corrosion damage, adhesion, and attachment to the car ball head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

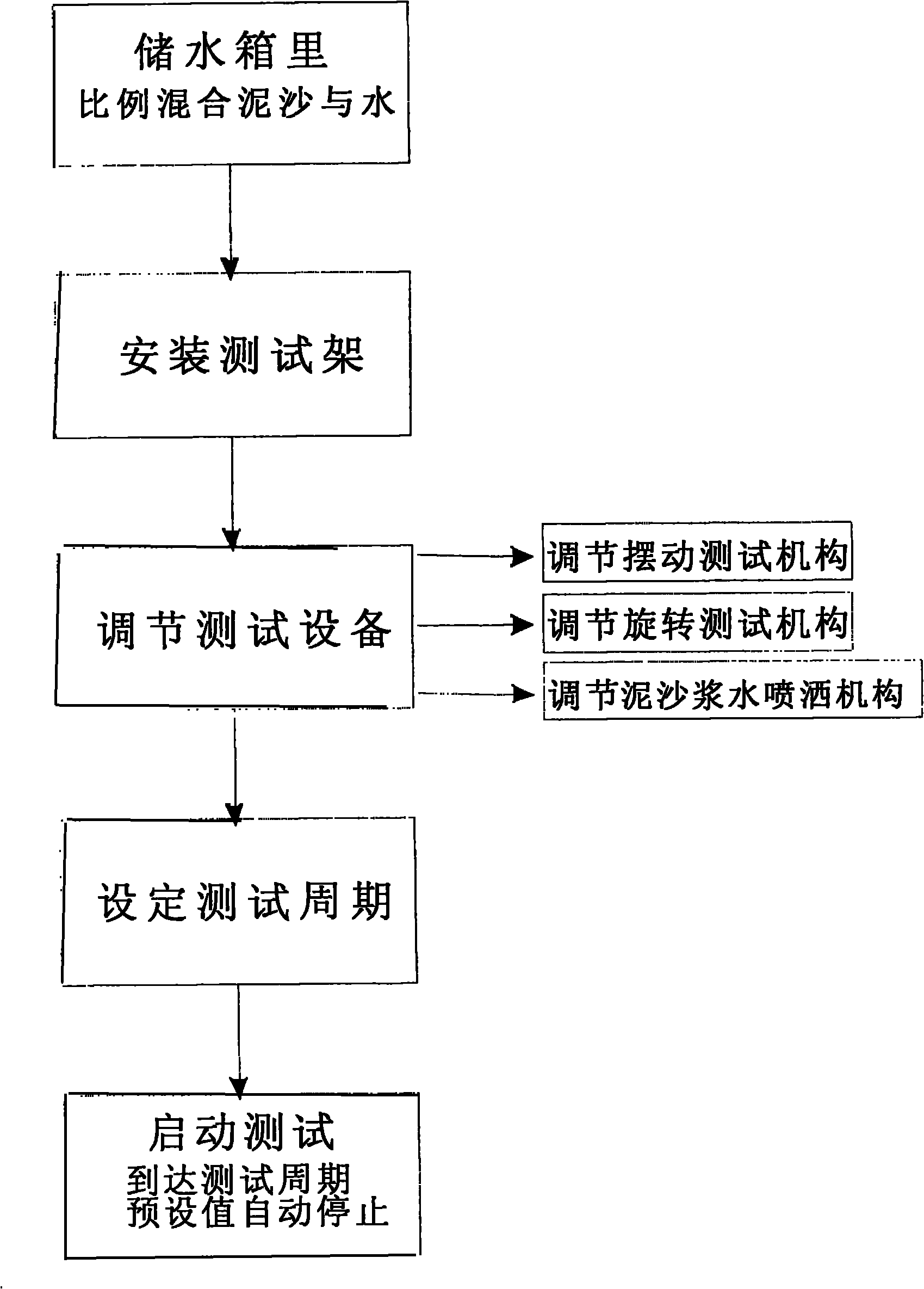

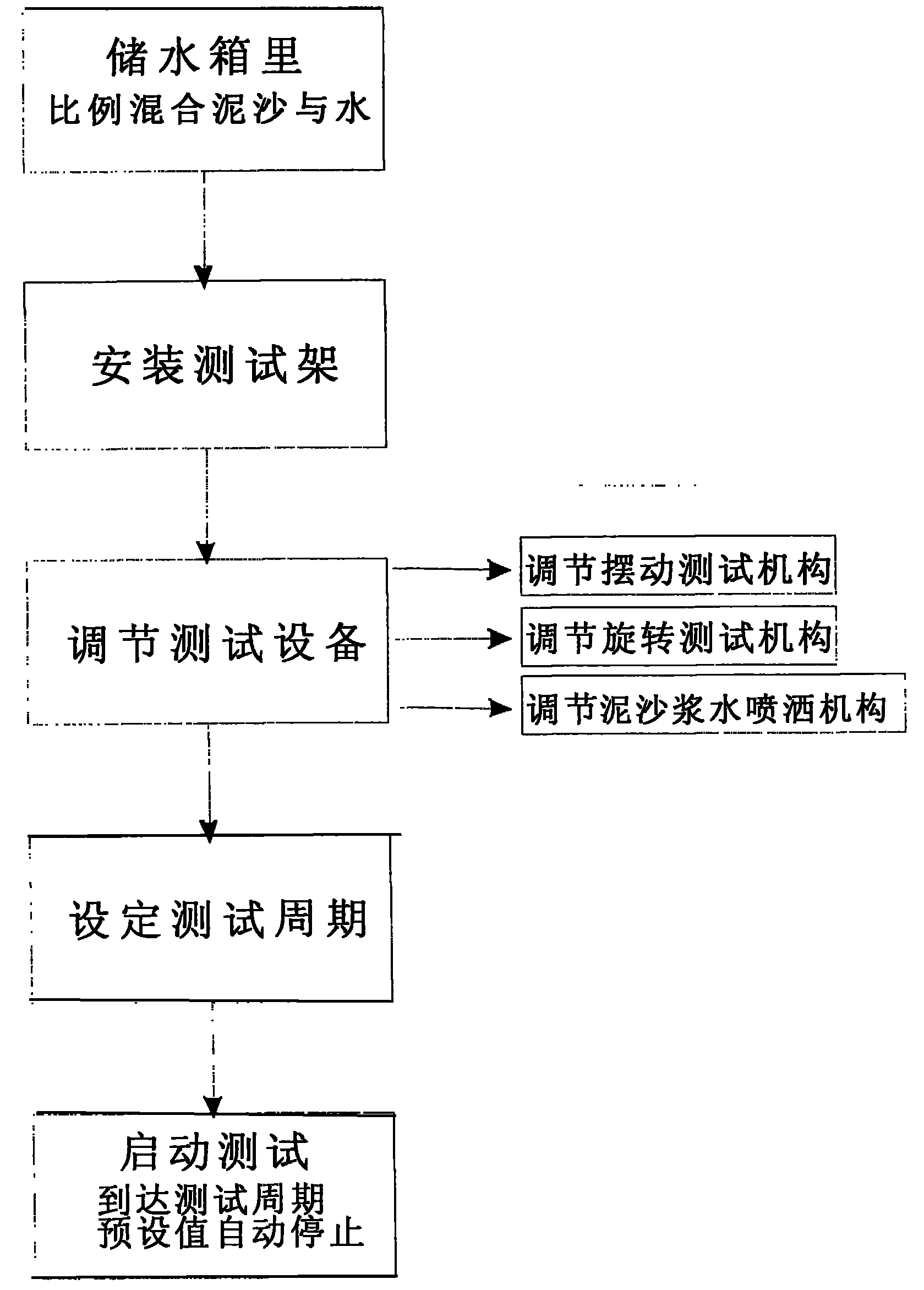

[0018] figure 1 Shown: a kind of automobile ball end durability test method, described test method comprises the steps:

[0019] ①. In the silt slurry water spraying mechanism, silt and water are mixed in the water storage tank 16 according to the ratio of 50g to 1 liter of water and fully stirred;

[0020] ②. Install the test piece 10, that is, the automobile ball head, on the test frame of the machine 1;

[0021] ③. Adjust the test equipment and adjust the swing test mechanism: the swing angle of the swing test mechanism can be adjusted from 0 to 70°, and the swing angle can be adjusted arbitrarily within this range, and the adjustment accuracy can reach 0.5°; swing The frequency is 0~5Hz; the accuracy of swing frequency adjustment can reach 5%;

[0022] During the test, adjust the swing angle and swing frequency of the swing test mechanism according to the specific test requirements, for example, when the swing angle is 15°, the swing frequency is 5Hz; when the swing angl...

Embodiment 2

[0030] figure 1 Shown: steps ①-③ in this embodiment are the same as embodiment one, only need to readjust the mud slurry water spraying mechanism in step ③, specifically:

[0031] Adjust the mud and mortar water spraying mechanism, the spraying speed is 50ml / s, the spraying method: synchronized with the test process, spraying continuously during the test, from the beginning of the test to the end of the test;

[0032] ④. Set the test cycle to 2 million times;

[0033] ⑤. Simultaneously start the swing test, rotation test and mud slurry water spraying program. When the test cycle reaches the set value, stop the machine and the test is completed.

Embodiment 3

[0035] figure 1 Shown: Steps ①-③ in this embodiment are the same as in Embodiment 1 or Embodiment 2, only need to readjust the mud slurry water spray mechanism in step ③, specifically: the spraying speed is set to 100ml / s, and the spraying method Set as: time-limited spraying, the entire test process only needs to be sprayed once, and the specific spraying time can be set according to the test requirements, such as 5h or 15h or 20h, etc. Of course, the entire spraying time should be shorter than the test time;

[0036] ④. Set the test cycle to 5 million times;

[0037] ⑤. Simultaneously start the swing test, rotation test and mud slurry water spraying program. When the test cycle reaches the set value, stop the machine and the test is completed.

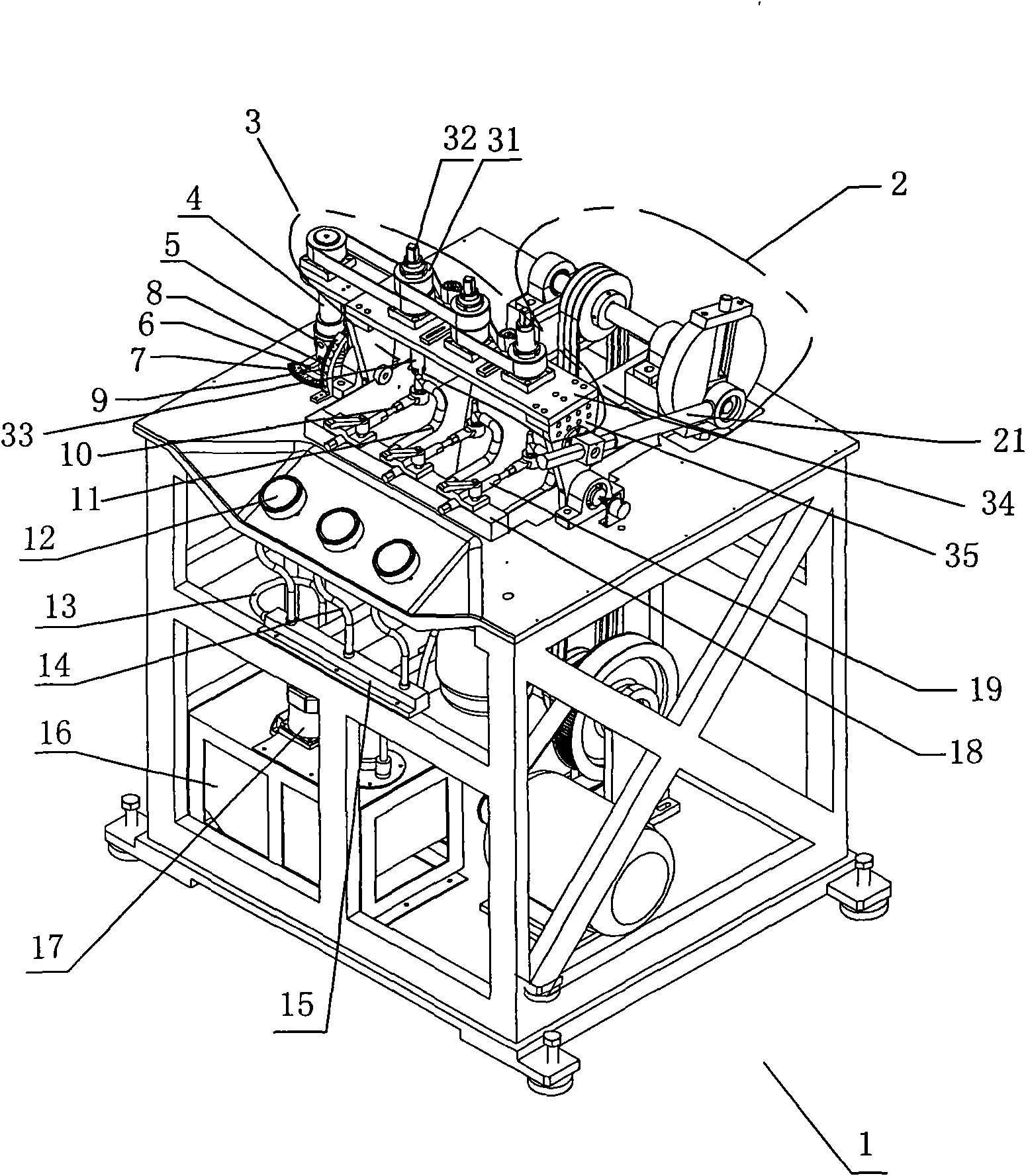

[0038] Above-mentioned test method is accomplished by means of testing equipment, and described testing equipment comprises organic table 1, swing testing mechanism 2, rotating testing mechanism and mud slurry spraying mechanism, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com