Equipment and method for testing bonding fatigue performance of pavement crack filling material

A technology for joint filling and fatigue performance, which is applied in the directions of analyzing materials, measuring devices, and using mechanical devices, can solve problems such as performance testing of pavement joint filling materials, and achieve the effect of ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

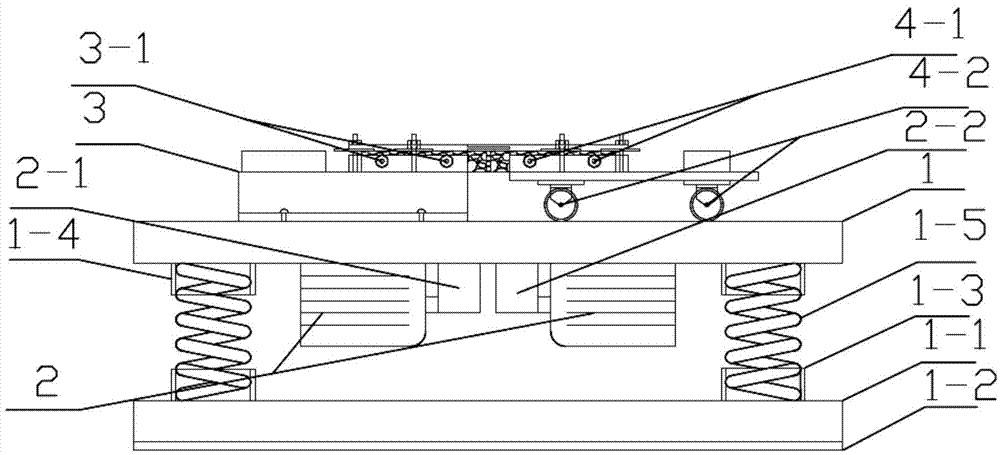

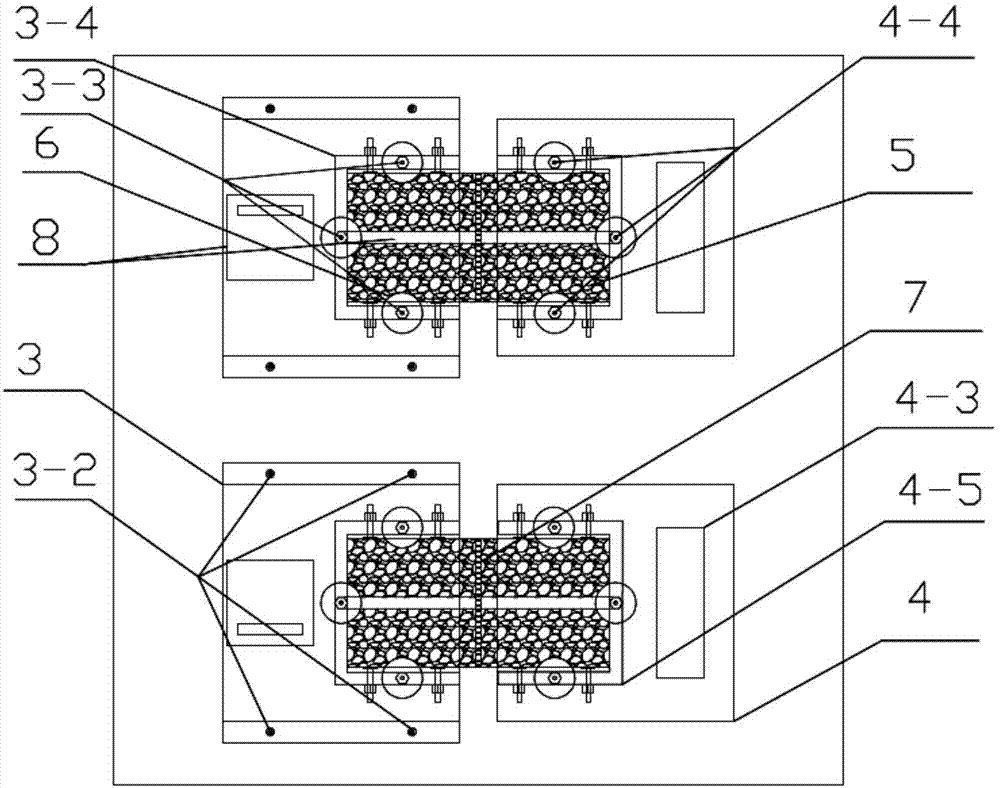

[0030] Such as figure 1 and figure 2 As shown, the present invention is a kind of equipment for testing the bonding fatigue performance of the pavement grouting material, comprising a base 1-1 and a vibration platform 1 arranged on the base 1-1, the base 1-1 is fixed on the test bench, Moreover, a rubber anti-slip layer 1-2 is also provided between the base 1-1 and the test platform to prevent the sliding caused by vibration when the whole device is running; a number of uniformly arranged springs 1-5 are passed between the base 1-1 and the vibration platform 1 The upper end of each spring 1-5 is fixed on the bottom of the vibration platform 1 through the upper spring fixing tube 1-4, and the lower end of each spring 1-5 is fixed on the base through the lower spring fixing tube 1-3 1-1; two motors 2 with adjustable speed are installed on the bottom of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com