High temperature high voltage electric machine testing device

A technology of motor testing, high temperature and high pressure, applied in the direction of motor generator testing, etc., can solve the problems of inability to accurately test the performance of motors and the working conditions of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

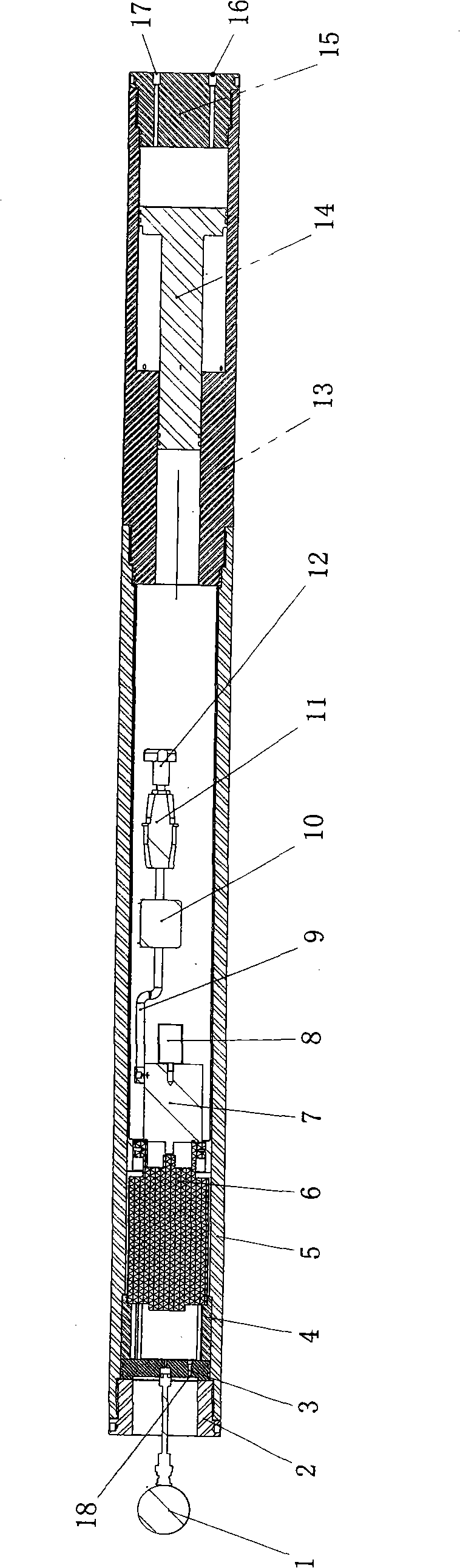

[0018] The high-temperature and high-voltage motor testing device of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] Such as figure 1 As shown, the high-temperature and high-voltage motor testing device of the present invention includes a high-pressure sealed cavity, and the high-pressure sealed cavity is composed of a cylindrical sealed cavity shell 6 and a small end face of a pressure-bearing joint 3, a booster cylinder 13, and a booster piston 14. Used to create a high-pressure sealed environment filled with hydraulic oil. A high-pressure watertight head and a cable outlet 18 are installed on the pressure-bearing joint 3, which are mainly used to connect the control signal line inside the high-pressure sealed cavity with the control signal line outside. In addition, there is a small hole in the center of the pressure joint 3. The diameter of the small hole is preferably 0.5 mm, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com