Revolving gear for spin-testing table for automobile gear box

A technology of rotating test bench and automobile gearbox, applied in the automobile field, can solve the problems of long cycle and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

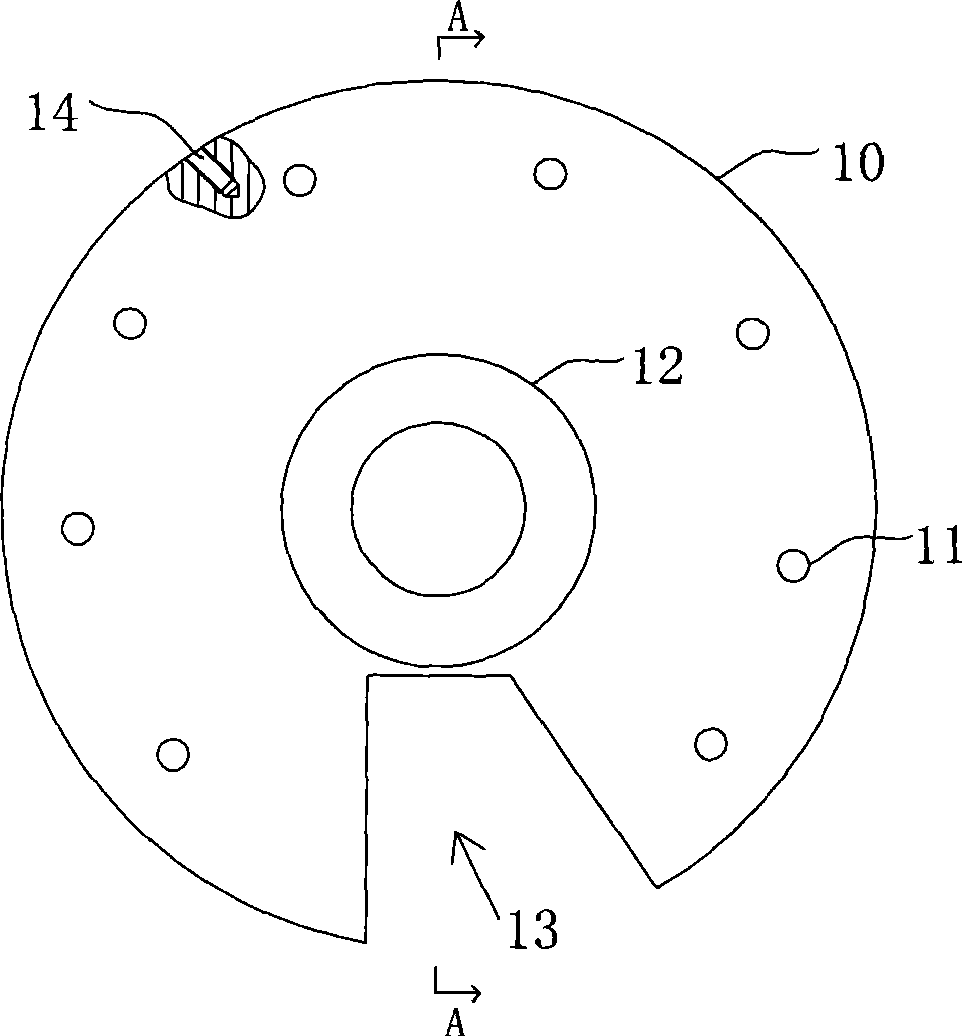

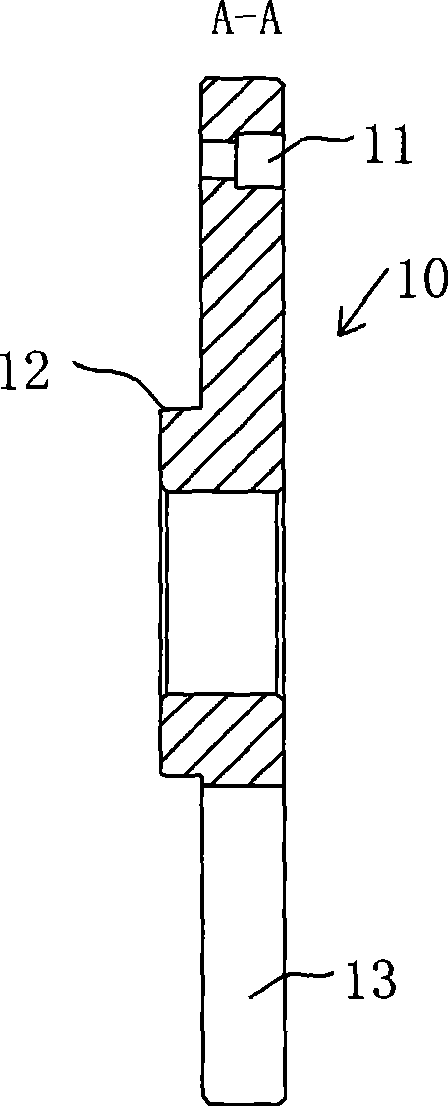

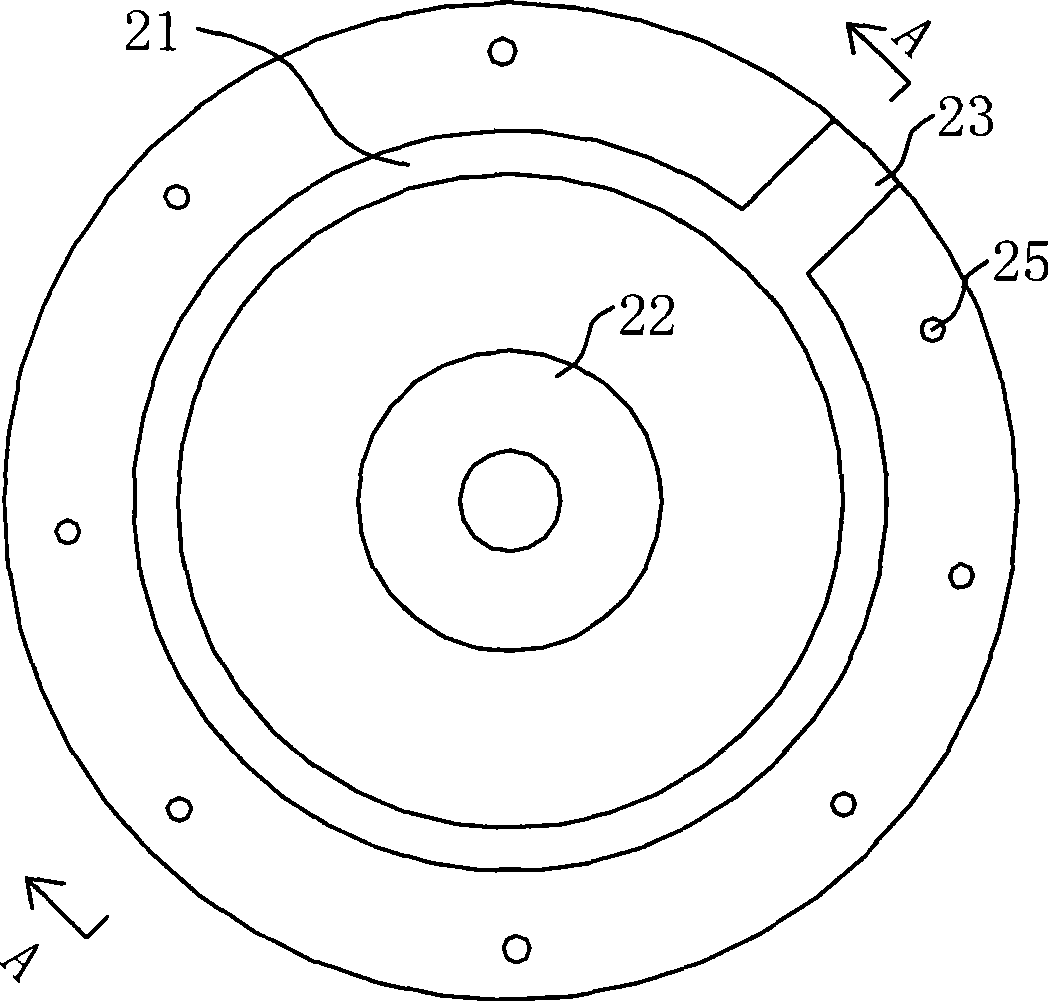

[0011] A rotating mechanism for an automobile gearbox rotating test bench, a gearbox 60 is fixedly arranged on one side of a first plate 10, and the other side of the first plate 10 is at the same position as the second plate 20. Shaft rotation and fixed two matching positions, the second plate body 20 is fixed on the bracket 40, the middle positions of the first and second plate bodies 10, 20 are provided with through holes for the transmission shaft 52 to pass through, and the transmission shaft 52 is located on the first plate body 10 The shaft end on one side is connected with the 60 power input shafts of the gearbox, as Figure 5 shown.

[0012] Combine the following figure 1 , 2 , 3, 4, 5 further describe the present invention.

[0013] The plate surface of the first plate body 10 is evenly distributed in the circumferential direction with connecting holes for installing countersunk bolts 15, and the connecting holes adopt counterbore holes 11. In the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com