Patents

Literature

96results about How to "Flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

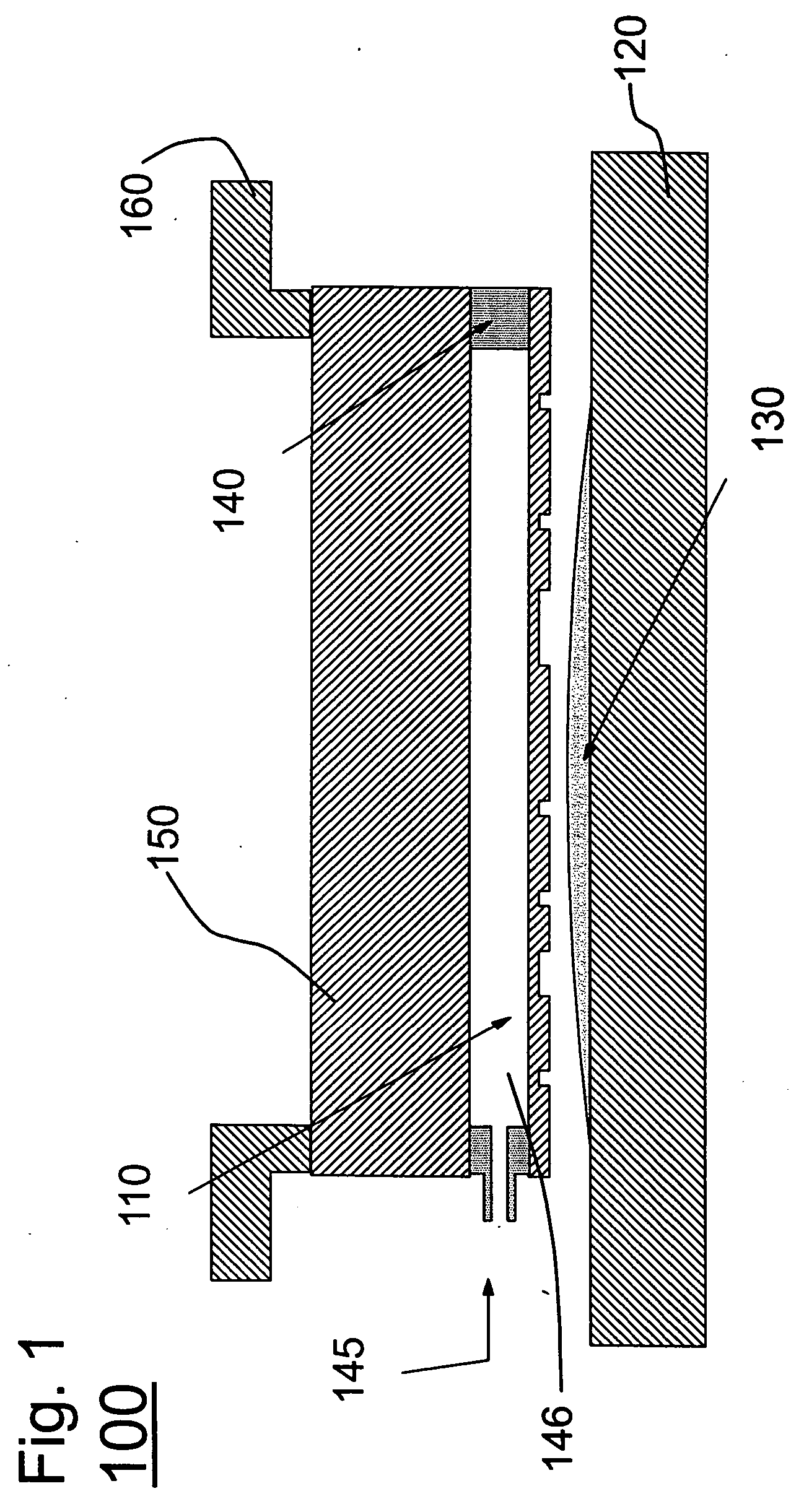

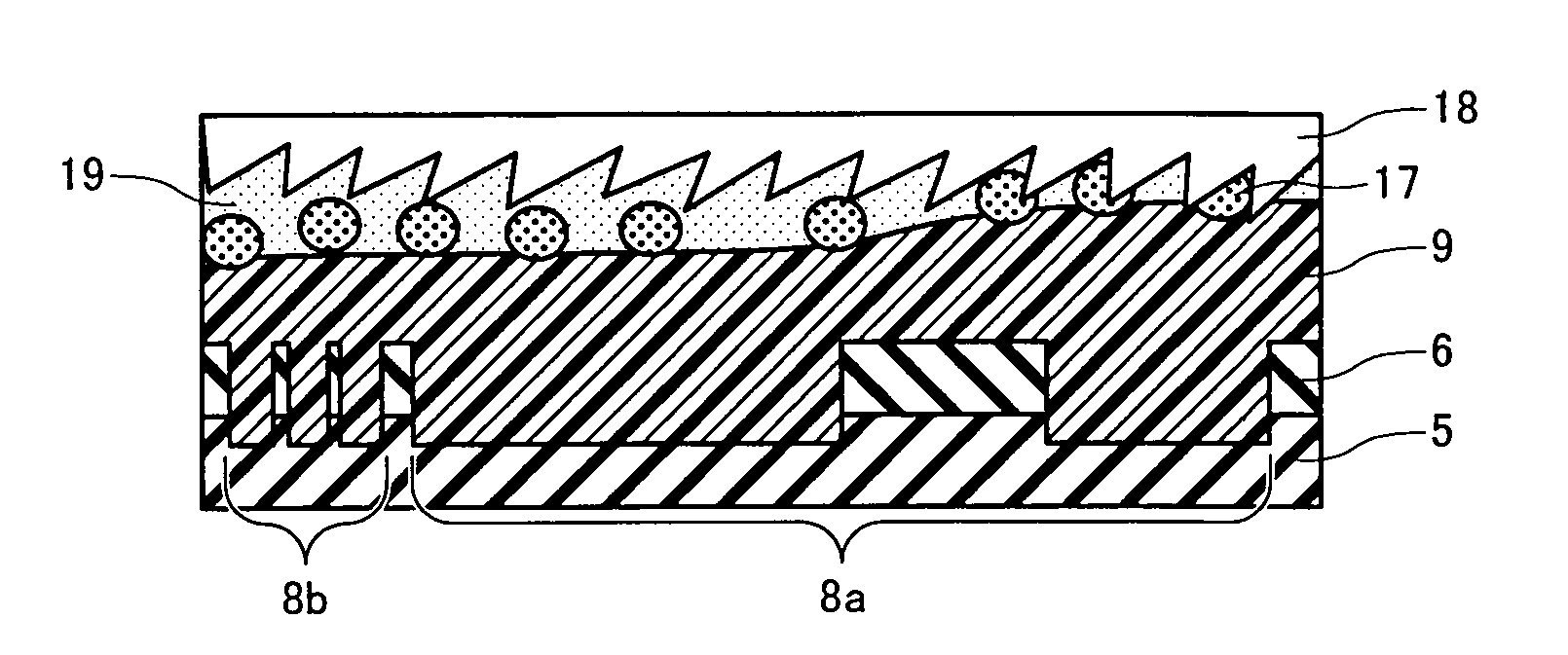

Display device and electronic equipment having the same comprising a region for reflecting a polarized light and a region for absorbing the polarized light

ActiveUS7268841B2Restrain deterioration of visibilityImprove robustnessStatic indicating devicesNon-linear opticsDisplay deviceElectron

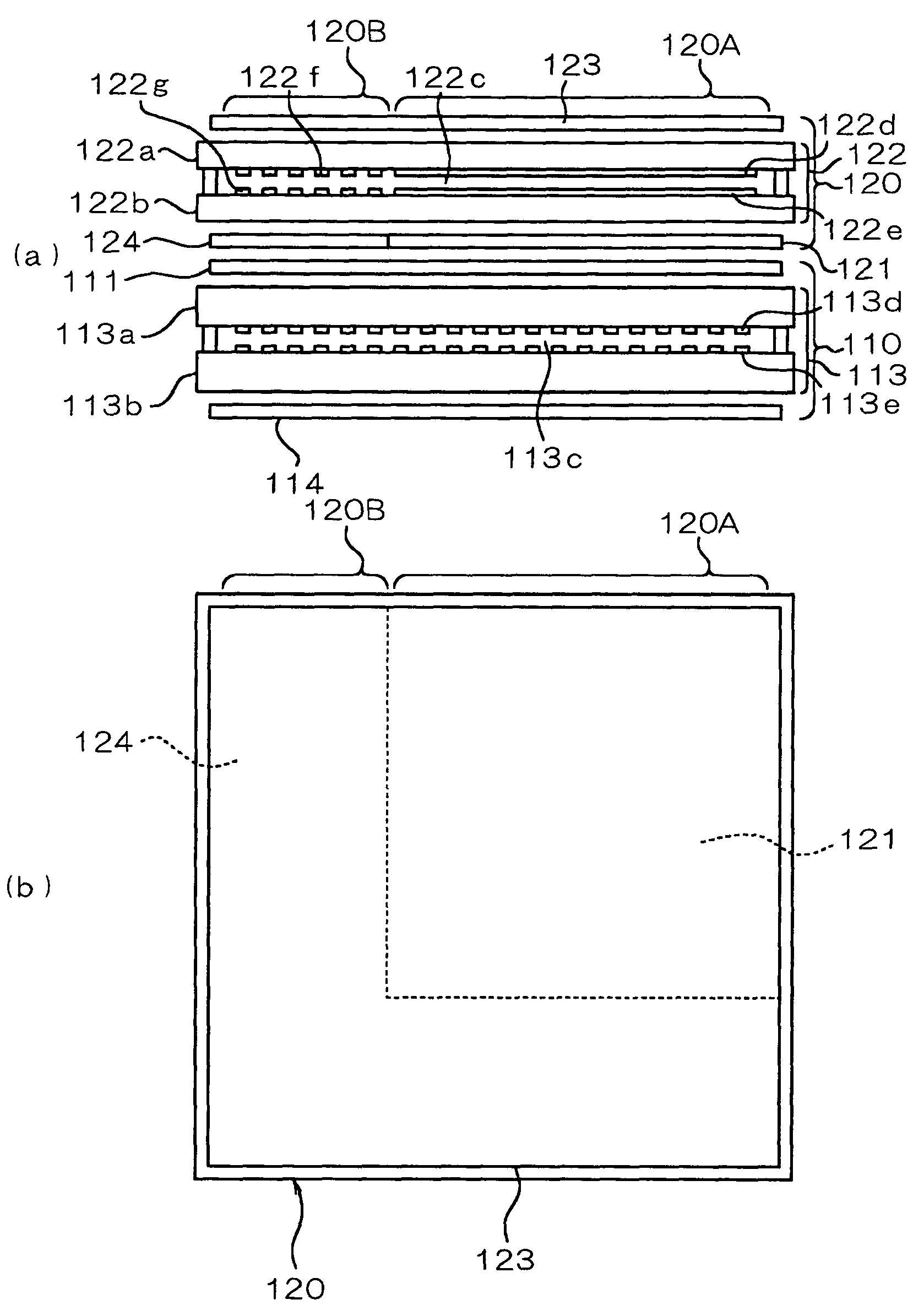

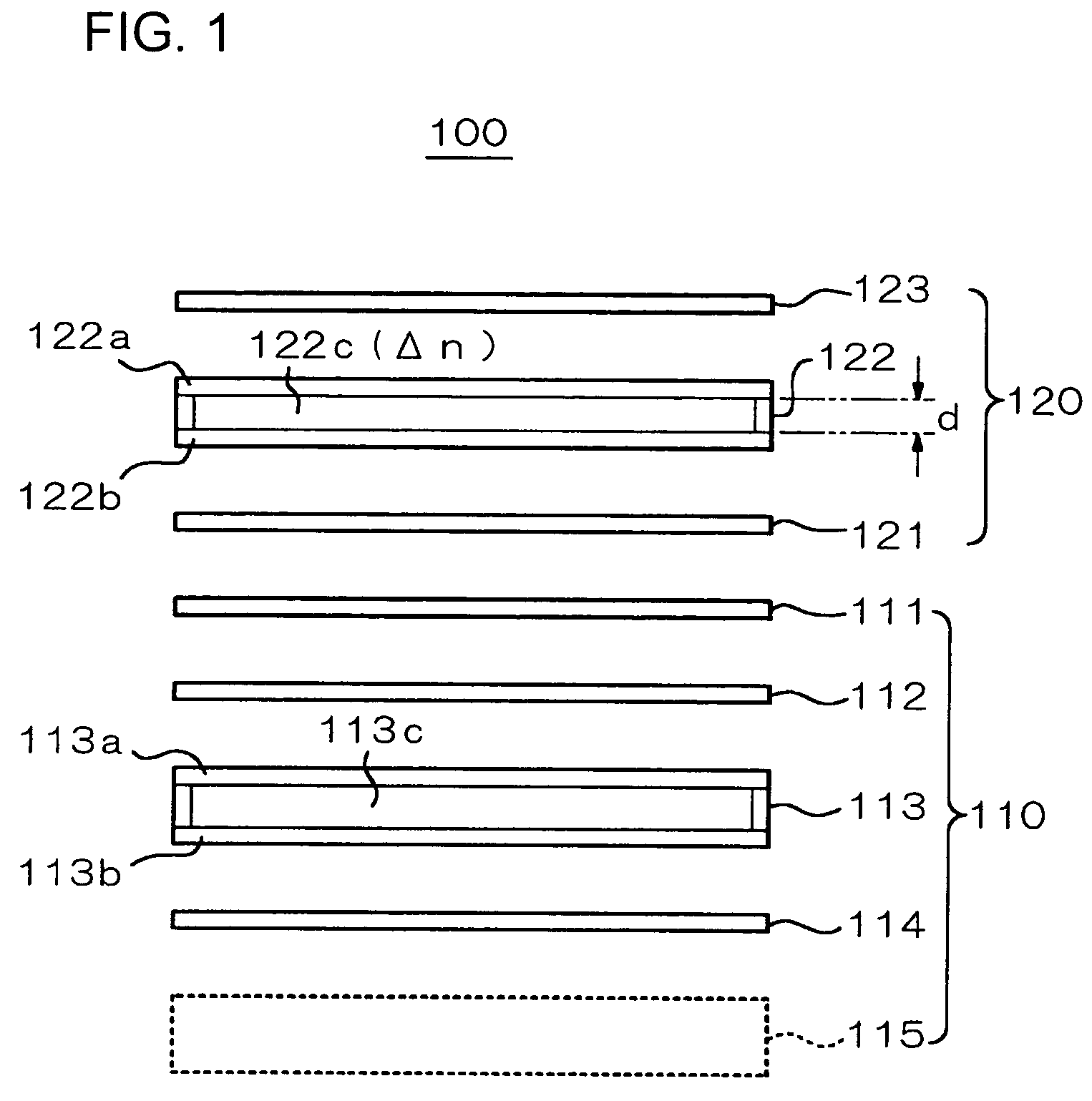

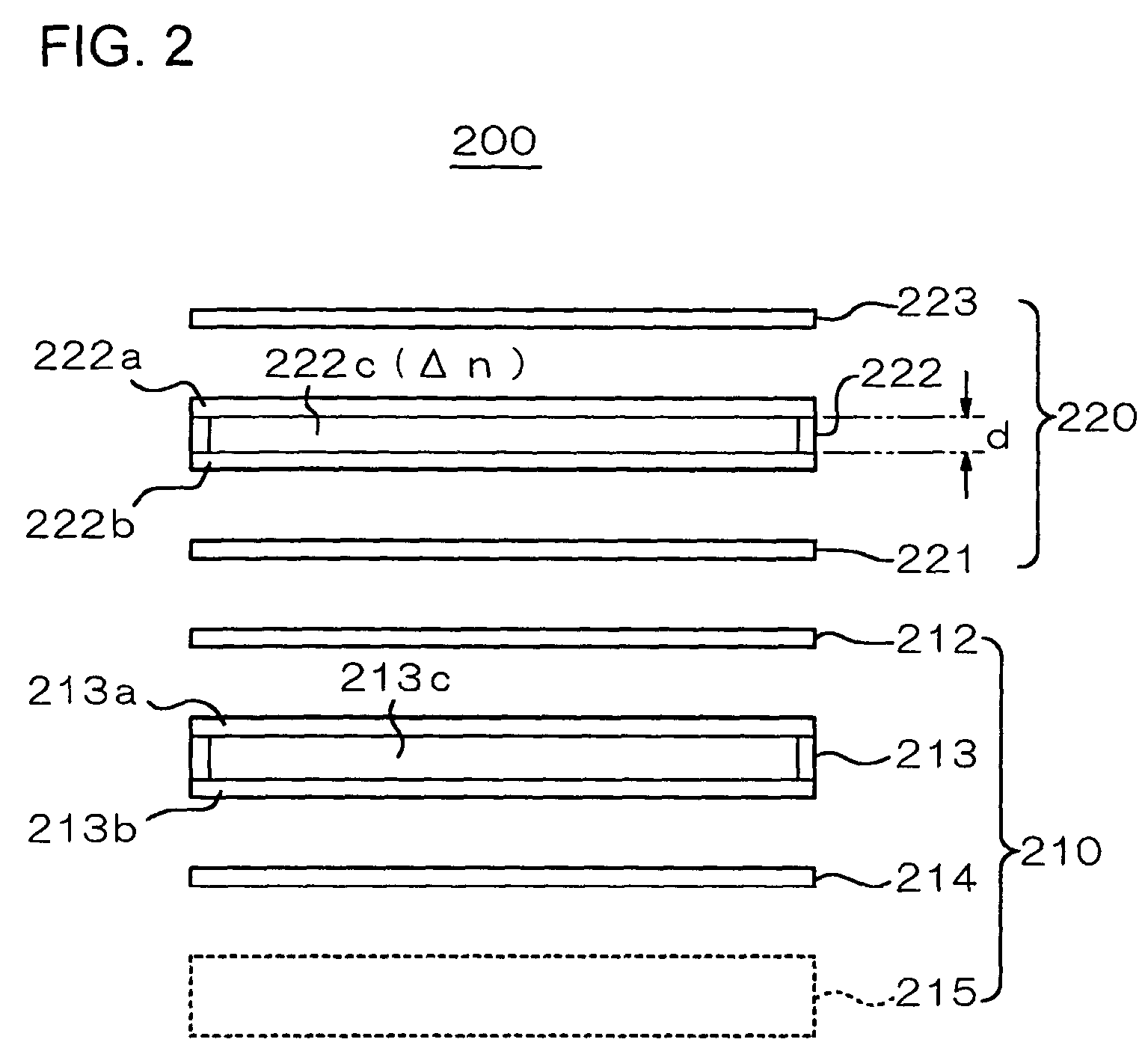

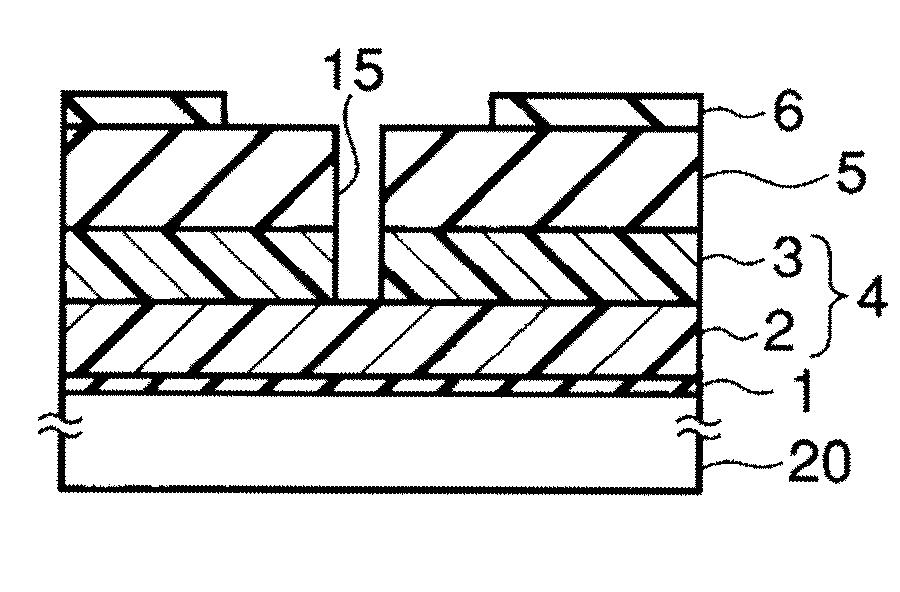

A display device 100 has a display unit 110 and a display switching unit 120. The display switching unit 120 is provided with a reflective polarizing plate 121, a liquid crystal panel 122, and a polarizing plate 123 arranged in this order from the side of the display unit 110 to the observation side. By controlling the liquid crystal panel 122, the display switching unit can be switched between a light transmissive state and a light reflective state. The display unit 110 and the display switching unit 120 are optically adhered to each other by an adhesive layer 131. Thus, deterioration of the contrast by boundary reflection can be restrained, and the flatness and the rigidity of the device can be improved.

Owner:BOE TECH GRP CO LTD

Chemical mechanical polishing method and method of manufacturing semiconductor device

InactiveUS20070128874A1Reduce capacitanceReduce resistance of metalOther chemical processesSemiconductor/solid-state device manufacturingOrganic filmPolymer science

A chemical mechanical polishing method comprises polishing an organic film using a slurry including polymer particles having a surface functional group and a water-soluble polymer.

Owner:JSR CORPORATIOON +1

Reciprocal form structure polymer solar cell and preparation method thereof

InactiveCN101577313AAvoid priceLow priceSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionEvaporation

The invention belongs to the technical field of polymer solar cells and particularly relates to a reciprocal form electrode polymer solar cell using TiO2 as an electronic transmission layer, CuPc as a cavity transmission layer and a preparation method thereof. The method includes the steps of: using sol-gel technology to grow a layer of uniform and compact nanocrystal titanium dioxide (TiO2) film on an ITO glass substrate, then spin-coating a layer of P3HT:PCBM solution dissolved by dichlorobenzene, after annealing, using thermal evaporation to grow a layer of CuPc with certain thickness and finally evaporating Au electrode. The polymer solar cell prepared by utilizing the method solves two problems of the traditional polymer solar cell, namely that the mixed solution of 3, 4-EDOT and polystyrolsulfon acid corrode the surface of ITO glass, and the excessive thinness of cathode buffer layer LiF causes the operating process to be difficult to be controlled accurately.

Owner:JILIN UNIV

Biaxially oriented laminated film

ActiveUS20100190037A1Good dimensional stabilityFew voidMagnetic materials for record carriersBase layers for recording layersBoPETSurface roughness

It is an object of the present invention to provide a biaxially oriented laminated polyester film which has excellent dimensional stability to environmental changes such as temperature and humidity variations and excellent flatness and windability.The present invention is a biaxially oriented laminated polyester film comprising a film layer B on one side of a film layer A and having a surface roughness (RaB) on the film layer B side which is 1.0 nm or more larger than the surface roughness (RaA) on the film layer A side, whereinat least one of the film layers comprises an aromatic polyester (I) composed of a glycol component and a dicarboxylic acid component containing 5 mol % or more and less than 80 mol % of a recurring unit represented by the following formula (A):wherein RA is an alkylene group having 1 to 10 carbon atoms.

Owner:TEIJIN LTD

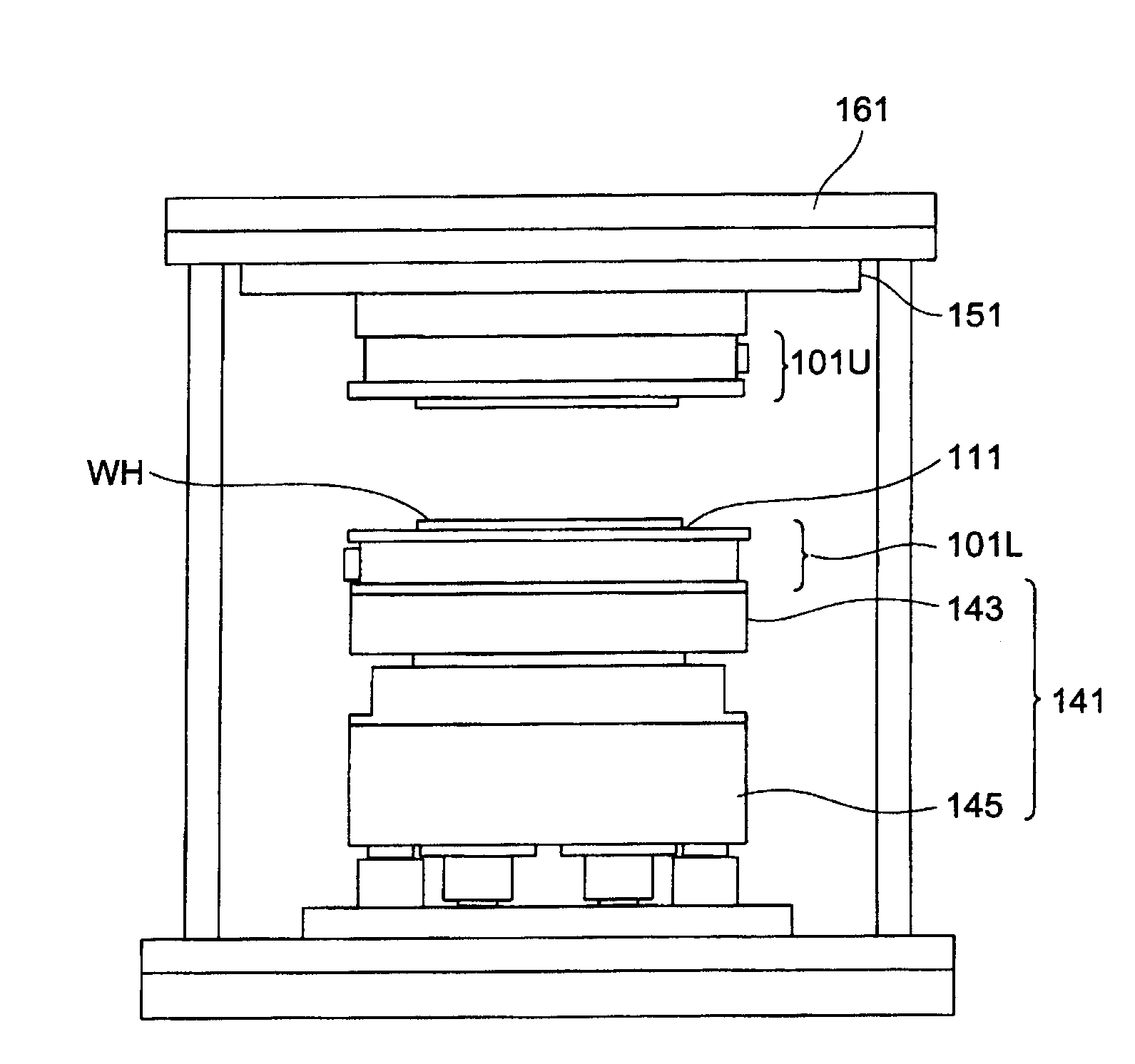

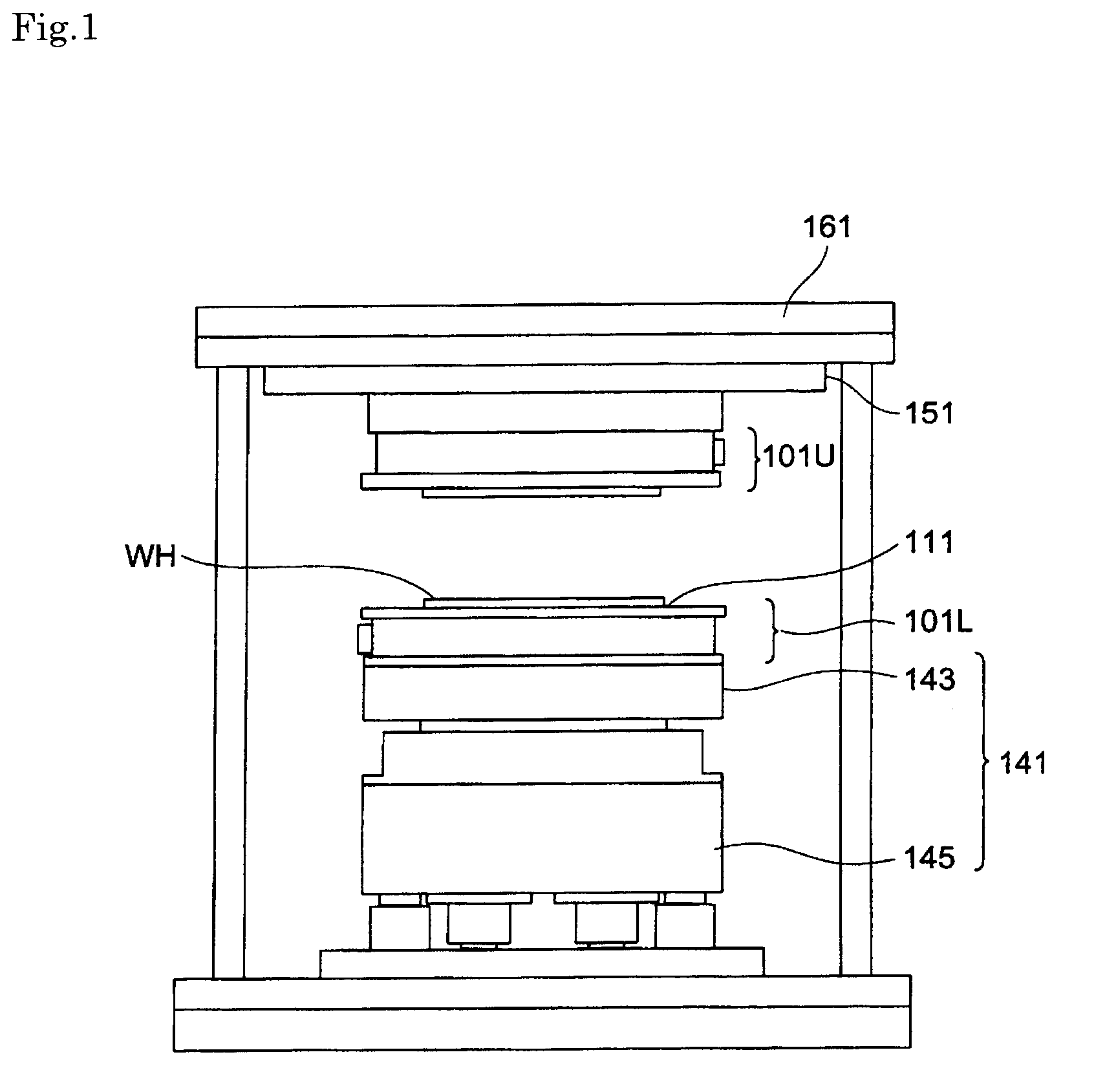

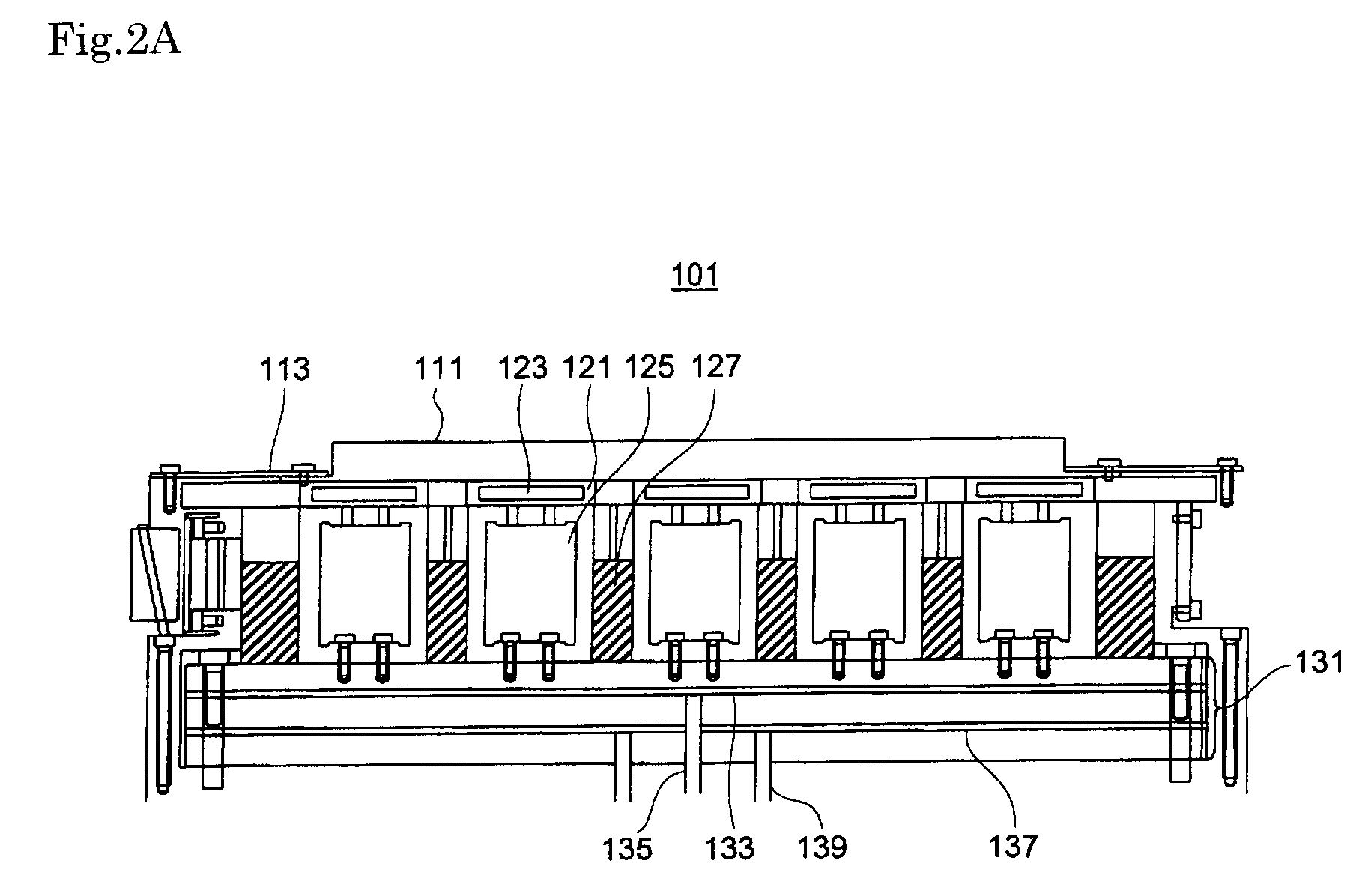

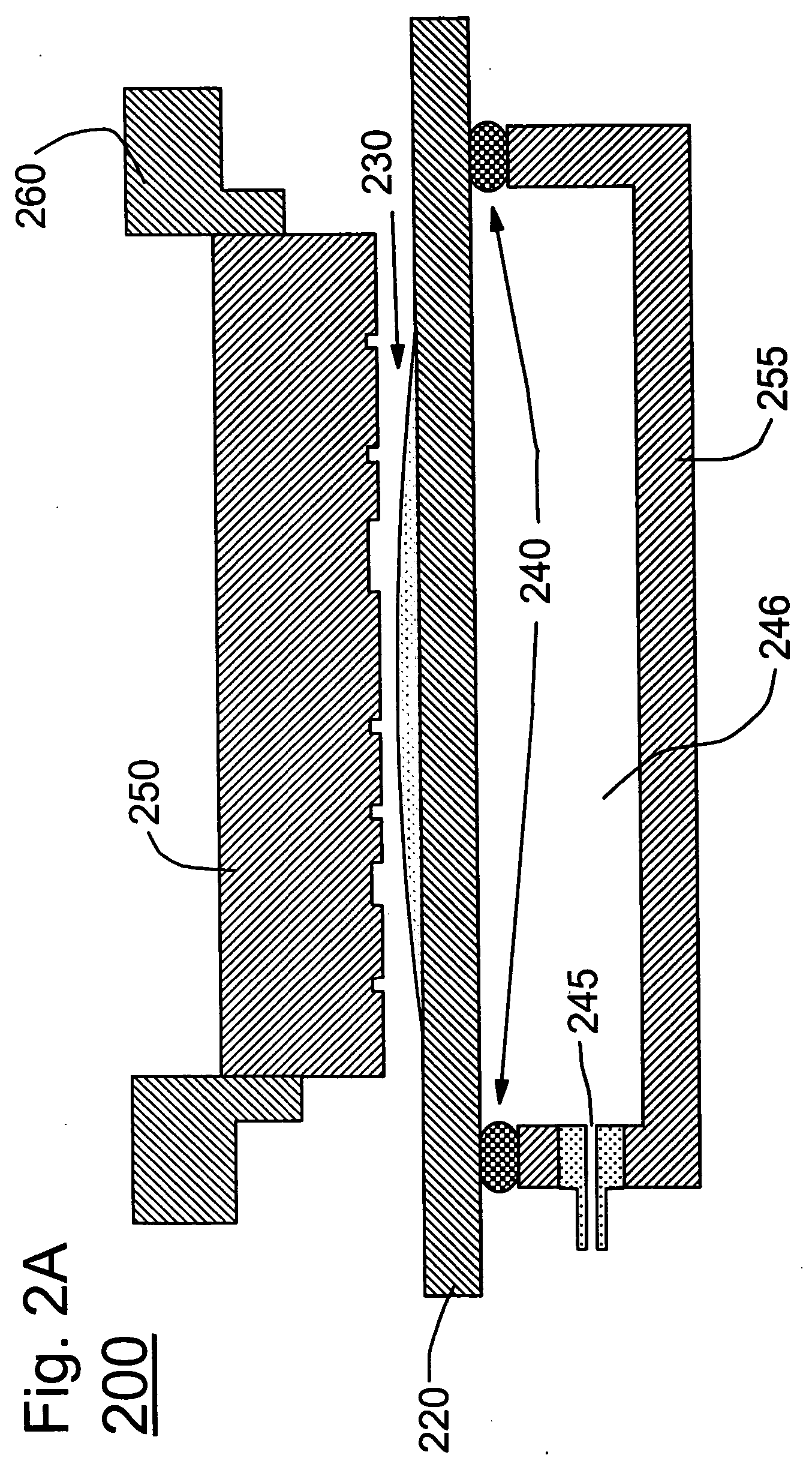

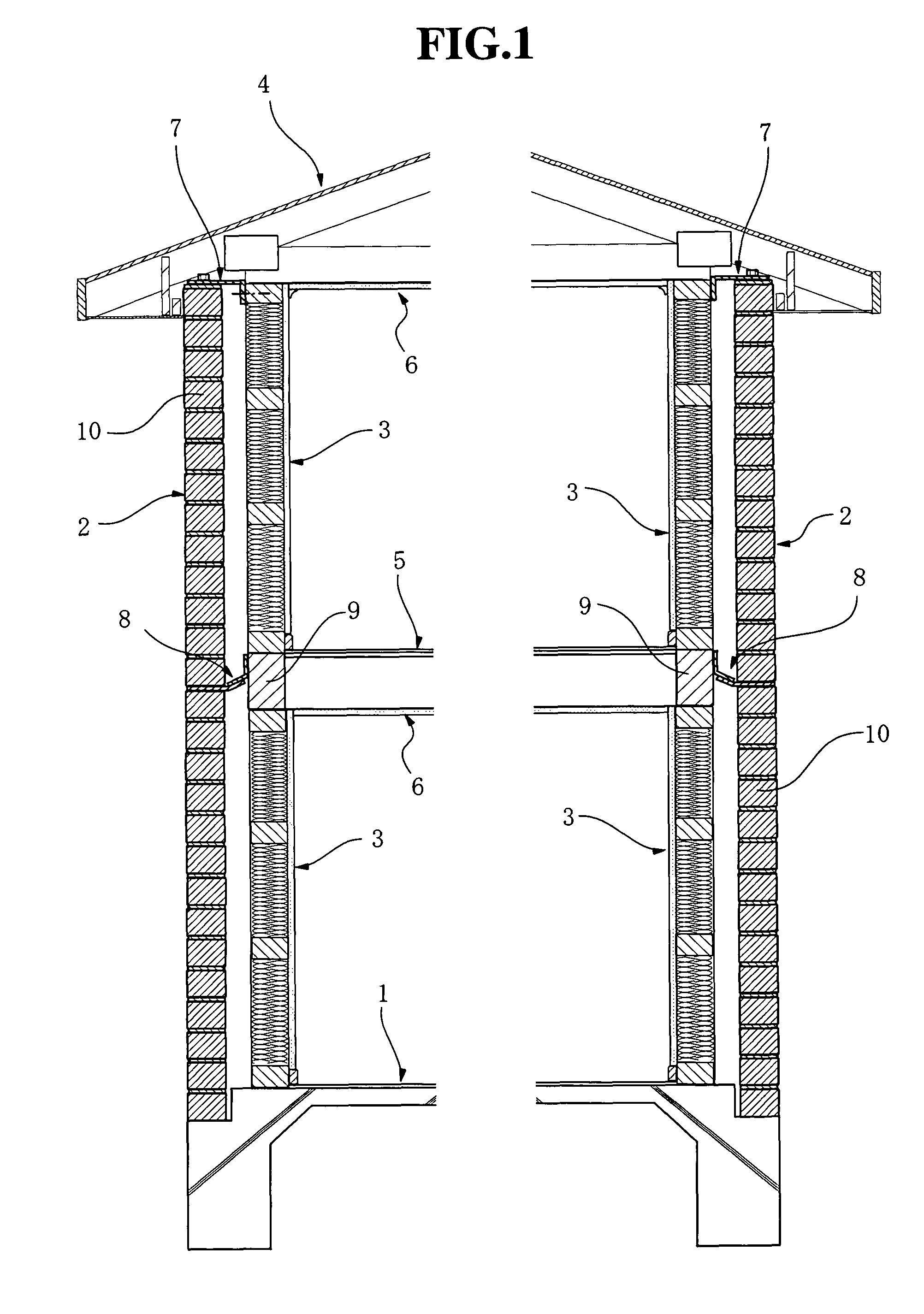

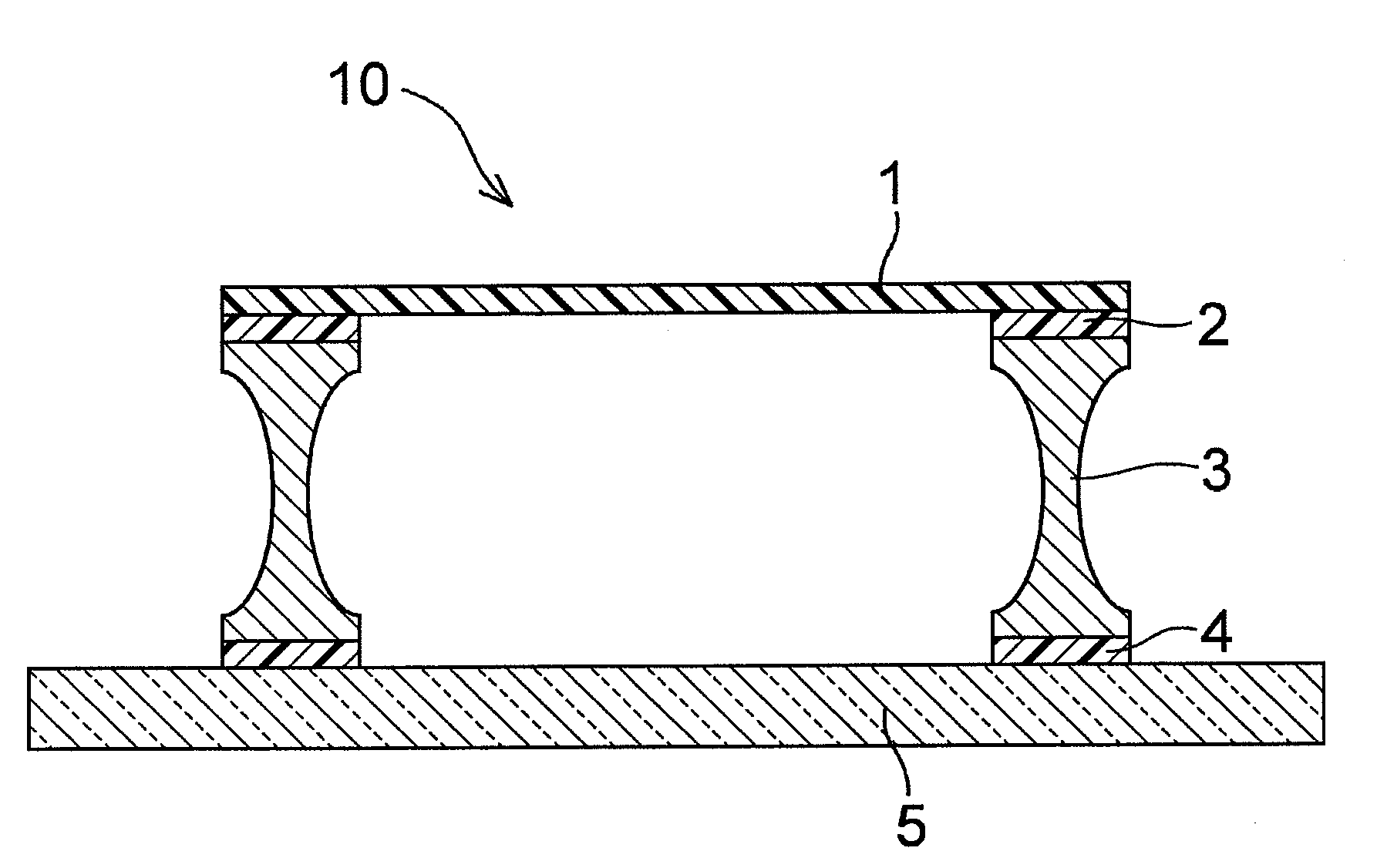

Wafer bonding apparatus

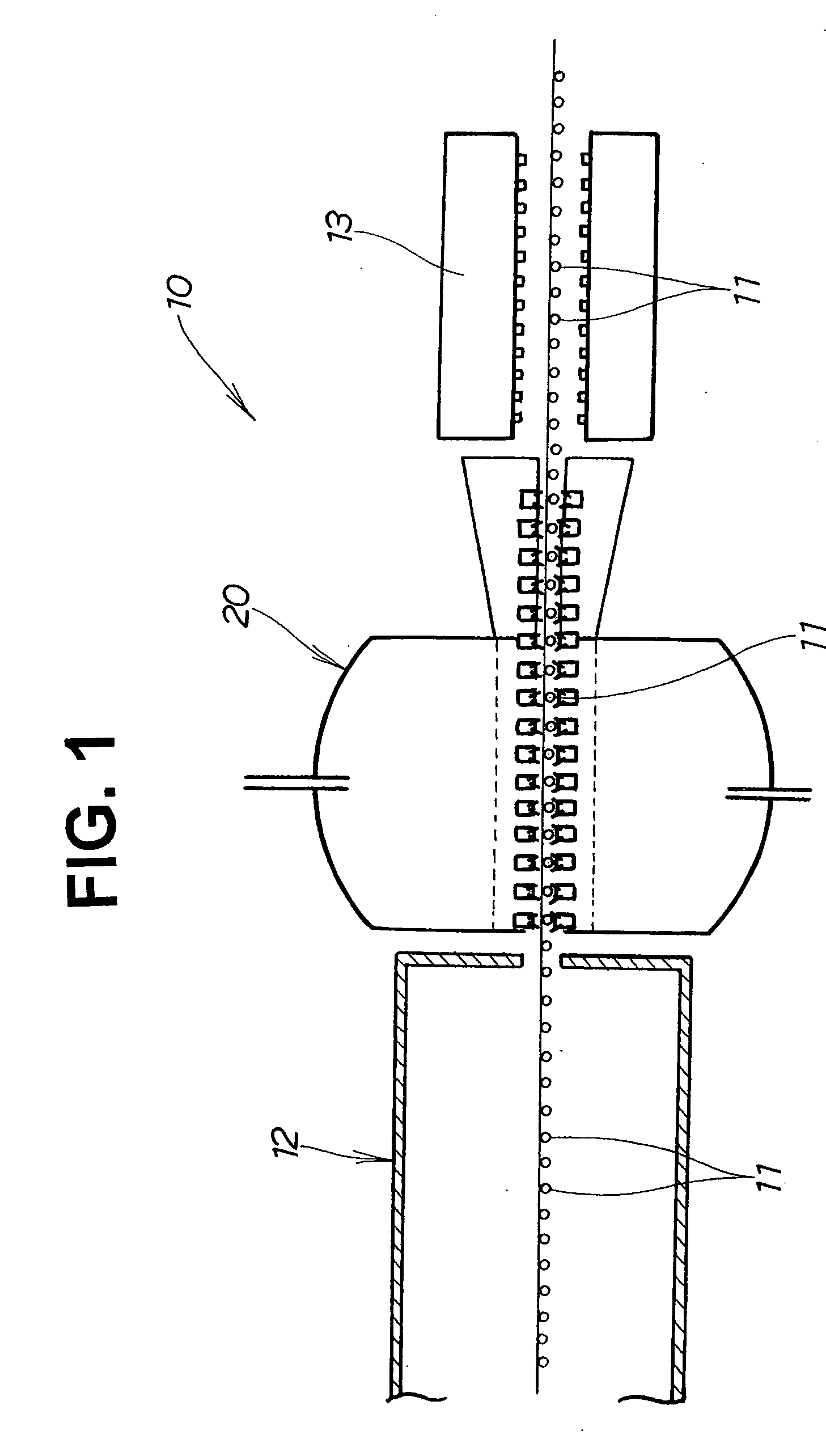

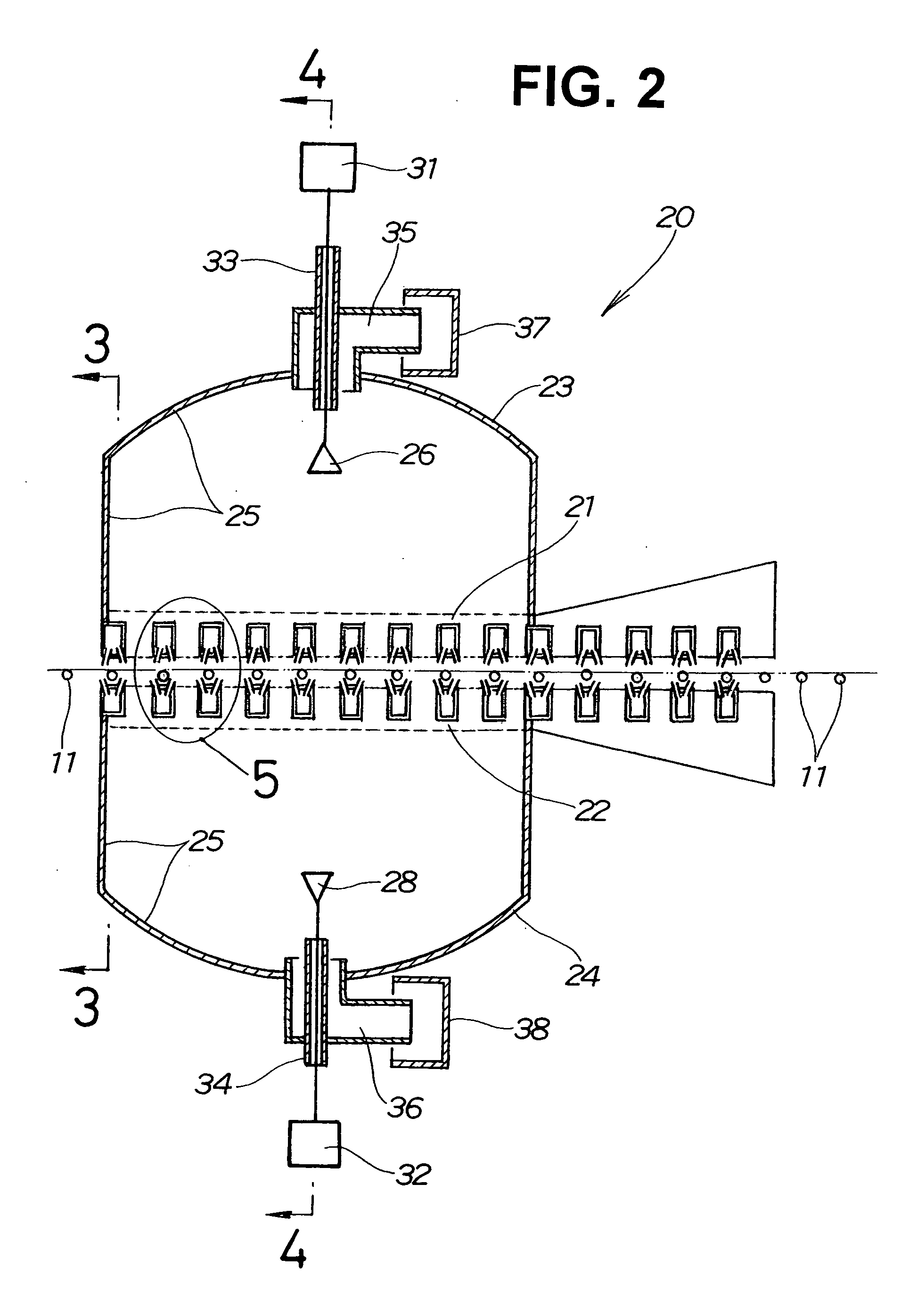

ActiveUS20090317960A1FlatnessImprove flatnessLamination ancillary operationsControlling laminationShape changeComputer module

Provided is a wafer bonding apparatus which performs pressurization and heating and eliminates nonuniformity of wafer thickness by changing the shape of a pressurizing surface so that planarity of a wafer bonding surface is improved. The wafer bonding apparatus places a plurality of wafers to be bonded between an upper unit (101U) and a lower unit (101L), and bonds the wafers by applying pressure and heat by the upper unit and the lower unit. The wafer bonding apparatus is provided with a top plate (111), a pressure profile control module (131), and a heater section arranged between the top plate and the pressure profile control module for heating. Shape change generated on the surface of the pressure profile control module causes change of the surface of the top plate.

Owner:NIKON CORP

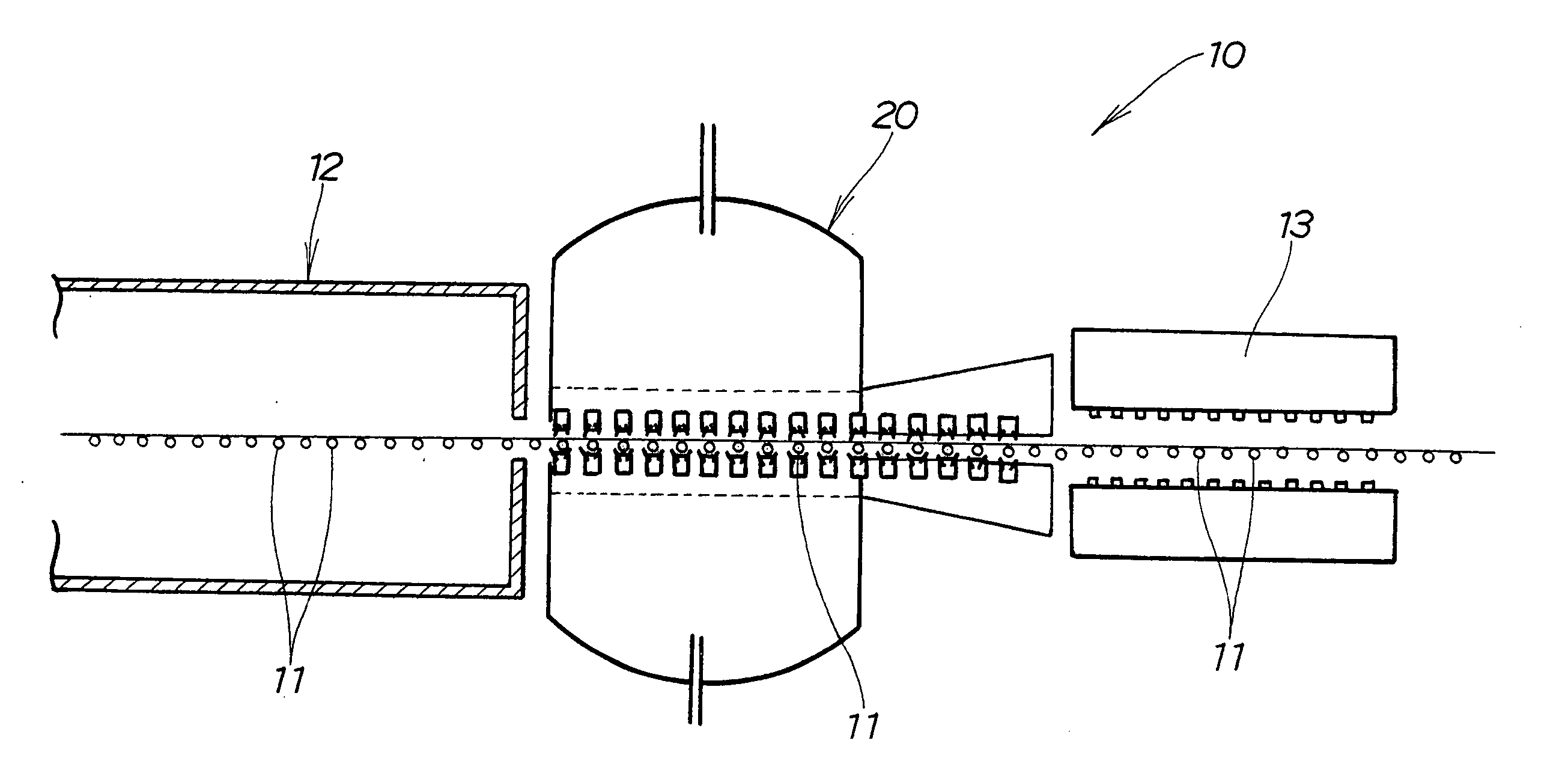

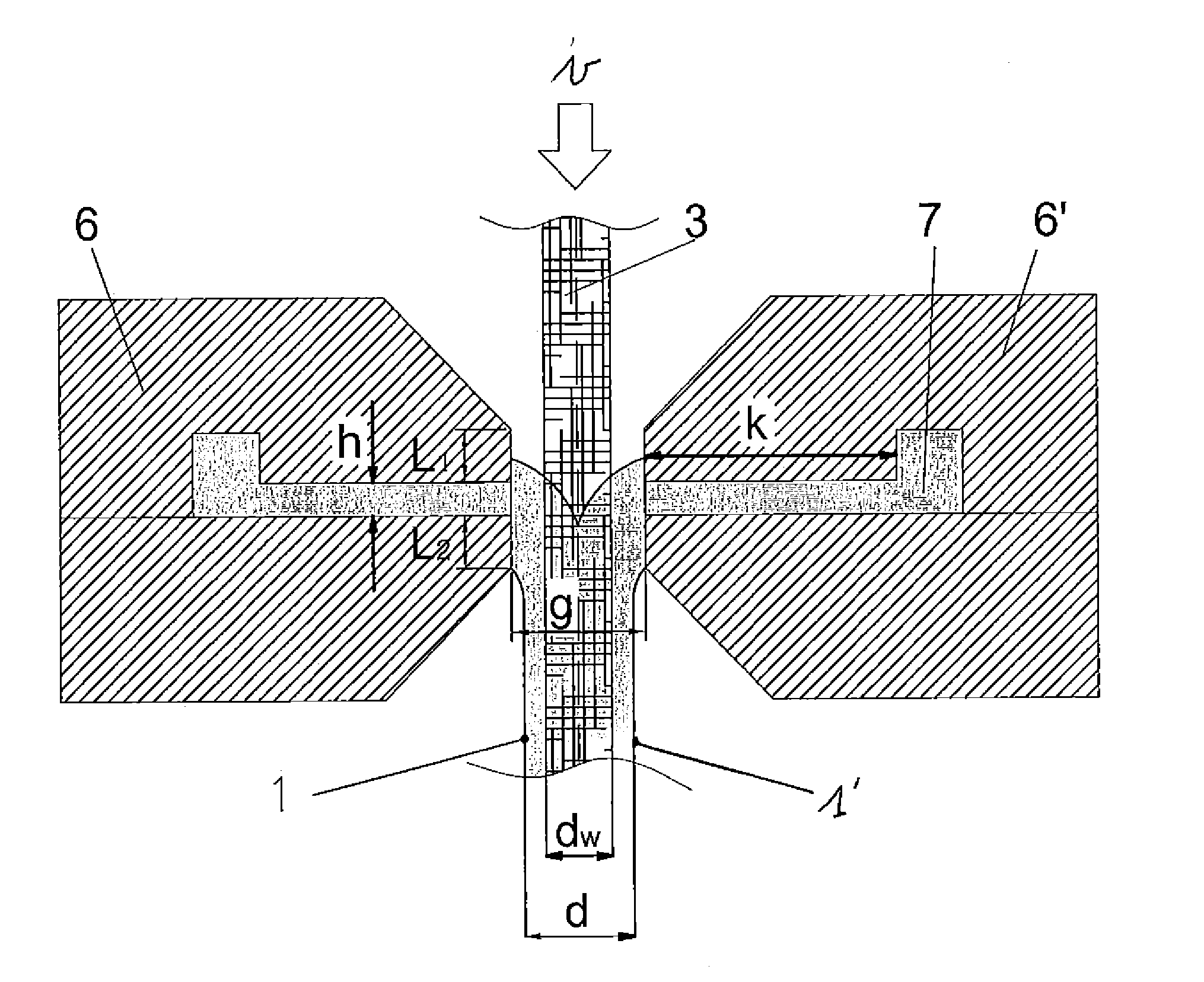

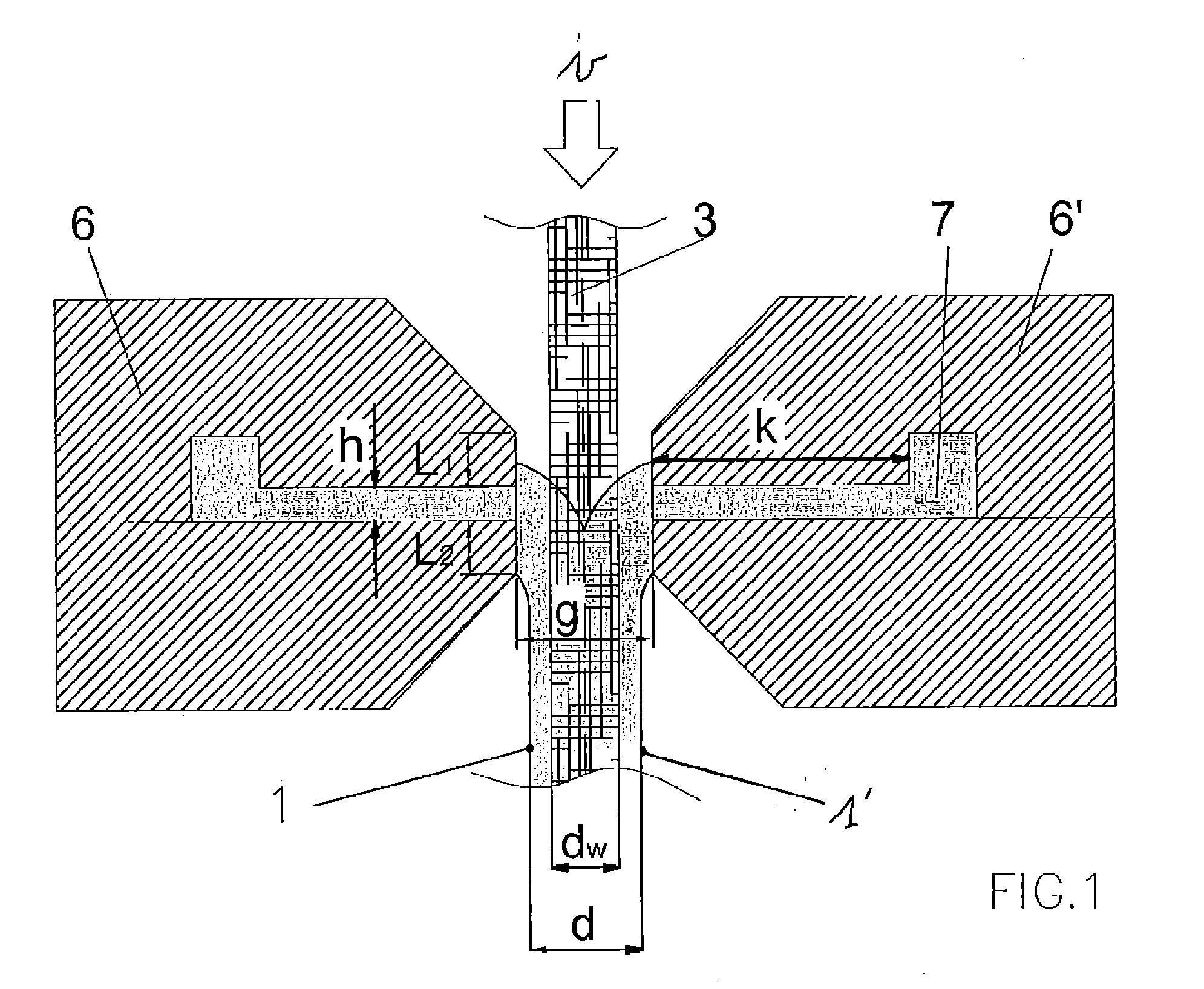

Method and device for reinforcing glass pane by rapid cooling

InactiveUS20060026994A1Heating evenlyFlatnessMicrowave heatingGlass tempering apparatusQuenchingGlass sheet

A method for quenching a glass sheet comprises the steps of radiating a microwave (46) at least on one surface of the glass sheet (G), and simultaneously air-quenching the glass sheet for tempering, wherein the microwave is radiated at the glass sheet through a gap (44) between adjacent air ducts (41A, 41A or 41B, 41B), and the quenching air is blown without hitting a plurality of conveying rollers (11) for conveying the glass sheet.

Owner:NIPPON SHEET GLASS CO LTD

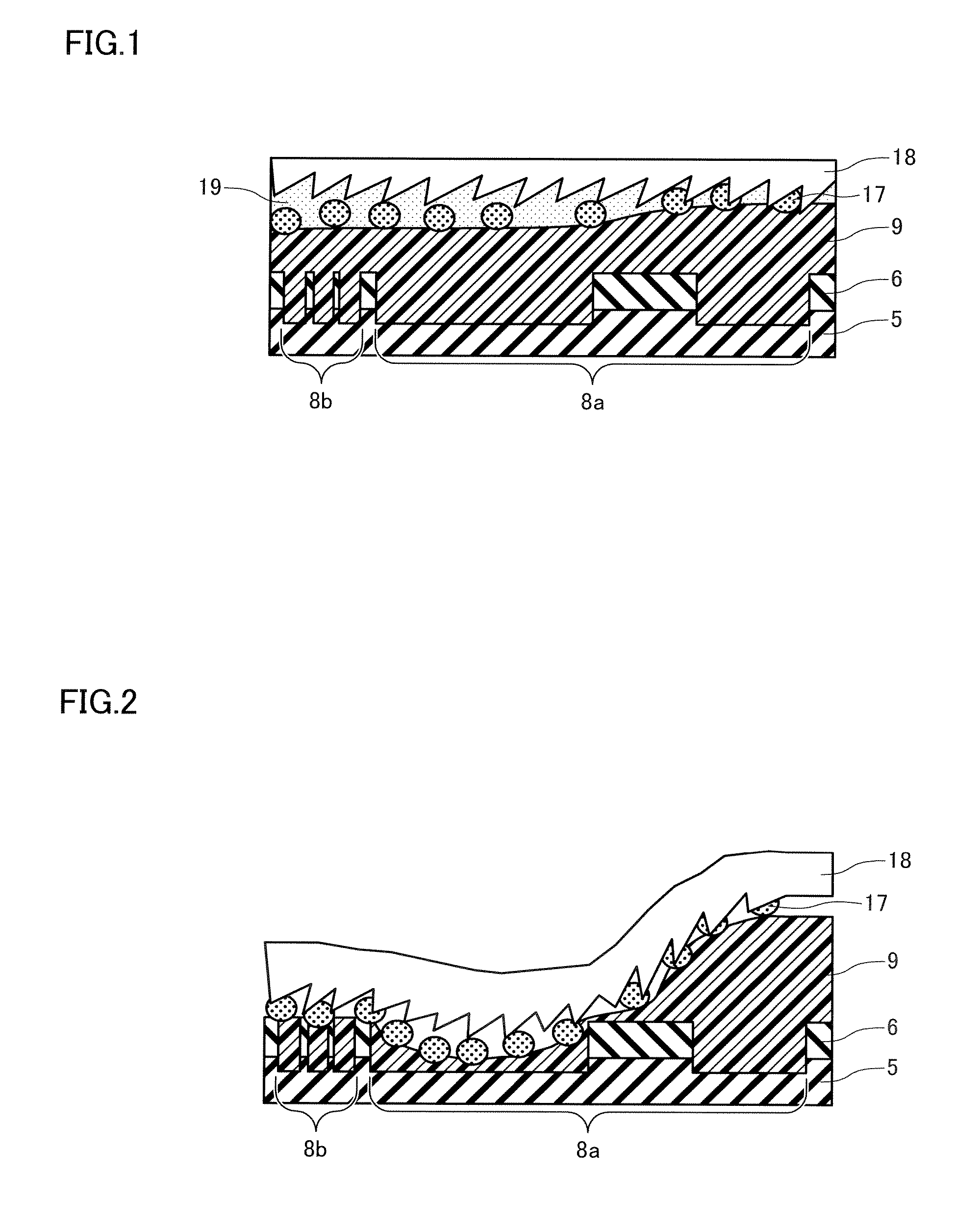

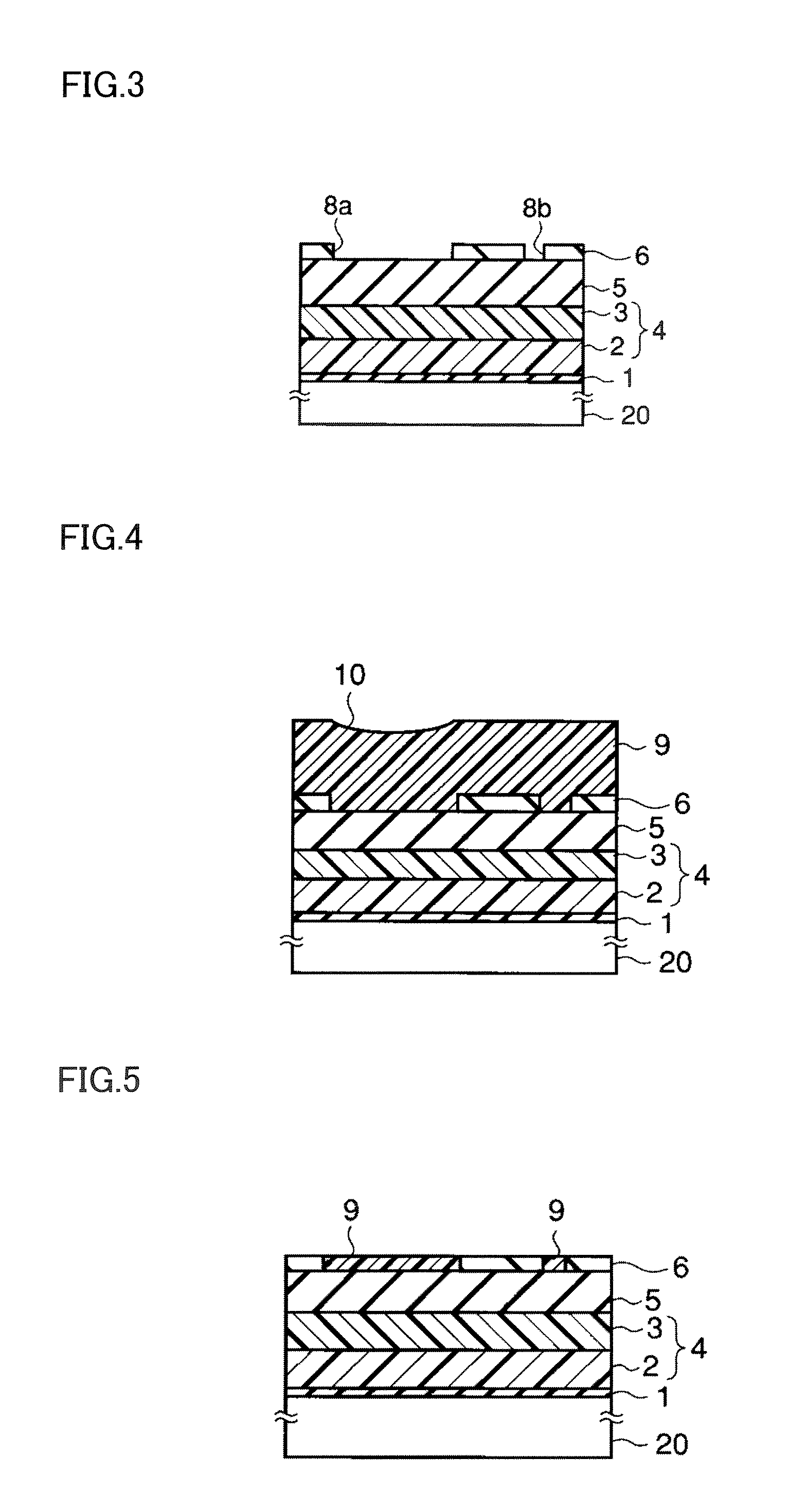

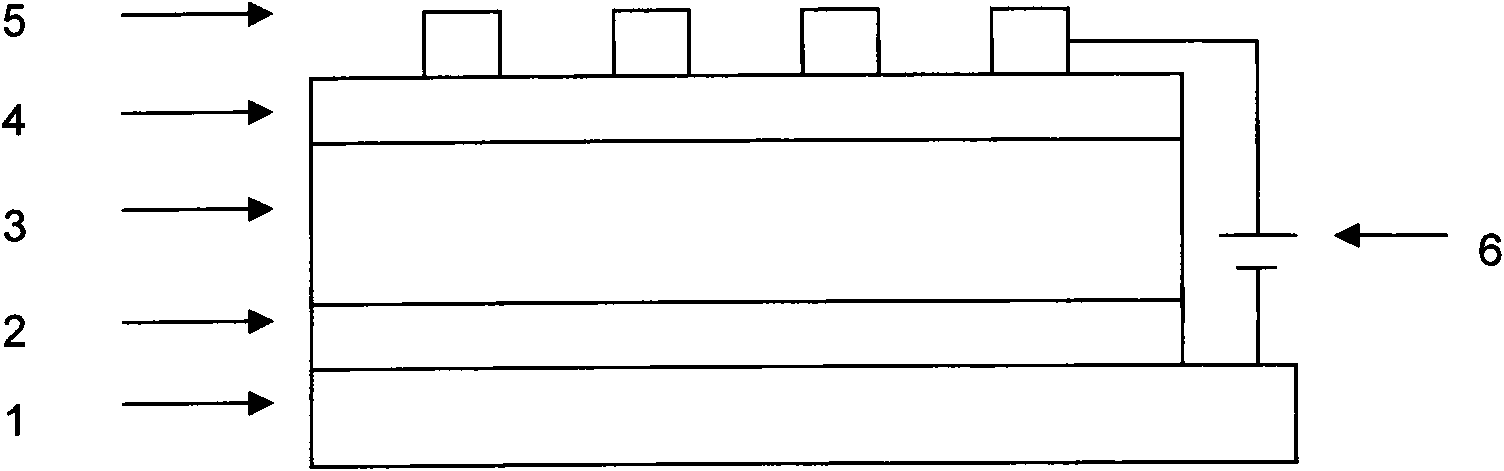

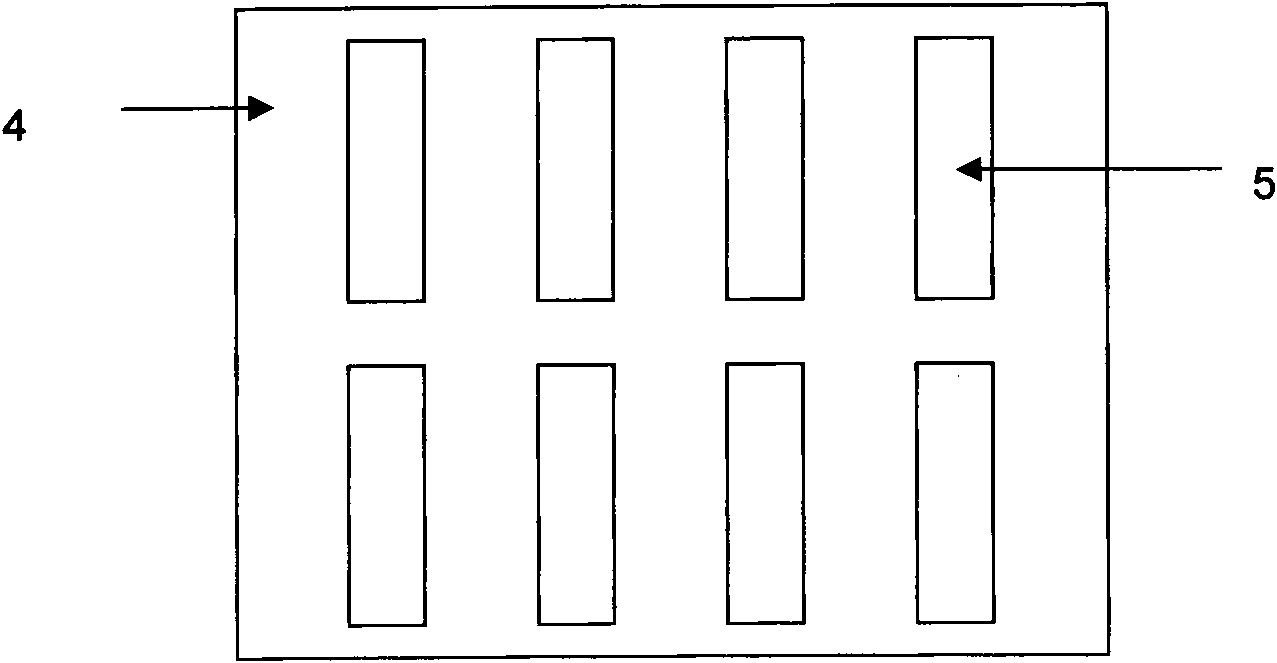

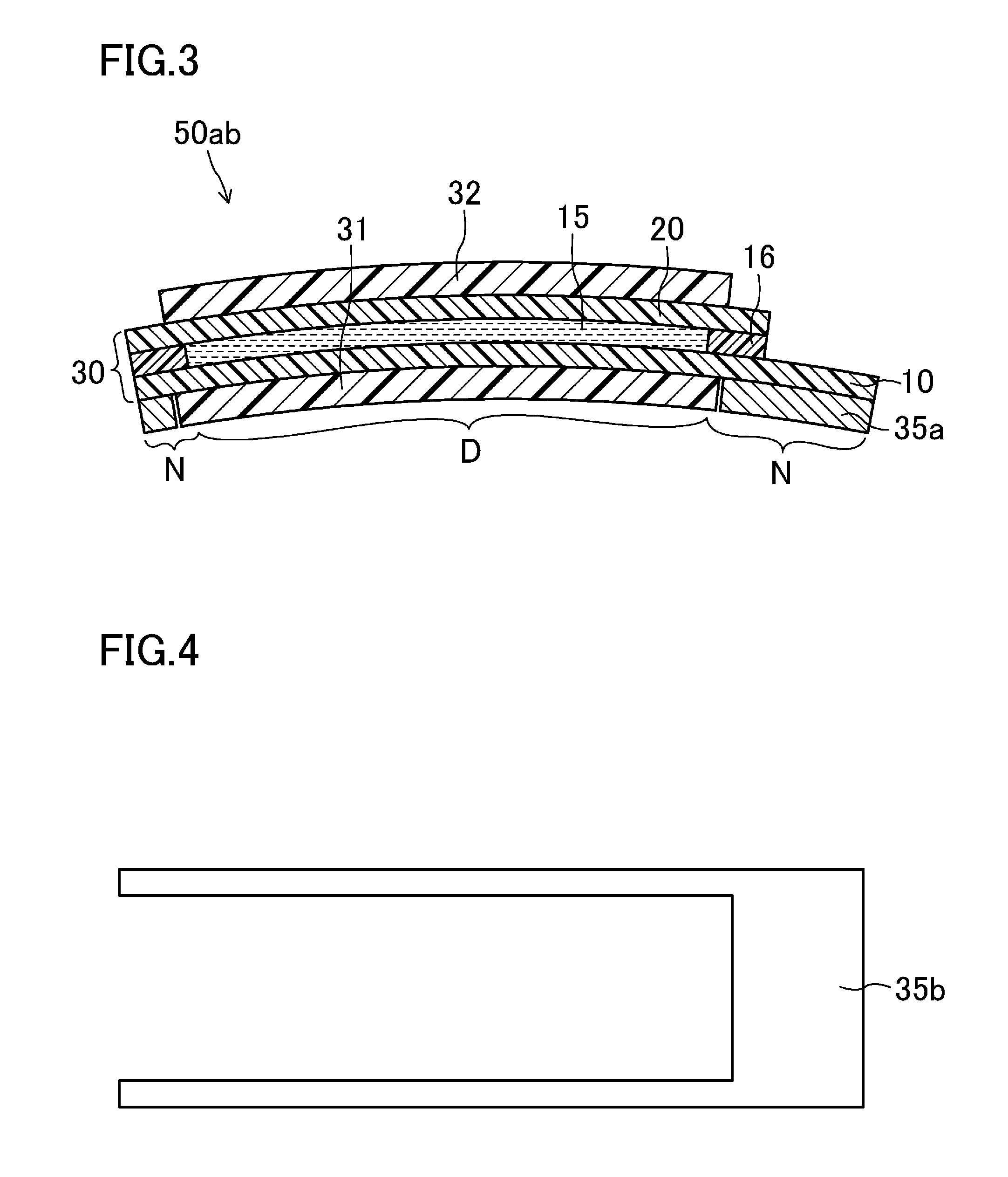

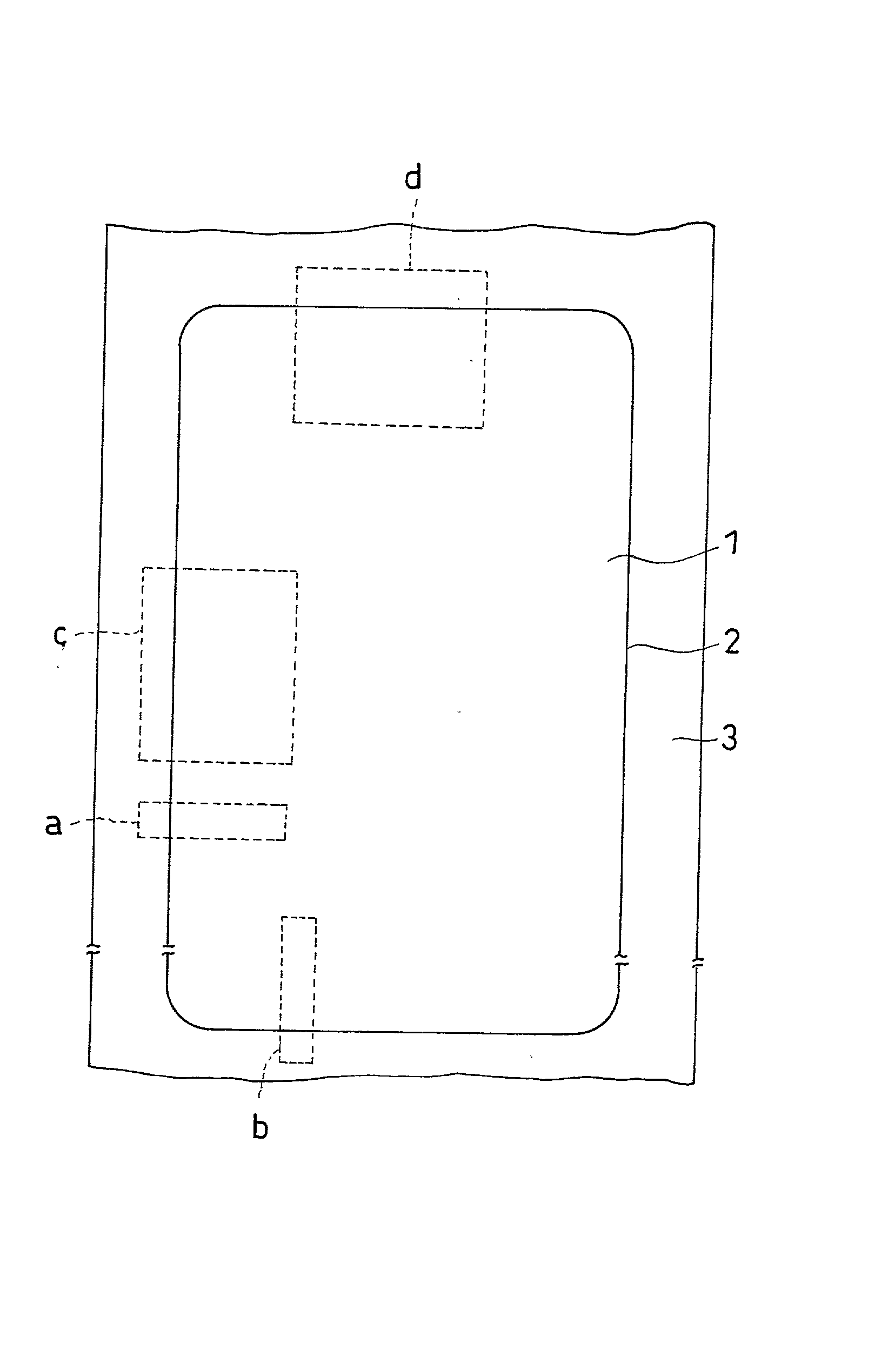

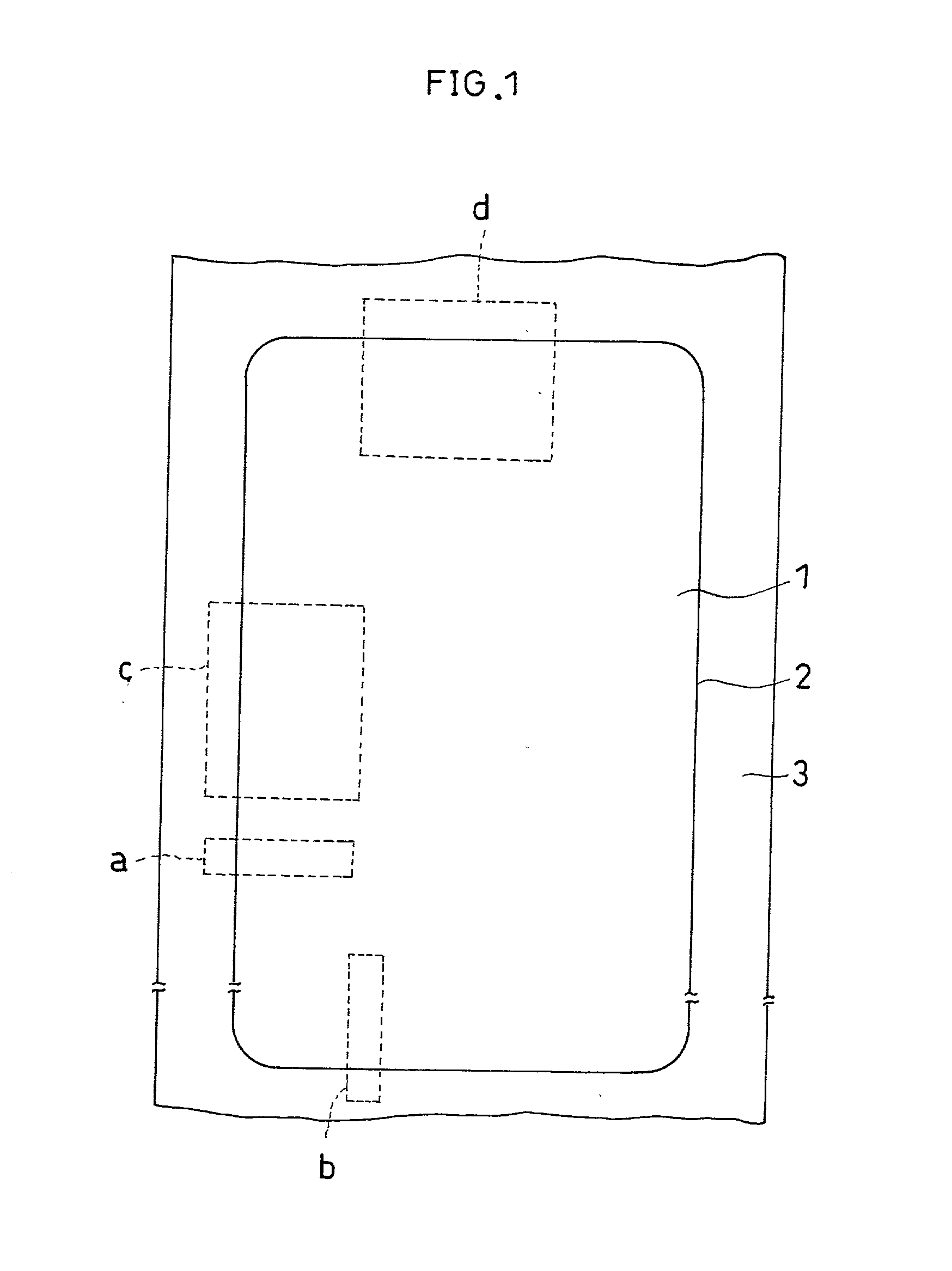

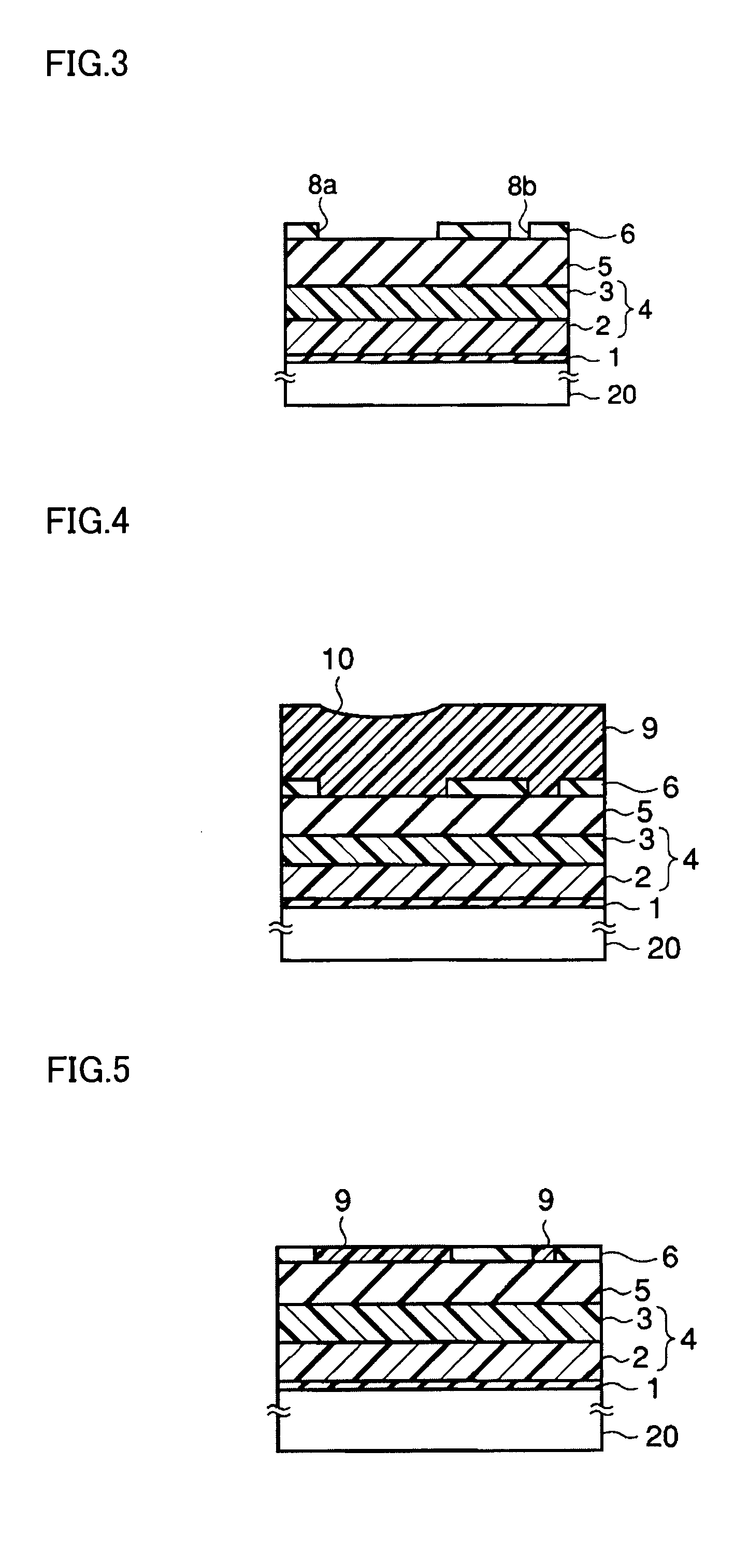

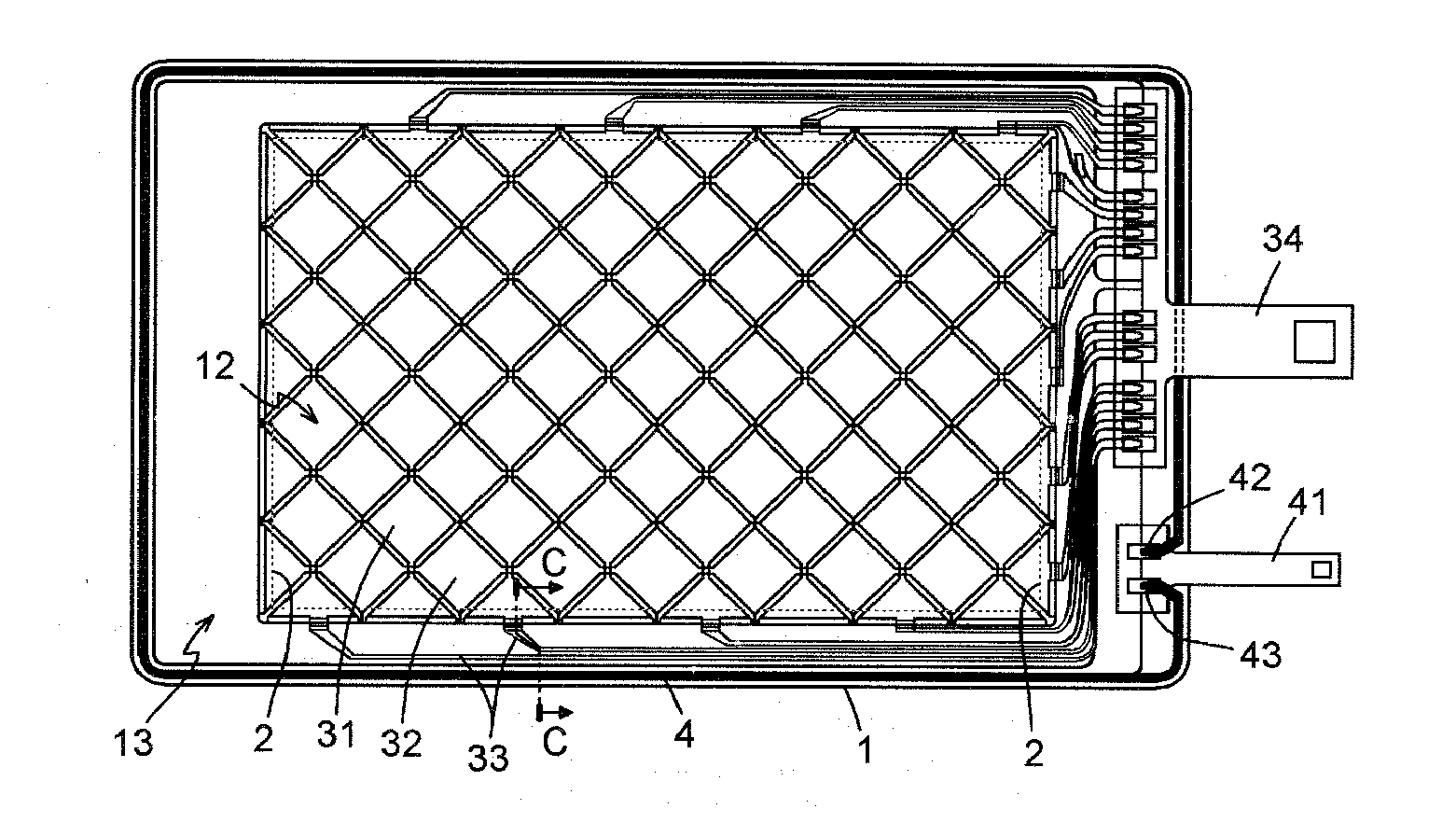

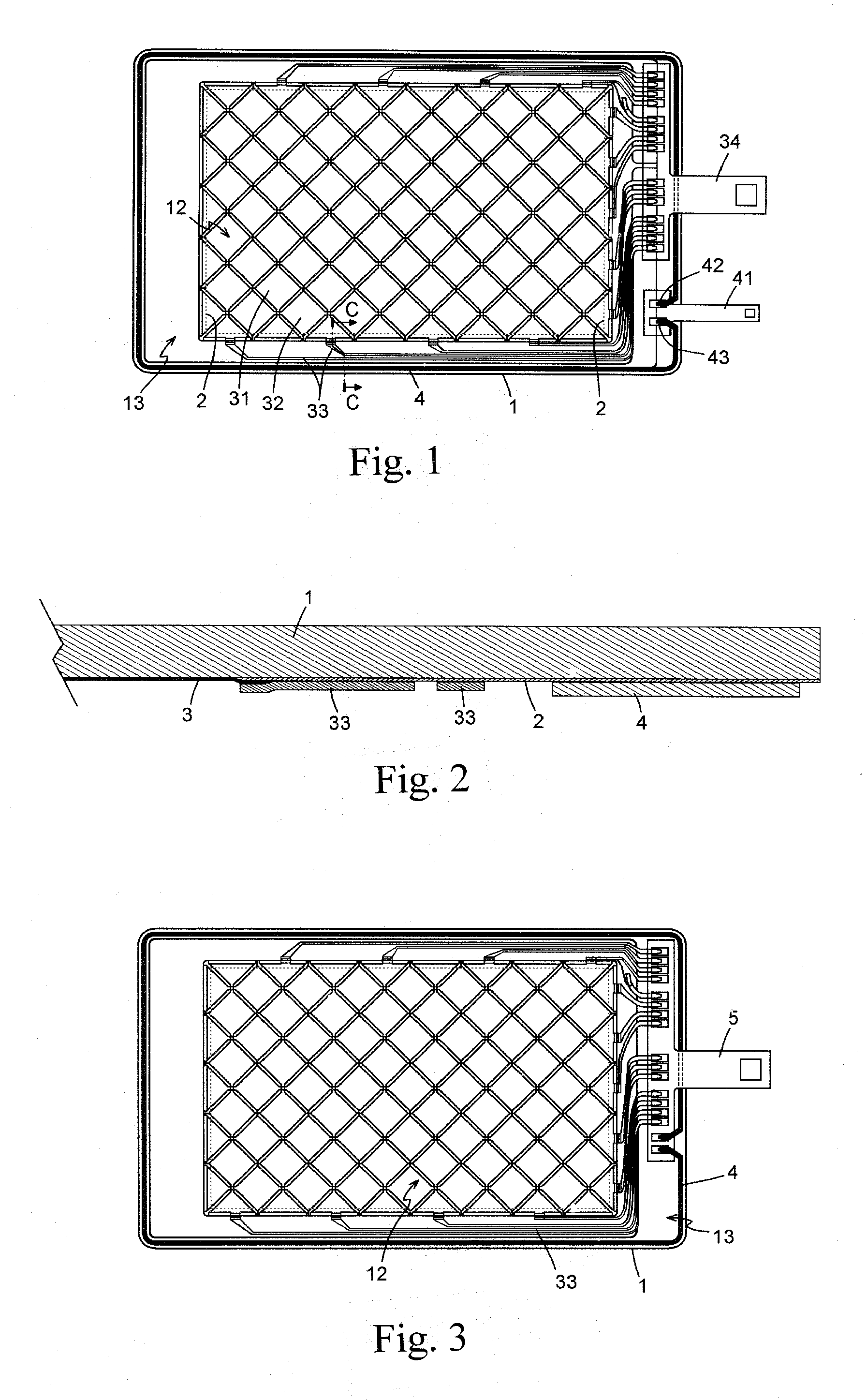

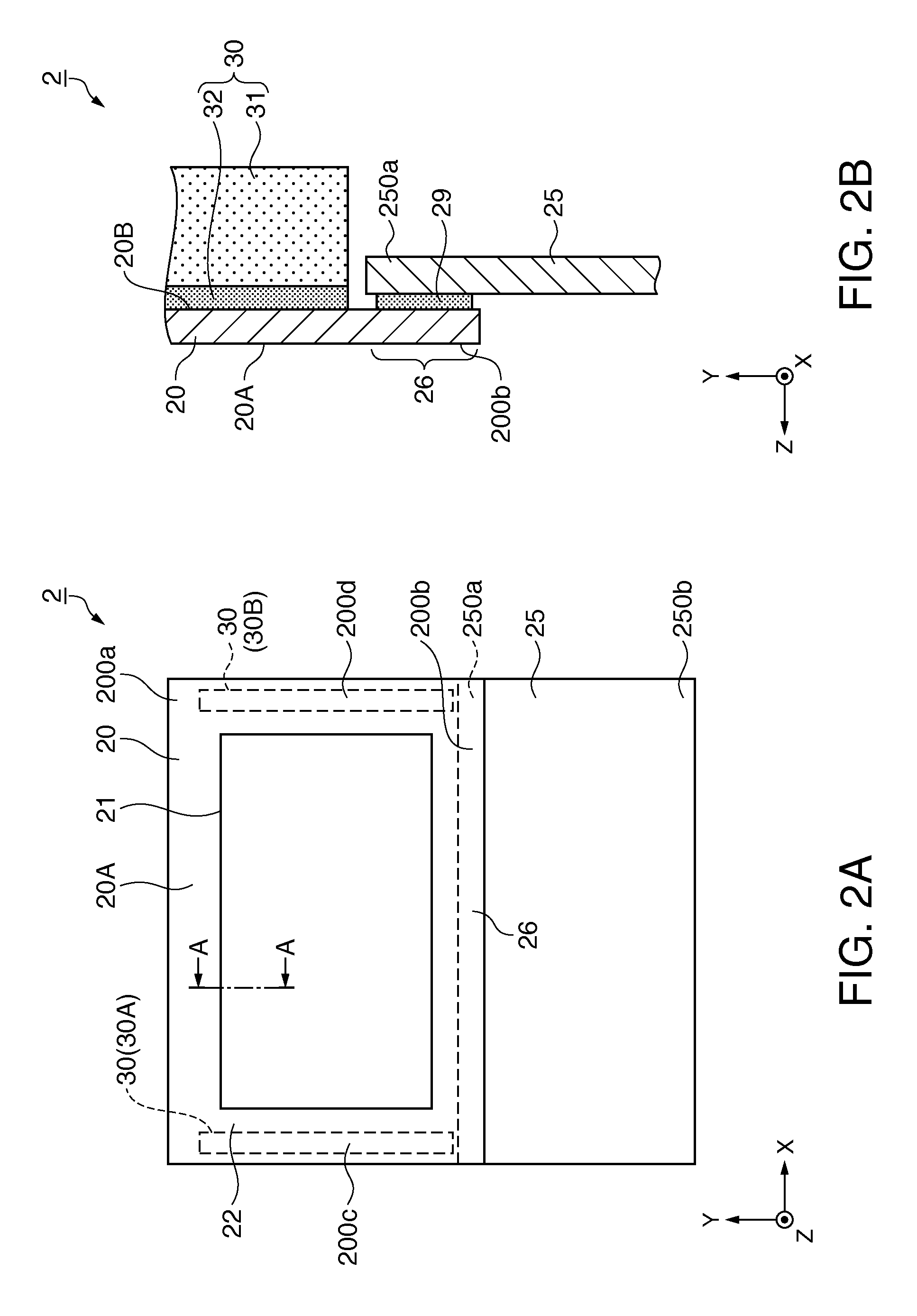

Display device

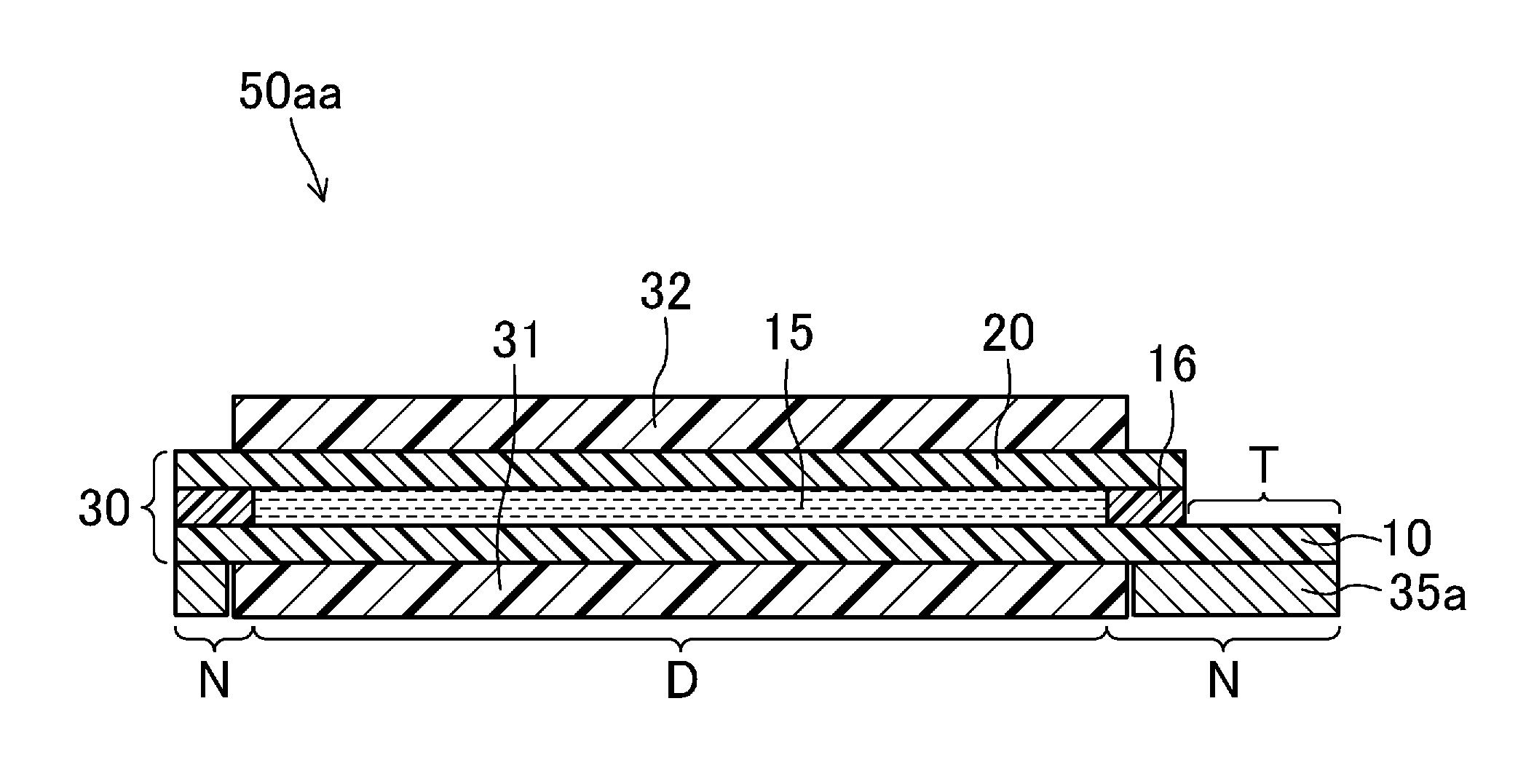

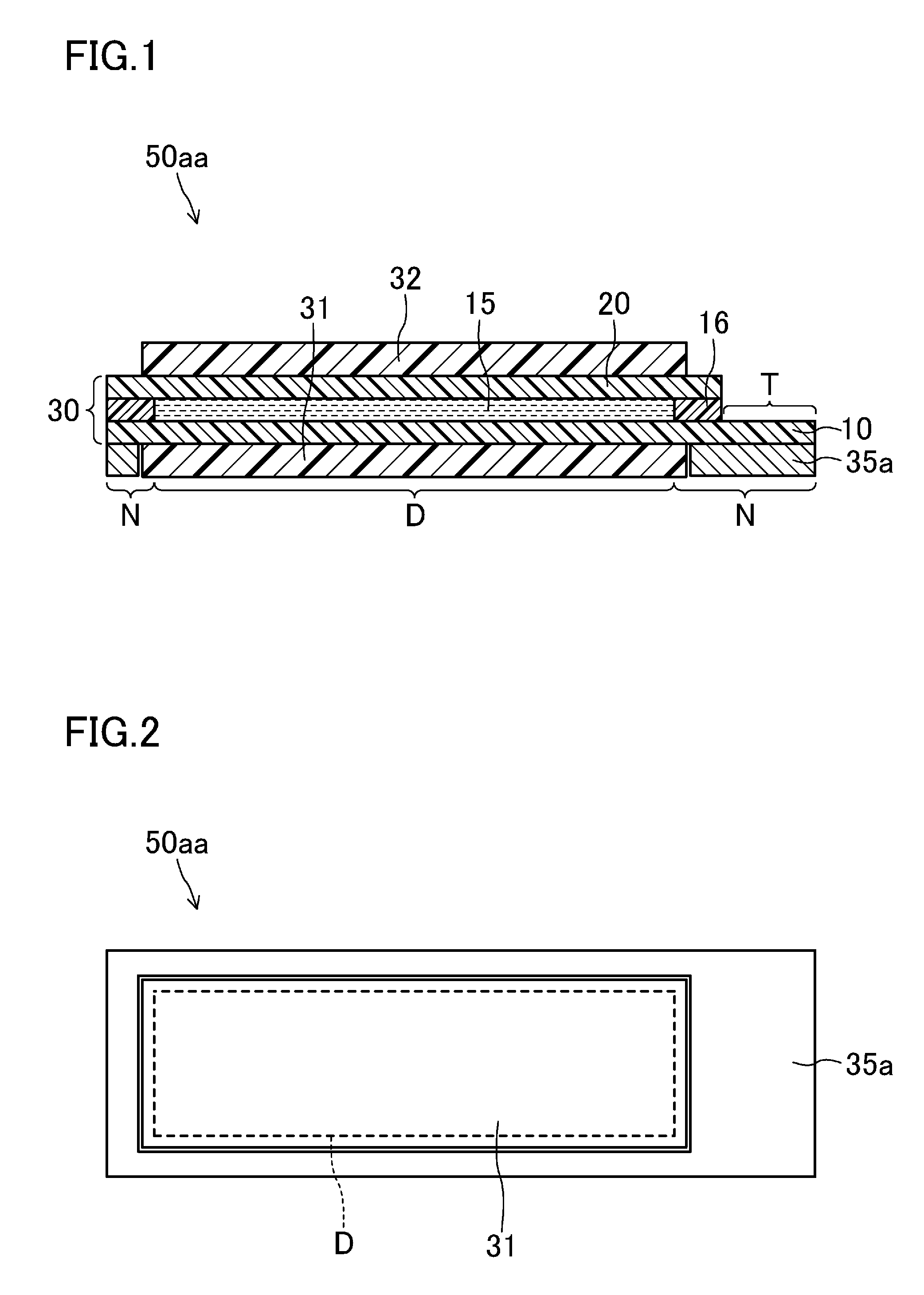

ActiveUS20130088662A1FlatnessFlexibilityNon-linear opticsIdentification meansDisplay deviceEngineering

A display device (50aa) includes a display panel (30) which has a display region (D) for image display and a non-display region (N) surrounding the display region (D), and has flexibility, wherein a reinforcing member (35a) is bonded to in the non-display region (N) of the display panel (30) such that the display region (D) is exposed.

Owner:SHARP KK

Base fabric for hollow-woven air bag and air bag

InactiveUS20020130503A1FlatnessImprove weaving performancePedestrian/occupant safety arrangementMulti-ply fabricsMechanical engineering

Owner:TOYO TOYOBO CO LTD

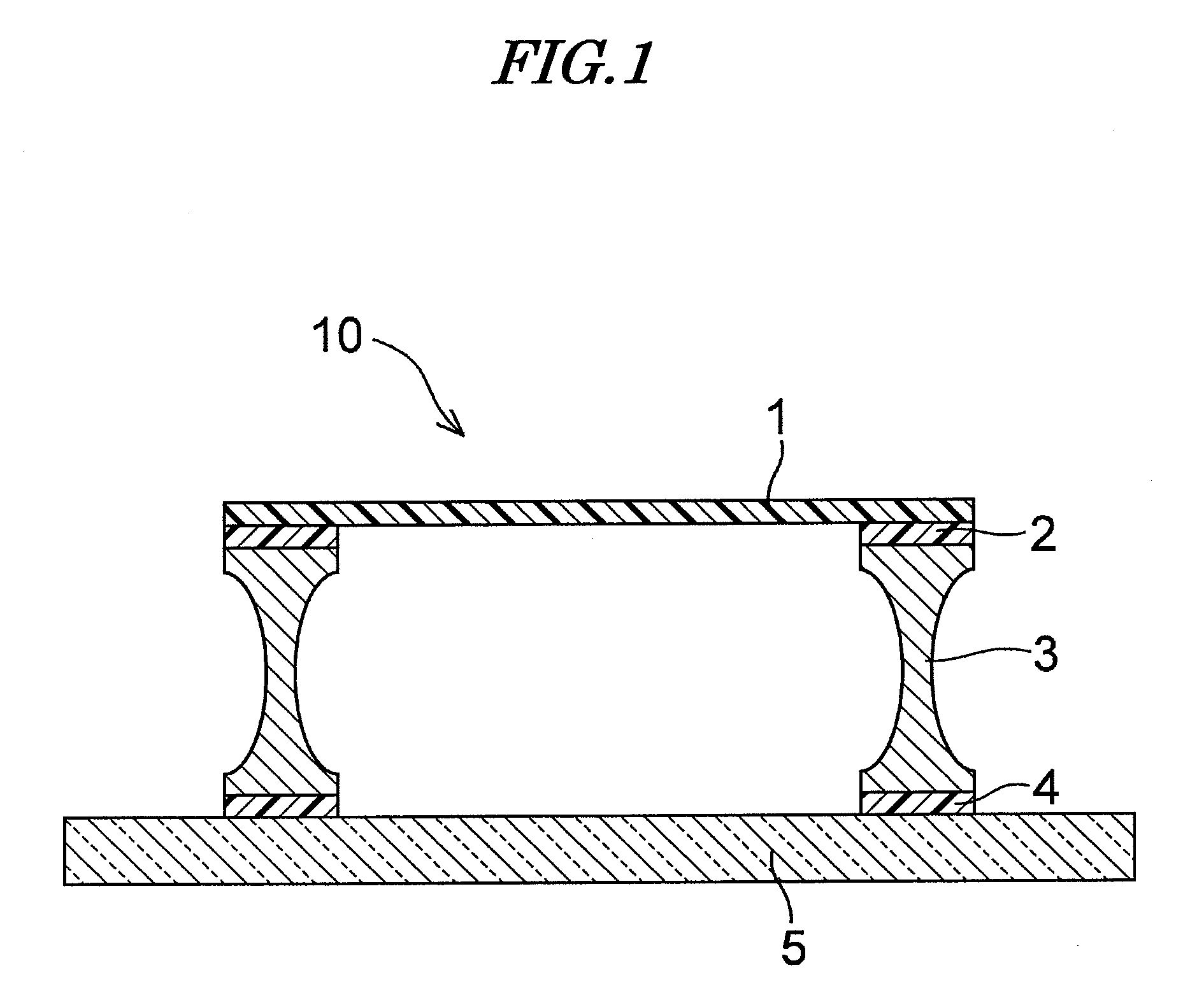

Strain relief for ball grid array connectors

InactiveUS7341482B2FlatnessLow costSubstation/switching arrangement detailsRelieving strain on wire connectionEngineeringElectrical connector

Strain relief devices for electrical connectors are disclosed and include an insert for insertion into a housing. The insert may include spring beams that deflect during insertion into the strain relief housing. When the insert is fully received in the housing, a slot in the housing may be shaped such that the spring beams return to a relaxed state, locking the insert in the housing. Alternatively, an end of a strain relief insert may be inserted into the housing until beams on the strain relief insert abut shoulders in the slot in the housing. The end may protrude beyond the housing, creating a tab that may be deformed or bent to prevent the insert from moving in a direction opposite the direction of insertion.

Owner:FCI AMERICAS TECH LLC

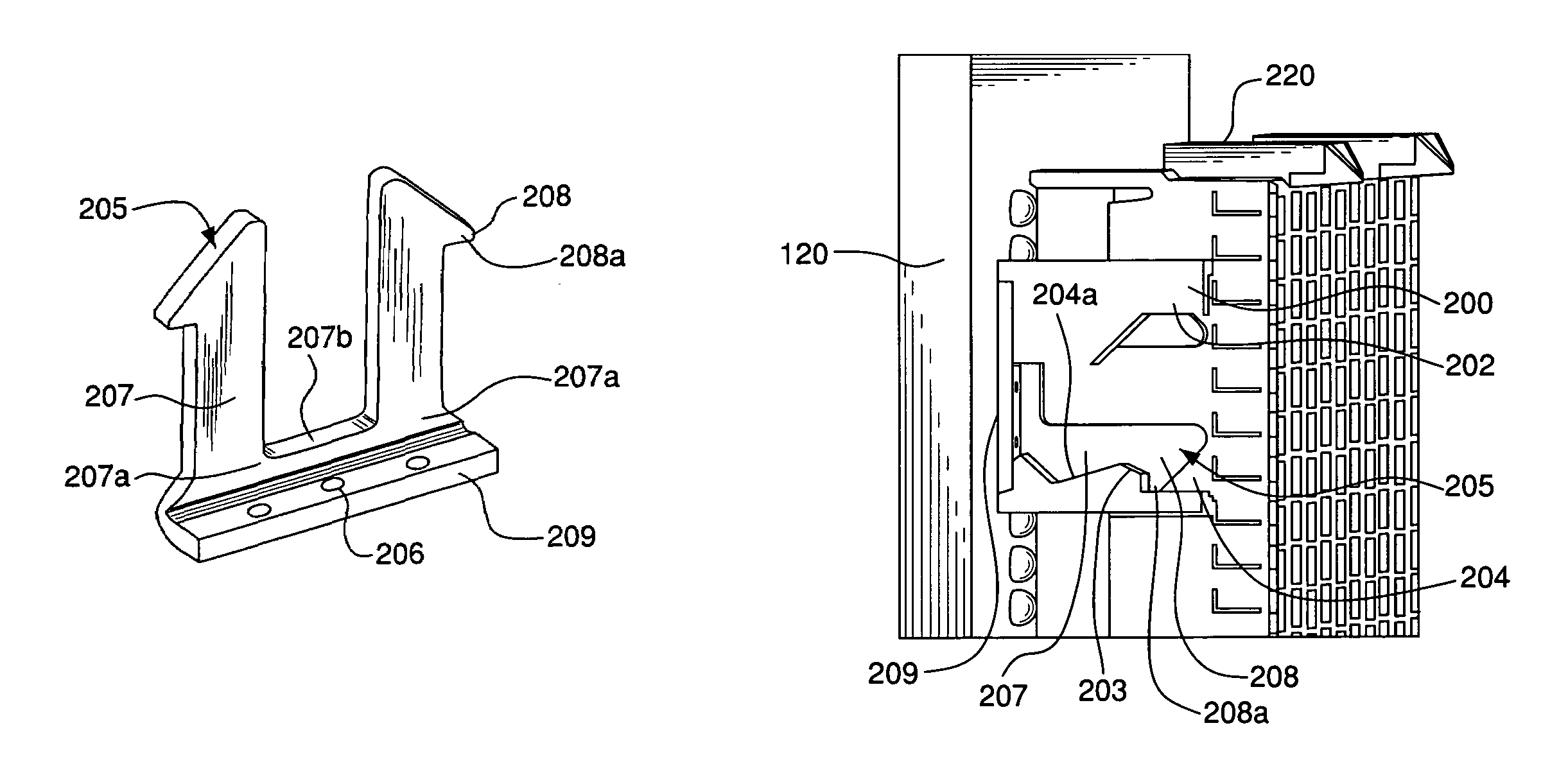

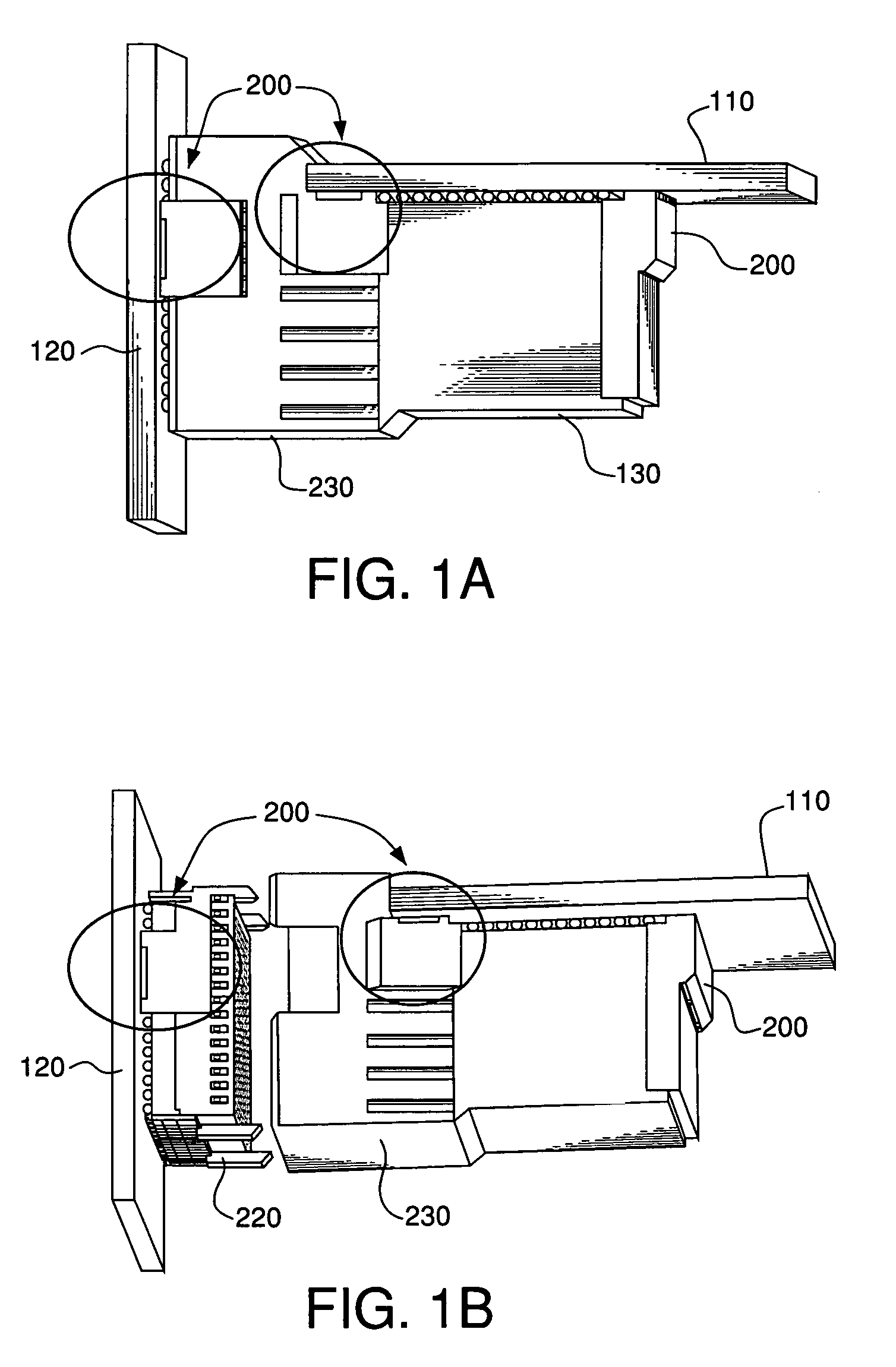

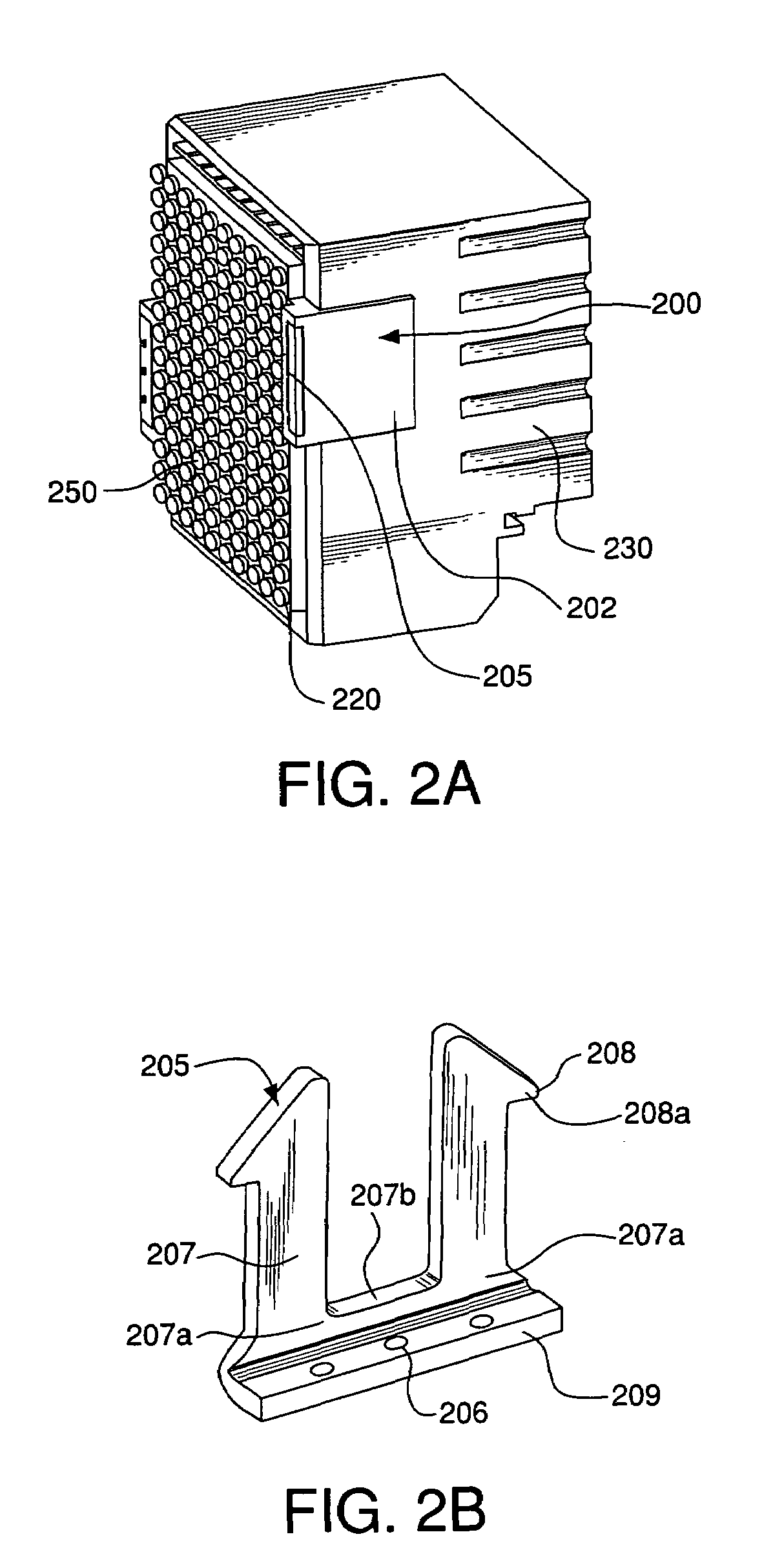

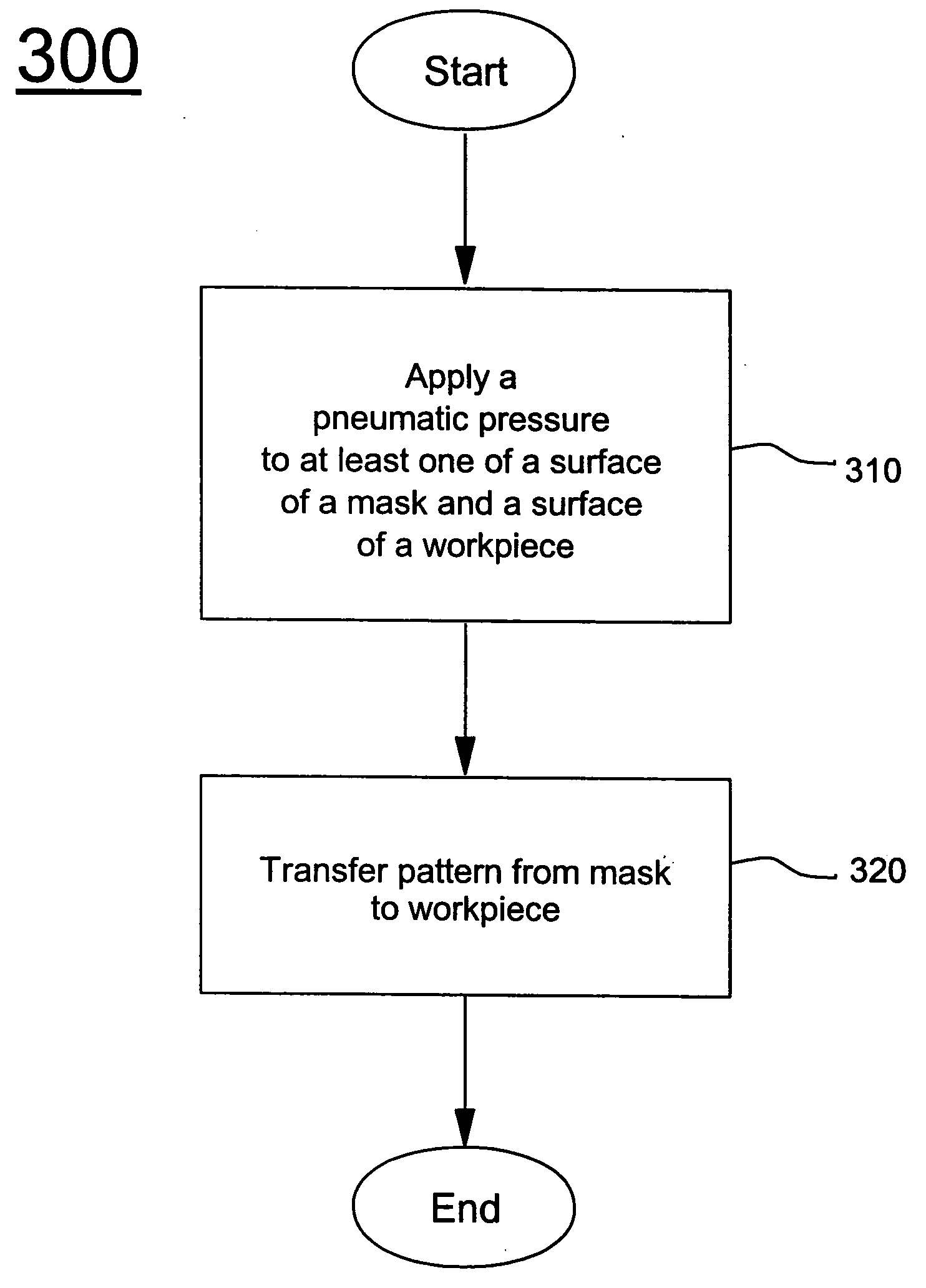

Pneumatic method and apparatus for nano imprint lithography

InactiveUS20060105571A1Expensive mechanical toleranceFlatnessNanoinformaticsPhotomechanical apparatusResistNanolithography

A method (and apparatus) for nano lithography, includes applying a pneumatic pressure to at least one of a surface of a semi-rigid mask or template and a portion of a surface of a resist-coated workpiece, and, by the applying of the pneumatic pressure, transferring a pattern from the mask to the workpiece.

Owner:GLOBALFOUNDRIES INC

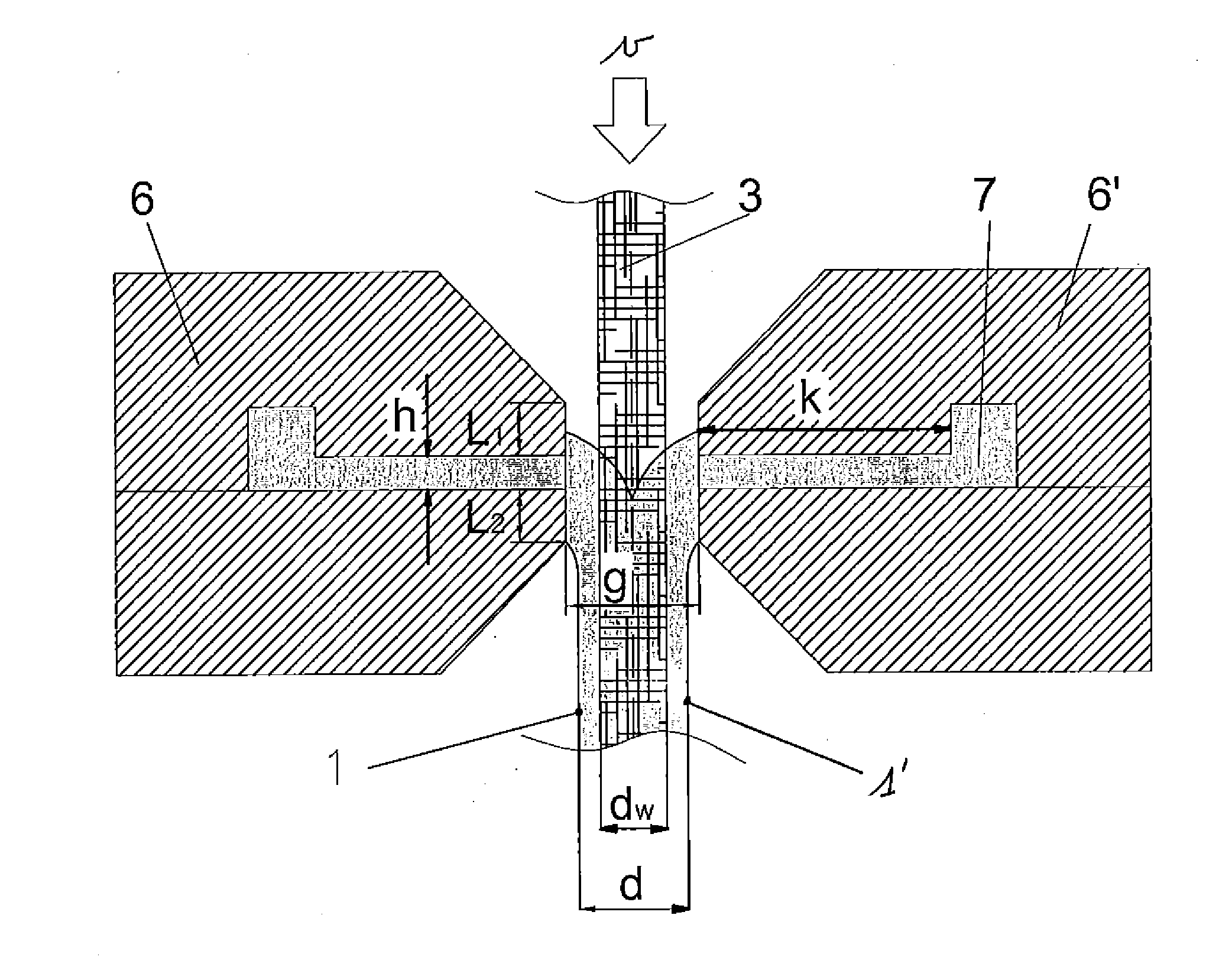

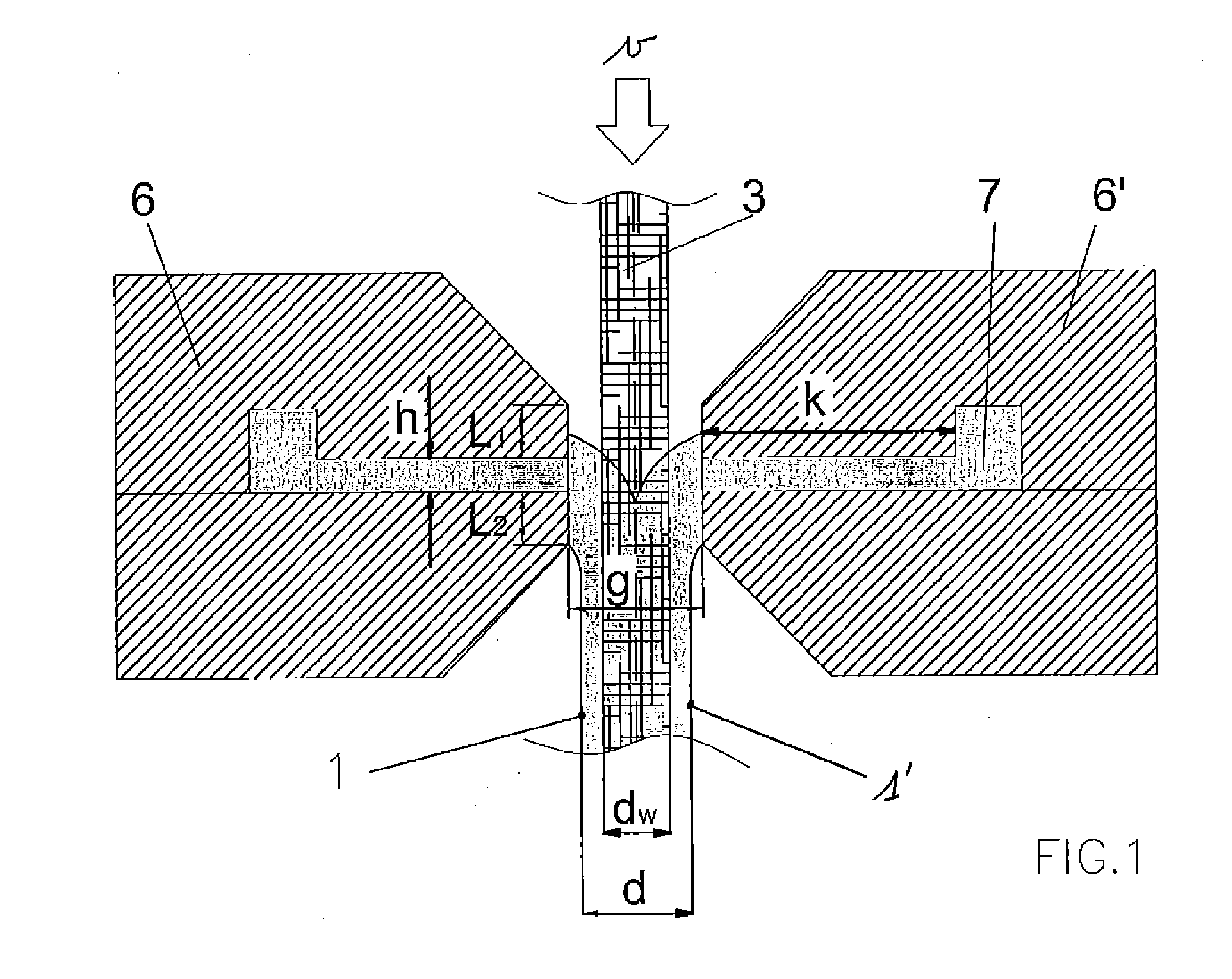

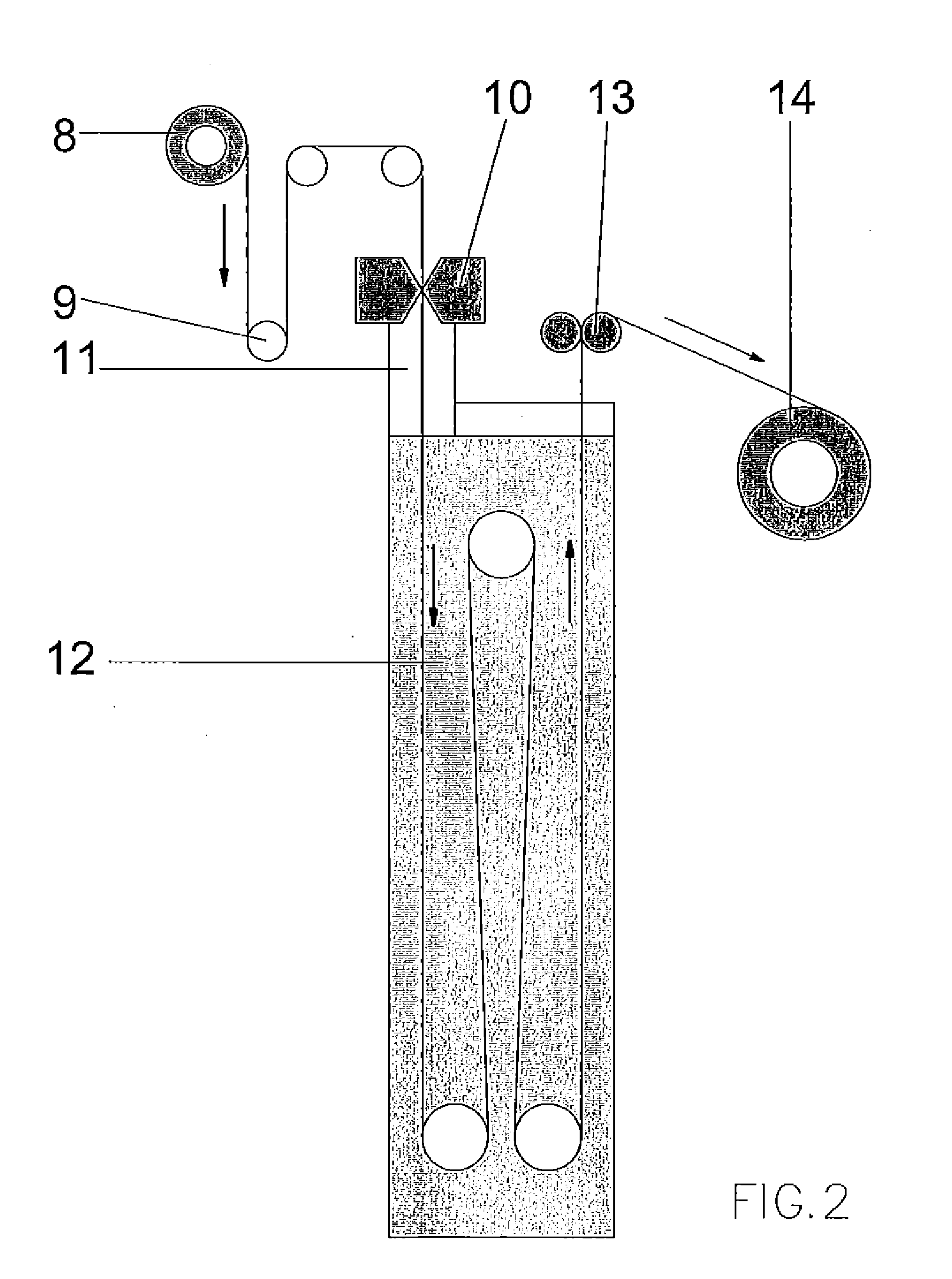

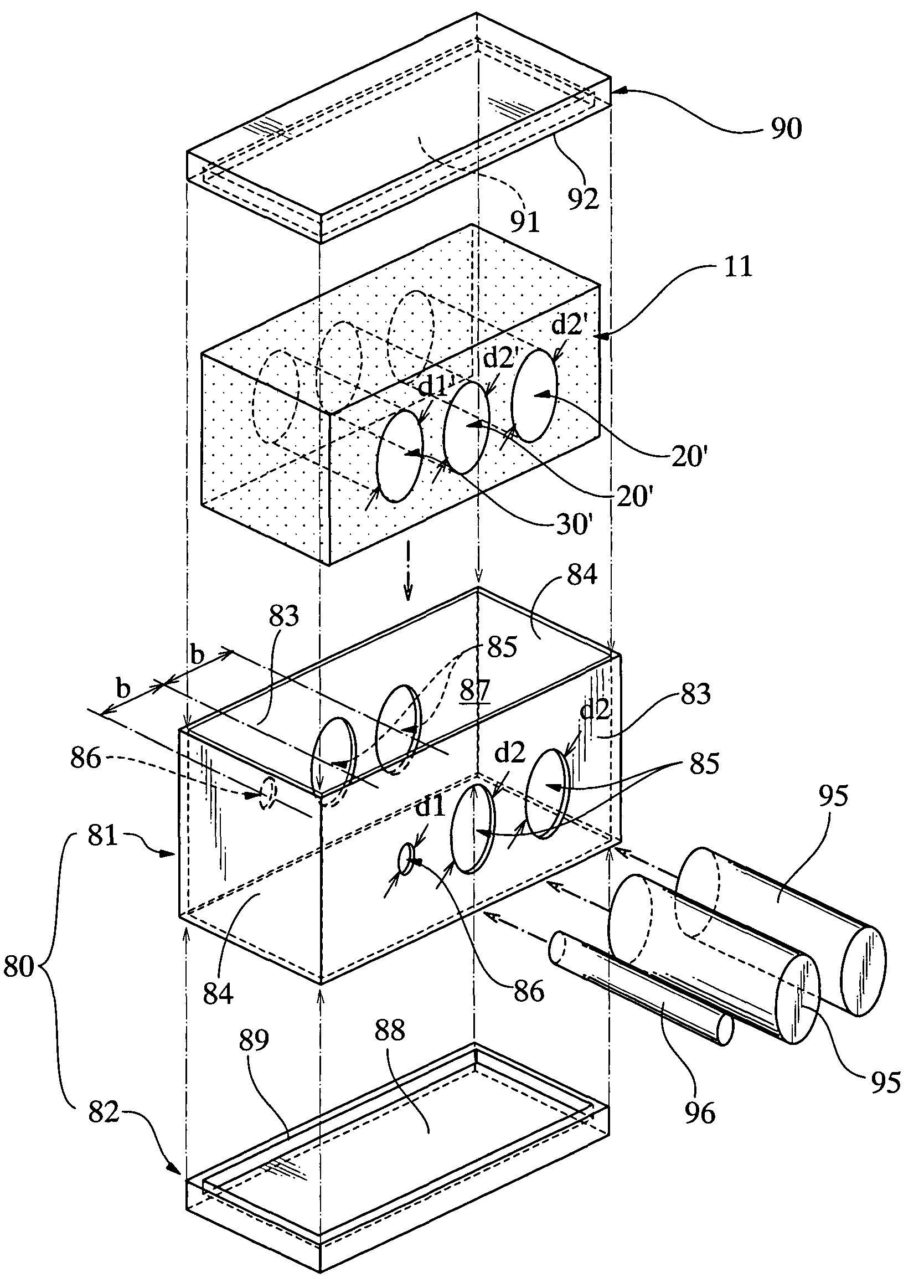

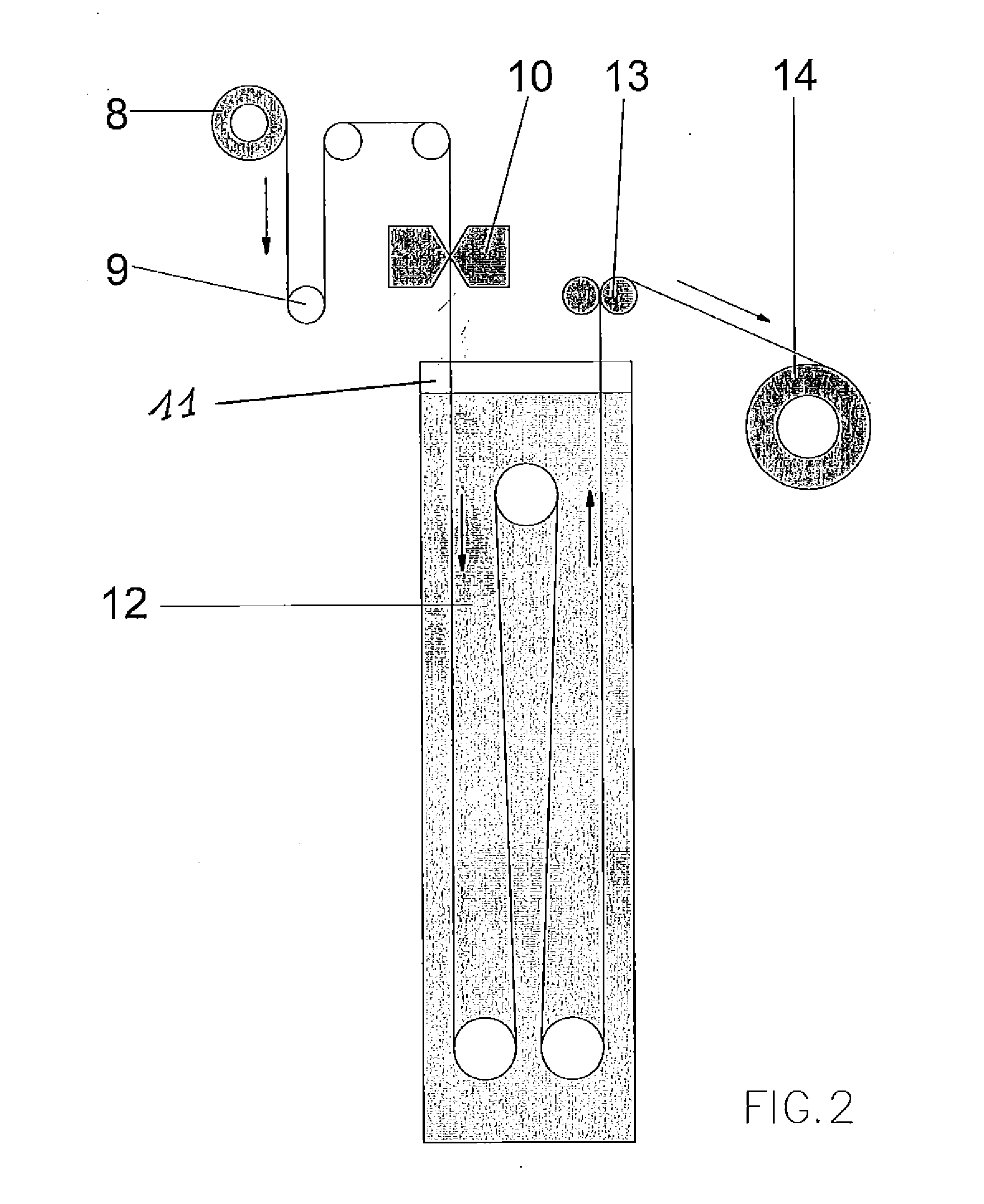

Process for producing an ion-permeable web-reinforced separator

Process comprising the steps of: (i) providing an elongated porous web, said elongated porous web comprising two outermost surfaces; (ii) transporting said elongated porous web downwards between two impregnating heads comprising two slots each with substantially vertical upper and lower slot faces substantially parallel to said elongated porous web providing simultaneously to both surfaces of said elongated porous web metered substantially identical quantities of a dope, comprising at least one membrane polymer and at least one solvent therefor; (iii) thereby impregnating said elongated porous web completely with said dope and providing substantially equally thick dope layers on each surface of said outermost surfaces of said elongated porous web with a thickness independent of the gap between one of said lower slot faces and the surface of said elongated porous web nearest thereto; (iv) subjecting said dope associated with said elongated porous web immediately after dope-impregnation to symmetric phase inversion with at least one non-solvent thereby forming a membrane; and (v) removing residues of said at least one solvent for said at least one membrane polymer from said membrane thereby producing an ion-permeable web-reinforced separator, wherein said dope is shear-thinning, and the separator obtainable therewith.

Owner:AGFA GEVAERT AG +1

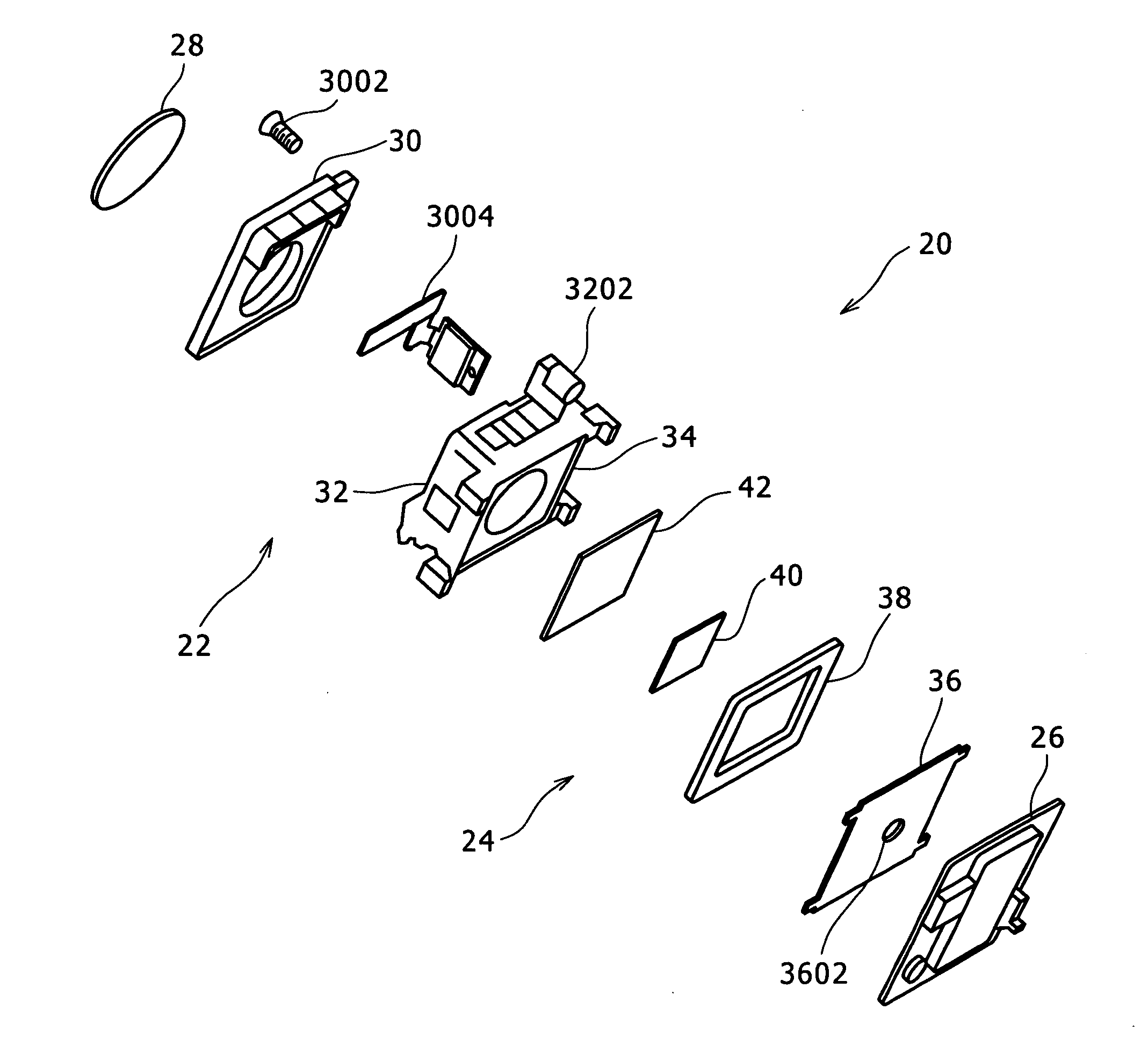

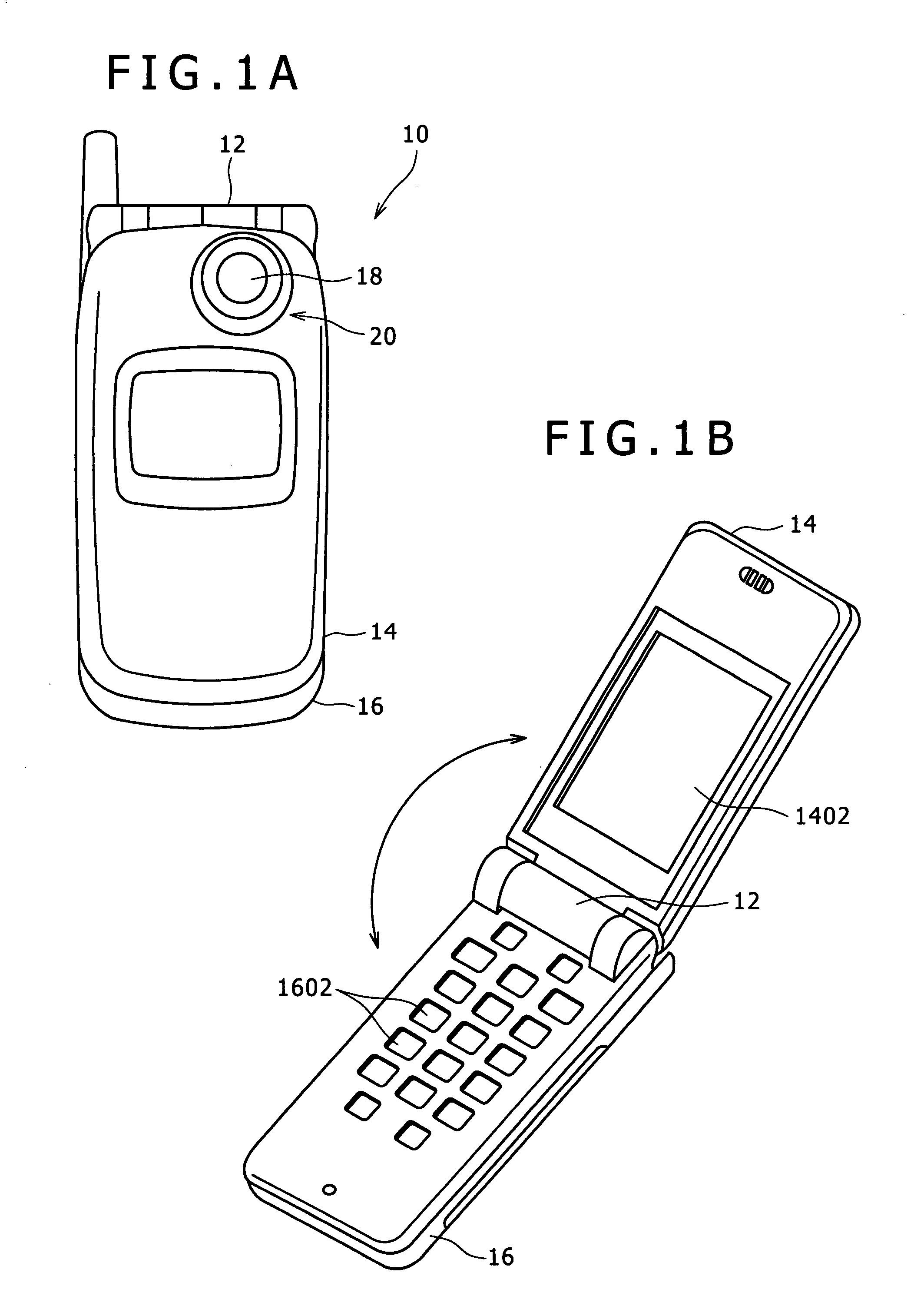

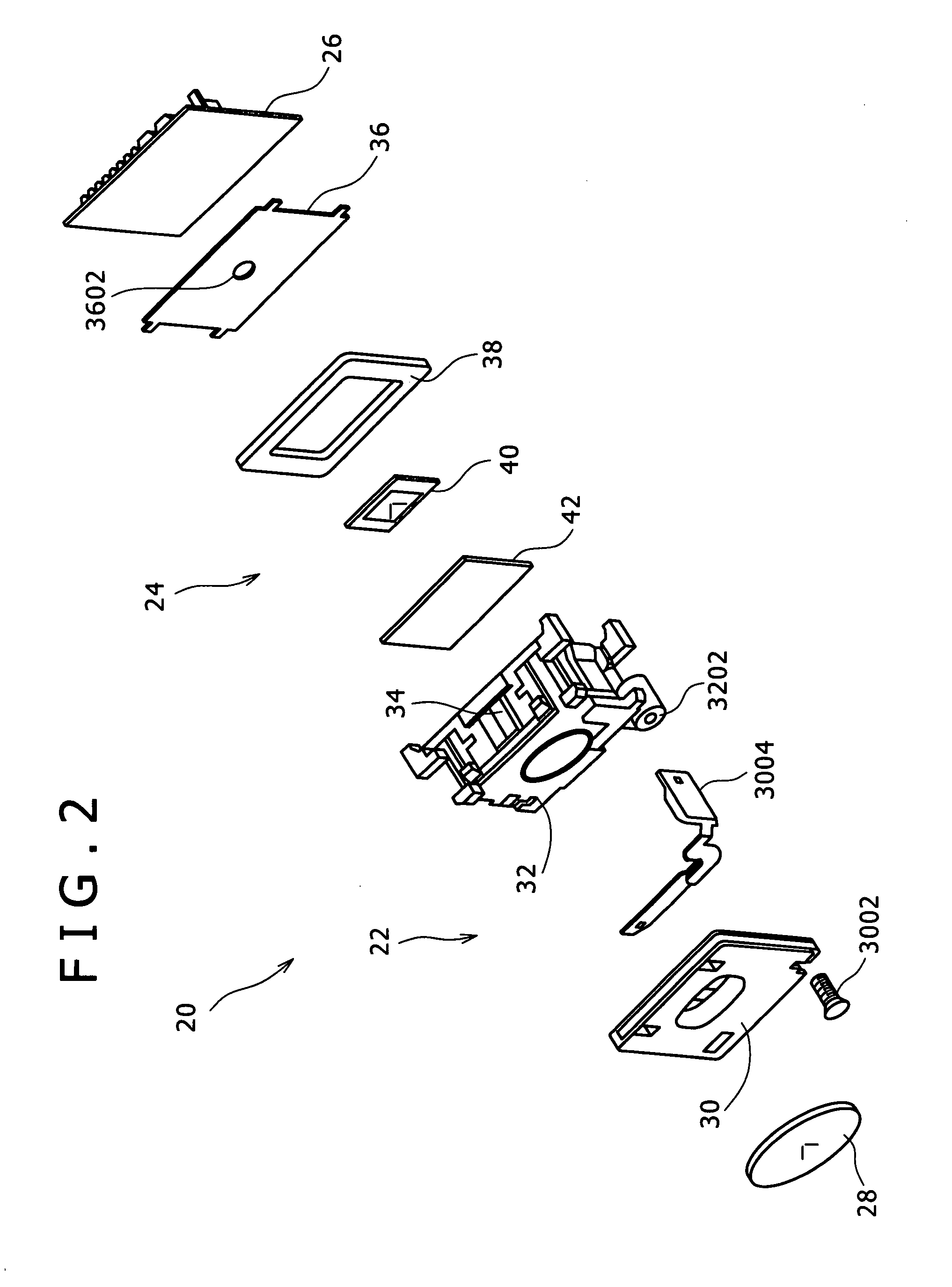

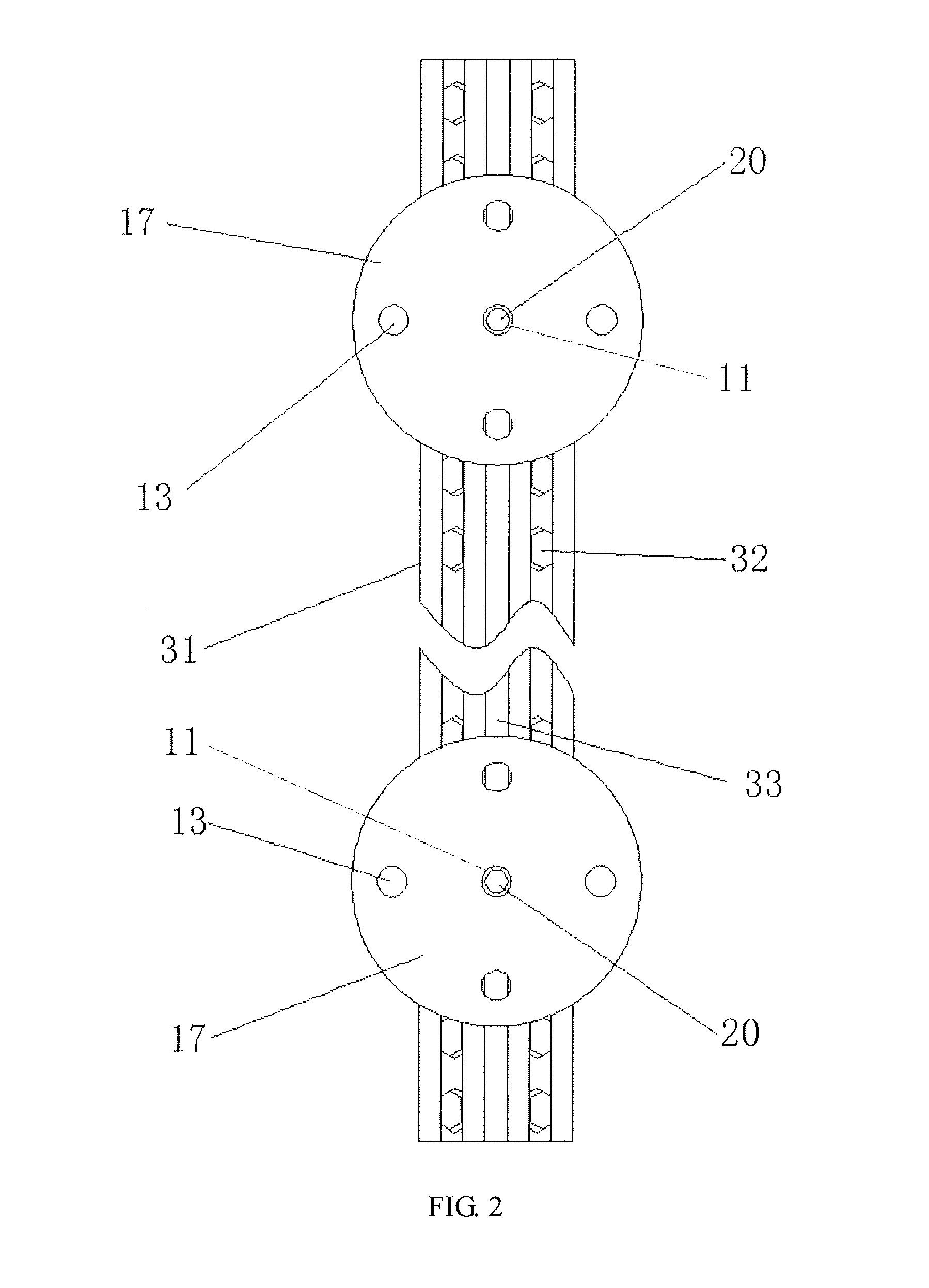

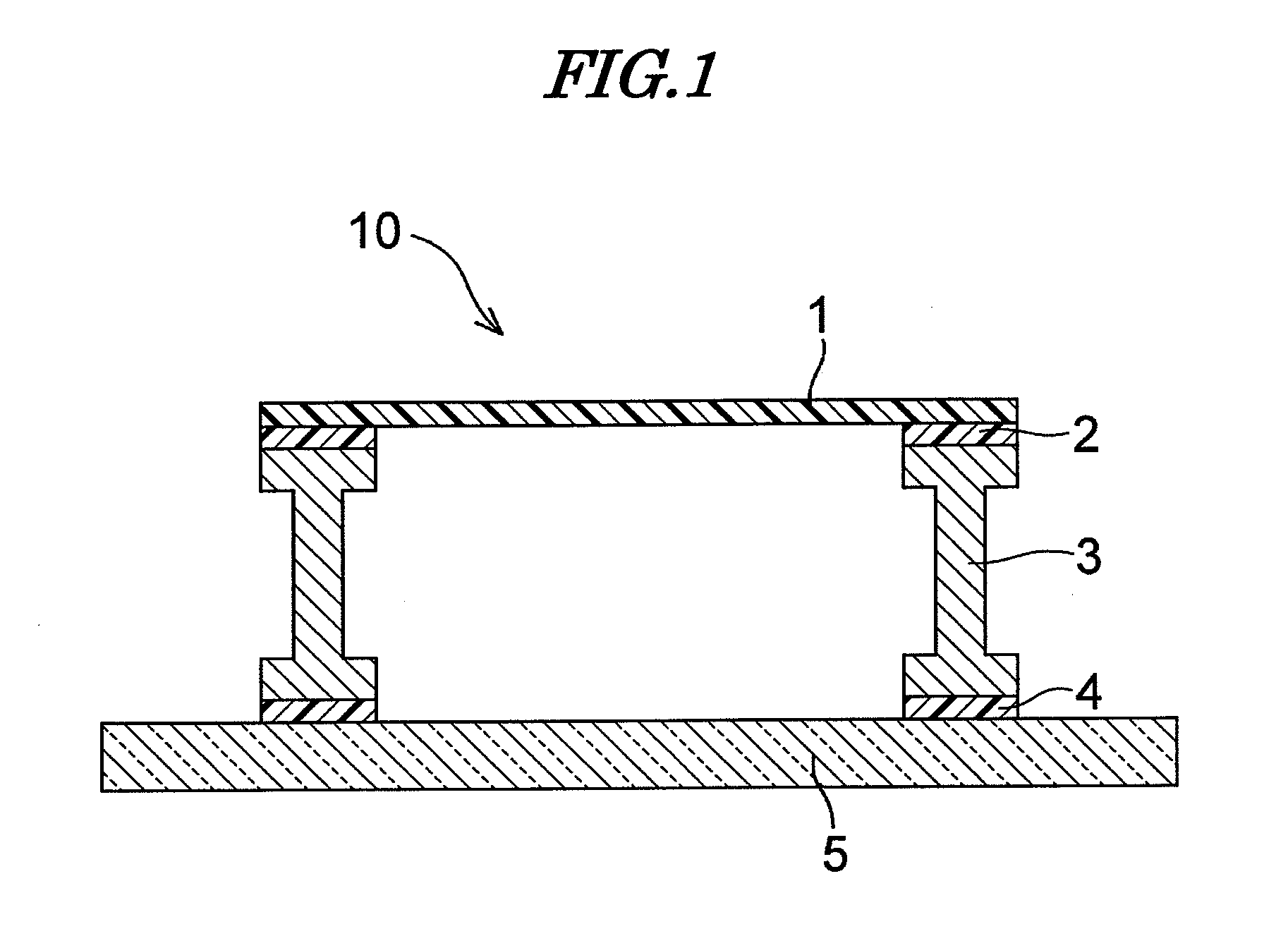

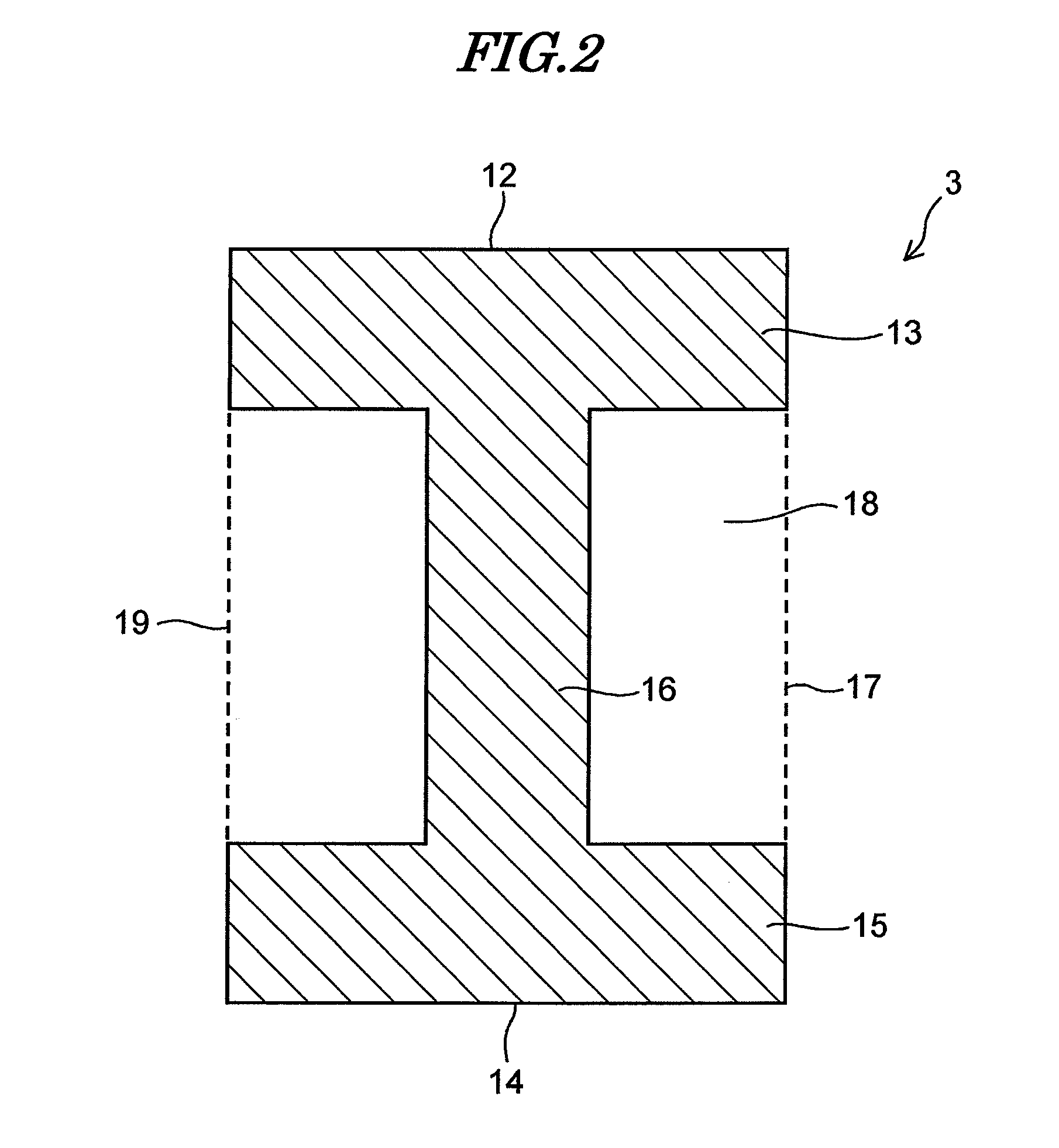

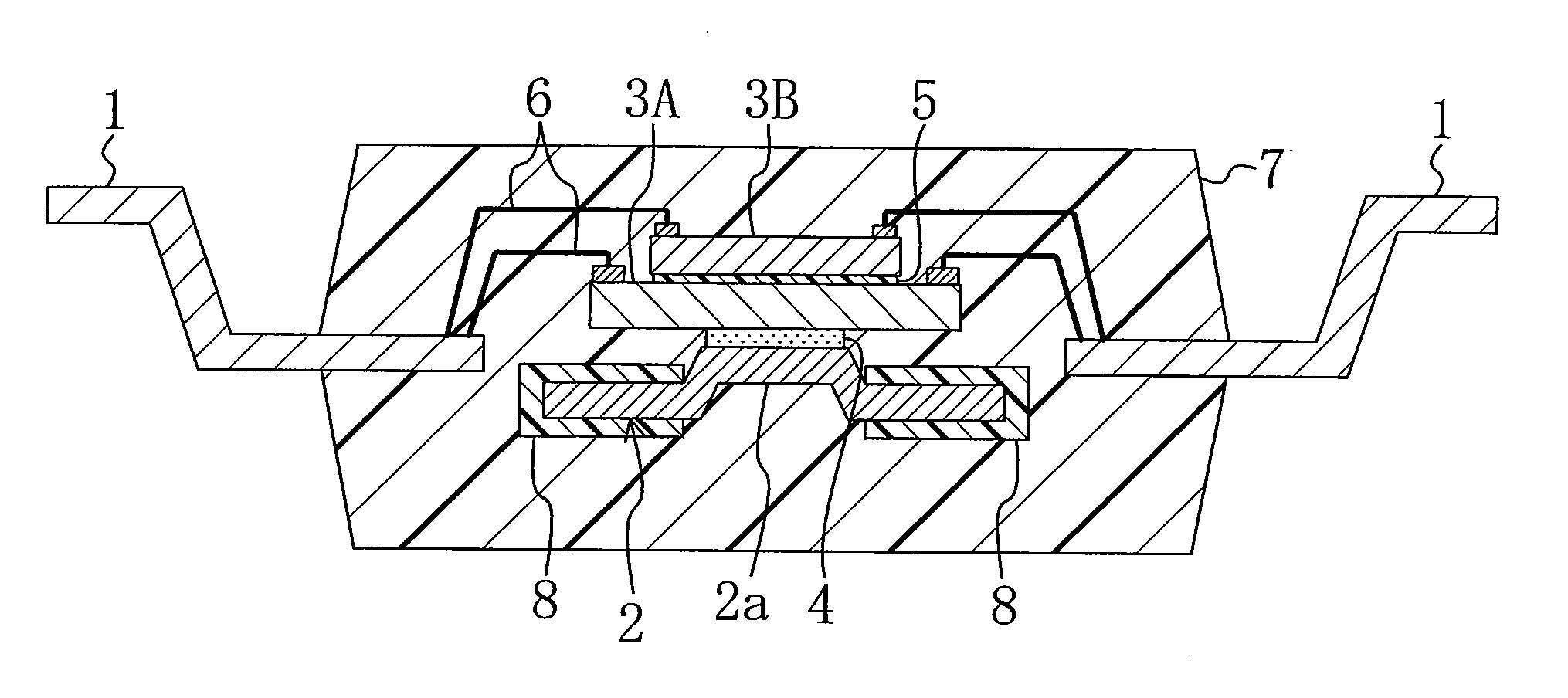

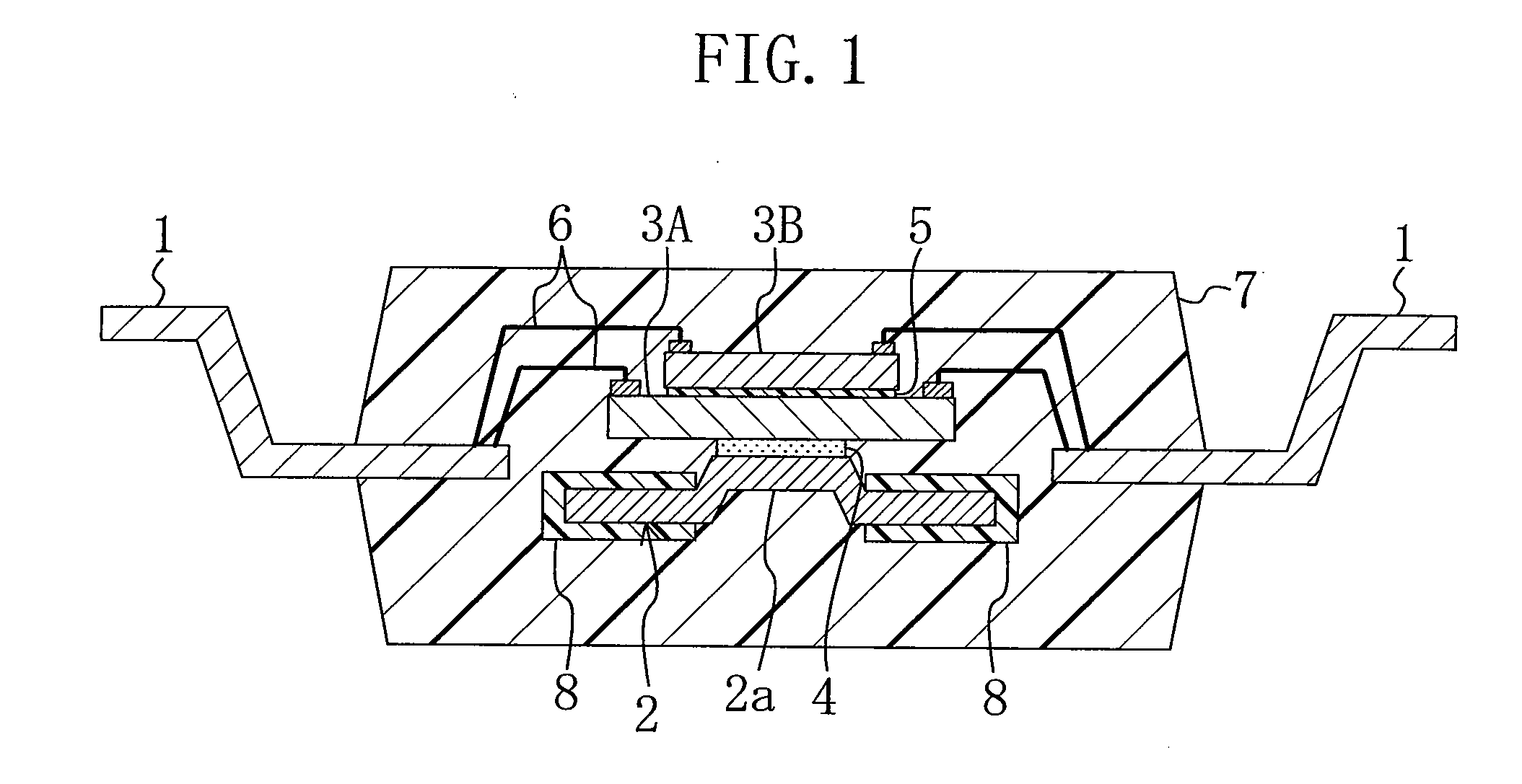

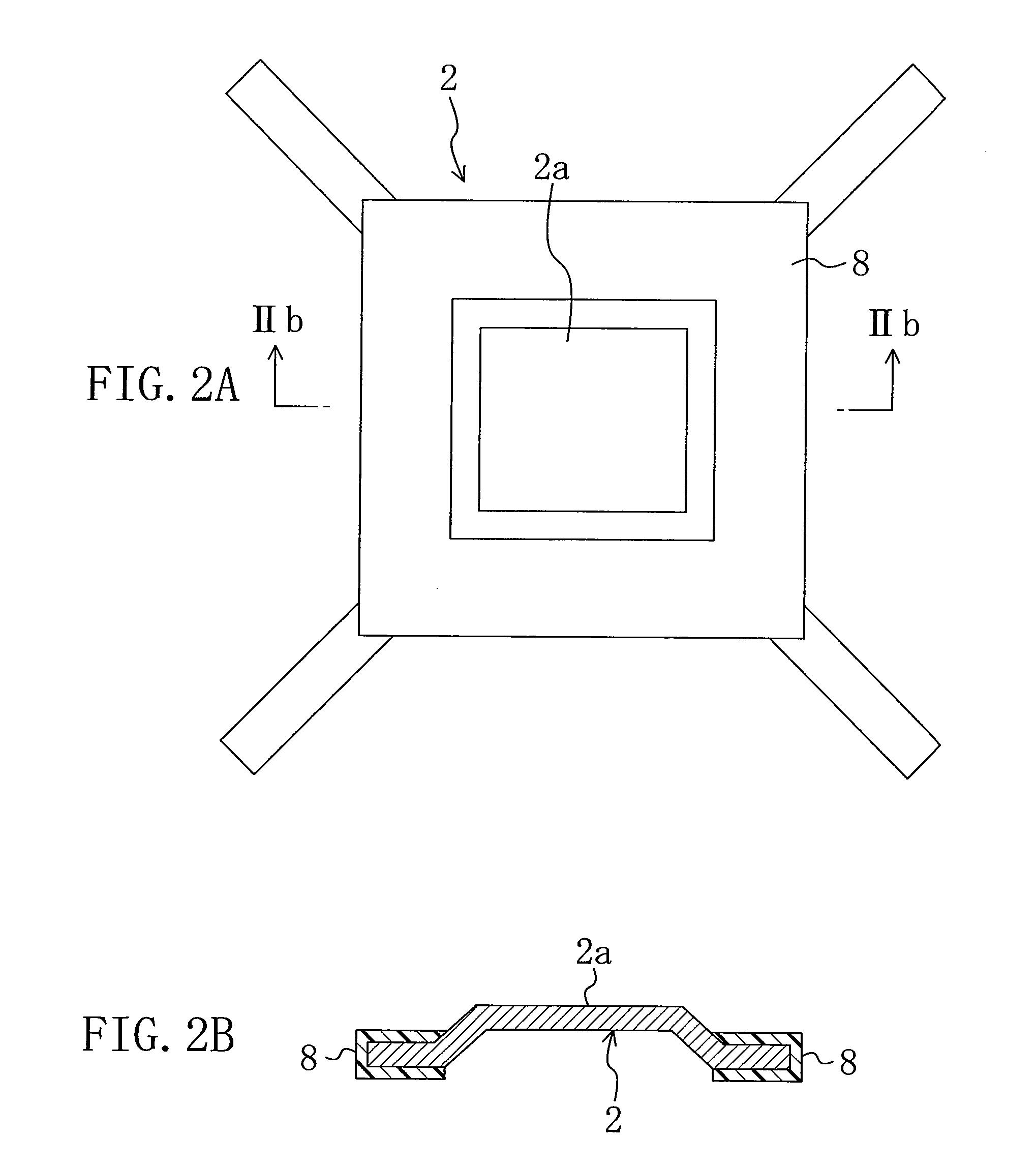

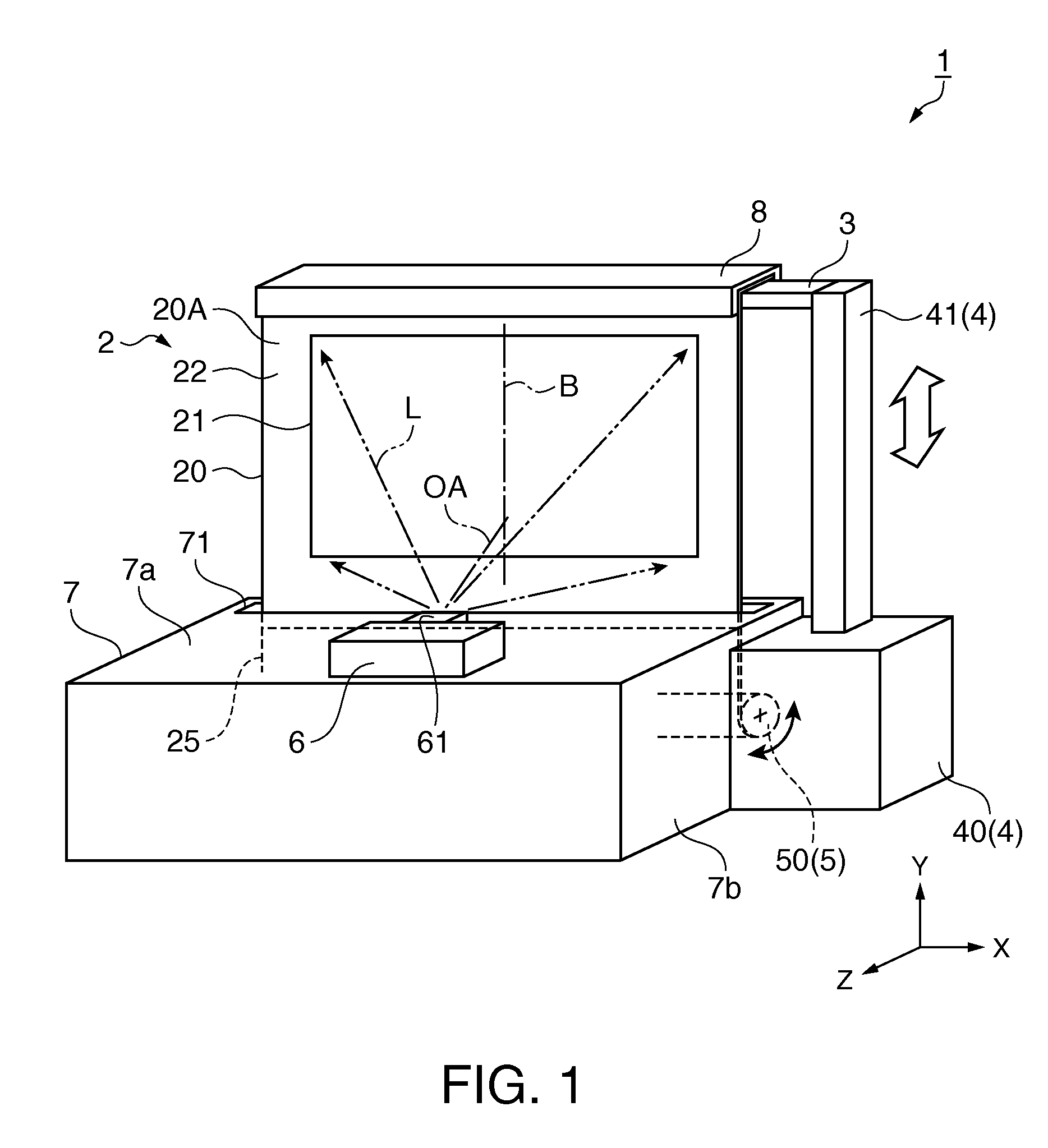

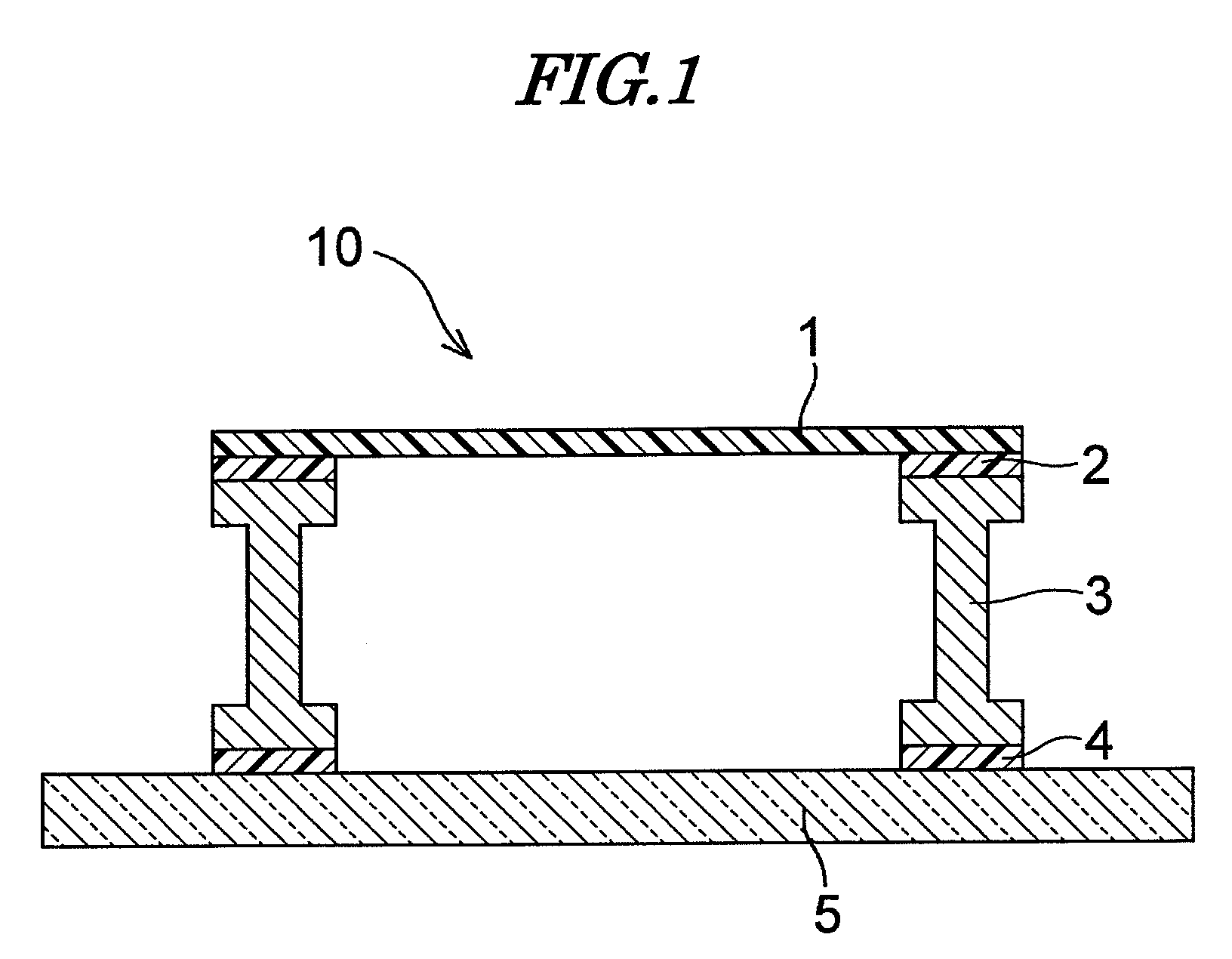

Image pickup apparatus, camera module, electronic device, and fabrication method for image pickup apparatus

InactiveUS20070200053A1Reduce image distortionGood adhesionTelevision system detailsSolid-state devicesAdhesiveCamera module

An image pickup apparatus may include a wiring board; a frame member having a framework-like shape and disposed on the wiring board, an image pickup element disposed on the inner side of the frame member on the wiring board, and a transparent cover disposed on the frame member. The wiring board and the frame member may be attached to each other by thermosetting adhesive. The frame member may be made of a material which has a coefficient of thermal expansion lower than that of the wiring board and has a rigidity higher than that of the wiring board.

Owner:SONY CORP

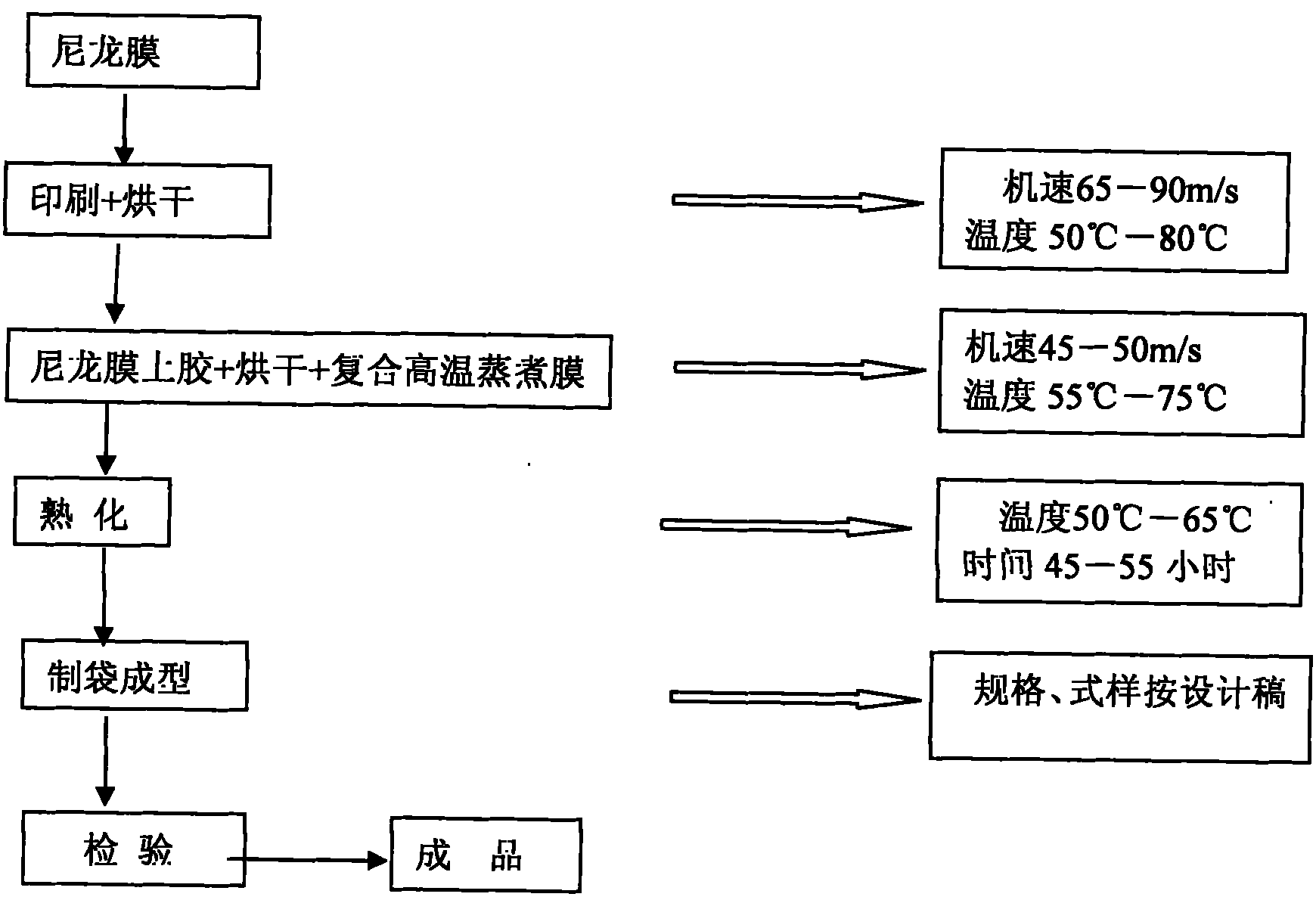

Manufacturing method of vacuum cooking and packaging bag for food

InactiveCN101837855AIncrease air flowImprove toughness and strengthLamination ancillary operationsBagsCompound aEngineering

The invention relates to a manufacturing method of a vacuum cooking and packaging bag for food, which comprises the following steps: selecting and proportioning raw materials and controlling the process flow; compounding a BOPA with an RCPP; firstly, delivering the printed BOPA into a compounding process; and proportioning a polyurethane glue and a solvent by weight; stirring uniformly and gluing on the BOPA; and manufacturing and forming a bag by heating in a drying tunnel, aging at constant temperature and heat sealing. After the food is packaged in vacuum, the vacuum package can resist high-temperature cooking and sterilizing at 135 DEG C for 30 minutes, and the packaging bag can not loose or leak air, can ensure the quality of the food and prolong the preservation and quality guarantee period of the food.

Owner:赵秀雄

Chemical mechanical polishing method and method of manufacturing semiconductor device

ActiveUS20090239373A1FlatnessOccurrence can be suppressedOther chemical processesSemiconductor/solid-state device manufacturingOrganic filmCompound (substance)

Owner:KIOXIA CORP

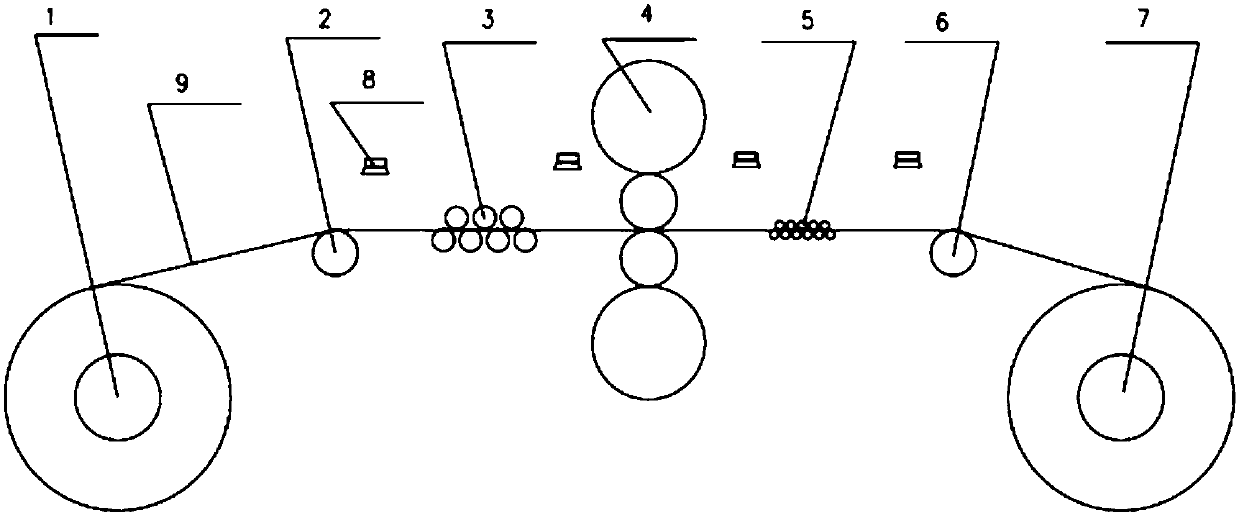

High-strength strip steel straightening, flattening and straightening process

ActiveCN107838199AReduce loadEasy to shapeProfile control deviceMetal rolling arrangementsStrip steelResidual stress

The invention discloses a high-strength strip steel straightening, flattening and straightening process. The high-strength strip steel straightening, flattening and straightening process is characterized in that a hot rolling high-strength steel plate or strip steel sequentially passes through an inlet straightening machine, a temper mill and an outlet straightening machine, and by means of the combined working procedures of straightening, flattening and straightening, the adjustment of the plate shape, the surface quality, the mechanical performance and the residual stress of the strip steelis completed; the inlet straightening machine is used for conducting rough straightening on the strip steel, on the one hand, the plate shape of the supplied material is improved, and on the other hand, the scale on the surface of the strip steel is reduced; the temper mill is used for conducting flattening on the strip steel, the plate shape of the strip steel is improved, the mechanical performance of the strip steel is adjusted, and the surface quality of the strip steel is improved; and the outlet straightening machine is used for conducting precise straightening on the strip steel, the unquenched plate shape problems and newly-generated plate shape problems in the flattening process are solved, and the unquenched residual stress and newly-generated residual stress in the flattening process are eliminated.

Owner:WISDRI ENG & RES INC LTD

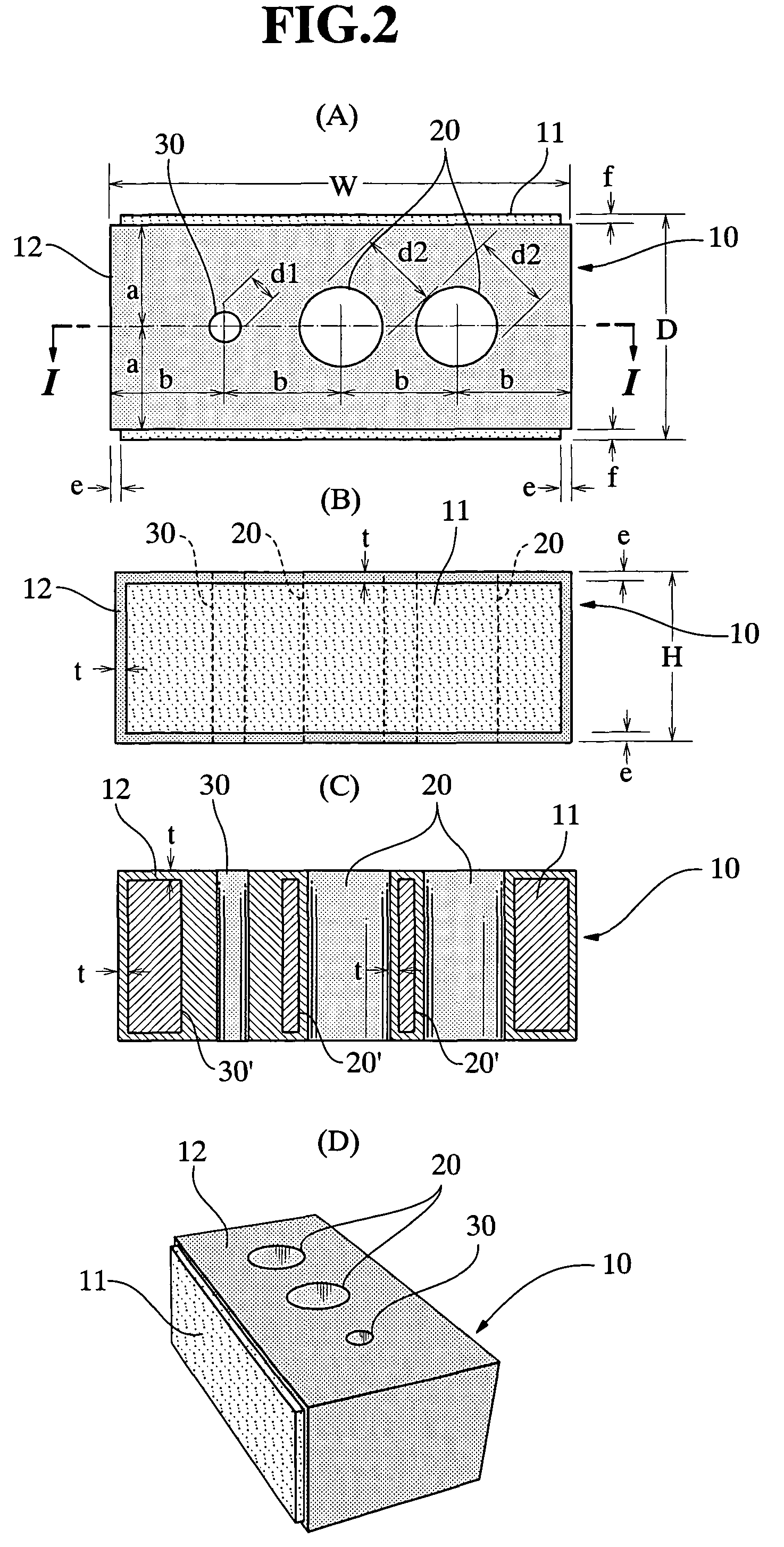

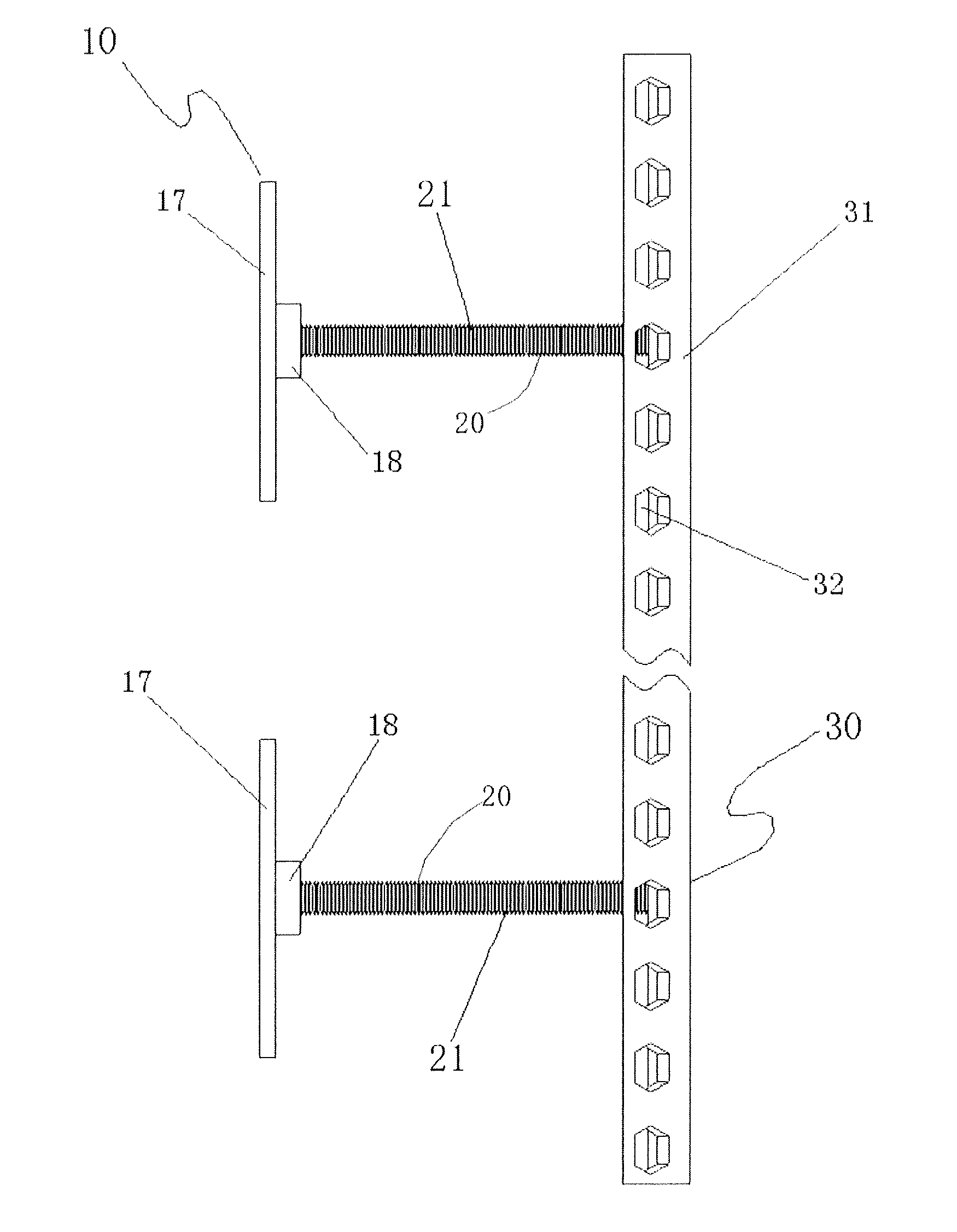

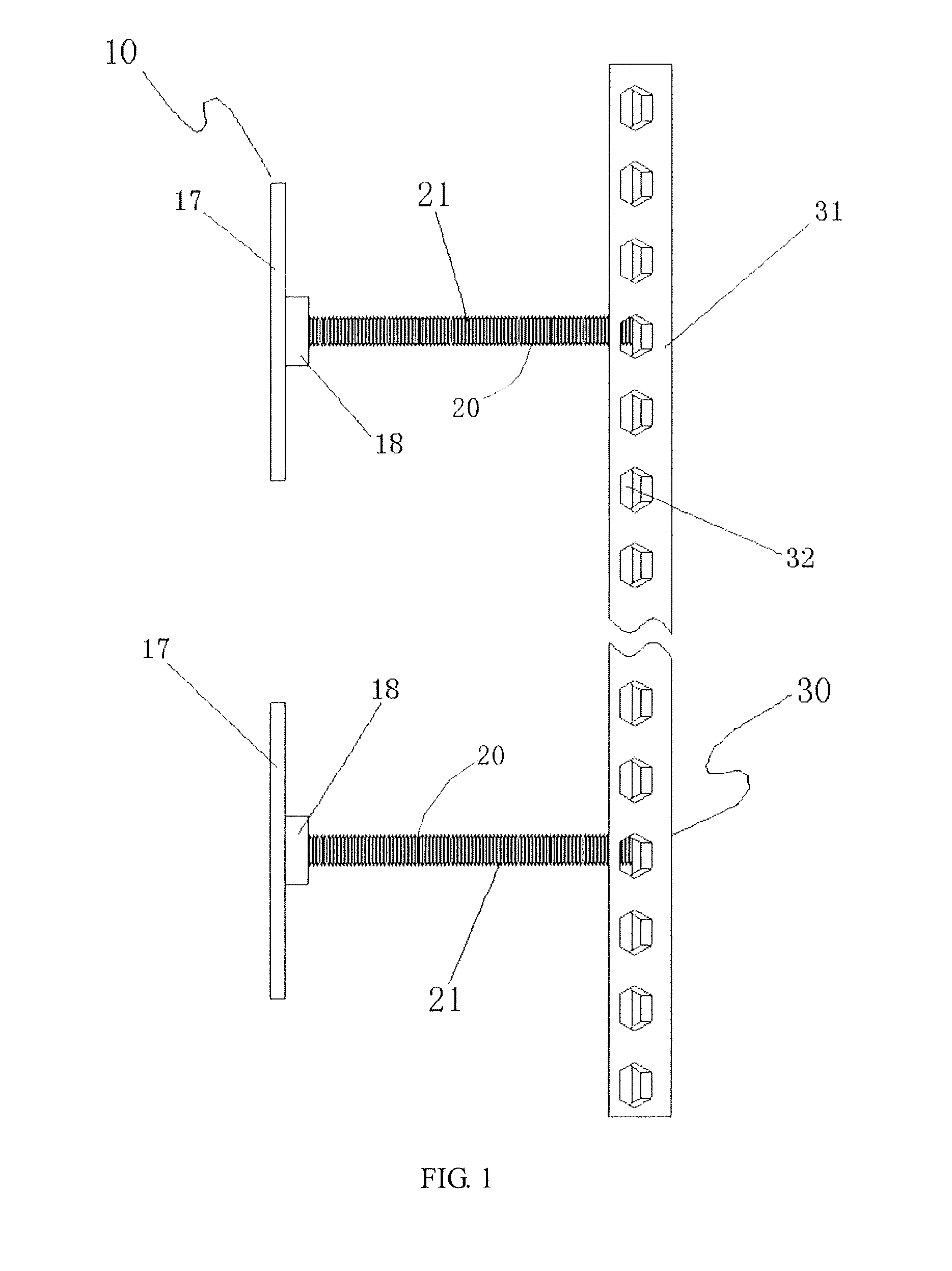

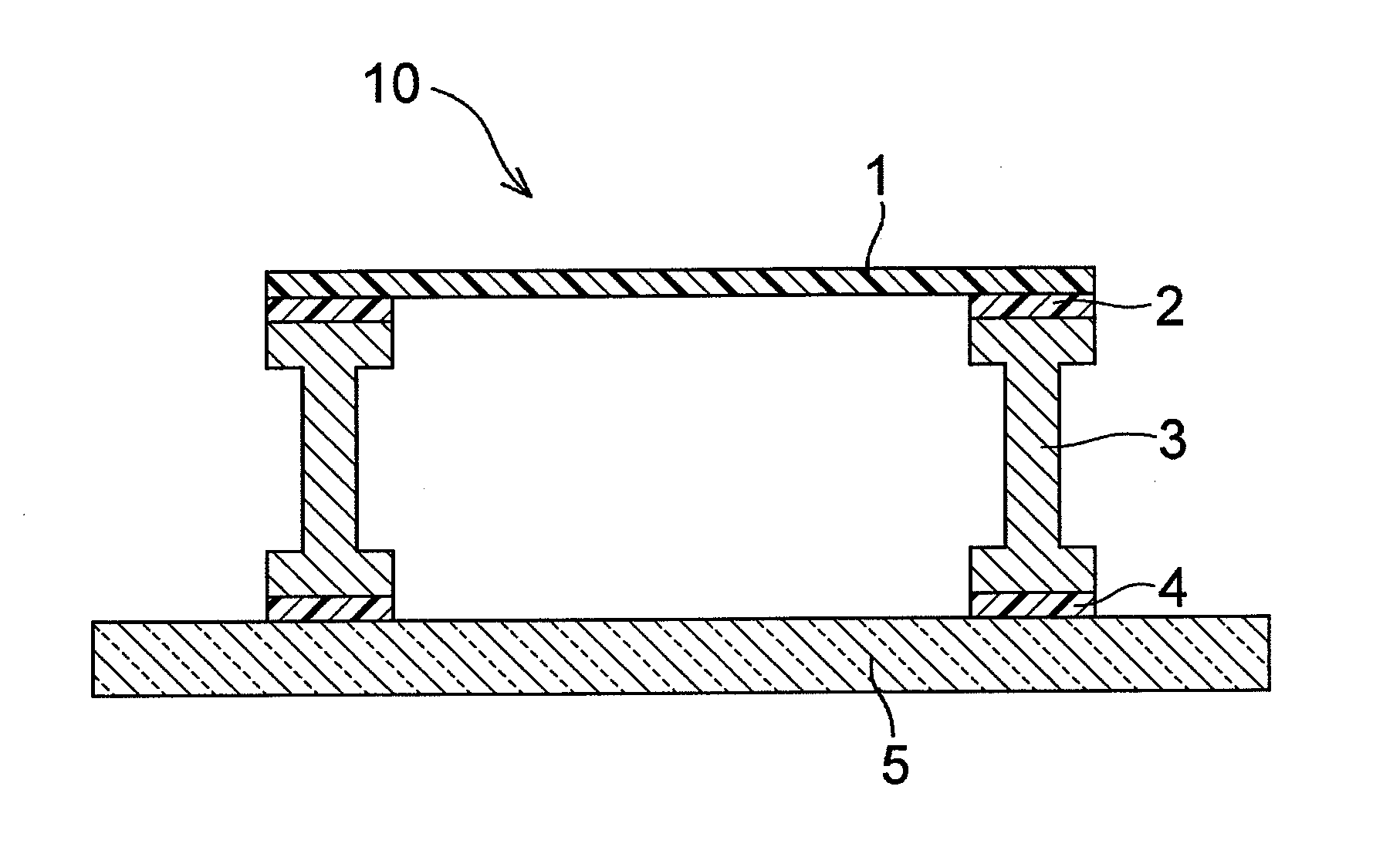

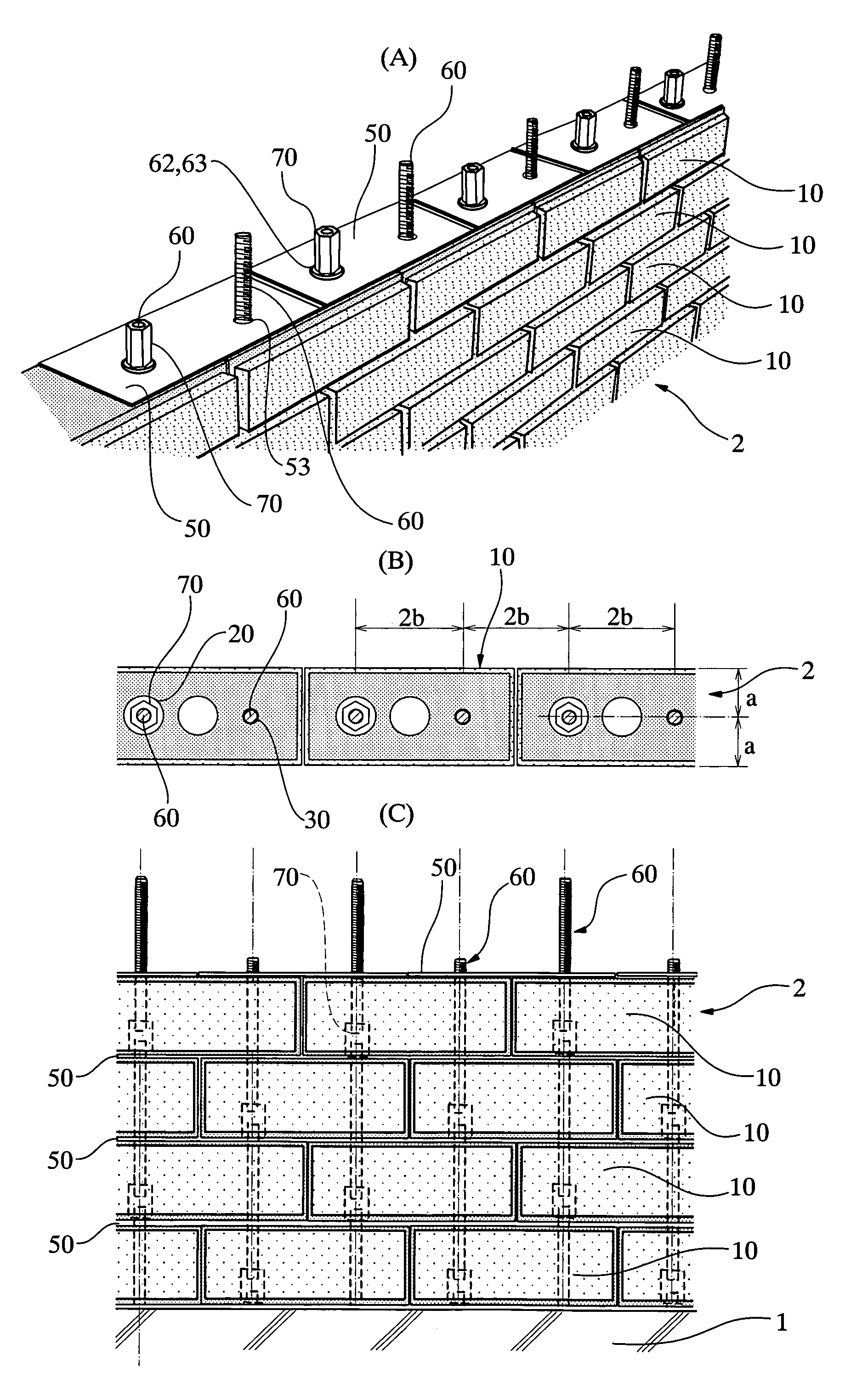

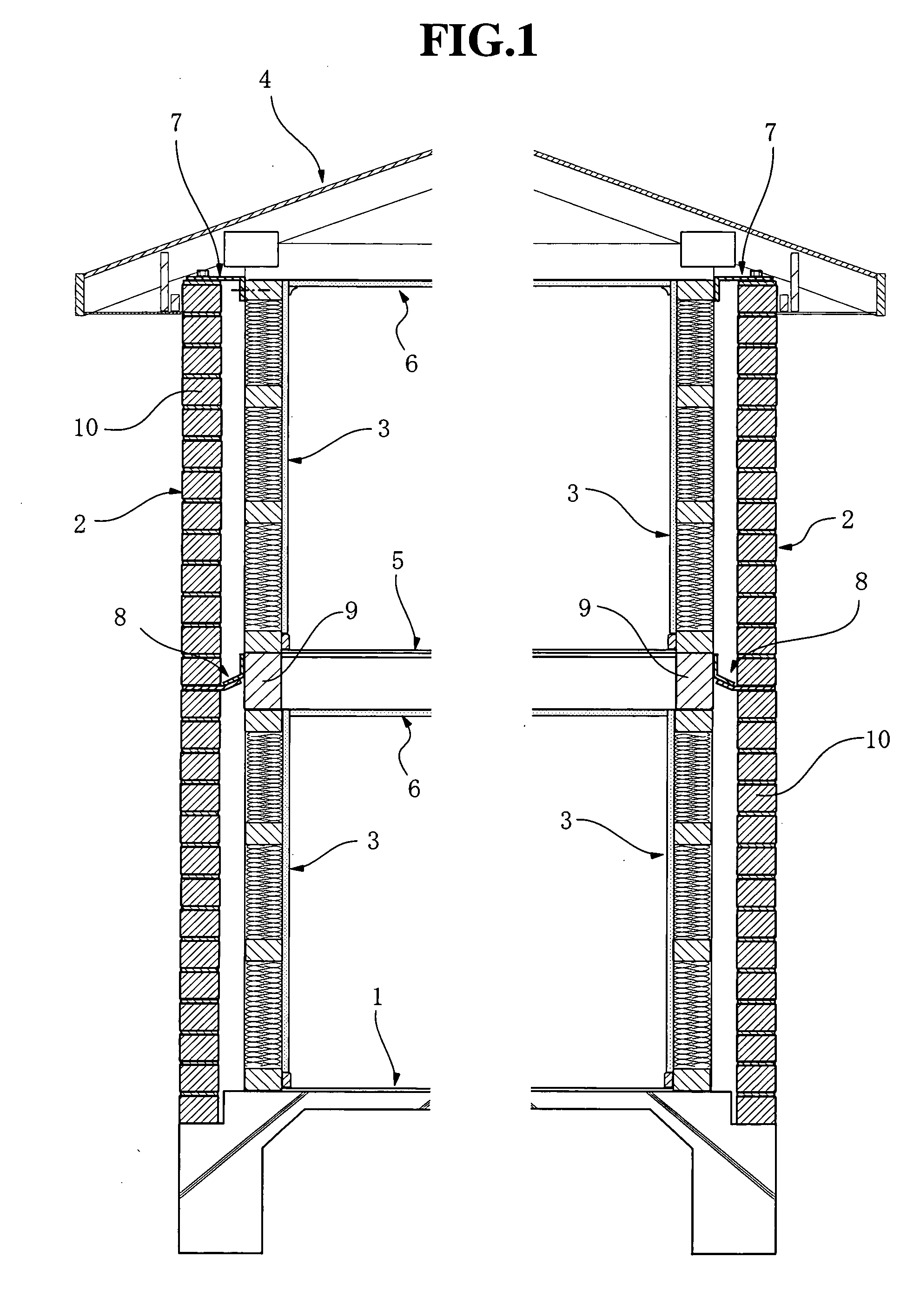

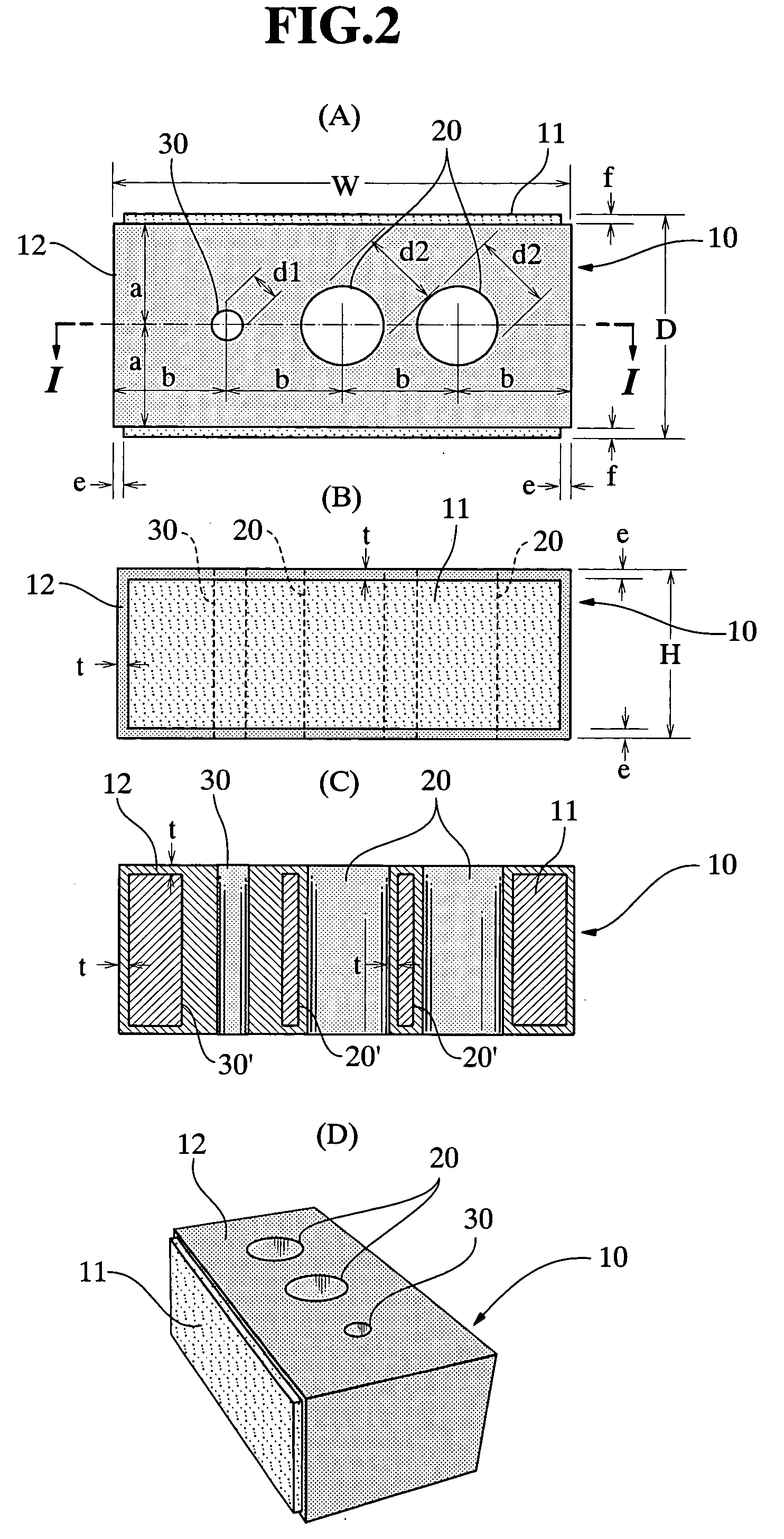

Method for forming masonry unit

InactiveUS7823858B2High dimensional accuracyFlatnessWallsMouldsProduction rateStructural engineering

Masonry units (10) are integrally assembled by tightening forces of bolts (60) and nuts (70), in a condition that interlayer metal plates (50) are interposed between the masonry units. A basic form (11) of the masonry unit is contained in a mold for forming the masonry unit. A space (98) for fluidic covering material, which is chargeable with the covering material, is defined between upper and lower faces of the form (11), and the fluidic covering material is charged in the space. The upper and lower faces of the masonry unit are covered with the solidified covering material (12). According to the present invention, high dimensional accuracy of the masonry unit can be ensured, and efficiency of the production process of the masonry units is promoted to improve productivity of the masonry units.

Owner:JAPAN SCI & TECH CORP

Apparatus and process for producing an ion-permeable web-reinforced separator and separator obtainable therewith

An apparatus for producing an ion-permeable web-reinforced separator comprising a duplex type impregnating apparatus comprising two slots each with substantially vertical upper and lower slot faces for providing premetered substantially identical quantities of a dope simultaneously to either side of an elongated porous web, a transport means providing for substantially vertical downwards transport of said elongated porous web through said duplex impregnating apparatus and subsequent phase inversion, coagulation and washing stations, said phase inversion station providing for phase inversion of said dope and said coagulation station providing for coagulation and washing of solvent from the resulting phase-inverted dope, wherein there is an air gap between said duplex impregnating apparatus and said phase inversion station and wherein the distance between the lower faces of each impregnating apparatus is greater than the distances between the upper faces of each impregnating apparatus; a process comprising the steps of: (i) providing an elongated porous web, said elongated porous web comprising two outermost surfaces; (ii) transporting said elongated porous web downwards between two impregnating heads comprising two slots each with substantially vertical upper and lower slot faces substantially parallel to said elongated porous web providing simultaneously to both surfaces of said elongated porous web metered substantially identical quantities of a dope, comprising at least one membrane polymer and at least one solvent therefor; (iii) thereby impregnating said elongated porous web completely with said dope and providing substantially equally thick dope layers on each surface of said outermost surfaces of said elongated porous web with a thickness independent of the gap between one of said lower slot faces and the surface of said elongated porous web nearest there-to; (iv) subjecting said dope associated with said elongated porous web to symmetric phase inversion with at least one non-solvent thereby forming a membrane, and (v) removing residues of said at least one solvent for said at least one membrane polymer from said membrane thereby producing an ion-permeable web-reinforced separator, wherein said dope is shear-thinning and steps (iv) and (v) are optionally performed simultaneously; and the separator obtainable therewith.

Owner:AGFA-GEVAERT NV +1

Method for plastering construction in architectural decoration

ActiveUS20150059284A1Improve efficiencyImprove construction qualityCovering/liningsBuilding repairsStructural engineeringBuilding construction

A method for plastering construction in architectural decoration comprises the following steps: (1) base treatment; (2) performing construction positioning paying-off according to the required plastering height, and longitudinally installing screeding templates along a wall surface subjected to the base treatment in Step (1) according to the paying-off height, a lateral space between adjacent screeding templates being 1.3 to 1.8 meters; (3) plastering; and (4) laying aside the wall surface subjected to the plastering for 12 to 24 hours till plastering mortar on the wall surface is in a half-dried compact hardened state, and using teeth of a saw blade for grinding the mortar along the two adjacent screeding templates through a ruler till the mortar is even. The method can improve the construction efficiency and guarantee the construction quality.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

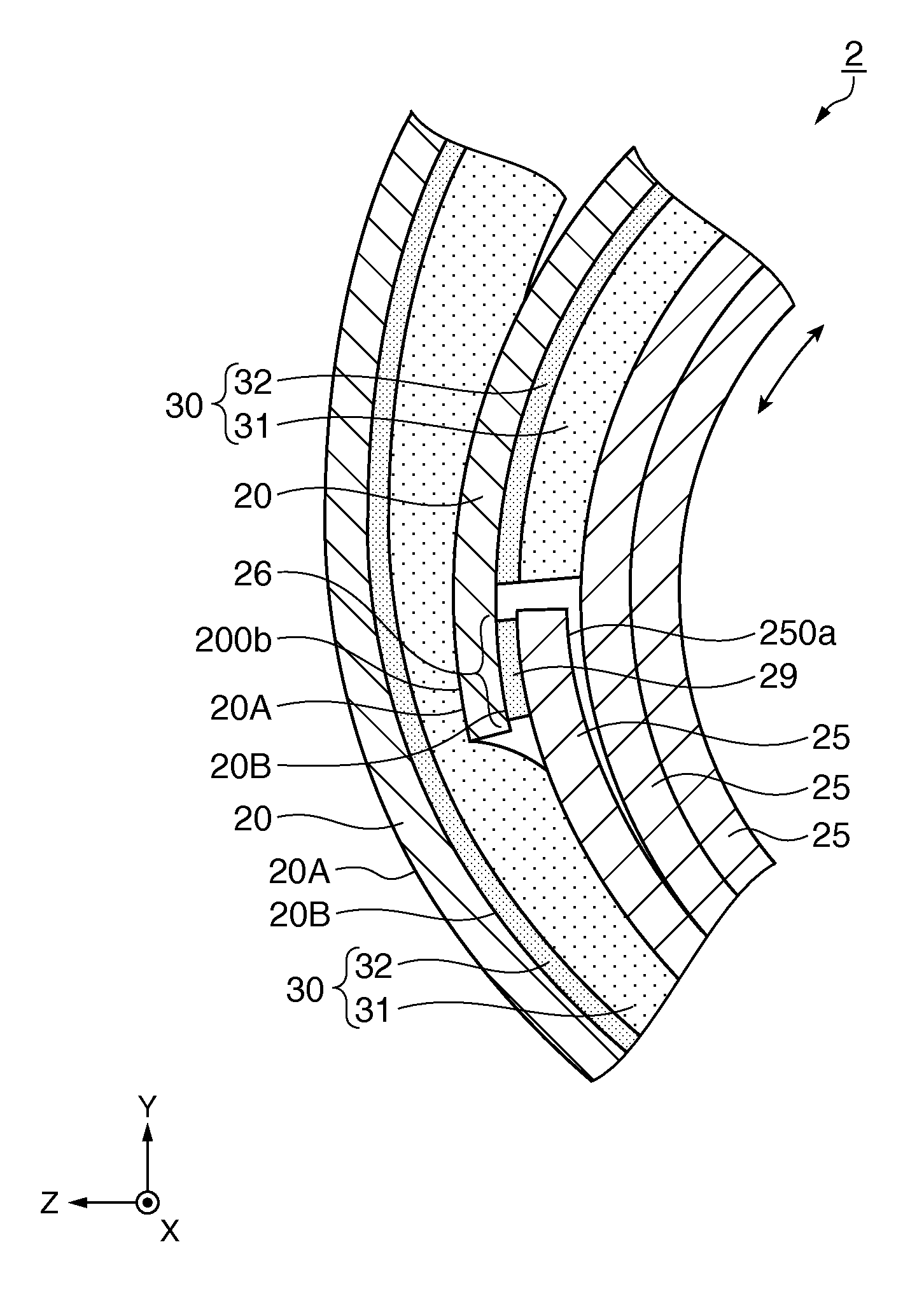

Pellicle for photolithography

ActiveUS20080063952A1Sufficient flatnessReduce the impactPhotomechanical apparatusOriginals for photomechanical treatmentEngineeringPhotolithography

In a photolithographic pellicle for dustproof protection of a photomask for photolithographic patterning by mounting thereon with the aid of a pressure-sensitive adhesive layer on one end surface of the pellicle frame, the adverse influence on the flatness of the photomask caused by mounting the pellicle can be minimized when the thickness of the pressure-sensitive adhesive layer is 0.4 mm or larger or when the elastic modulus of the layer does not exceed 0.5 MPa.

Owner:SHIN ETSU CHEM IND CO LTD

Substrate for information recording medium, information recording medium and process for producing the same

InactiveUS20050117438A1Improve heat resistanceLow alkali-elution propertyMagnetic materials for record carriersBase layers for recording layersAlkali ionsVitrification

A substrate for an information recording medium, which substrate is made of a highly heat-resistant and low-alkali-elution glass and is suitable as a substrate for forming a perpendicular-magnetic-recording-mode layers thereon at a high temperature with a sputtering machine, the substrate being made of an alkali-metal-oxide-containing glass having a glass transition temperature (Tg) of 620° C. or higher and satisfying a requirement that the alkali ion elution amount per a unit area when the glass is immersed in water having a temperature of 80° C. for 24 hours is 0.2 μmol / cm2 or less, an information recording medium having an information recording layer formed on the substrate, and a process for producing the information recording medium.

Owner:HOYA CORP

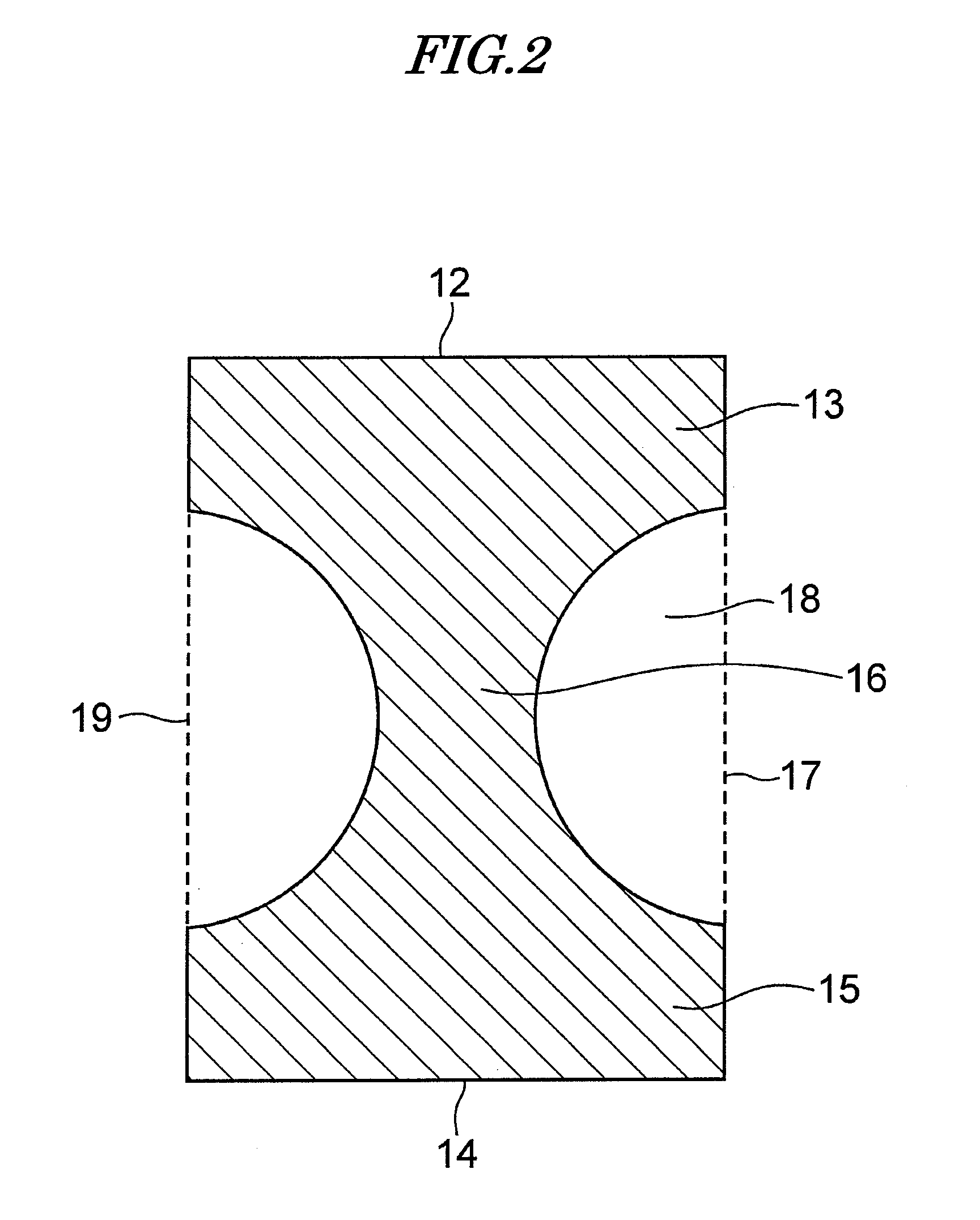

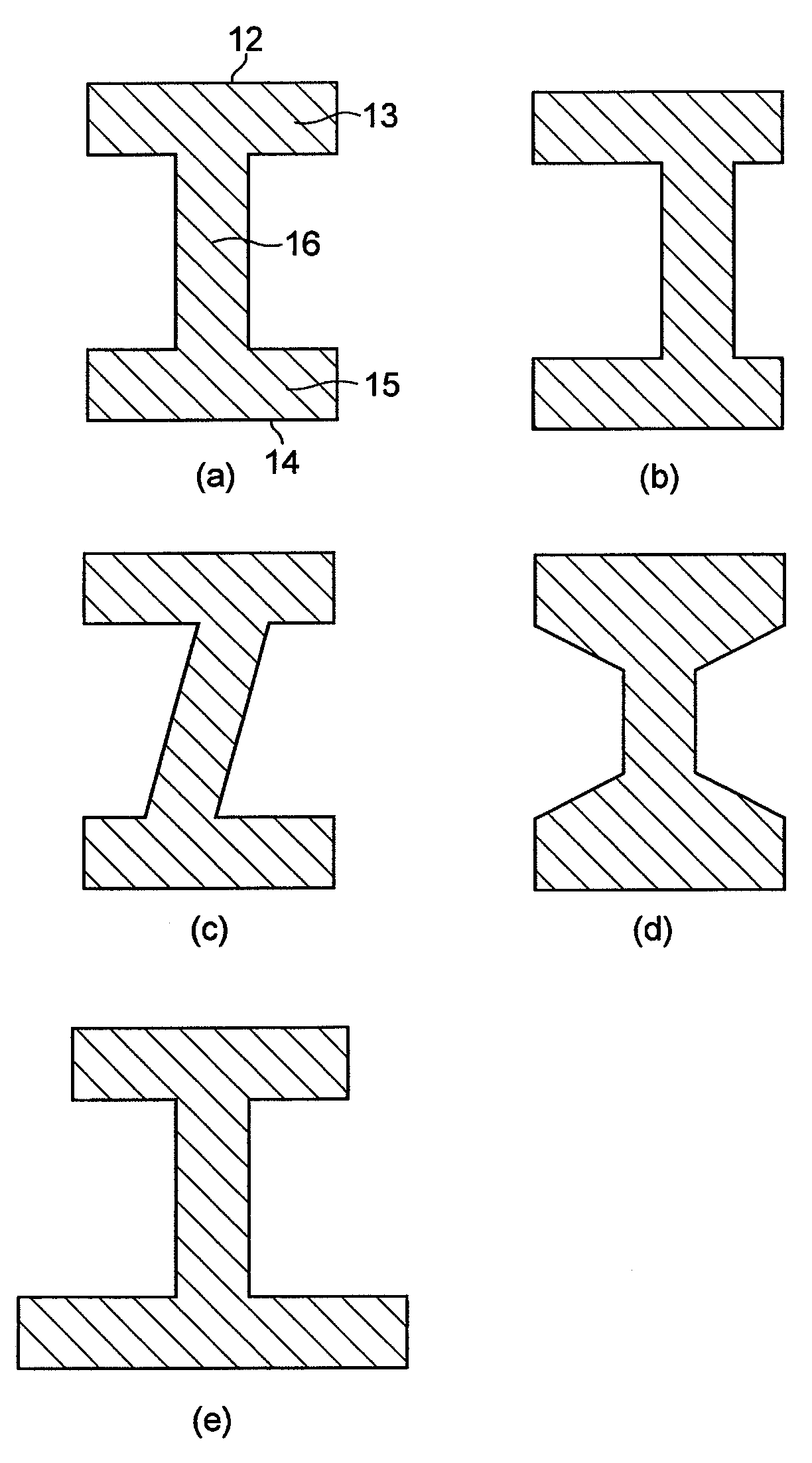

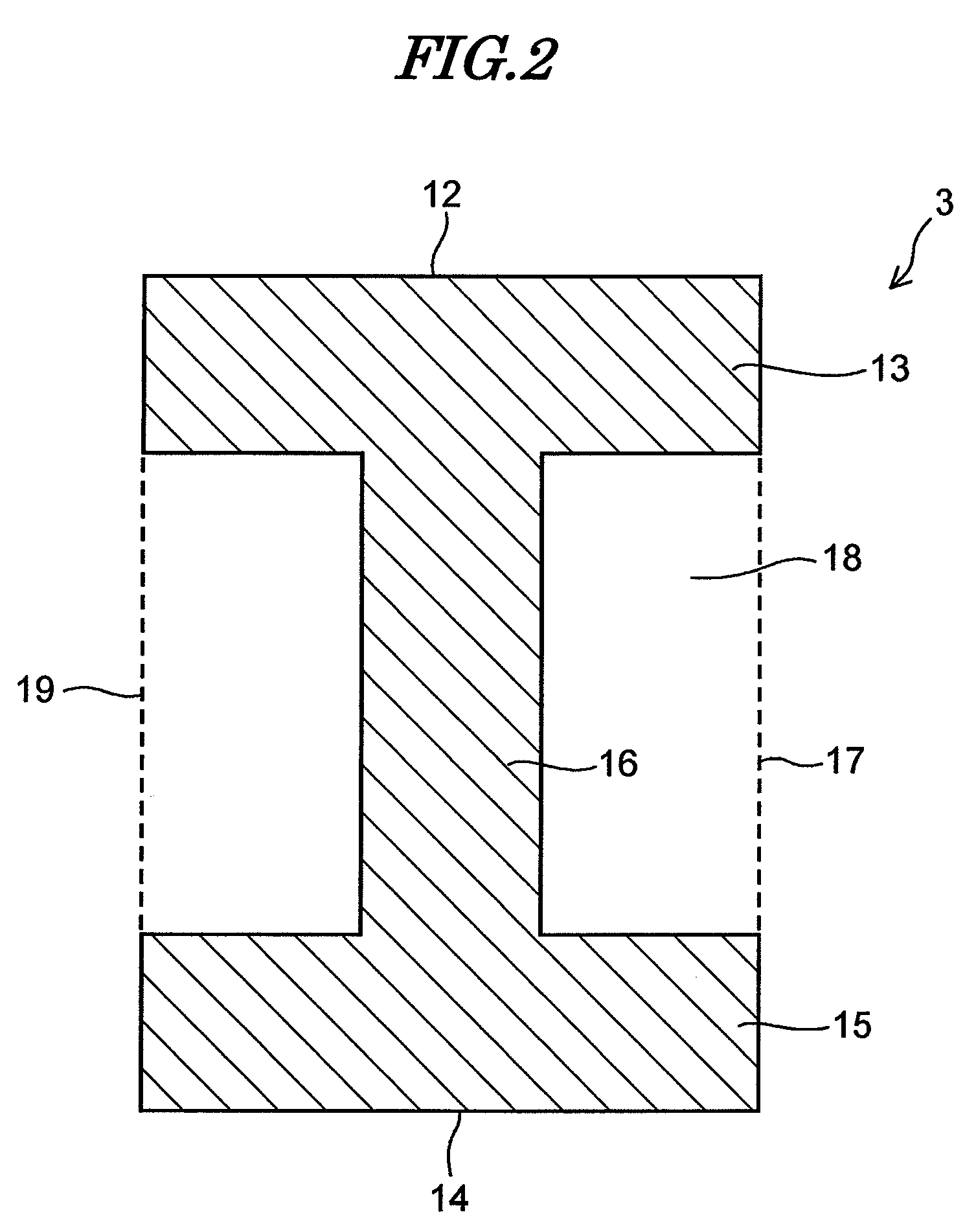

Pellicle frame and lithographic pellicle

ActiveUS20100330466A1Avoid deformationFlatnessSemiconductor/solid-state device manufacturingPackagingAdhesiveEngineering

A pellicle frame is provided that comprises a pellicle frame bar having a quadrilateral cross-section, wherein an upper edge and a lower edge of a basic quadrilateral forming said cross-section are parallel to each other and each of side edges of the basic quadrilateral has one quadrilateral recess. There is also provided a lithographic pellicle that includes a pellicle film stretched over one end face of the pellicle frame via a pellicle film adhesive, and that includes an exposure master plate adhesive on the other end face.

Owner:SHIN ETSU CHEM IND CO LTD +1

Multi-function touch panel

InactiveUS20130043081A1Reduce manufacturing processReduce production processTransmission systemsAntenna equipments with additional functionsTouch panelEngineering

A multi-function touch panel includes a transparent substrate and an opaque color frame formed by an edge of the substrate so as to form a visible area and a shelter area on the substrate. A transparent touch sensing unit is formed to the visible area on a surface of the substrate. A signal wiring under the shelter area is formed around the touch sensing unit. The signal wiring is electrically connected between the touch sensing unit and a first signal bus. A flat antenna is insulatedly formed outside the signal wiring under the shelter area. Two ends of the flat antenna are electrically connected to a second signal bus. The color frame is made of insulated material. The first signal bus and the second signal bus are integrated as one signal bus.

Owner:LUMINOUS OPTICAL TECH

Semiconductor device

InactiveUS20100102459A1Improve heat dissipationHigh riskSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor chip

The semiconductor device includes: a semiconductor chip; a die pad for holding the semiconductor chip; a lead; and a sealing resin material for sealing the semiconductor chip, the die pad and an inner portion of the lead. The die pad has an upset portion protruding upward to form a flat face smaller in area than the semiconductor chip, and the portion of the die pad excluding the upset portion is covered with a buffer resin material smaller in elasticity than the sealing resin material.

Owner:PANASONIC CORP

Pellicle frame and lithographic pellicle

ActiveUS20100330467A1Avoid deformationFlatnessSemiconductor/solid-state device manufacturingPackagingEngineeringPellicle membrane

A pellicle frame is provided that includes a pellicle frame bar having a cross-section with a shape that has a curved line-containing recess in at least one side edge of a quadrilateral having an upper edge and a lower edge parallel to each other and an area of no greater than 20 mm2.

Owner:SHIN ETSU CHEM IND CO LTD +1

Screen and screen unit

Owner:SEIKO EPSON CORP

Pellicle frame and lithographic pellicle

ActiveUS8221944B2FlatnessPoor flatnessSemiconductor/solid-state device manufacturingPackagingAdhesiveEngineering

A pellicle frame is provided that comprises a pellicle frame bar having a quadrilateral cross-section, wherein an upper edge and a lower edge of a basic quadrilateral forming said cross-section are parallel to each other and each of side edges of the basic quadrilateral has one quadrilateral recess. There is also provided a lithographic pellicle that includes a pellicle film stretched over one end face of the pellicle frame via a pellicle film adhesive, and that includes an exposure master plate adhesive on the other end face.

Owner:SHIN ETSU CHEM CO LTD +1

Method For Forming Masonry Unit

InactiveUS20090100790A1Improve efficiencyImprove productivityWallsMouldsStructural engineeringHigh dimensional

Masonry units (10) are integrally assembled by tightening forces of bolts (60) and nuts (70), in a condition that interlayer metal plates (50) are interposed between the masonry units. A basic form (11) of the masonry unit is contained in a mold for forming the masonry unit. A space (98) for fluidic covering material, which is chargeable with the covering material, is defined between upper and lower faces of the form (11), and the fluidic covering material is charged in the space. The upper and lower faces of the masonry unit are covered with the solidified covering material (12). According to the present invention, high dimensional accuracy of the masonry unit can be ensured, and efficiency of the production process of the masonry units is promoted to improve productivity of the masonry units.

Owner:JAPAN SCI & TECH CORP

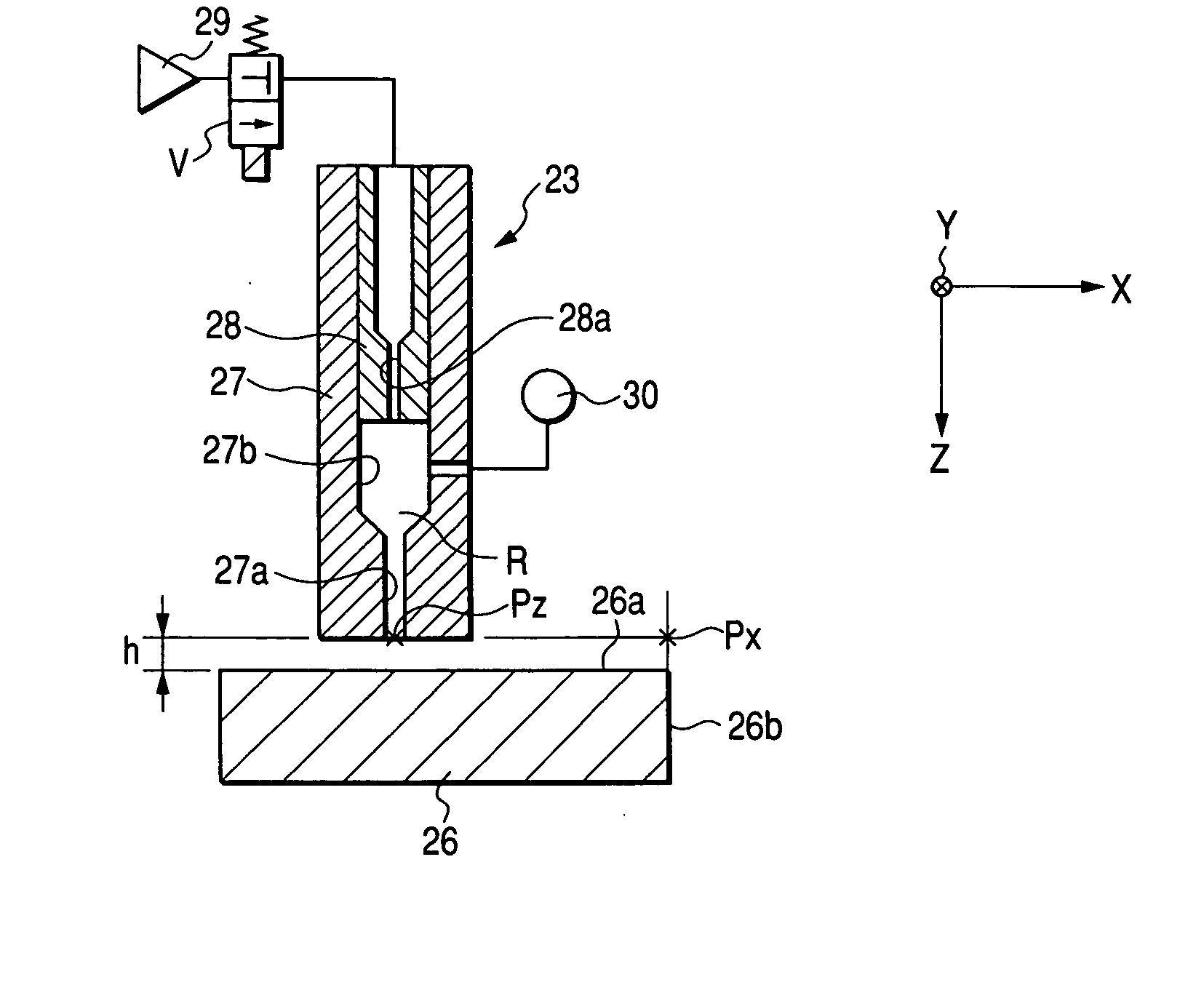

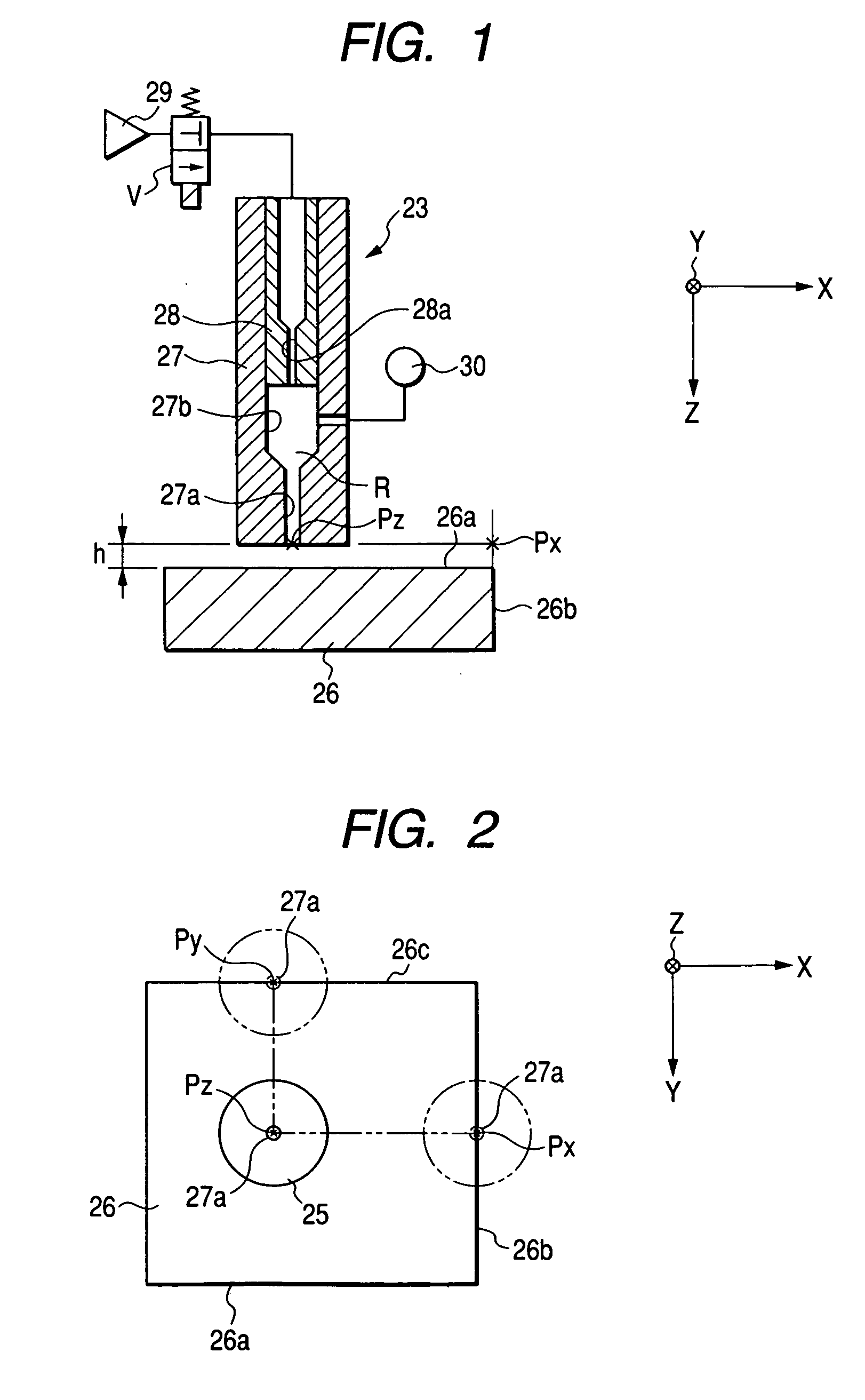

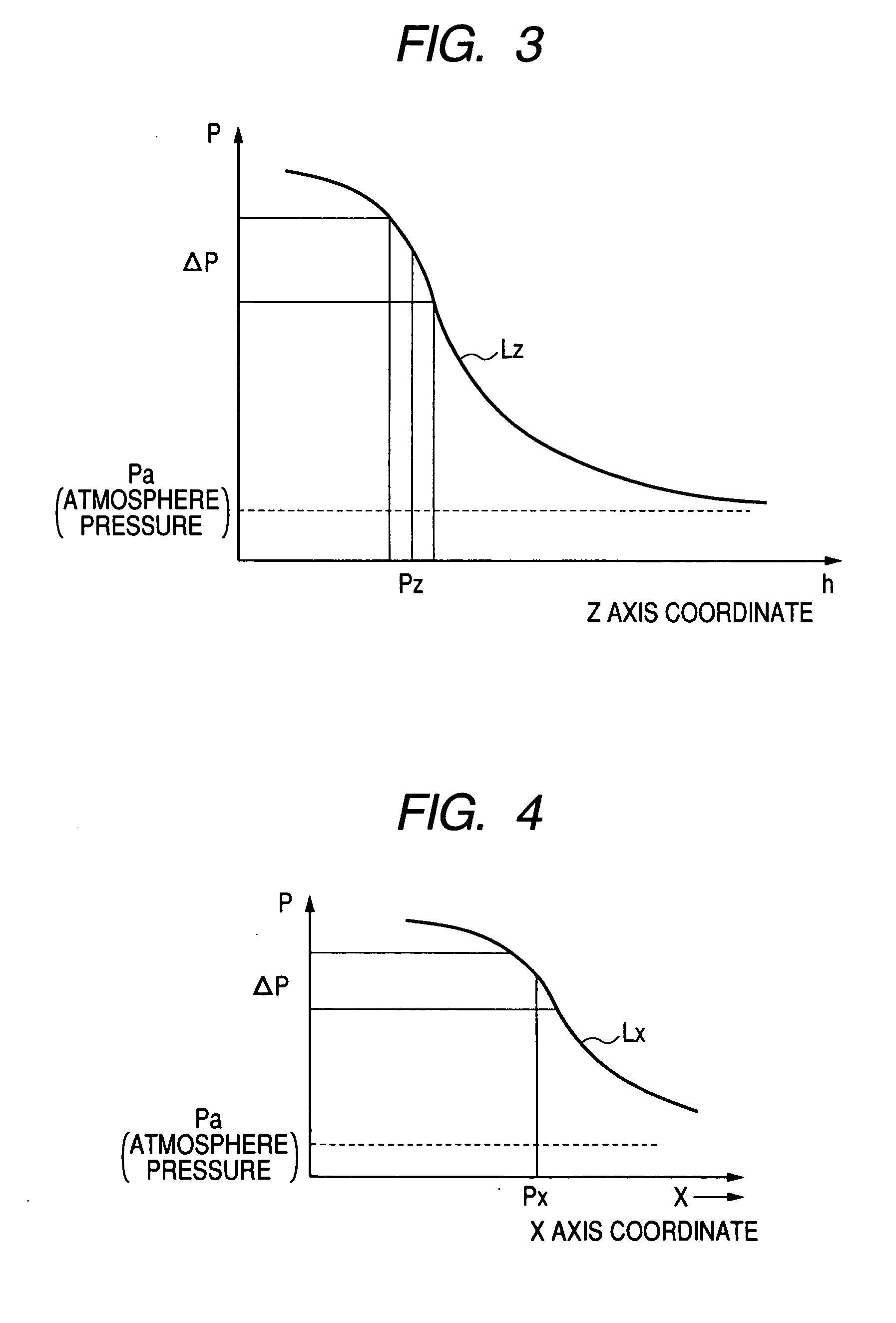

Surface shape determining device for a machining apparatus and surface shape determining method

InactiveUS20050288816A1FlatnessImprove accuracyFeeler-pin gaugesUsing subsonic/sonic/ultrasonic vibration meansEngineeringPressure measurement

In a state of separating a front end face of an air injecting nozzle 23 from a worked work W by a predetermined interval h, the air injecting nozzle 23 is moved at a constant speed in an X axis direction, injects air from an injecting hole 27a of a nozzle main body 27 and is moved to pass centers O1, O2 of worked holes Wb, Wc of the work W. A variation in a pressure is measured by a pressure measuring unit 30. X axis coordinates of the centers O1, O2 of the holes Wb, Wc, a hole diameter E and a center interval distance D1 are calculated based on coordinates of center points T1, T2 of inclined portions Ld, Lu of a curve Lx of the pressure relative to the measured X axis coordinate.

Owner:KOMATSU NTC LTD

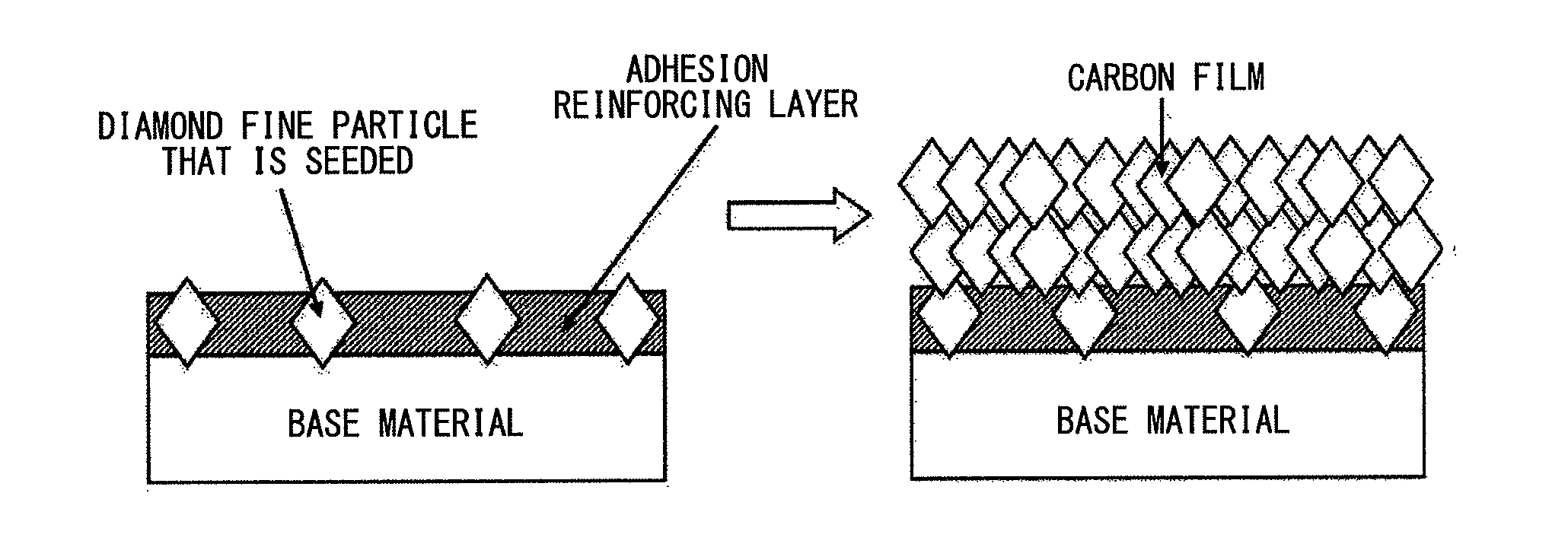

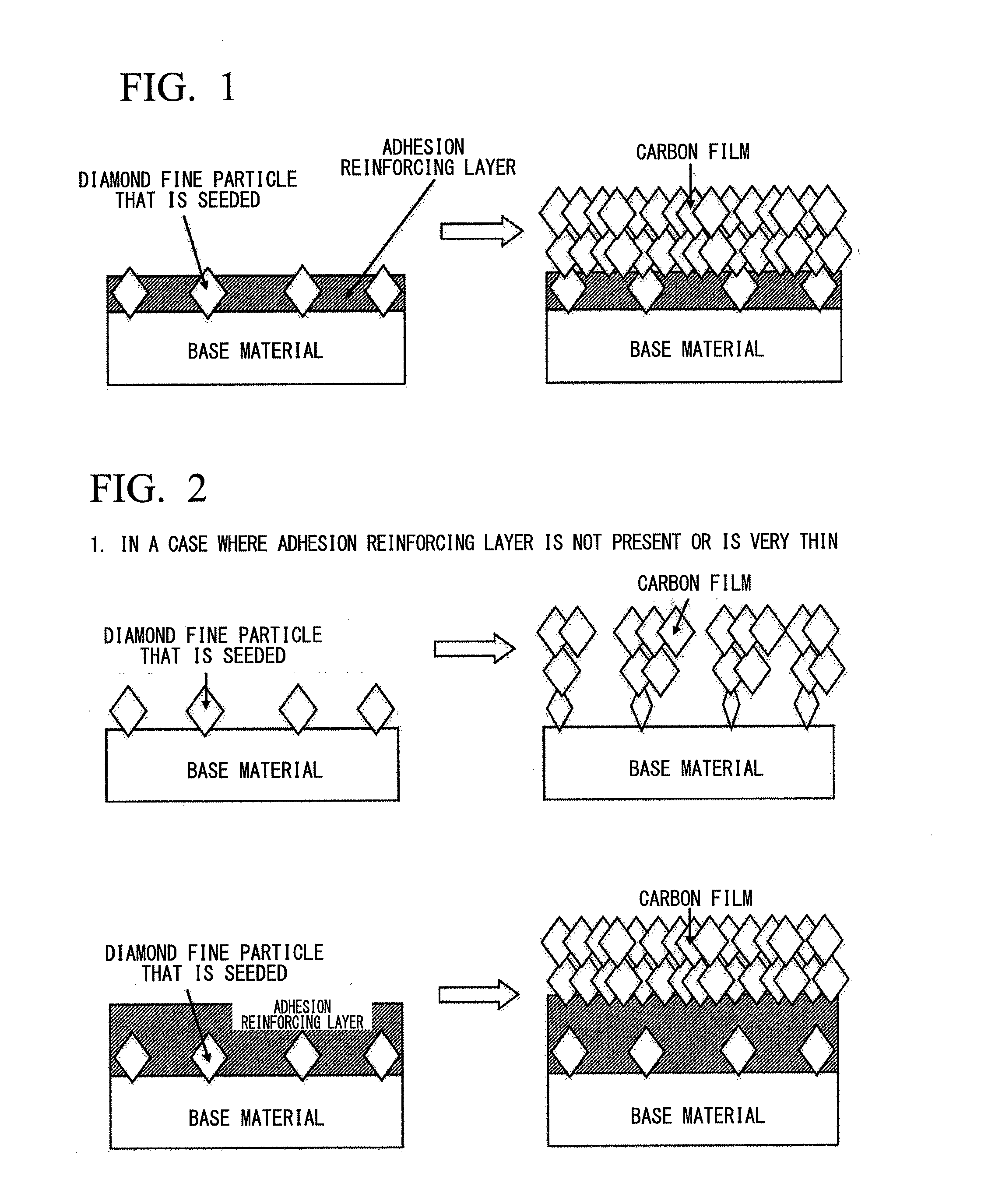

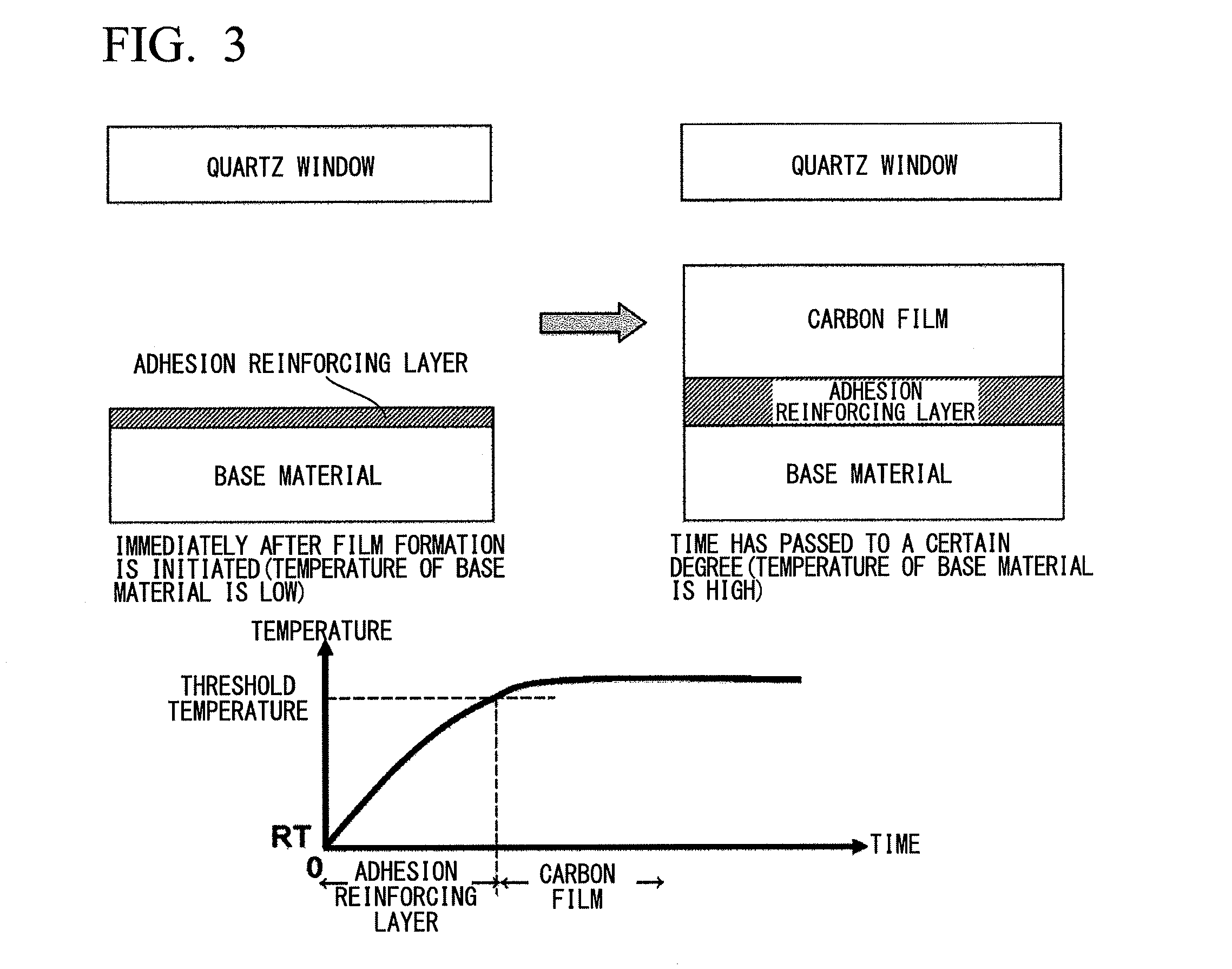

Carbon film laminate, method of manufacturing said laminate, and lubricant using said laminate

InactiveUS20140079910A1Increase stickinessReduce coefficient of frictionLayered productsRecord information storageCarbon filmX-ray

An object of the invention is to provide a carbon film laminate having a sliding surface with low friction, low abrasion, and low counterpart aggressiveness using high adhesiveness to a base material, hardness, surface flatness, low counterpart aggressiveness, transparency, and high thermal conductivity which are provided to the carbon film without using liquid and semiliquid lubricants such as lubricating oil. Provided is a carbon film laminate including a base material, a carbon film adhesion reinforcing layer which is provided on the base material and which is formed from silicon oxide (SiOx, x=1 to 2) containing fluorine atoms (F) in a concentration of 1×1019 atoms / cm3 or more, and a carbon film that is formed on the carbon film adhesion reinforcing layer. The carbon film contains fluorine atoms in the film in a concentration of 1×1019 to 1×1021 atoms / cm3, and has an approximate spectrum curve obtained by superimposing, on a peak fitting curve A at a Bragg angle (2θ±0.5°) of 43.9° in an X-ray diffraction spectrum by CuKα1 rays, a peak fitting curve B at 41.7° and a baseline.

Owner:NAT INST OF ADVANCED IND SCI & TECH

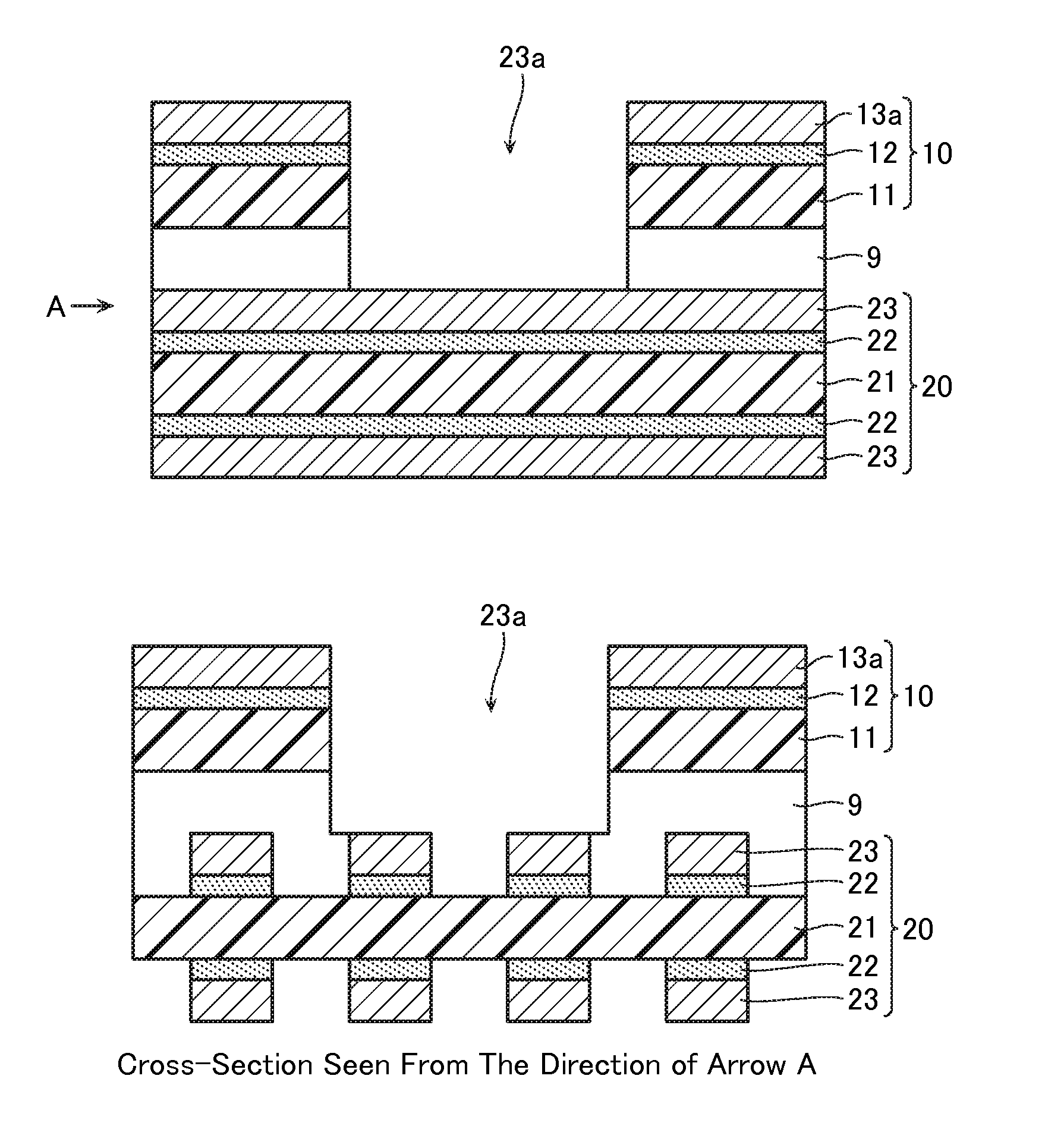

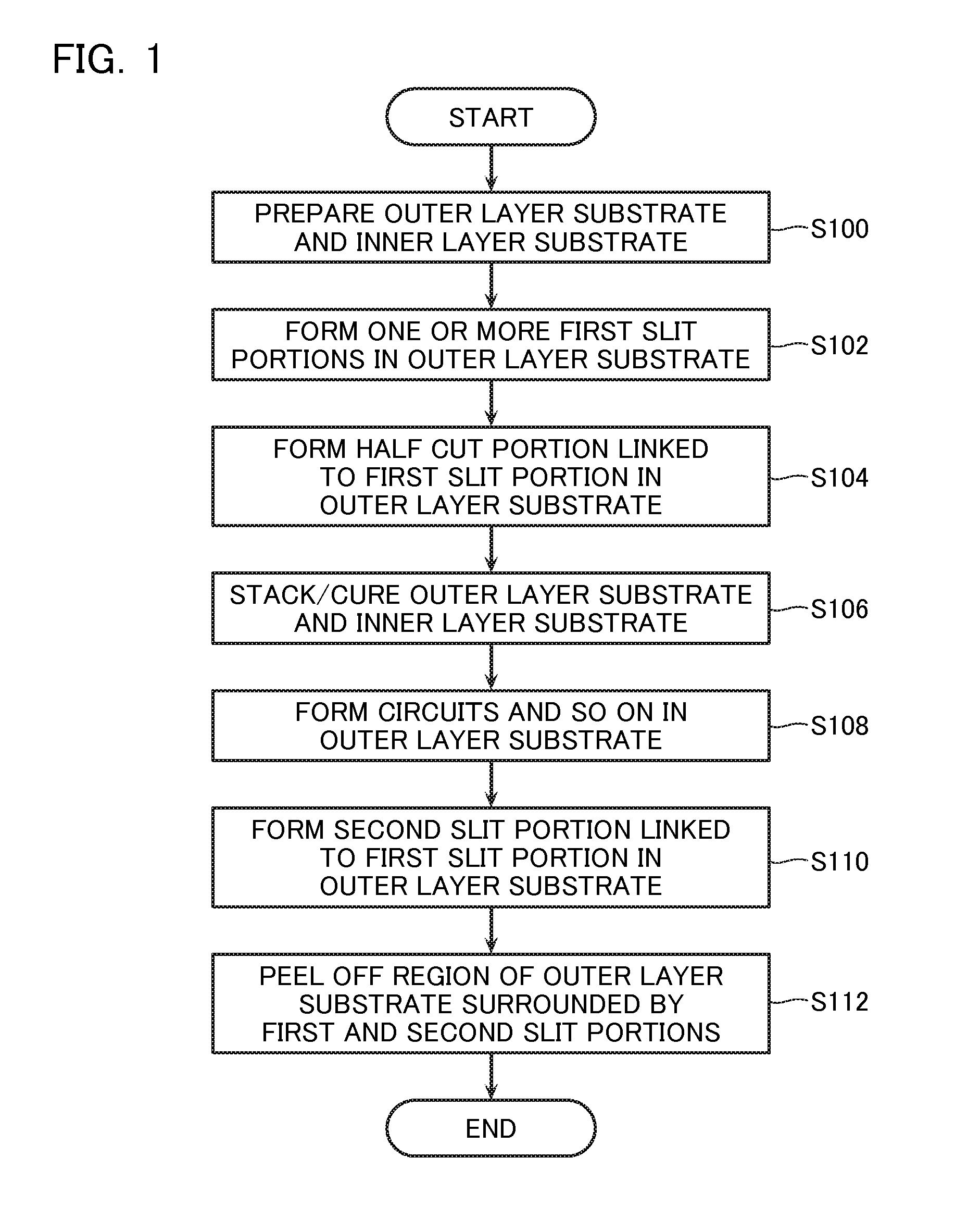

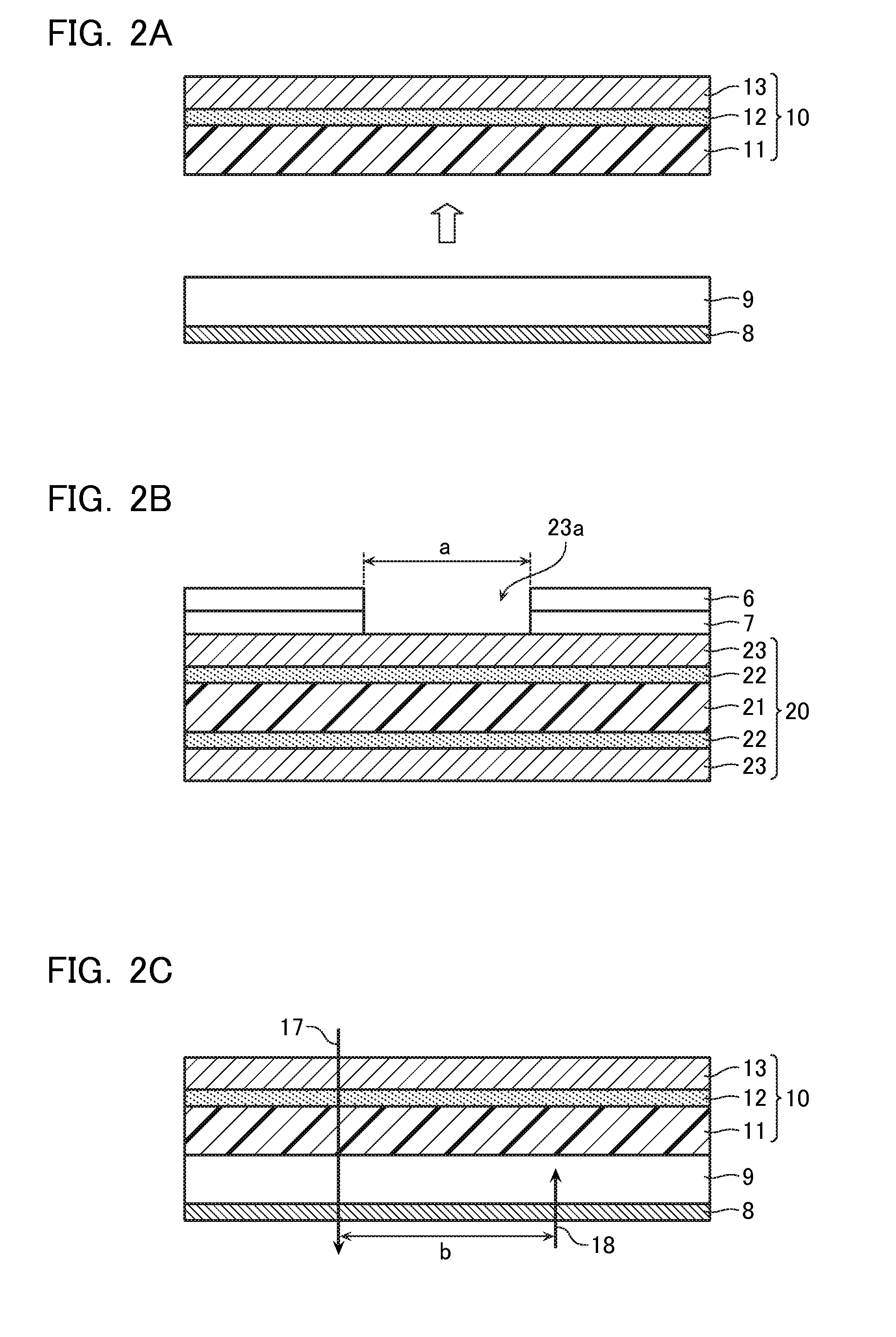

Method of manufacturing multi-layer circuit board, and multi-layer circuit board

ActiveUS8884166B2Increase productionFlatnessPrinted circuit assemblingPrinted circuit aspectsElectrical conductorEngineering

A multi-layer circuit board having a connector portion of an inner layer substrate being exposed, the multi-layer circuit board comprising: an inner layer substrate in which an inner layer circuit is formed, the inner layer circuit including the connector portion; and an outer layer substrate having an outer layer circuit formed on an insulating layer and having a region corresponding to the connector portion peeled off, an inner layer circuit side of the inner layer substrate and an insulating layer side of the outer layer substrate being adhered to one another via an adhesive layer so as to face one another, and a conductor layer other than the connector portion of the inner layer circuit being adhered to the outer layer substrate directly by the adhesive layer.

Owner:FUJIKURA PRINTED CIRCUITS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com