Multi-temperature-zone transportation refrigerating unit performance testing device and testing method

A technology of refrigeration unit and test device, which is applied in the direction of measuring device, machine/structural component test, instrument, etc., which can solve obstacles to the promotion of such products, manufacturers cannot provide design parameters to users, and affect the promotion and use of multi-temperature zone units effect and other issues, to achieve the effect of strong function and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

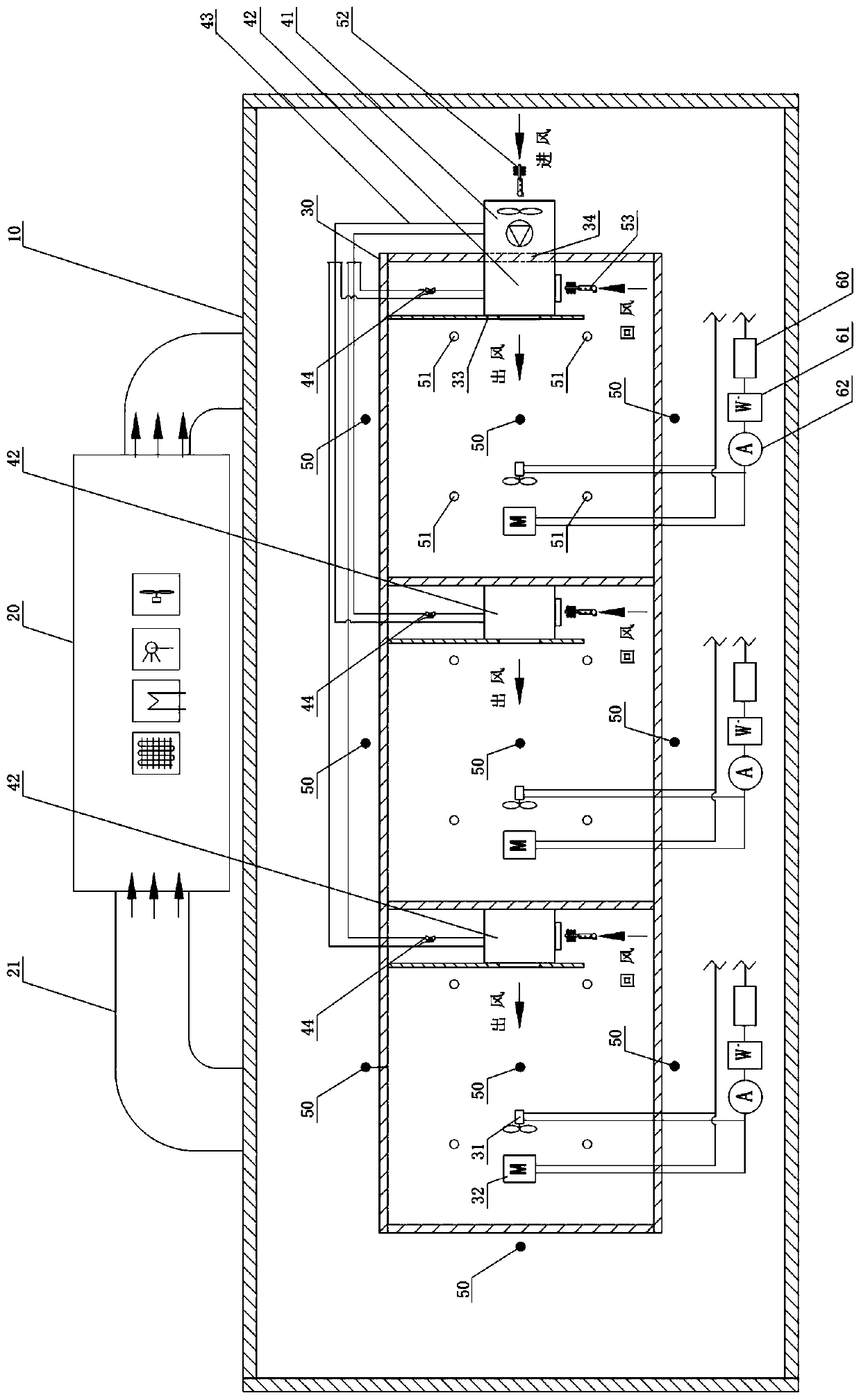

[0036] Such as figure 1 As shown, the multi-temperature zone transport refrigeration unit performance test test device includes a plurality of closed and insulated test rooms 30 arranged adjacently in sequence, and an external environment room 10 surrounding all test rooms 30 as a simulated environment.

[0037] The test device also includes a heating module for heating the air in each test room 30 , and a first temperature measurement module, and the first temperature measurement module is used to measure the air temperature in each test room 30 . The external environment room is provided with an air treatment module 20 and a control module for adjusting the air state in the external environment room, and a second temperature measurement module for measuring the temperature of the external environment room is provided inside, and the second temperature measurement module is used for The temperature in the external environment room 10 is measured.

[0038] The multi-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com