Turbine compressor test system

A turbo compressor and test system technology, applied in the field of compressors, can solve the problems of not being able to test the force performance of the blades, not being able to measure the performance, etc., to achieve the effect of reducing power consumption and strengthening the effect of airflow excitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

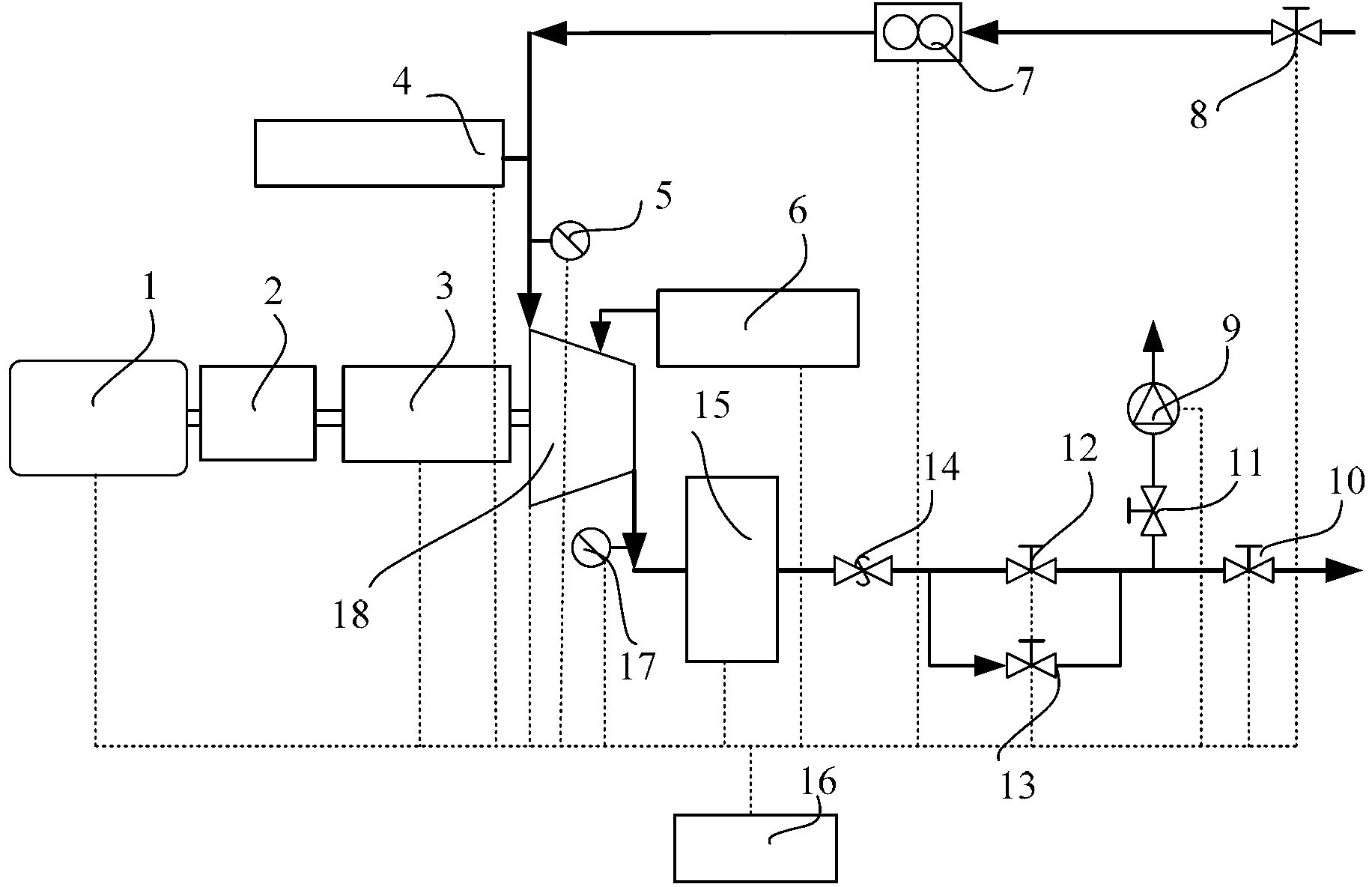

[0026] see figure 1 , the turbocompressor test system in this embodiment is set to:

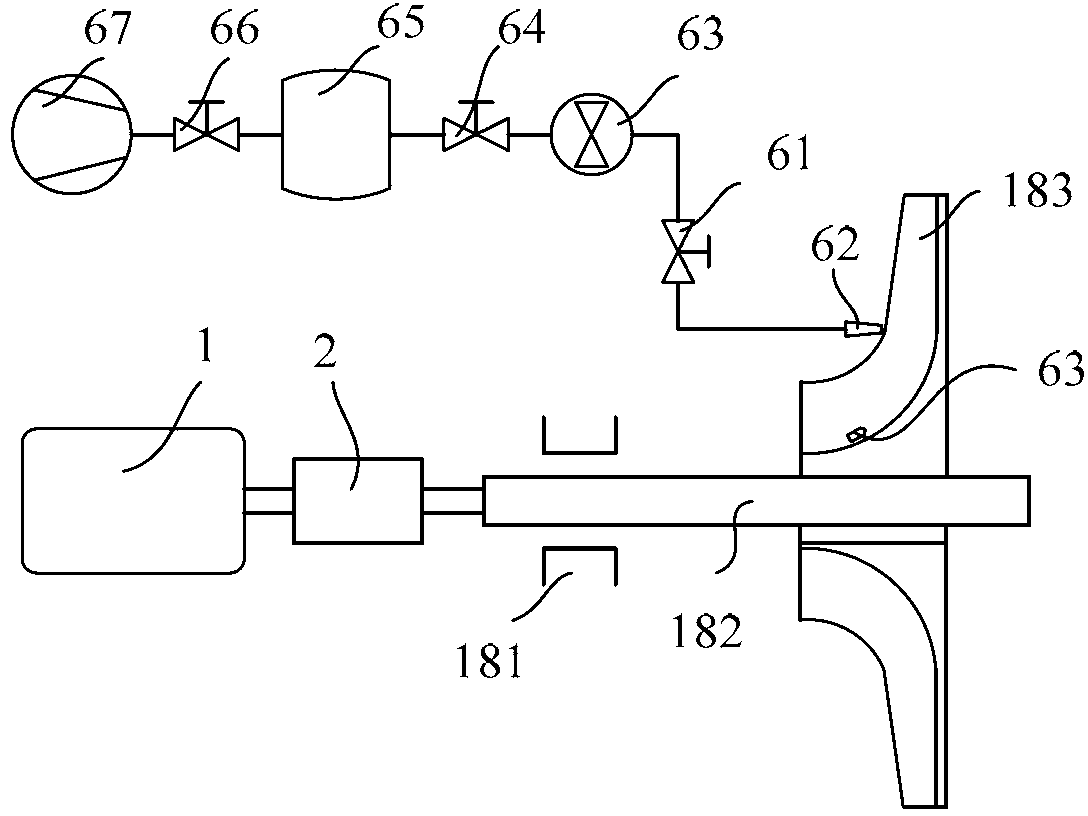

[0027] The rotational output of the motor 1 is transmitted to the main shaft 182 of the turbocompressor 18 through the gearbox 2 and the torque sensor 3 to form a test host.

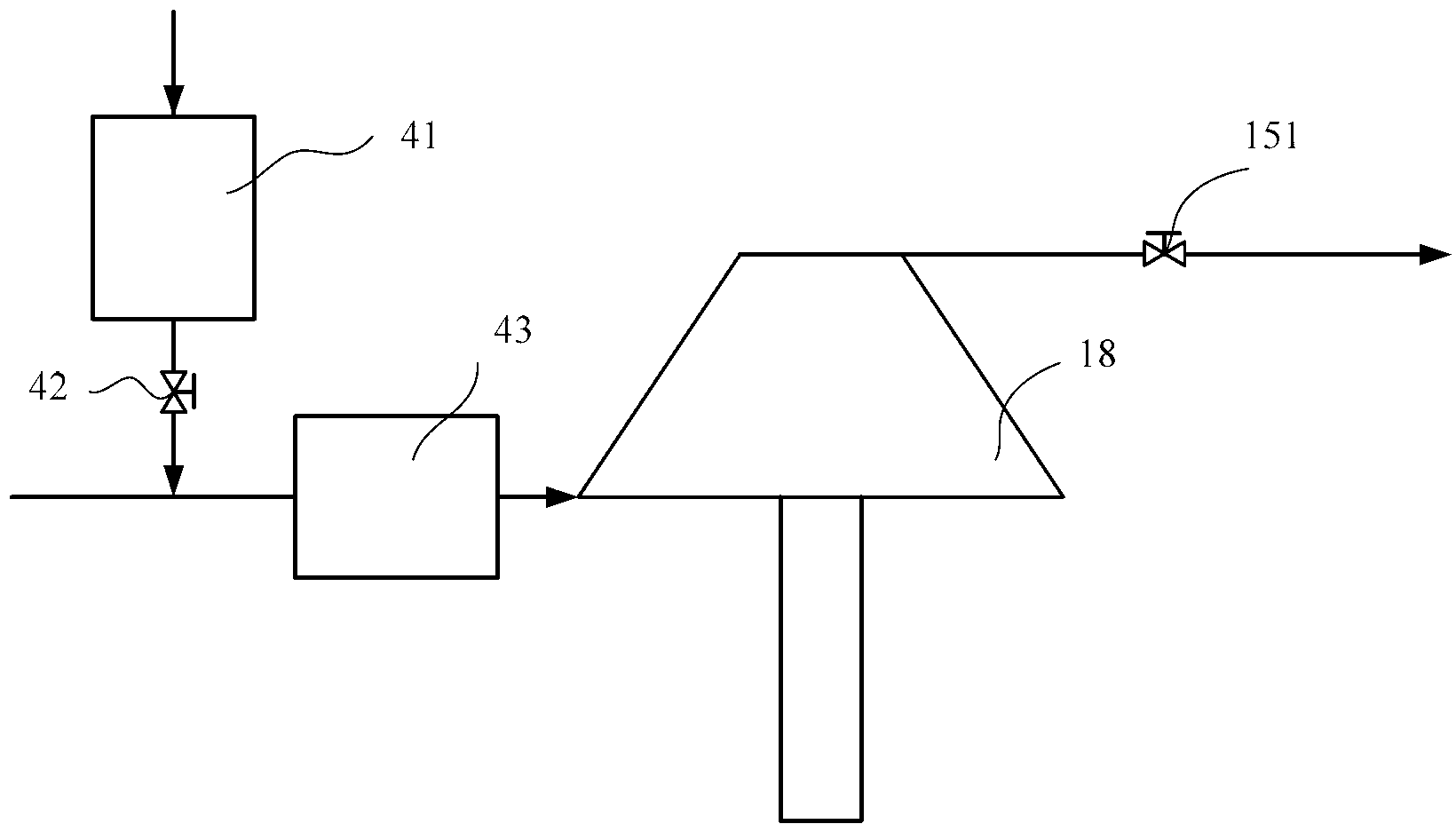

[0028] The intake disturbance unit is set at the air inlet of the turbocompressor 18, and the intake disturbance unit is to arrange an inlet pressure temperature sensor 5, an intake disturbance device 4, a flow rate sensor, etc. meter 7 and intake valve 8; an exhaust disturbance unit is arranged at the exhaust port of the turbocompressor 18, and the exhaust disturbance unit is provided with outlet pressure and temperature sensors sequentially on the exhaust pipeline from the exhaust port of the turbocompressor 17. Outlet disturbing device 15, safety valve 14, main regulating valve 12 and exhaust valve 10, auxiliary regulating valve 13 is arranged in parallel on main regulating valve 12, parallel outlet of main regulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com