Patents

Literature

38results about How to "Sufficient flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

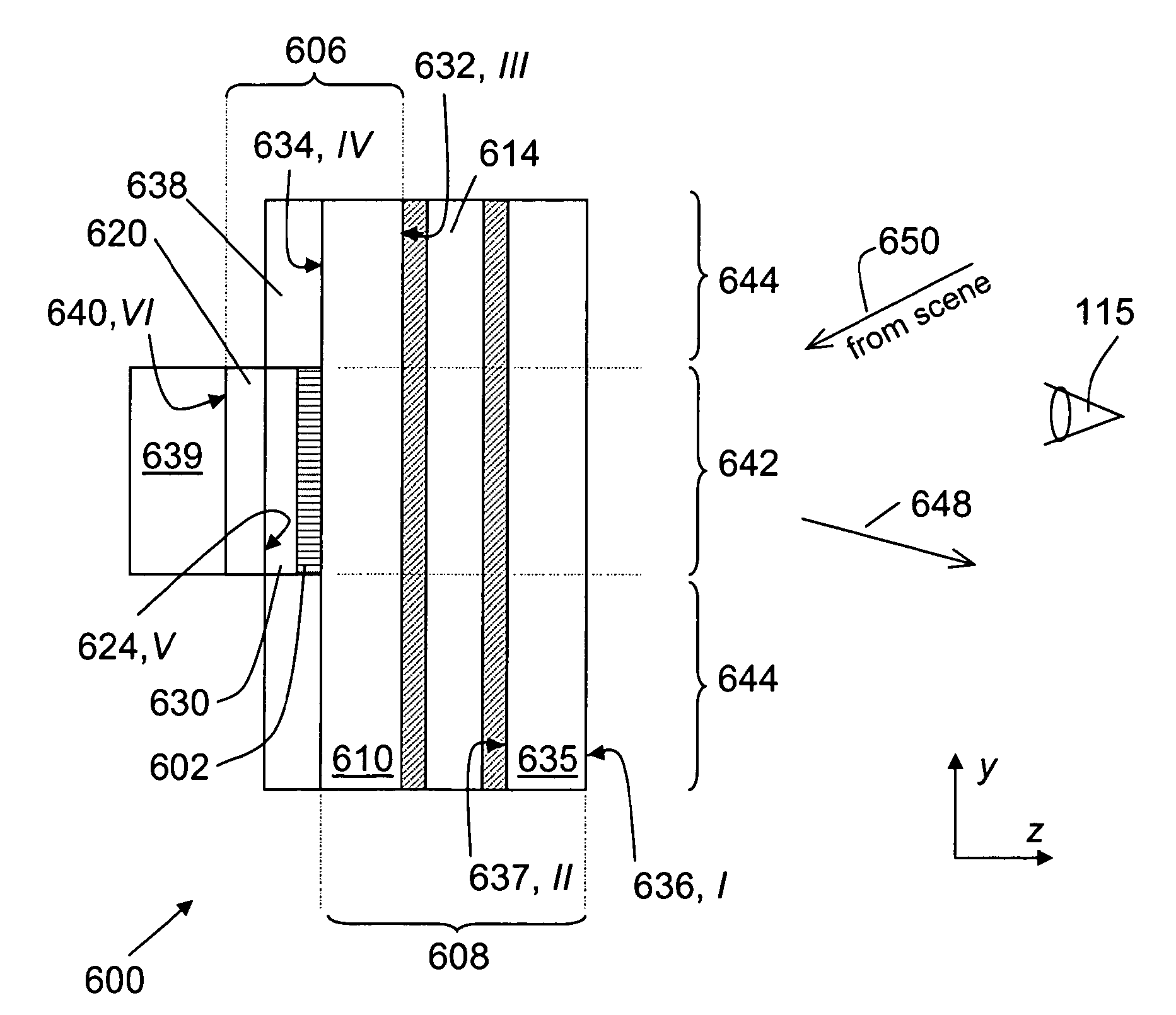

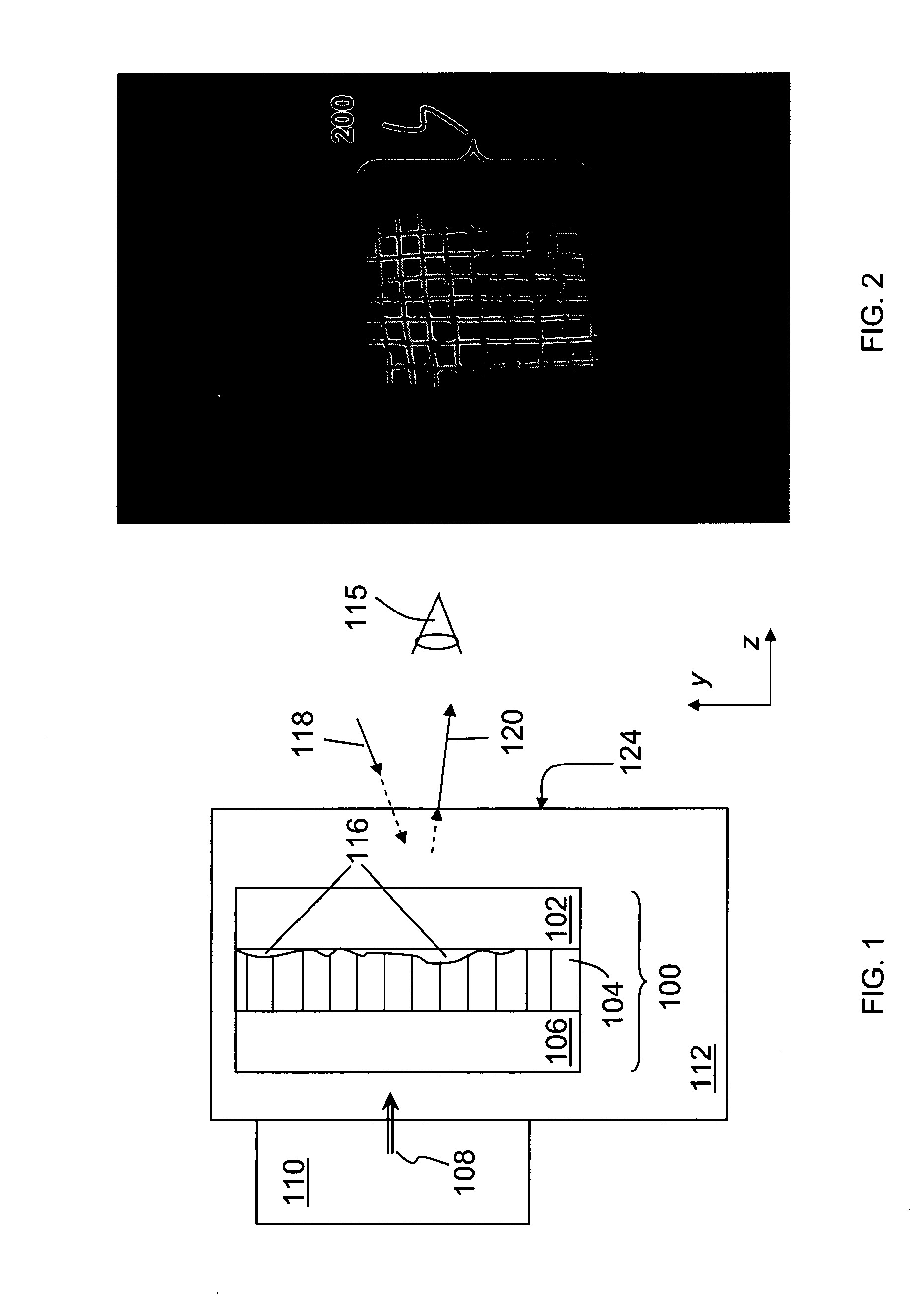

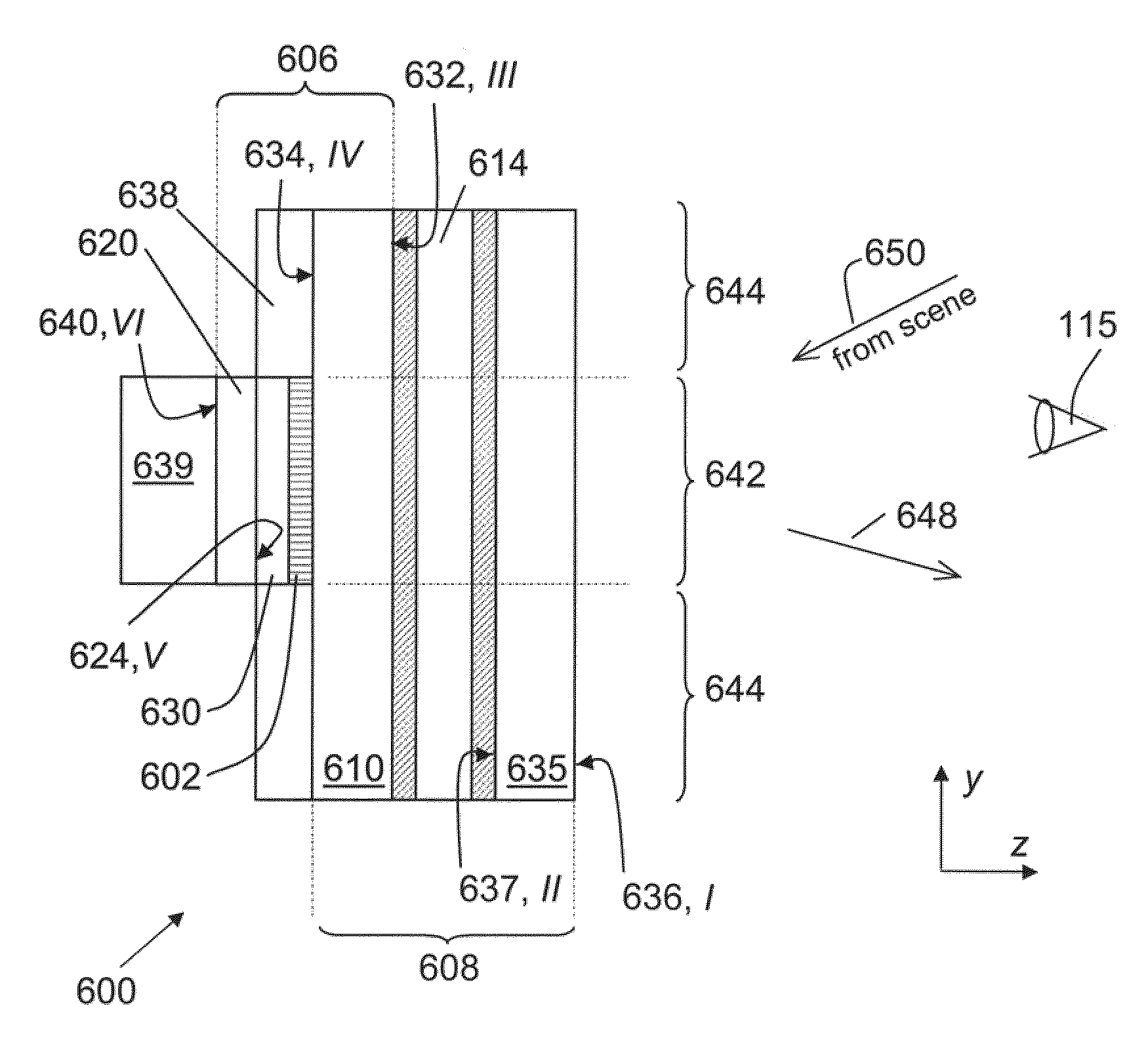

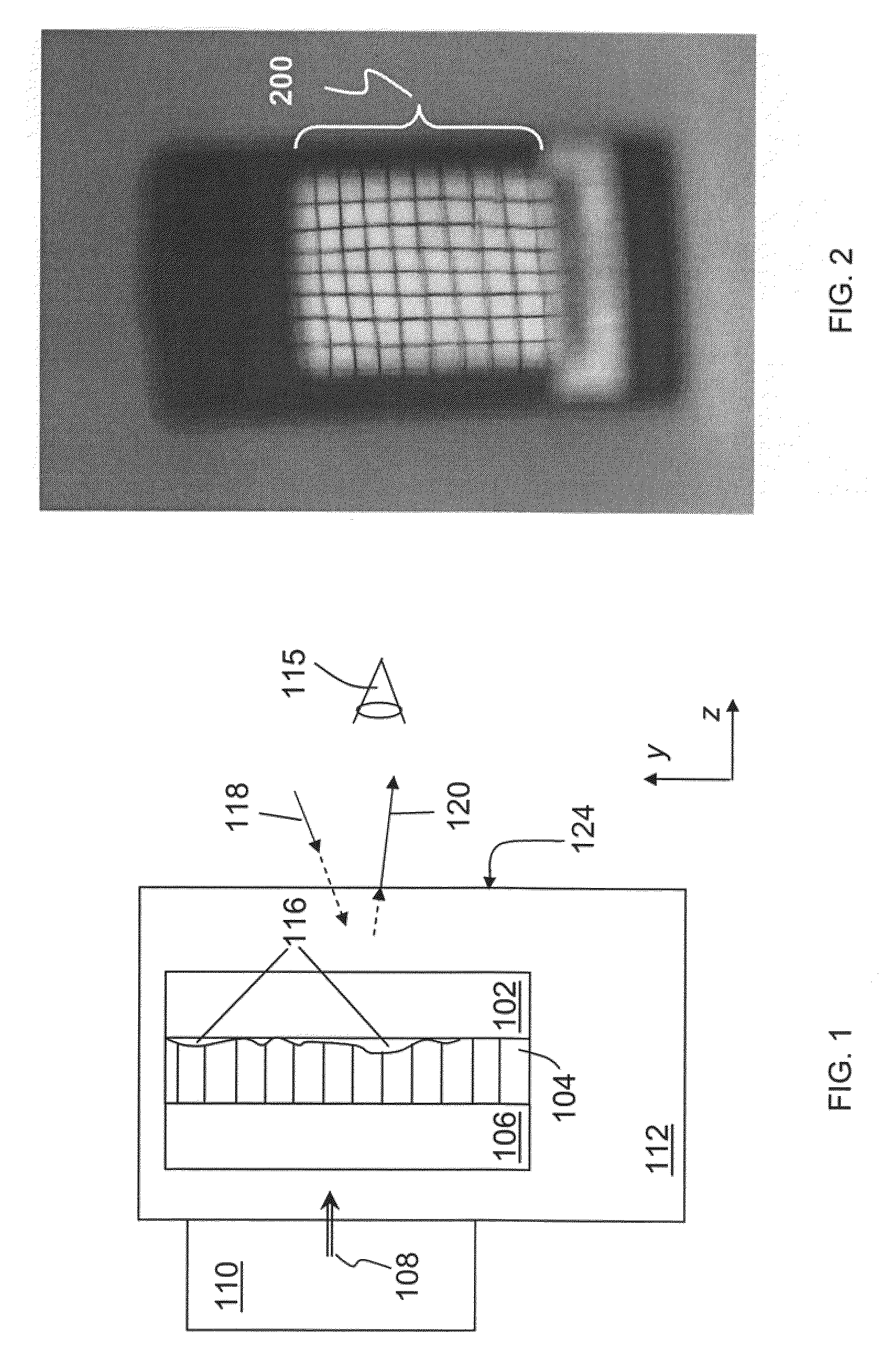

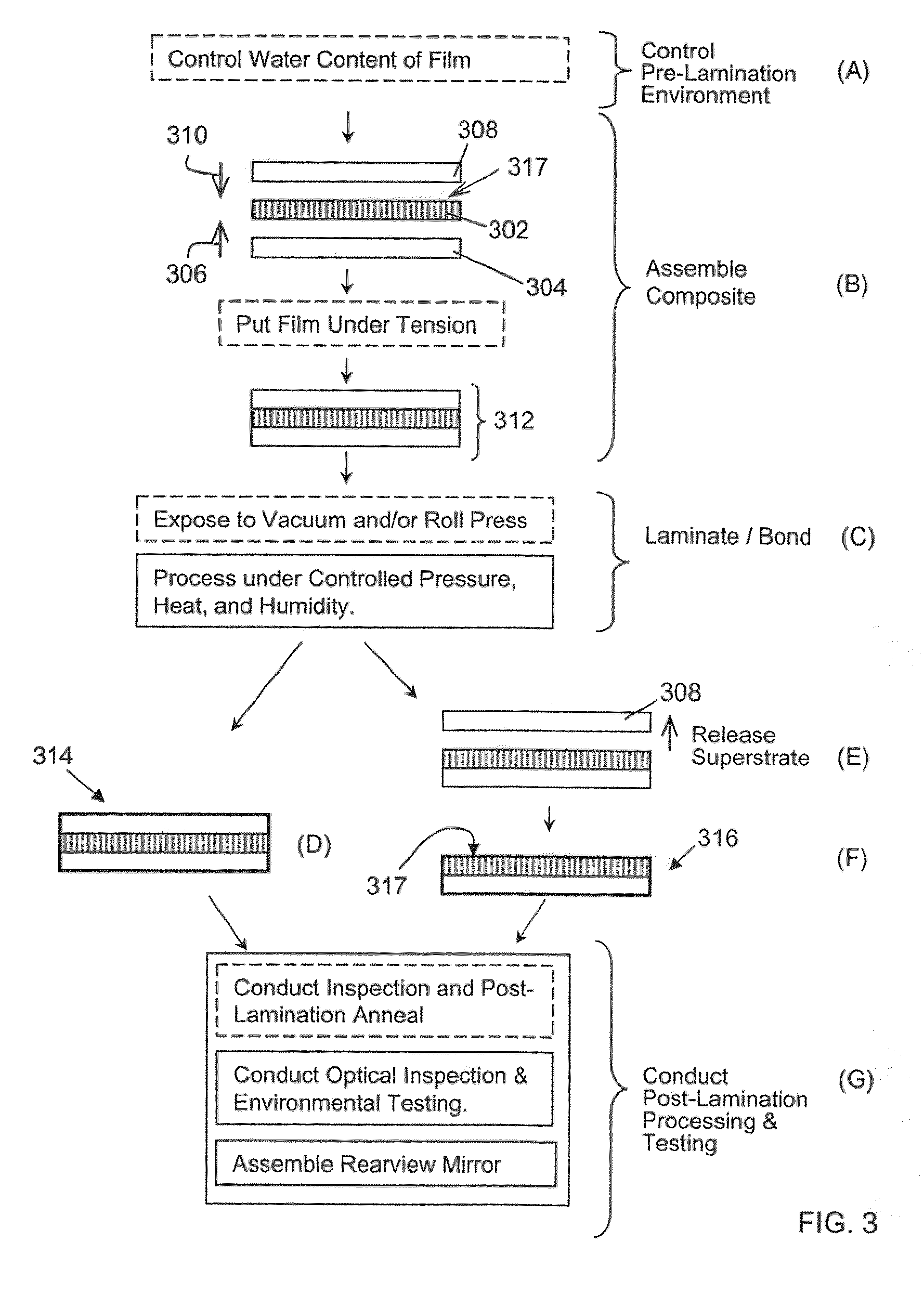

Rearview Mirror Assemblies With Anisotropic Polymer Laminates

ActiveUS20090296190A1High strengthAdequate flatness of filmMirrorsSynthetic resin layered productsLower limitWing mirror

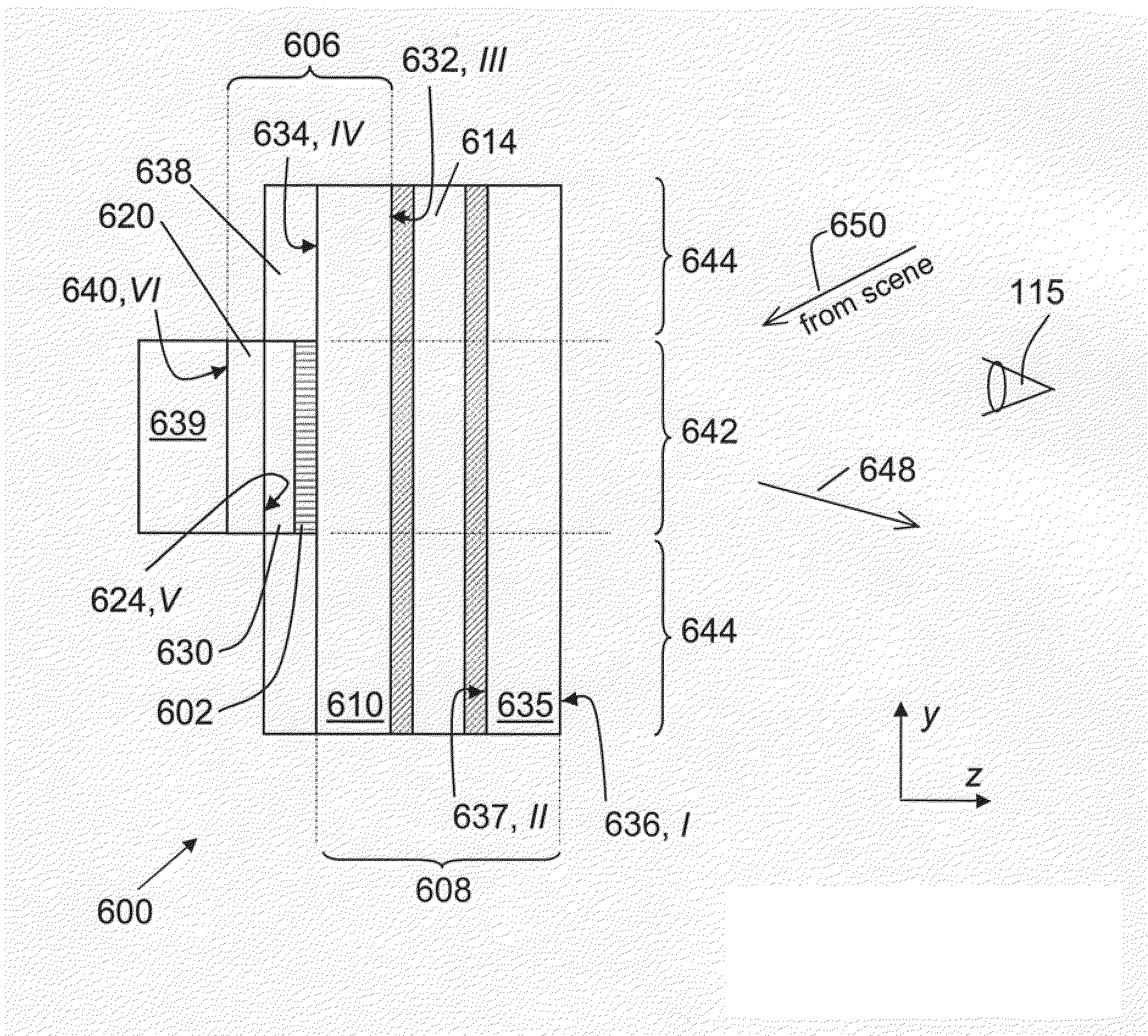

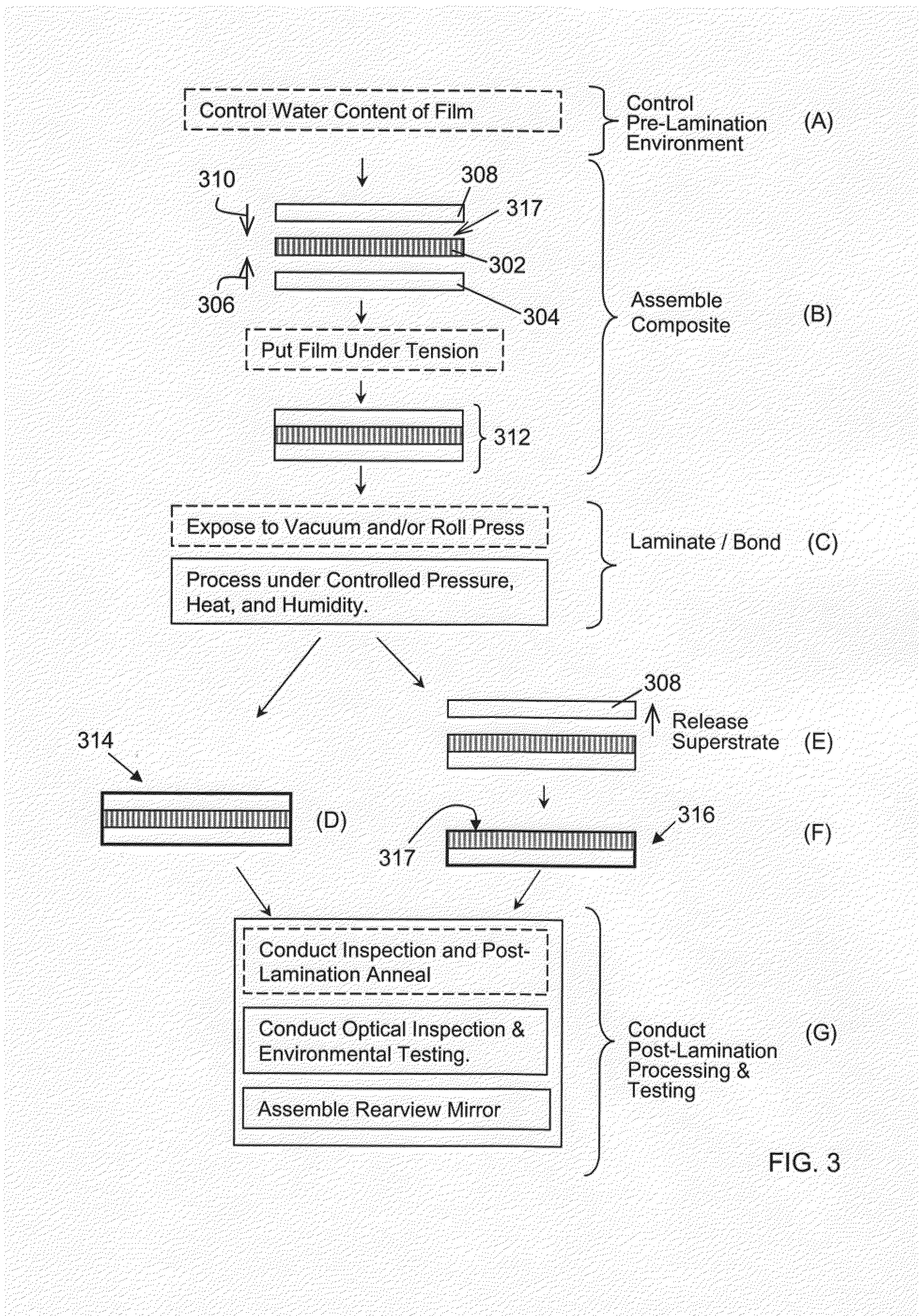

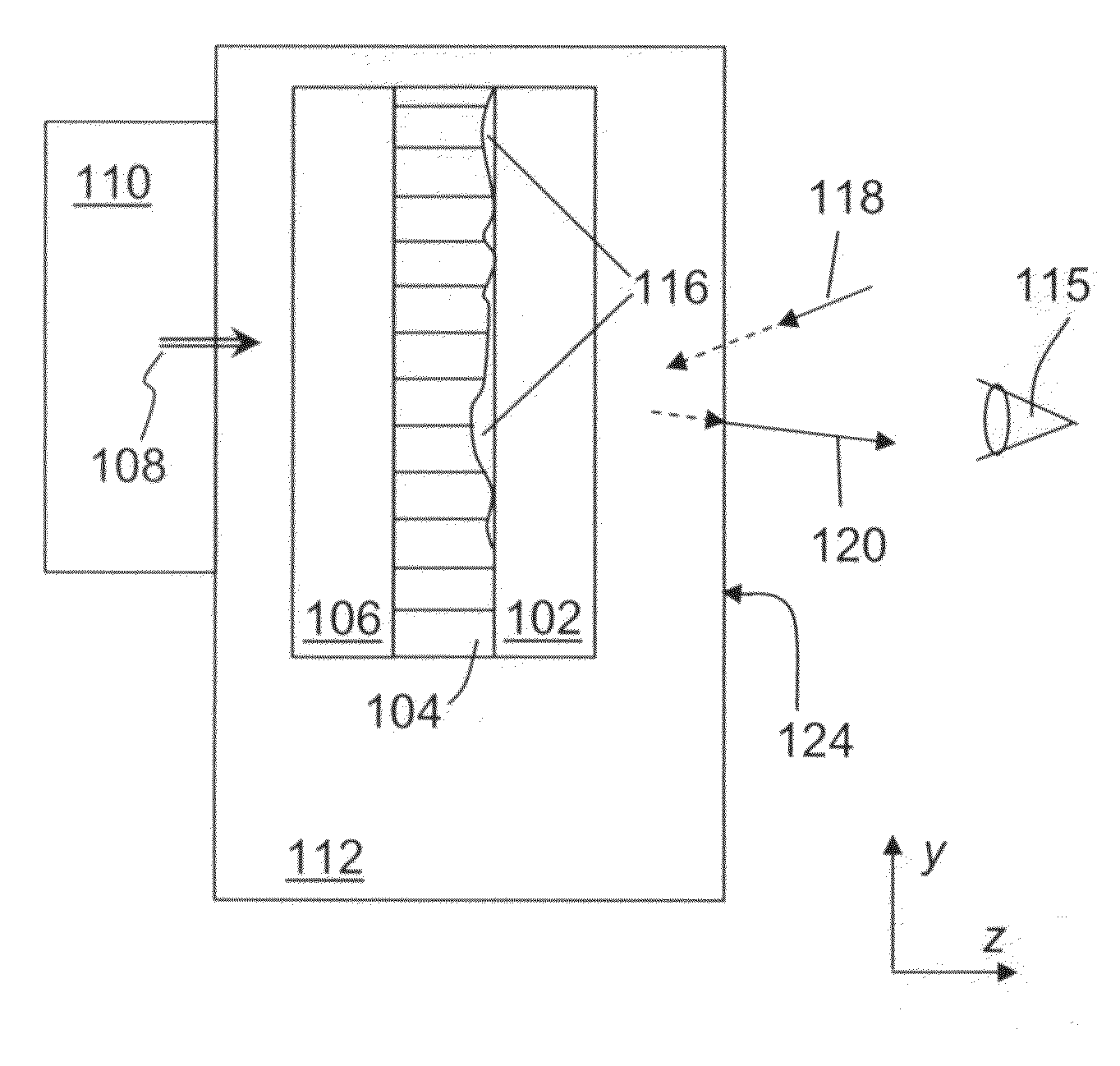

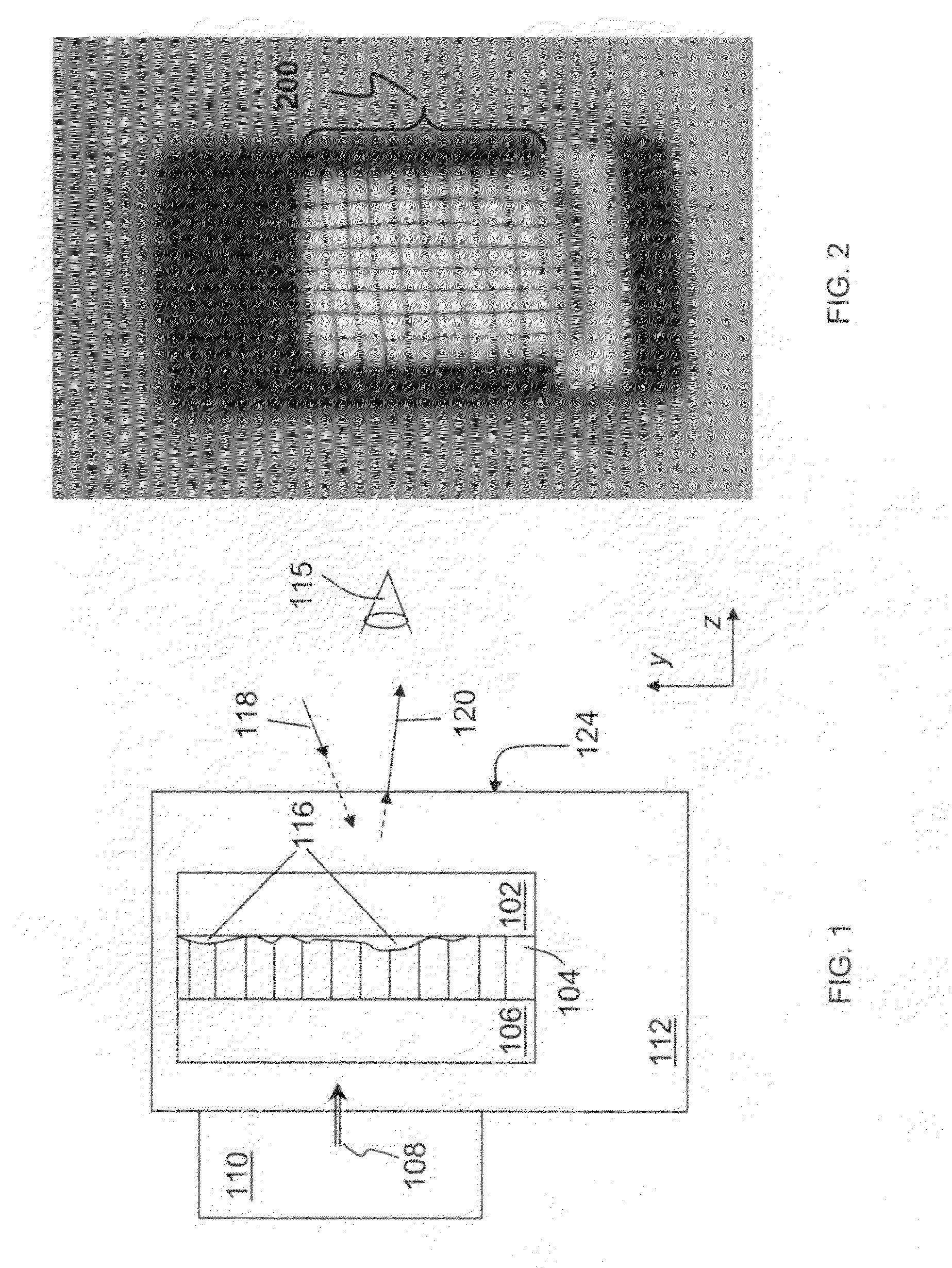

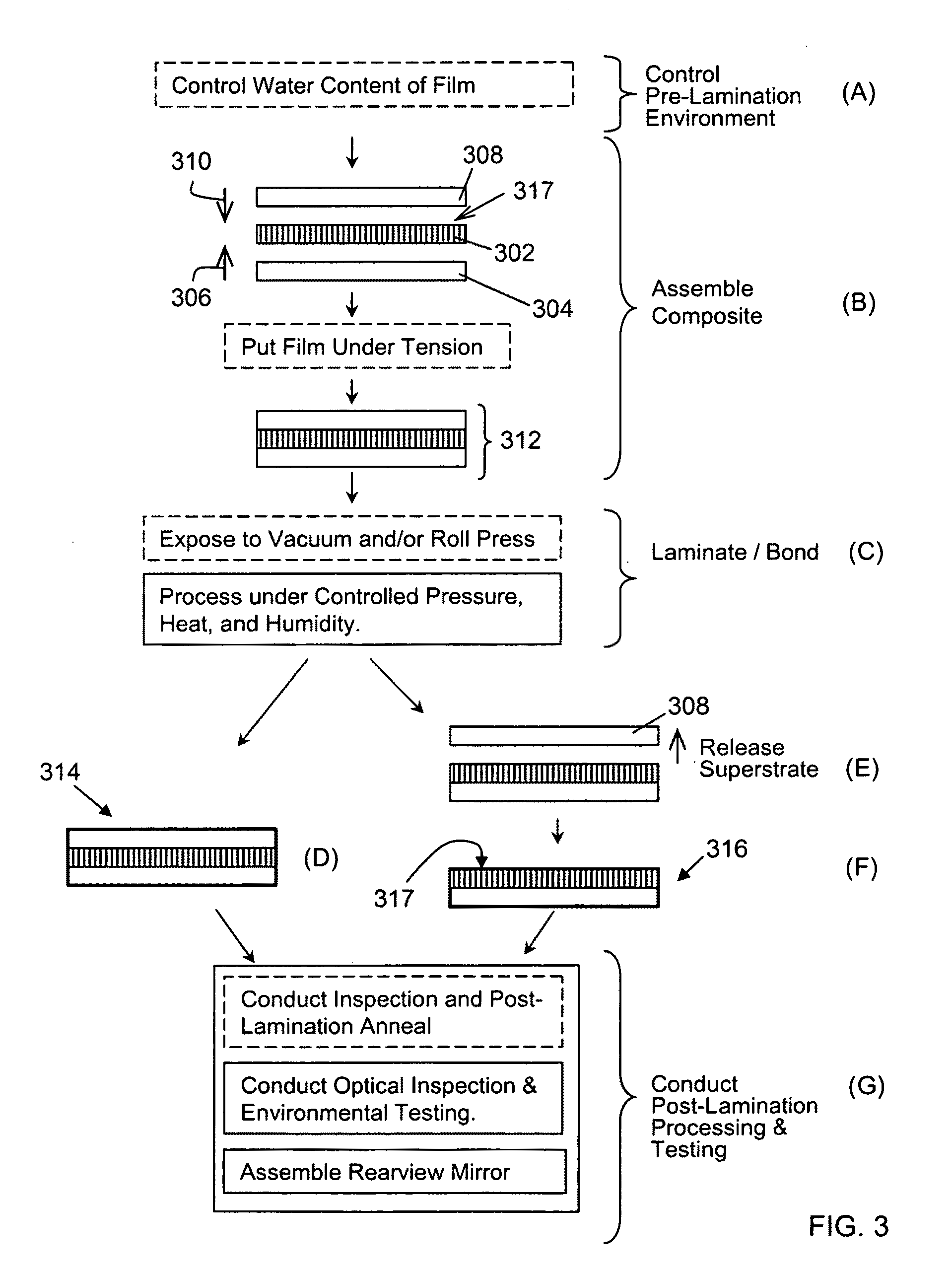

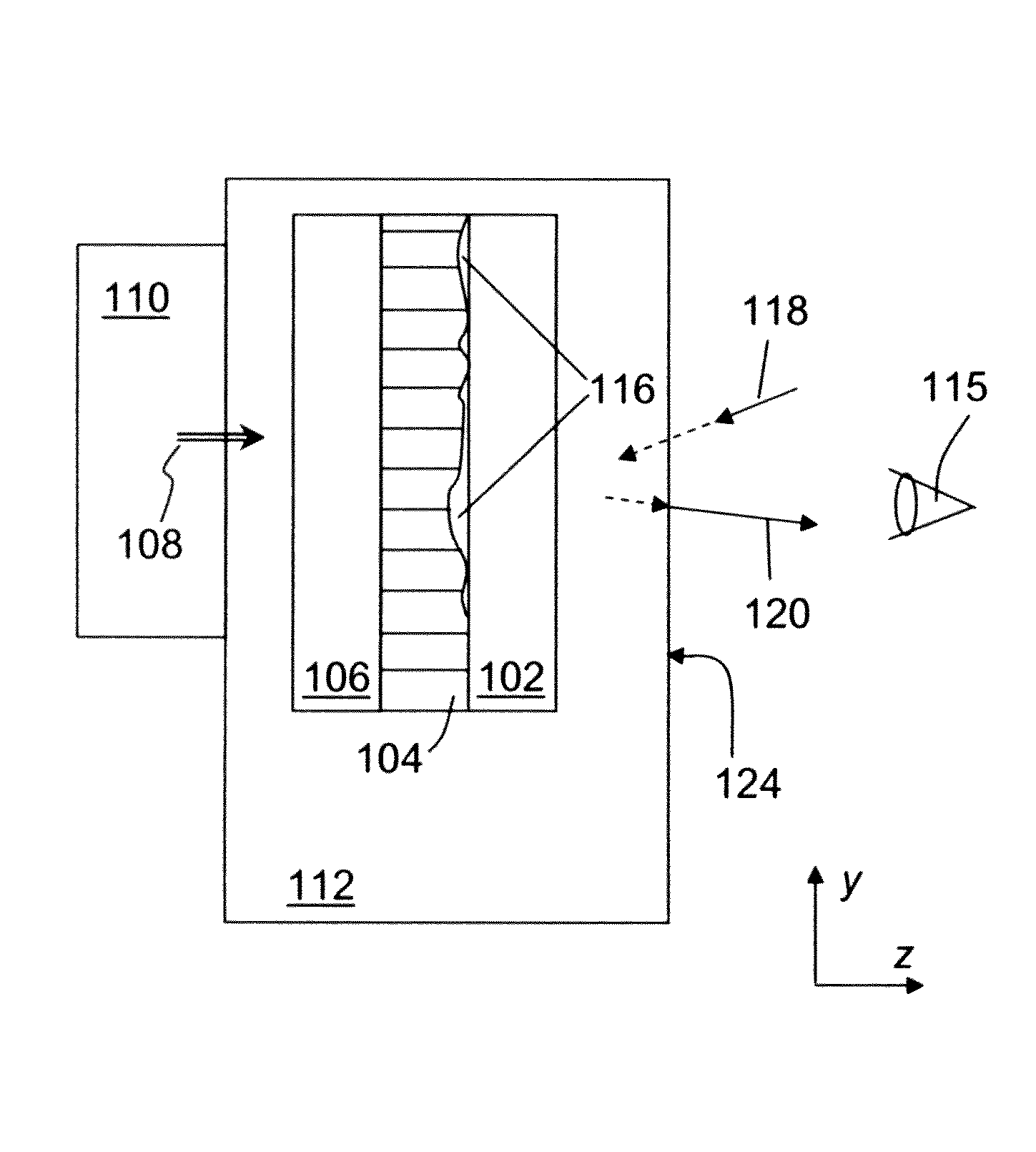

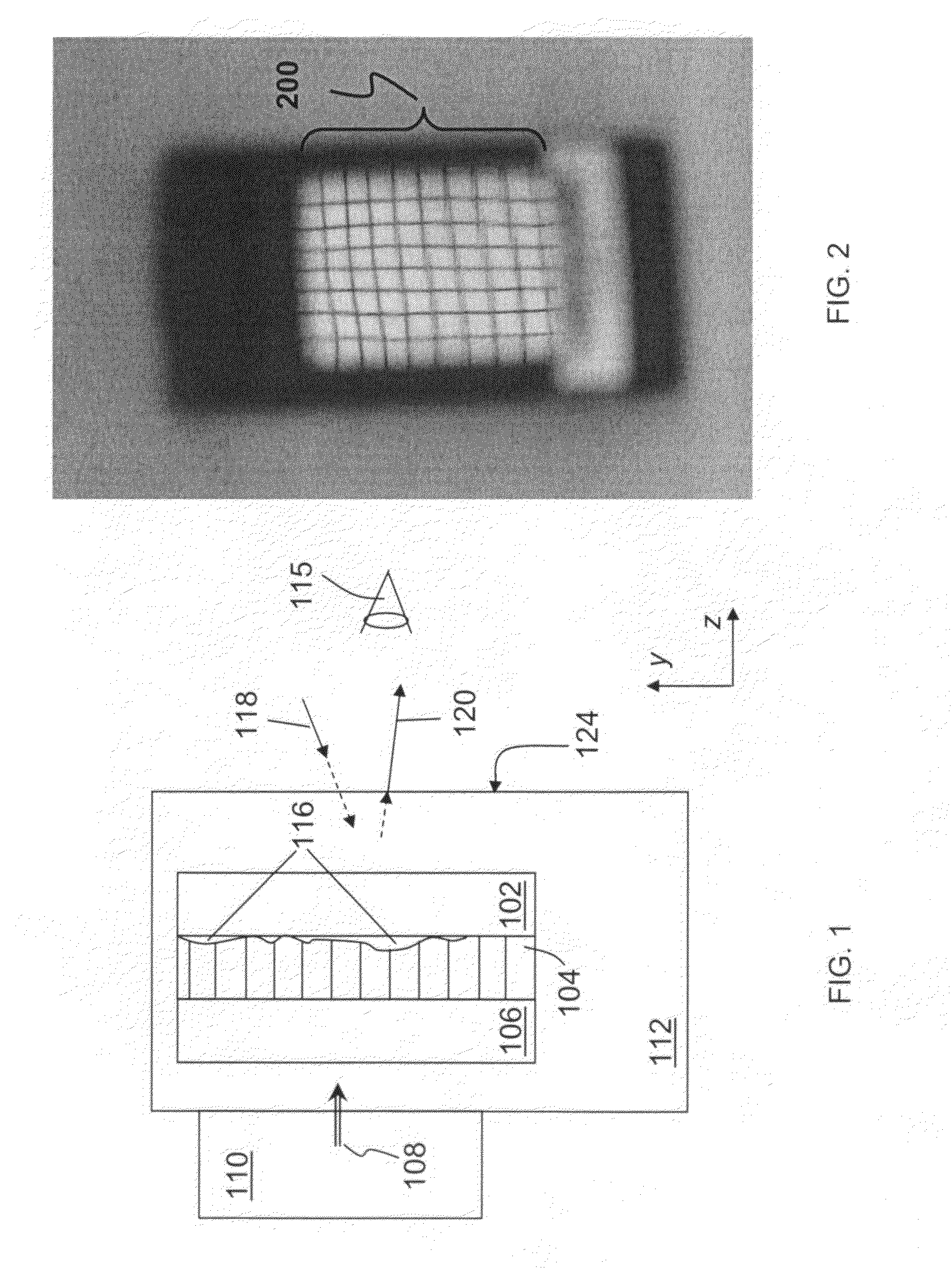

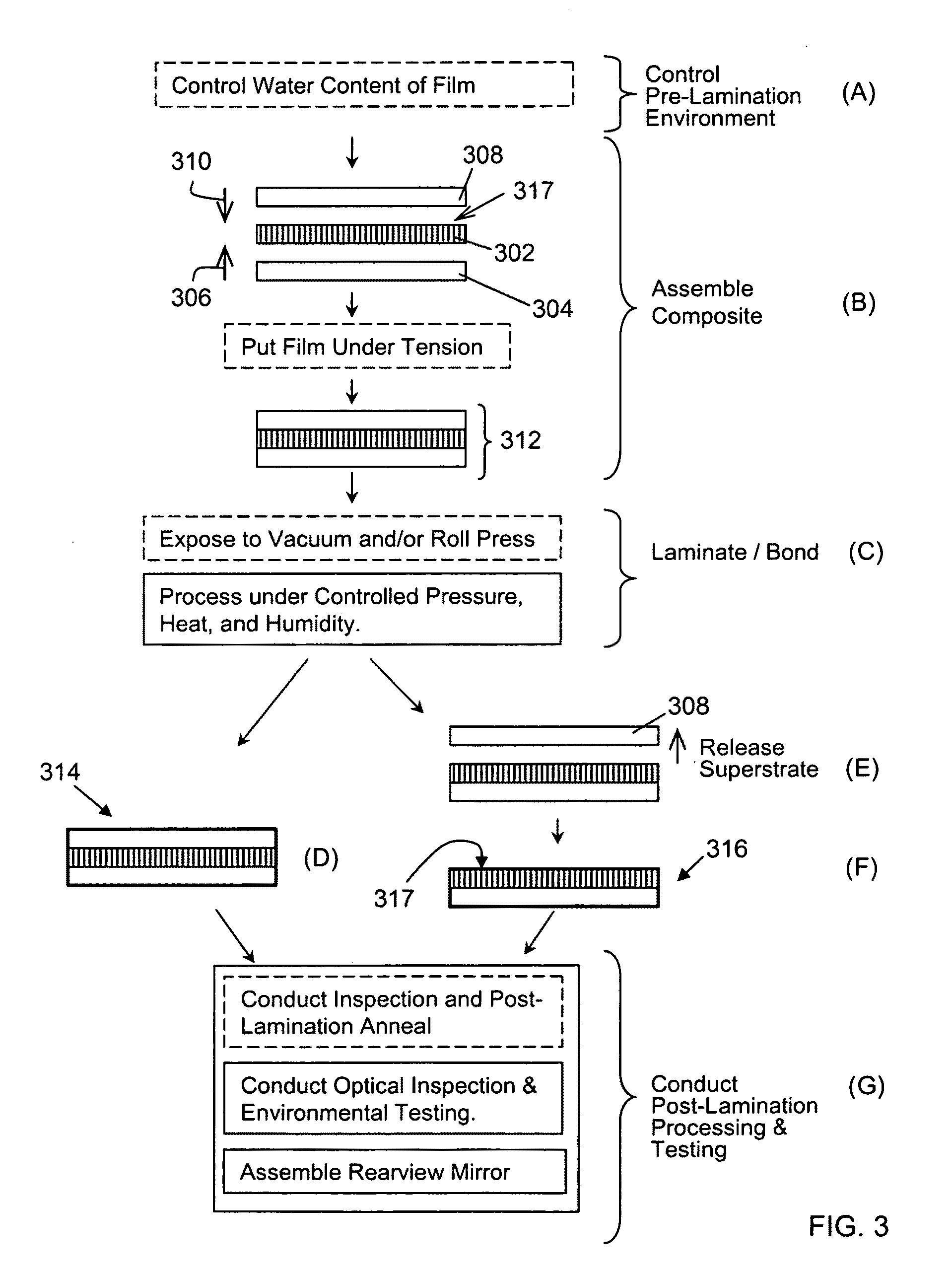

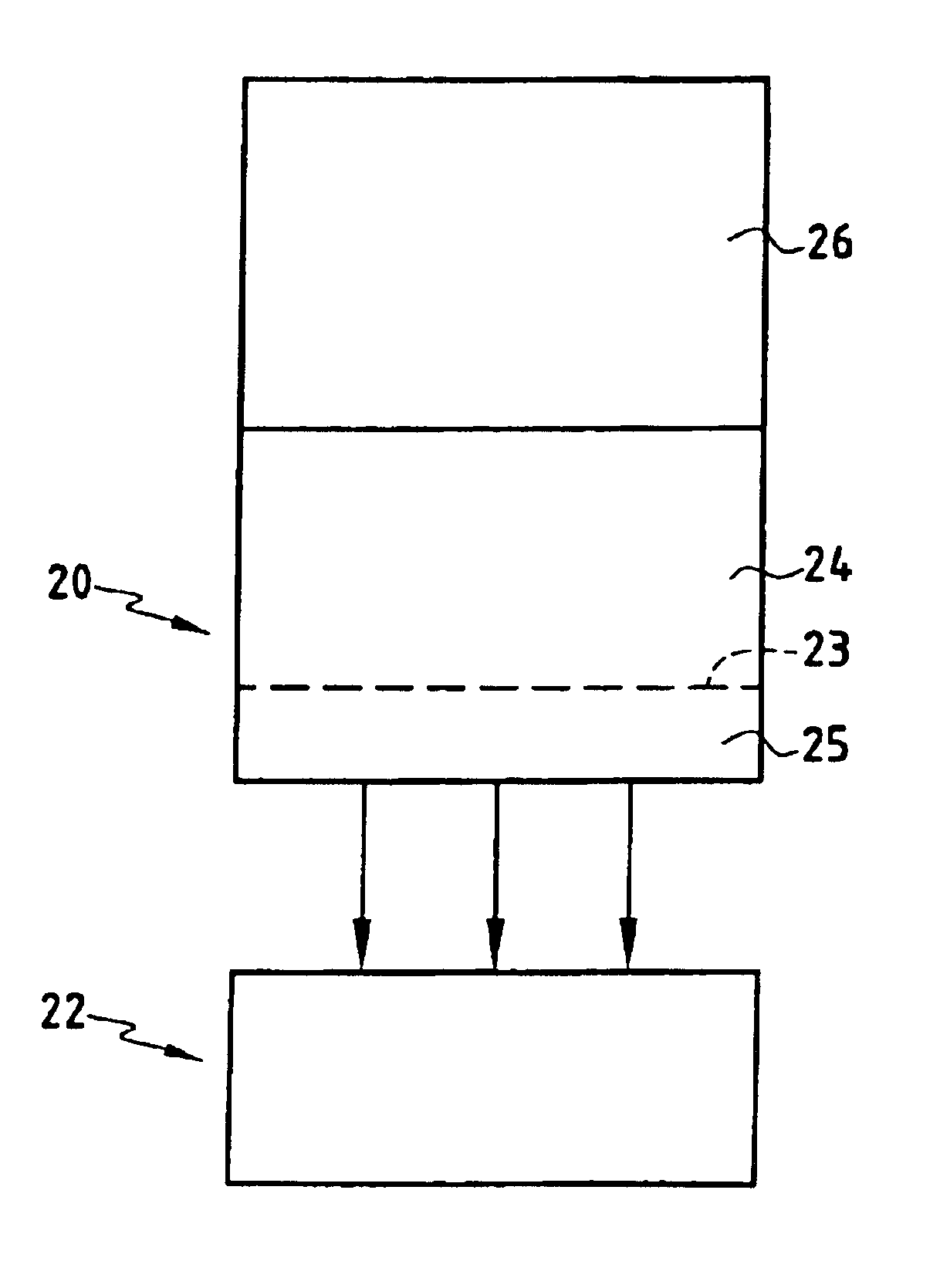

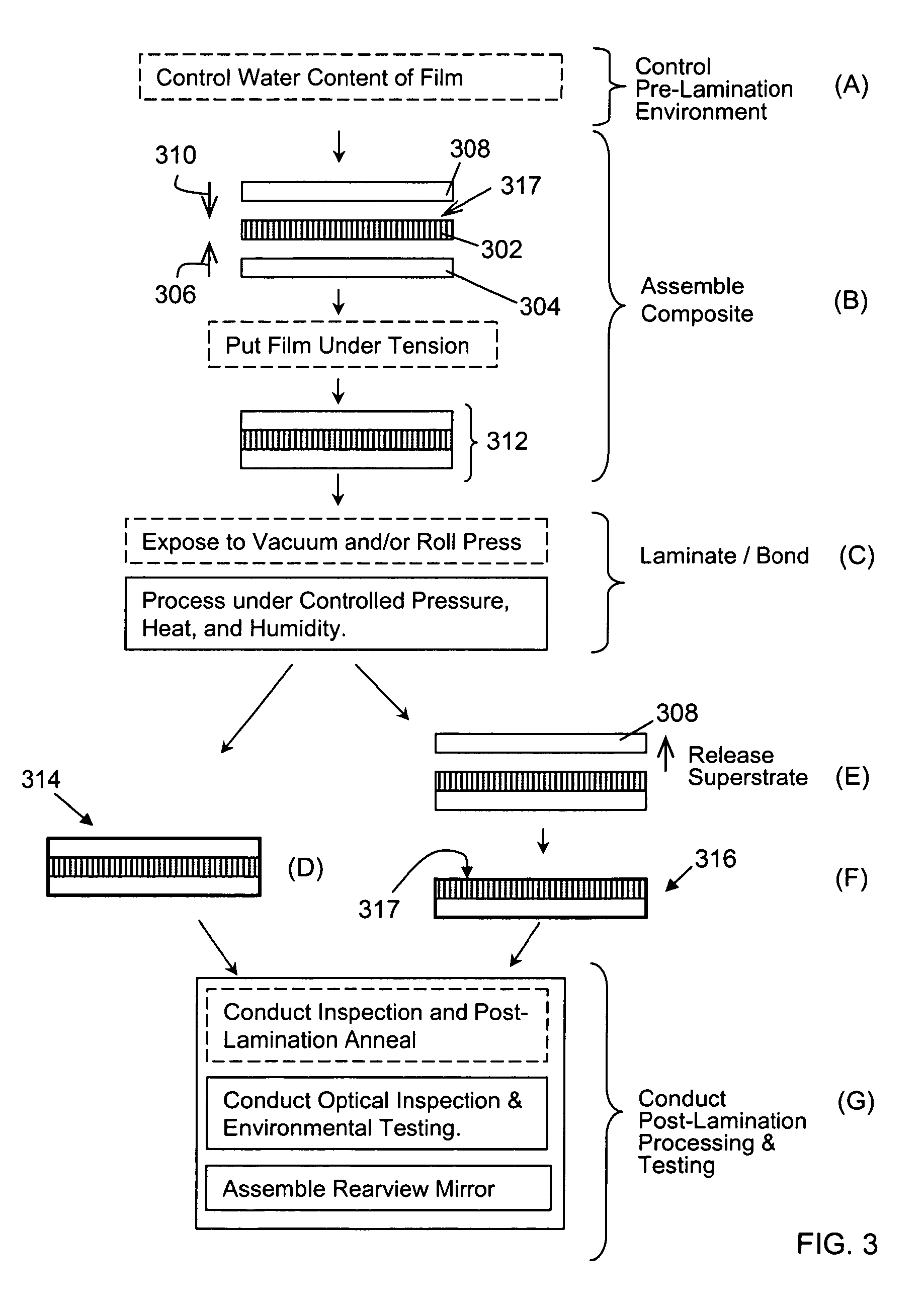

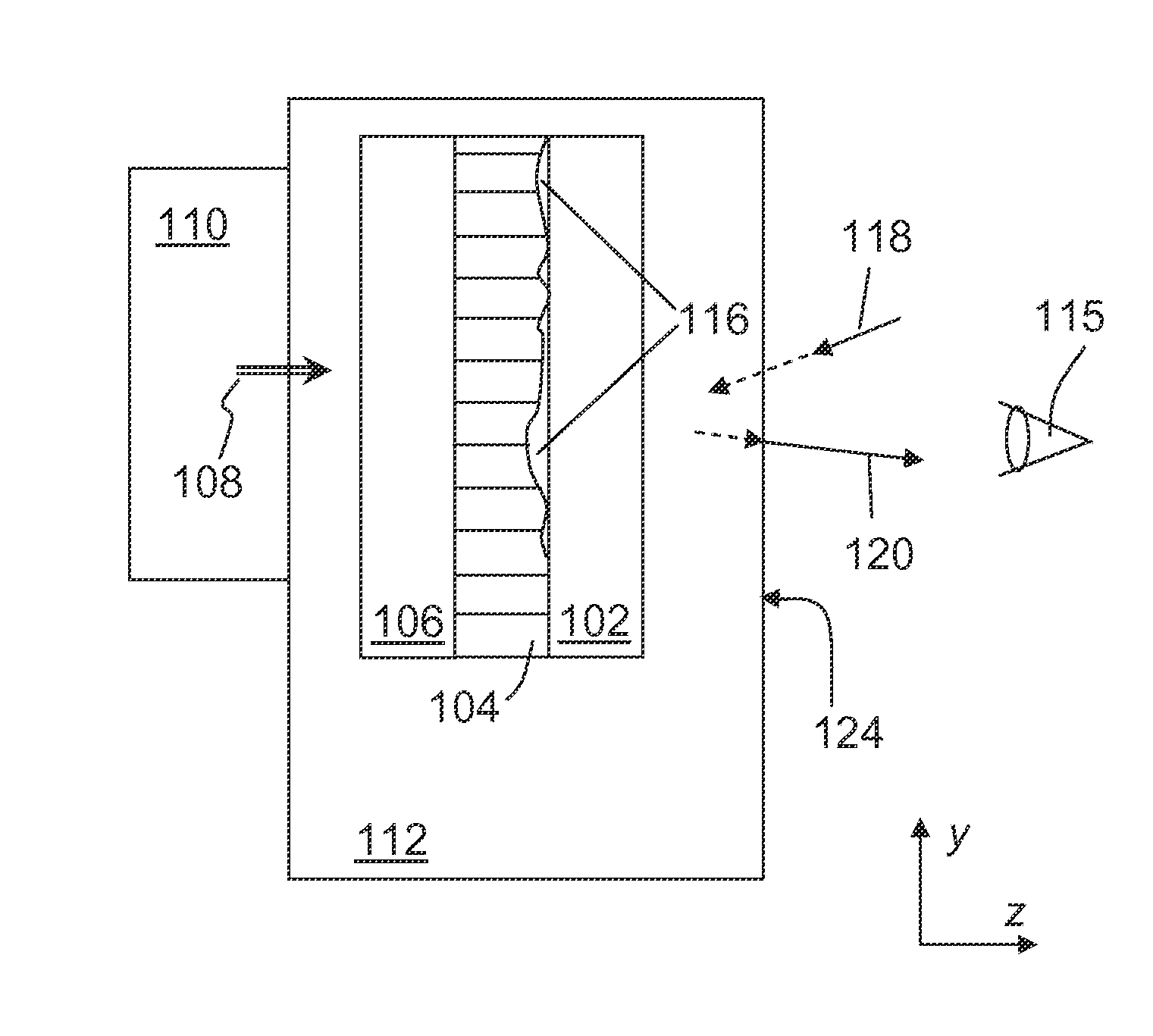

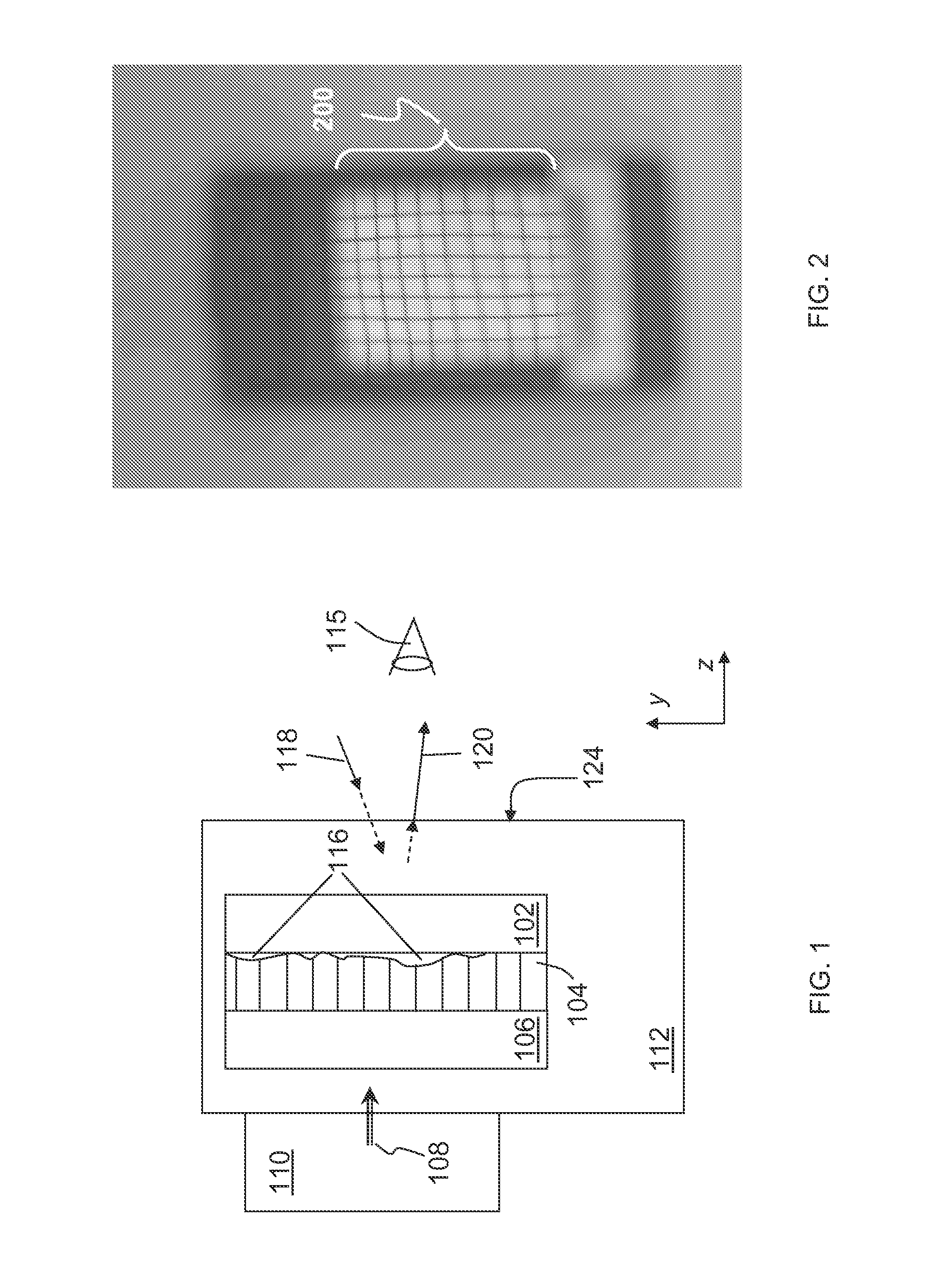

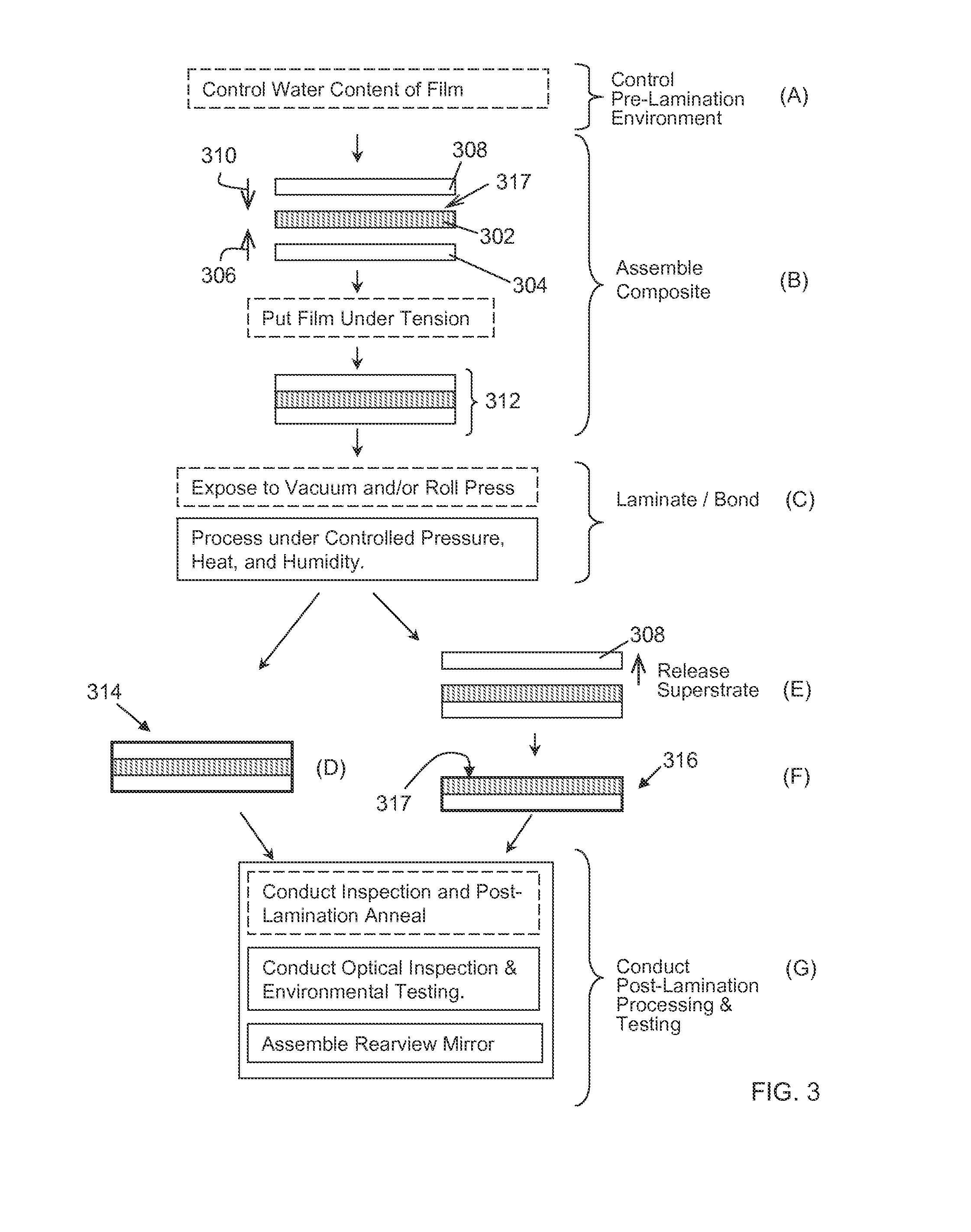

Anisotropic film laminates for use in image-preserving reflectors such as rearview automotive mirror assemblies, and related methods of fabrication. A film may comprise an anisotropic layer such as a light-polarizing layer and other functional layers. The film having controlled water content is heated under omnidirectional pressure and vacuum to a temperature substantially equal to or above a lower limit of a glass-transition temperature range of the film so as to be laminated to a substrate. The laminate is configured as part of a mirror structure so as to increase contrast of light produced by a light source positioned behind the mirror structure and transmitted through the mirror structure towards a viewer. The mirror structure is devoid of any extended distortion and is characterized by SW and LW values less than 3, more preferably less than 2, and most preferably less than 1.

Owner:GENTEX CORP

Rearview Mirror Assemblies with Anisotropic Polymer Laminates

ActiveUS20100110553A1High strengthAdequate flatness of filmMirrorsNon-linear opticsLower limitWing mirror

Anisotropic film laminates for use in image-preserving reflectors such as rearview automotive mirror assemblies, and related methods of fabrication. A film may comprise an anisotropic layer such as a light-polarizing layer and other functional layers. The film having controlled water content is heated under omnidirectional pressure and vacuum to a temperature substantially equal to or above a lower limit of a glass-transition temperature range of the film so as to be laminated to a substrate. The laminate is configured as part of a mirror structure so as to increase contrast of light produced by a light source positioned behind the mirror structure and transmitted through the mirror structure towards a viewer. The mirror structure is devoid of any extended distortion and is characterized by SW and LW values less than 3, more preferably less than 2, and most preferably less than 1.

Owner:GENTEX CORP

Rearview mirror assemblies with anisotropic polymer laminates

ActiveUS8282224B2High strengthAdequate flatness of filmMirrorsNon-linear opticsLower limitGlass transition

Owner:GENTEX CORP

Methods of producing a heterogeneous semiconductor structure

ActiveUS6858517B2Reduce curvatureReduce deformationSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureThermal expansion

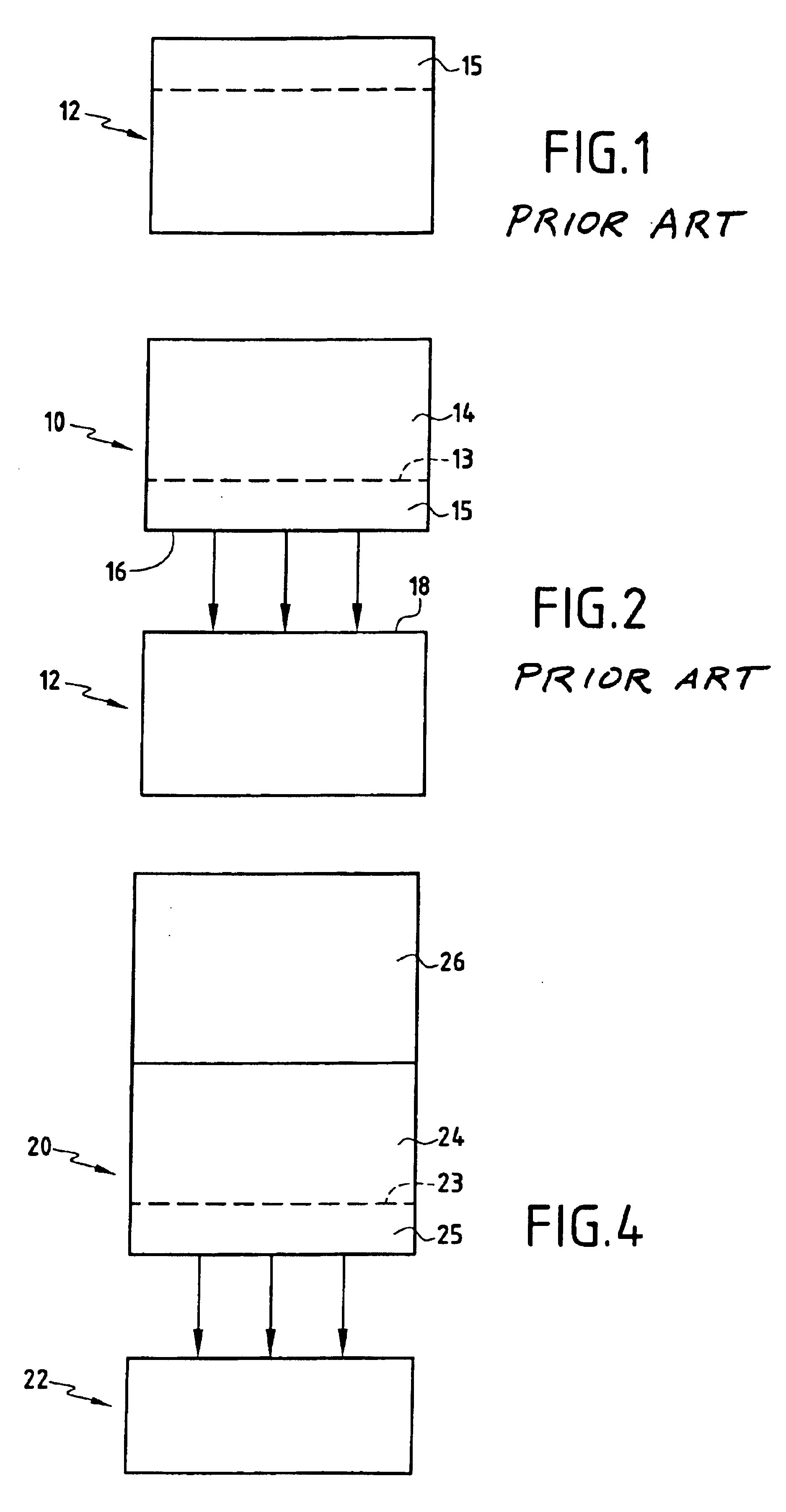

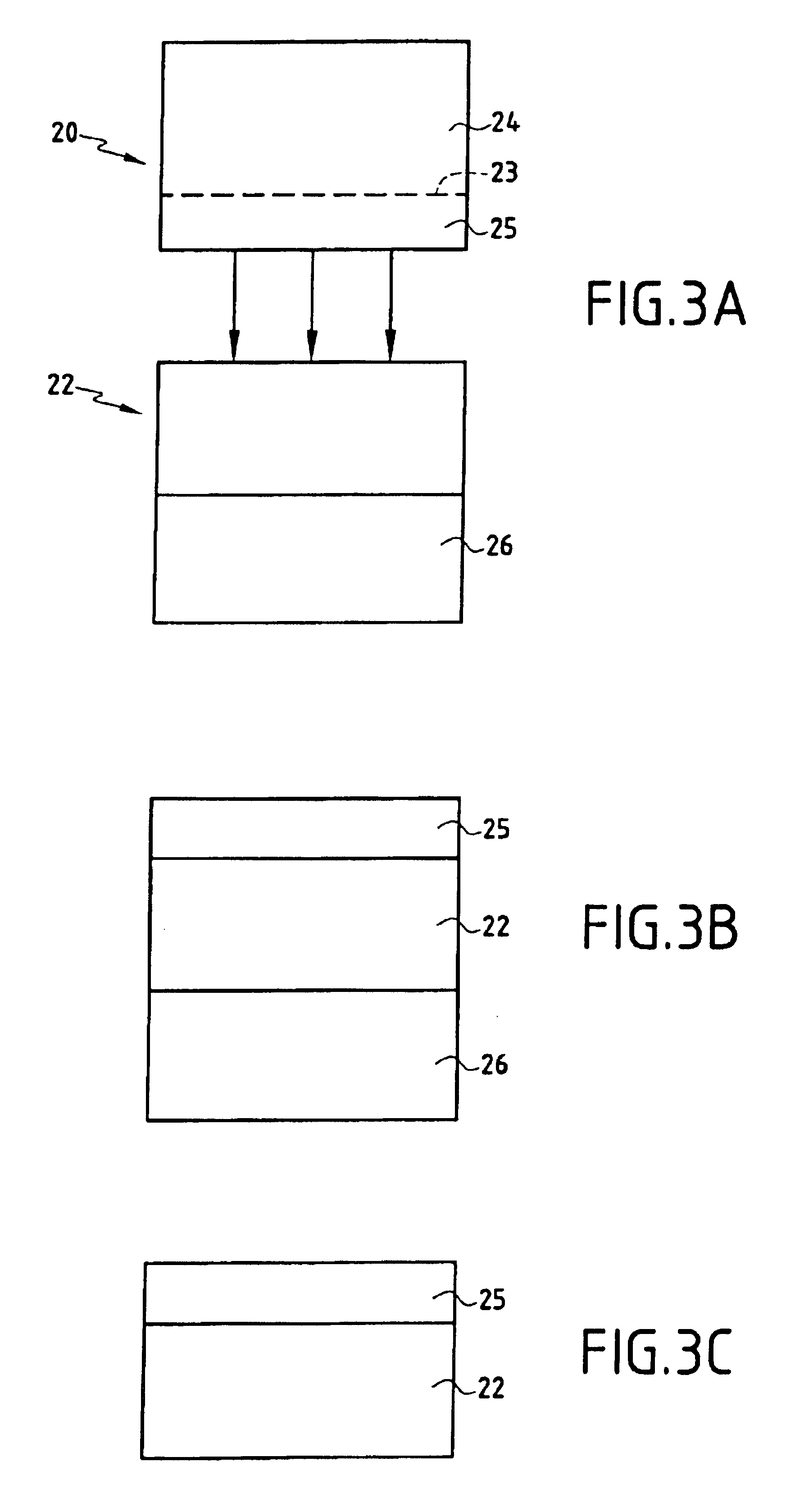

The present invention relates to a method for forming a heterogeneous assembly of first and second materials having different coefficients of thermal expansion. The method includes bonding a surface of a first substrate of a first material to a surface of a second substrate of a second material wherein the first substrate includes a zone of weakness therein to define a transfer layer adjacent the first surface, providing a stiffening substrate of a third material to maintain sufficient flatness and prevent breakage of the transfer layer during detachment from the first substrate, and detaching the transfer layer from the first substrate along the zone of weakness to form a heterogeneous assembly of the transfer layer and second substrate. The stiffening substrate is bonded to one of the first or second substrates and the third material has a coefficient of thermal expansion that is the same as or close to that of the material of the substrate to which the stiffening substrate is bonded to facilitate a successful detachment of the transfer layer from the first substrate.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

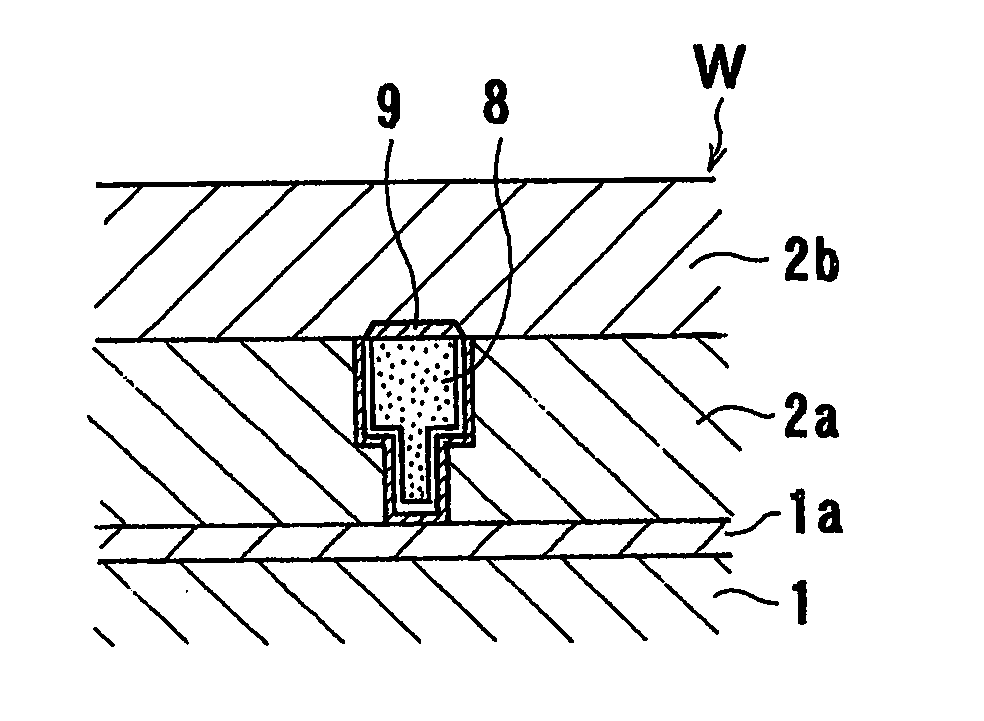

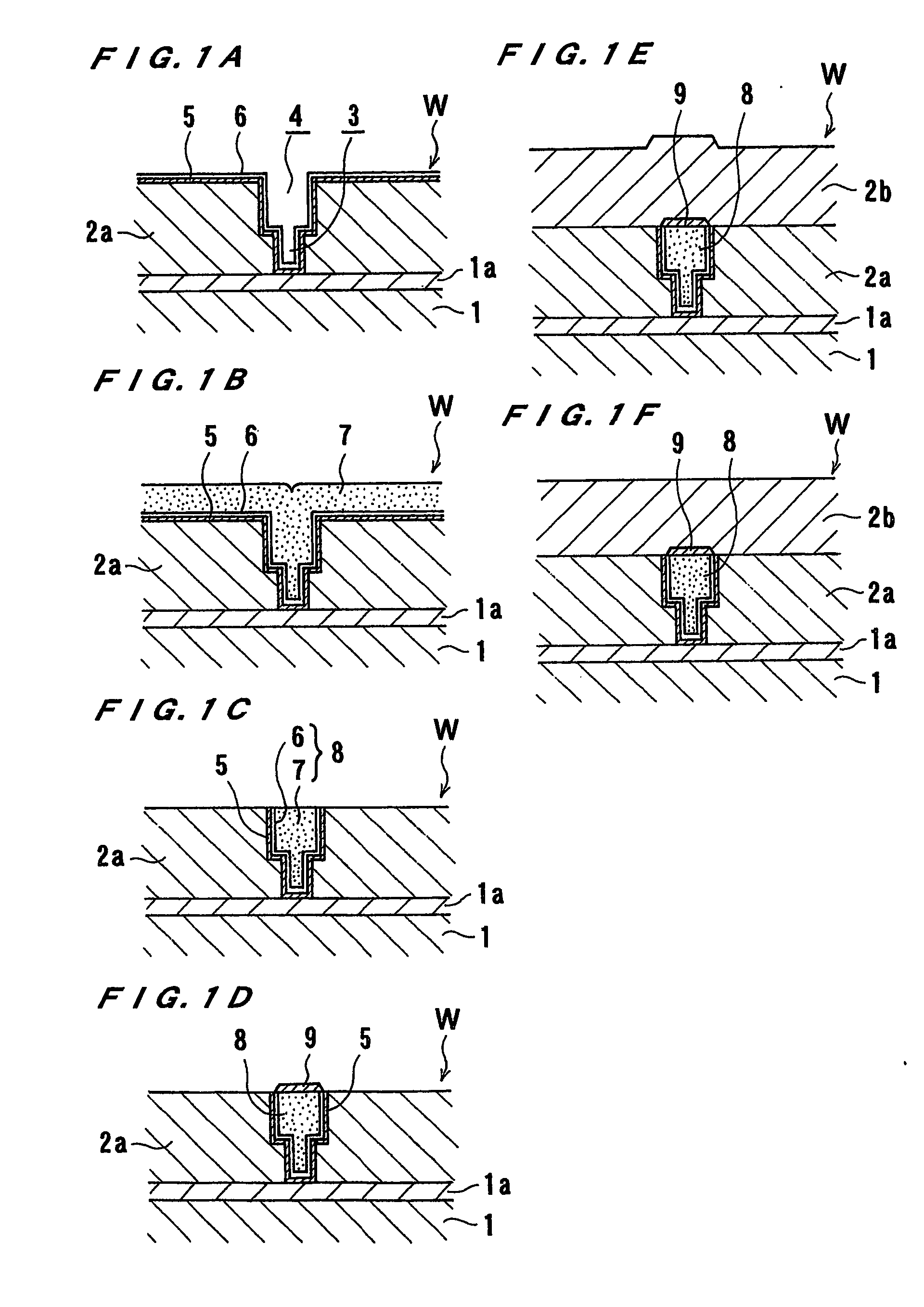

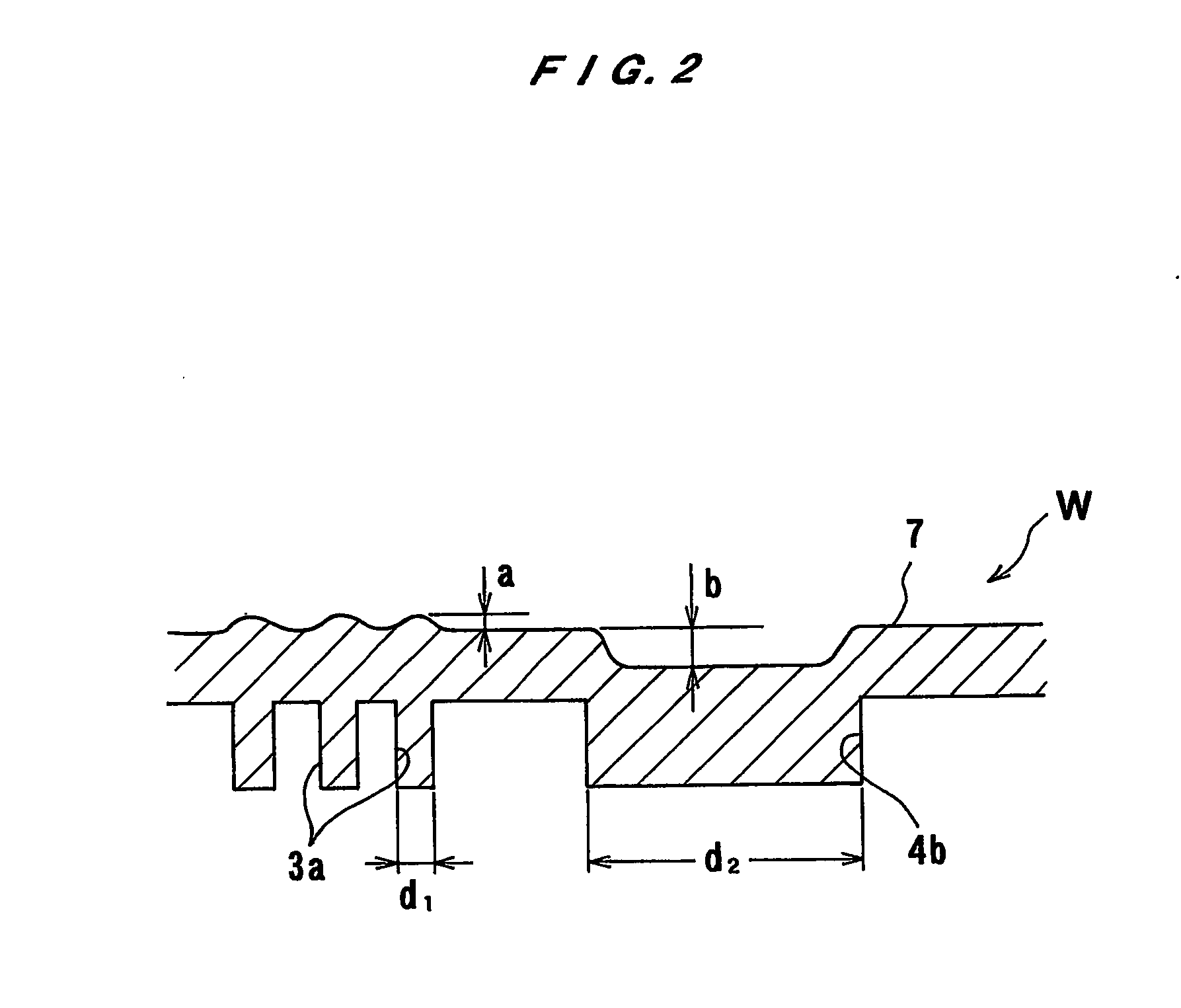

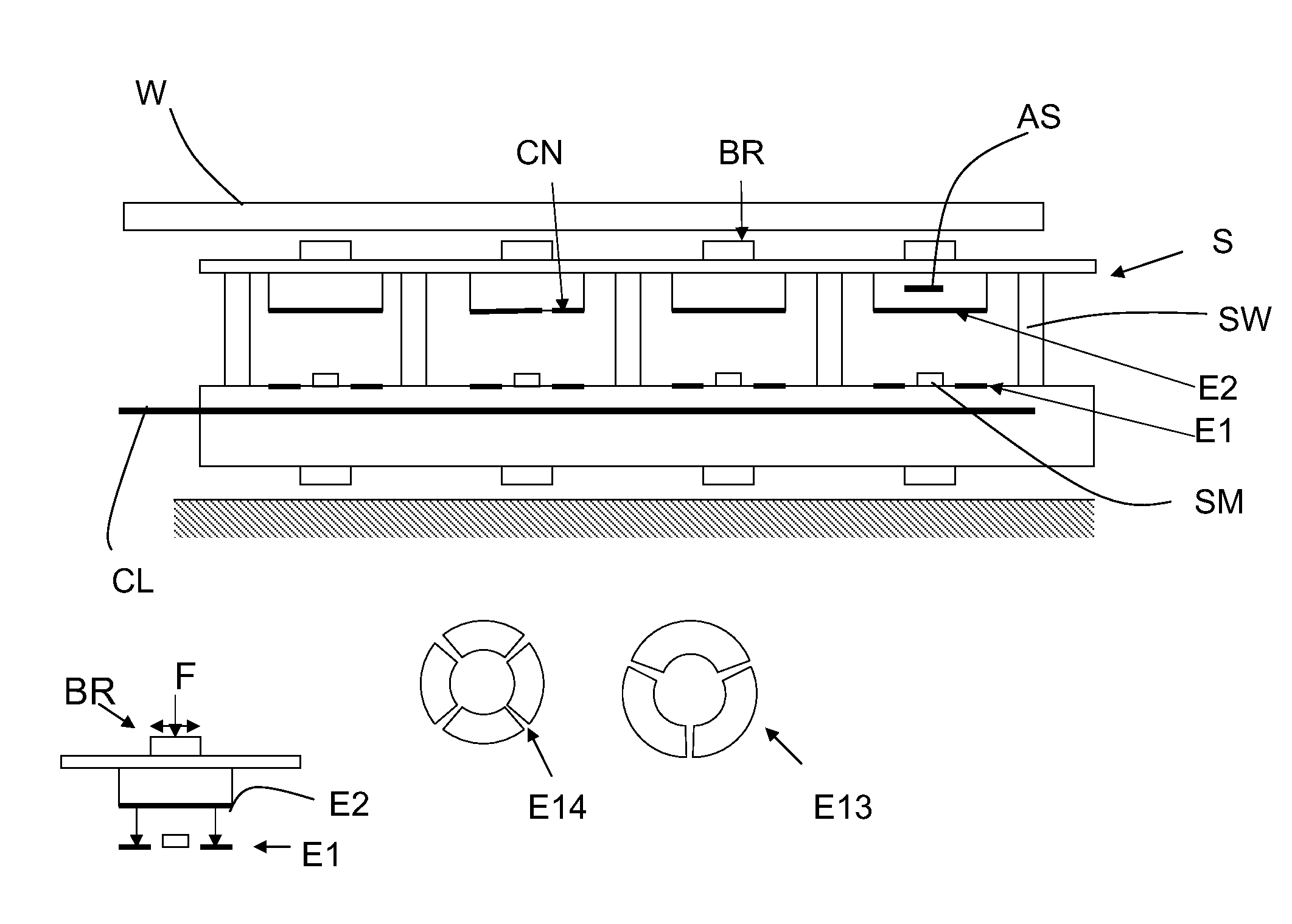

Substrate processing apparatus and substrate processing method

InactiveUS20060234508A1Reduce loadSufficient flatnessElectrolysis componentsSemiconductor/solid-state device manufacturingMaterials scienceElectrolysis

There is provided a substrate processing apparatus which can process a substrate by using an electrolytic processing method, while reducing a load upon a CMP processing to the least possible extent. The substrate processing apparatus of the present invention includes: an electrolytic processing unit (36) for electrolytically removing the surface of the substrate W having a to-be-processed film formed in said surface, said unit including a feeding section (373) that comes into contact with said surface of the substrate W; a bevel-etching unit (48) for etching away the to-be-processed film remaining unprocessed at the portion of the substrate that has been in contact with the feeding section (373) in the electrolytic processing unit (36); a chemical mechanical polishing unit (34) for chemically and mechanically polishing the surface of the substrate.

Owner:EBARA CORP

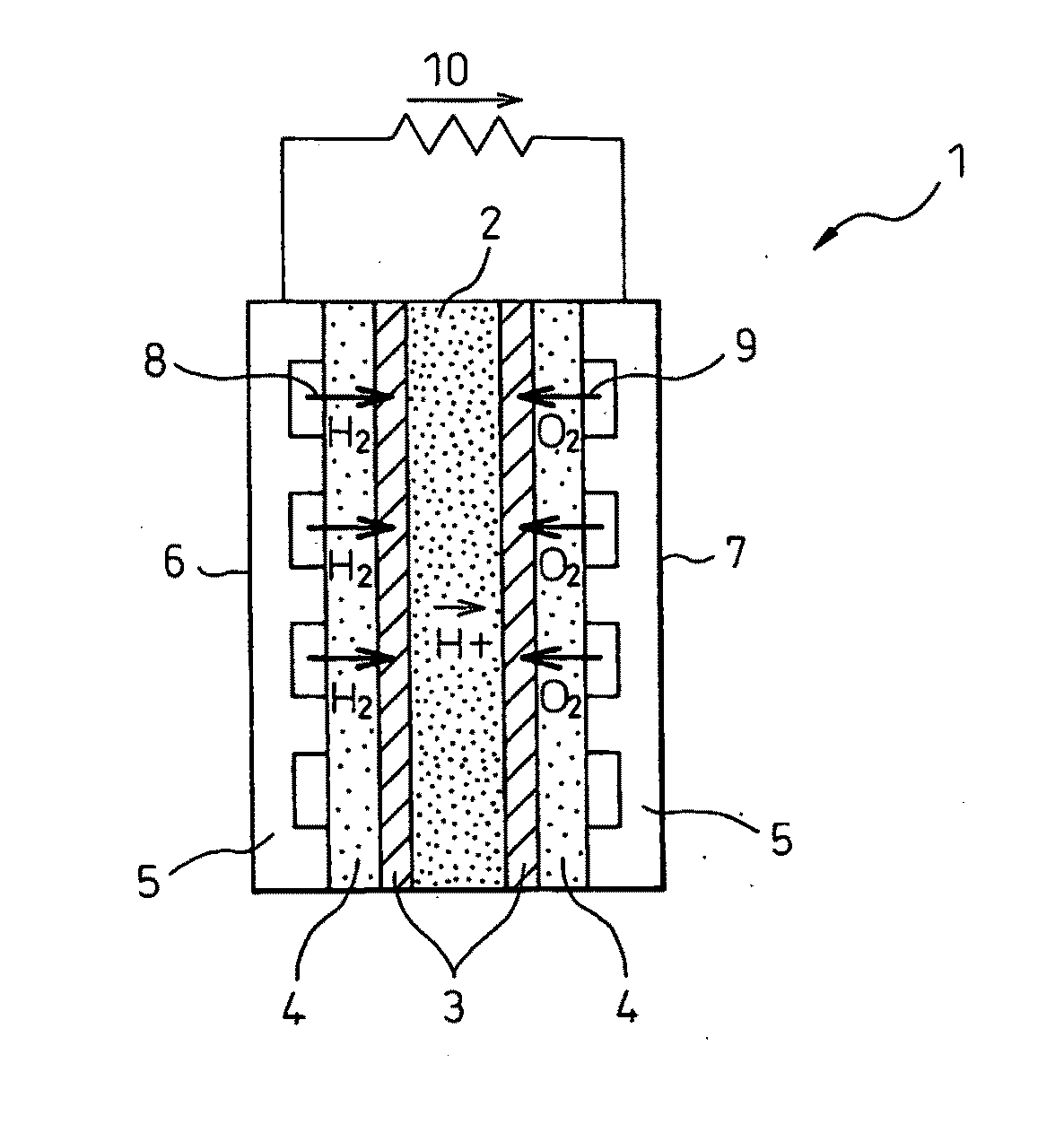

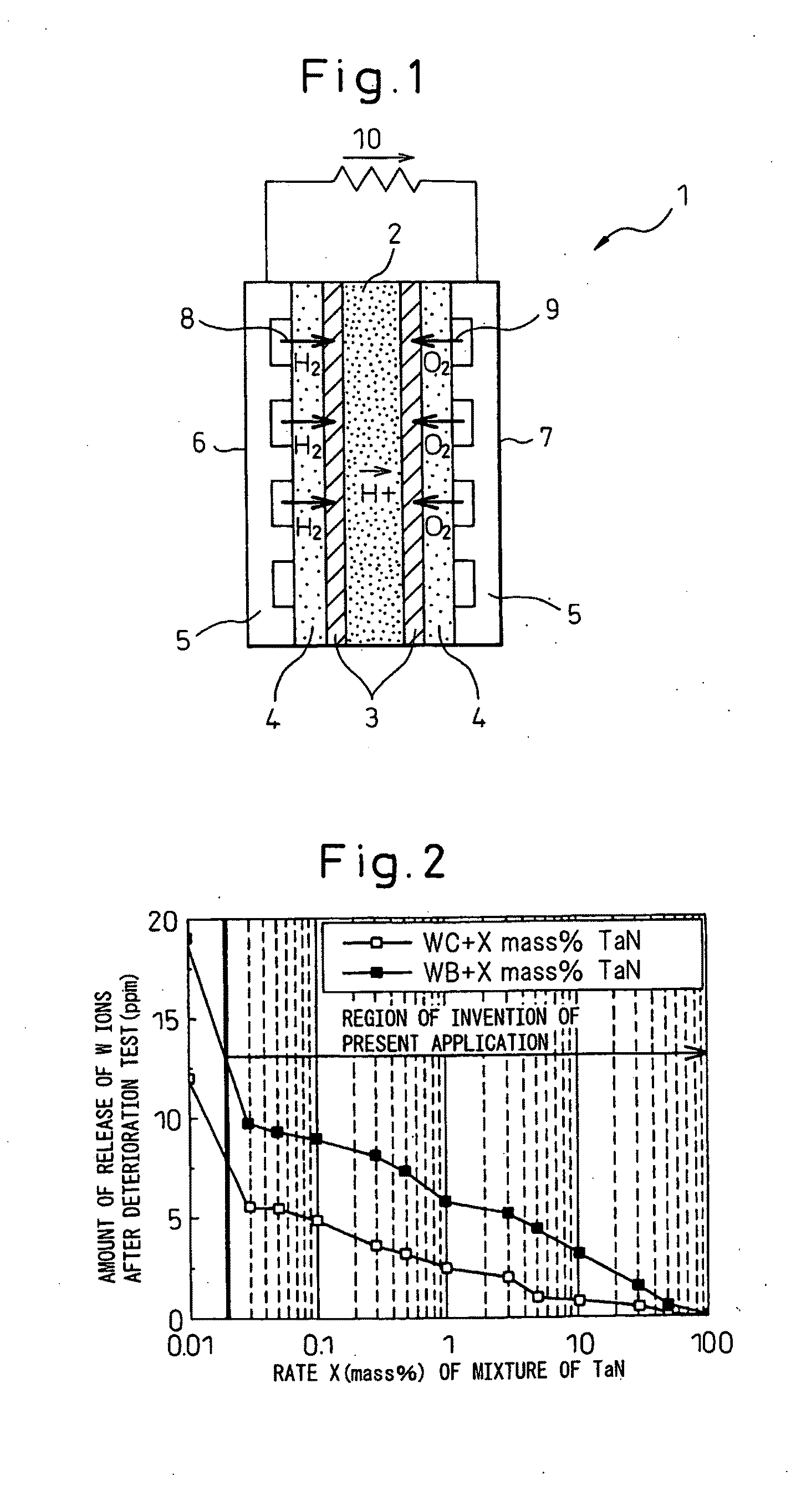

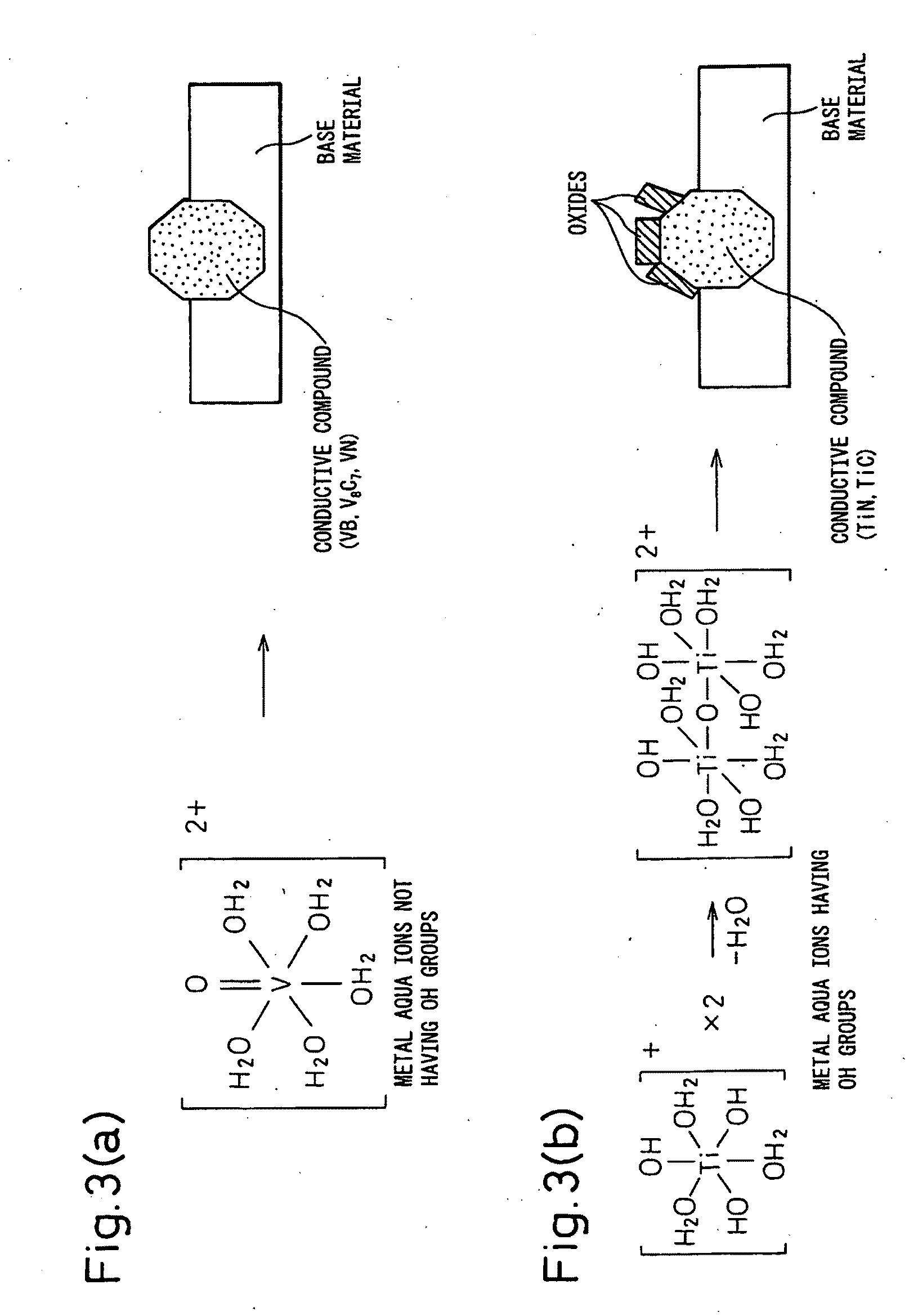

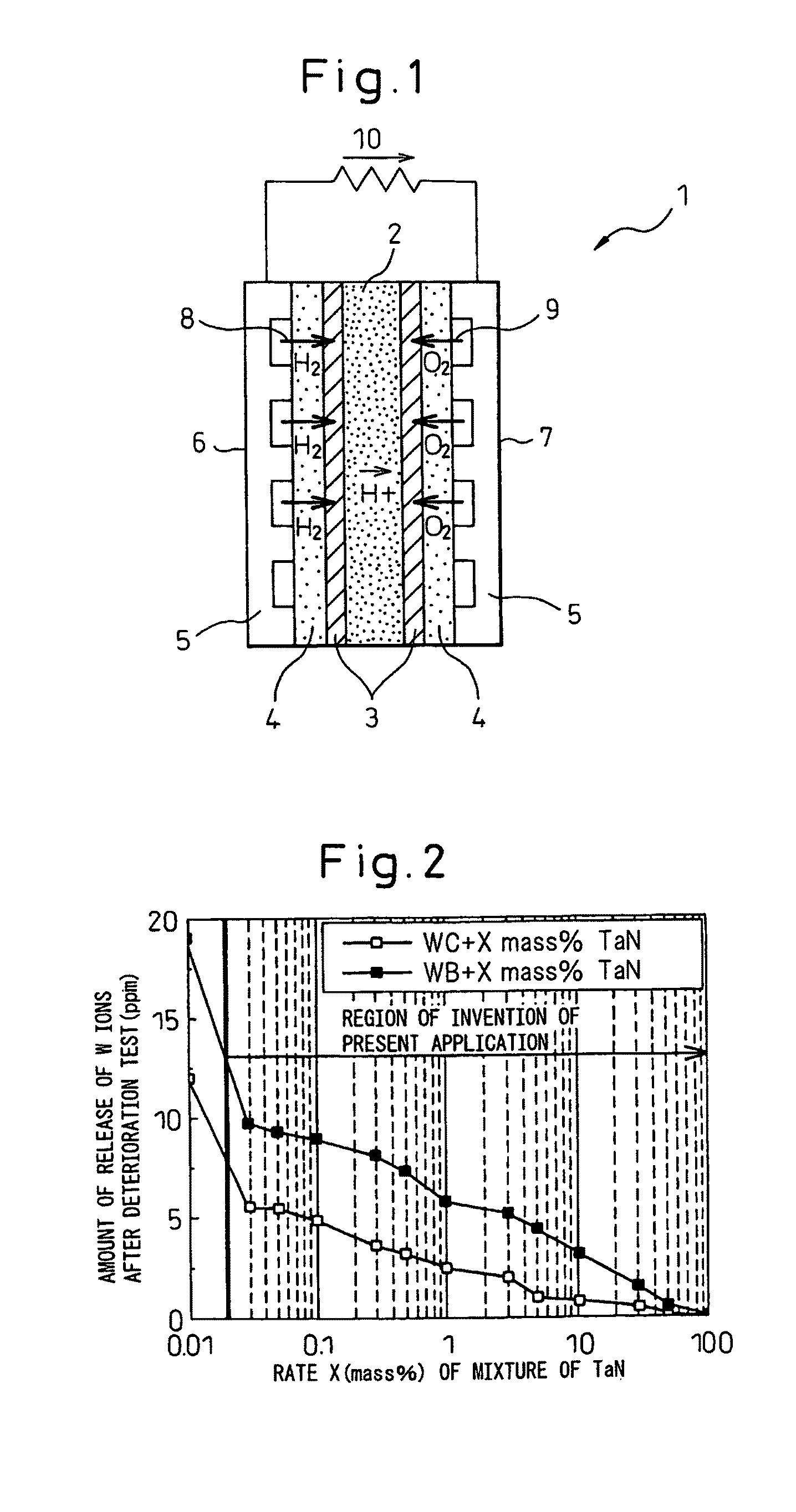

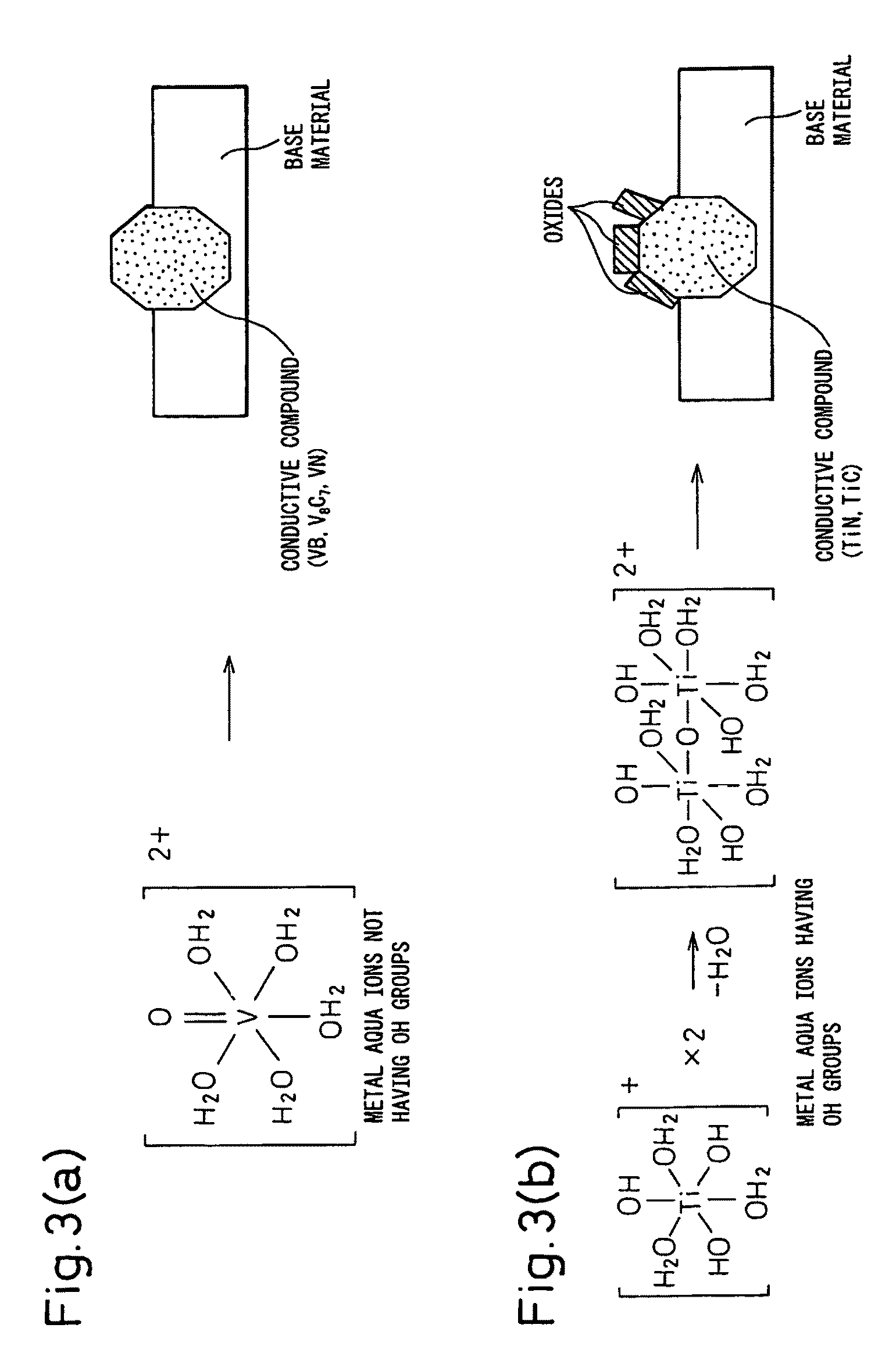

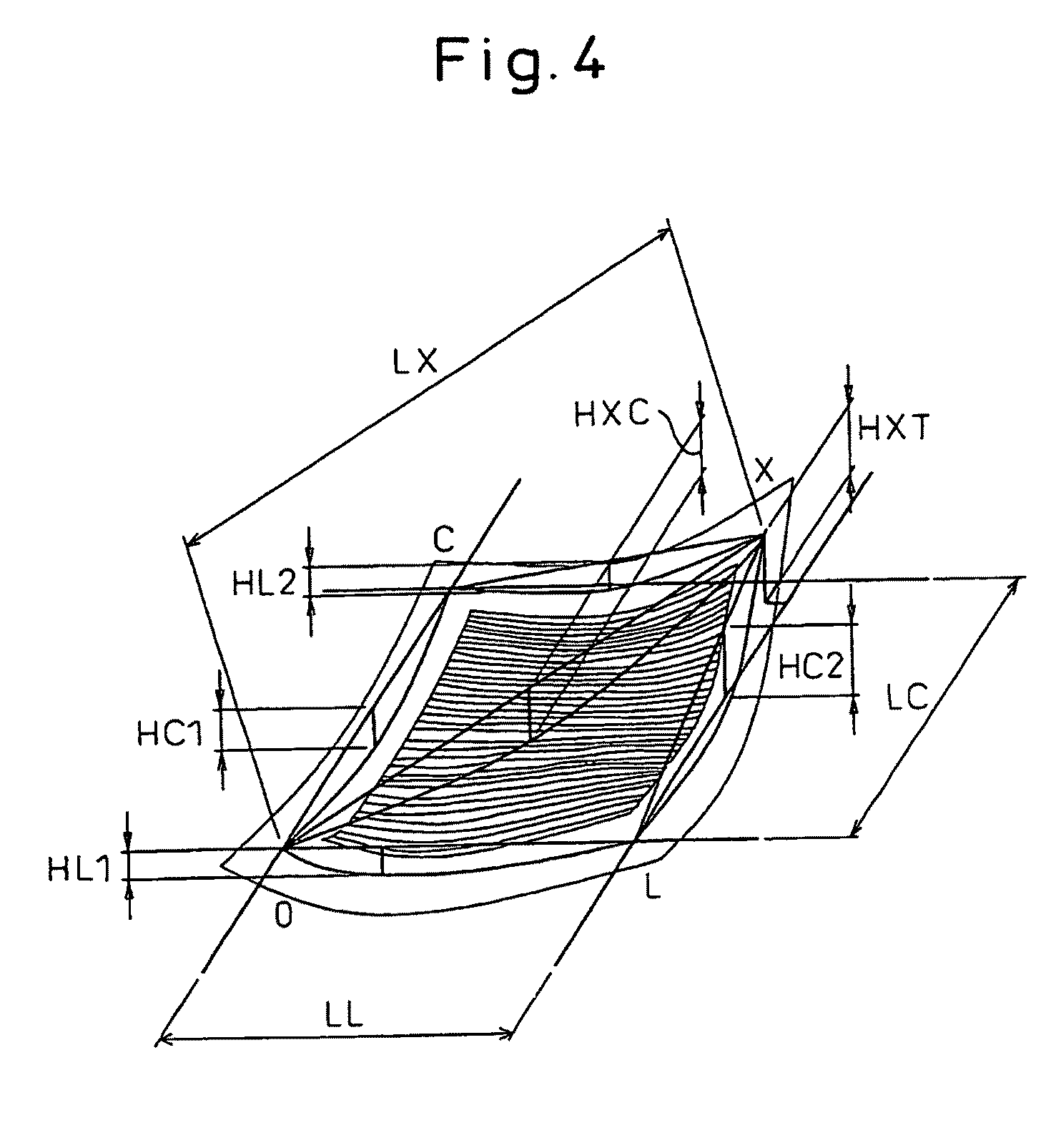

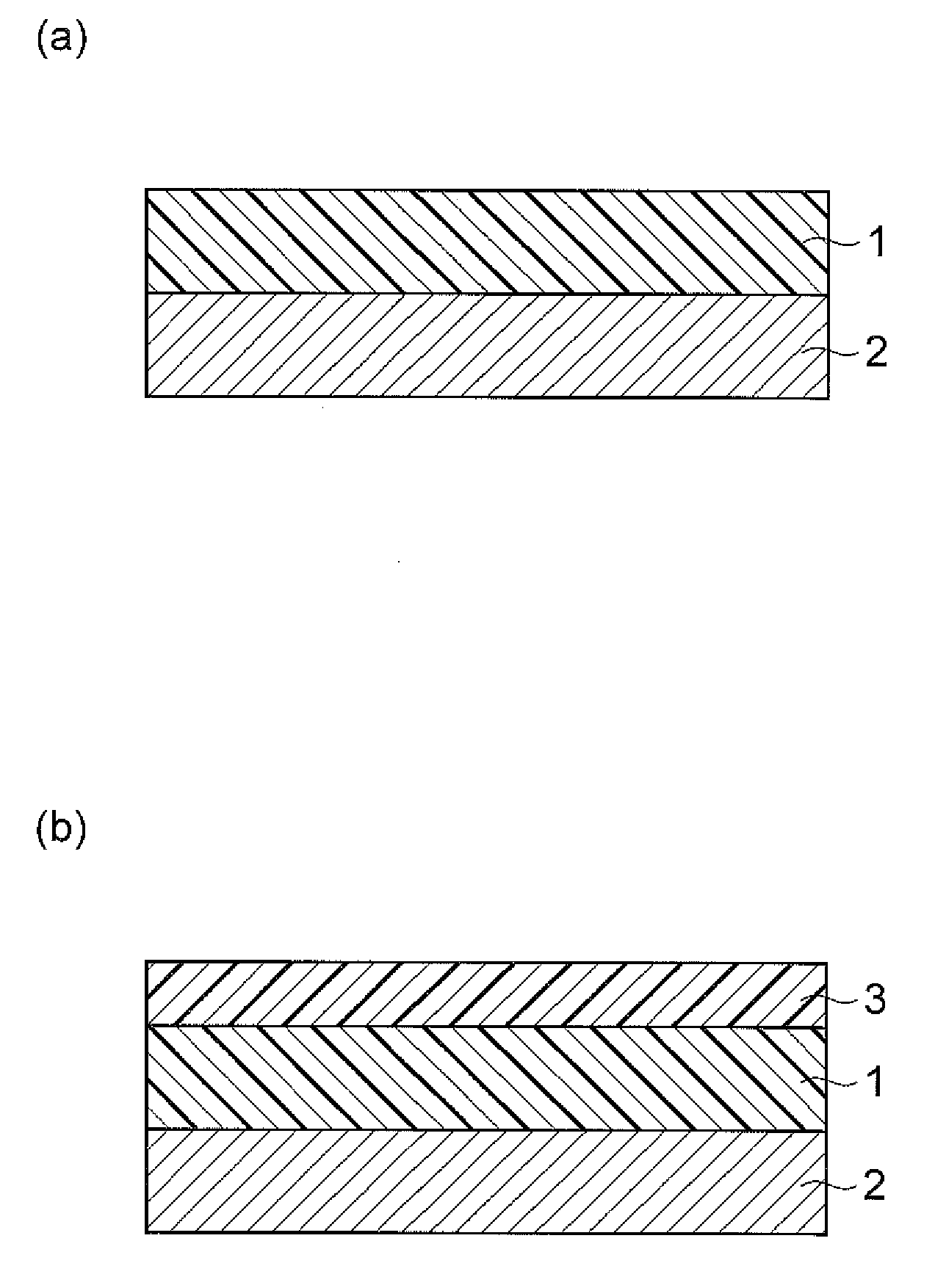

Stainless Steel, Titanium, or Titanium Alloy Solid Polymer Fuel Cell Separator and Its Method of Produciton and Method of Evaluation of Warp and Twist of Separator

ActiveUS20090226785A1Little dropLow costTransportation and packagingFinal product manufactureTitanium alloyContact resistance

The present invention releases a method of producing a metal separator for a solid polymer fuel cell by stainless steel, titanium, or titanium alloy during which securing lower cost and mass producibility by using a material having a high workability to form a complicated shape by a high productivity, then using an inexpensive blast process to drive a conductive substance into the surface of the metal separator member, that is, provides a stainless steel, titanium, or titanium alloy solid polymer fuel cell separator comprised of stainless steel, titanium, or titanium alloy in the surface of which a low ion release conductive substance is buried, having an arithmetic mean roughness (Ra) of the separator surface of 0.5 to 5.0 μm, having a 10-point mean roughness (Rz) of 3 to 20 μm, having an average spacing of surface relief shapes (Sm) of 300 μm or less, having values of a warp rate and twist rate of a separator of 0.1 or less, and having a contact resistance value with respect to carbon paper of 15 mΩcm2 or less at a surface pressure of 1 MPa.

Owner:SINTOKOGIO LTD

Rearview mirror assemblies with anisotropic polymer laminates

ActiveUS9254789B2High strengthAdequate flatness of filmMirrorsPolarising elementsVitrificationLower limit

Anisotropic film laminates for use in image-preserving reflectors such as rearview automotive mirror assemblies, and related methods of fabrication. A film may comprise an anisotropic layer such as a light-polarizing layer and other functional layers. The film having controlled water content is heated under omnidirectional pressure and vacuum to a temperature substantially equal to or above a lower limit of a glass-transition temperature range of the film so as to be laminated to a substrate. The laminate is configured as part of a mirror structure so as to increase contrast of light produced by a light source positioned behind the mirror structure and transmitted through the mirror structure towards a viewer. The mirror structure is devoid of any extended distortion and is characterized by SW and LW values less than 3, more preferably less than 2, and most preferably less than 1.

Owner:GENTEX CORP

Variable reflectance mirror system

ActiveUS20140036339A1High strengthAdequate flatness of filmSynthetic resin layered productsOptical articlesLower limitGlass transition

Anisotropic film laminates for use in image-preserving reflectors such as rearview automotive mirror assemblies, and related methods of fabrication. A film may comprise an anisotropic layer such as a light-polarizing layer and other functional layers. The film having controlled water content is heated under omnidirectional pressure and vacuum to a temperature substantially equal to or above a lower limit of a glass-transition temperature range of the film so as to be laminated to a substrate. The laminated film is configured as part of a mirror structure so as to increase contrast of light produced by a light source positioned behind the mirror structure and transmitted through the mirror structure towards a viewer. The mirror structure is devoid of any extended distortion and is characterized by SW and LW values less than 3, more preferably less than 2, and most preferably less than 1.

Owner:GENTEX CORP

Rearview mirror assemblies with anisotropic polymer laminates

ActiveUS8545030B2High strengthAdequate flatness of filmMirrorsSynthetic resin layered productsLower limitOptoelectronics

Anisotropic film laminates for use in image-preserving reflectors such as rearview automotive mirror assemblies, and related methods of fabrication. A film may comprise an anisotropic layer such as a light-polarizing layer and other functional layers. The film having controlled water content is heated under omnidirectional pressure and vacuum to a temperature substantially equal to or above a lower limit of a glass-transition temperature range of the film so as to be laminated to a substrate. The laminate is configured as part of a mirror structure so as to increase contrast of light produced by a light source positioned behind the mirror structure and transmitted through the mirror structure towards a viewer. The mirror structure is devoid of any extended distortion and is characterized by SW and LW values less than 3, more preferably less than 2, and most preferably less than 1.

Owner:GENTEX CORP

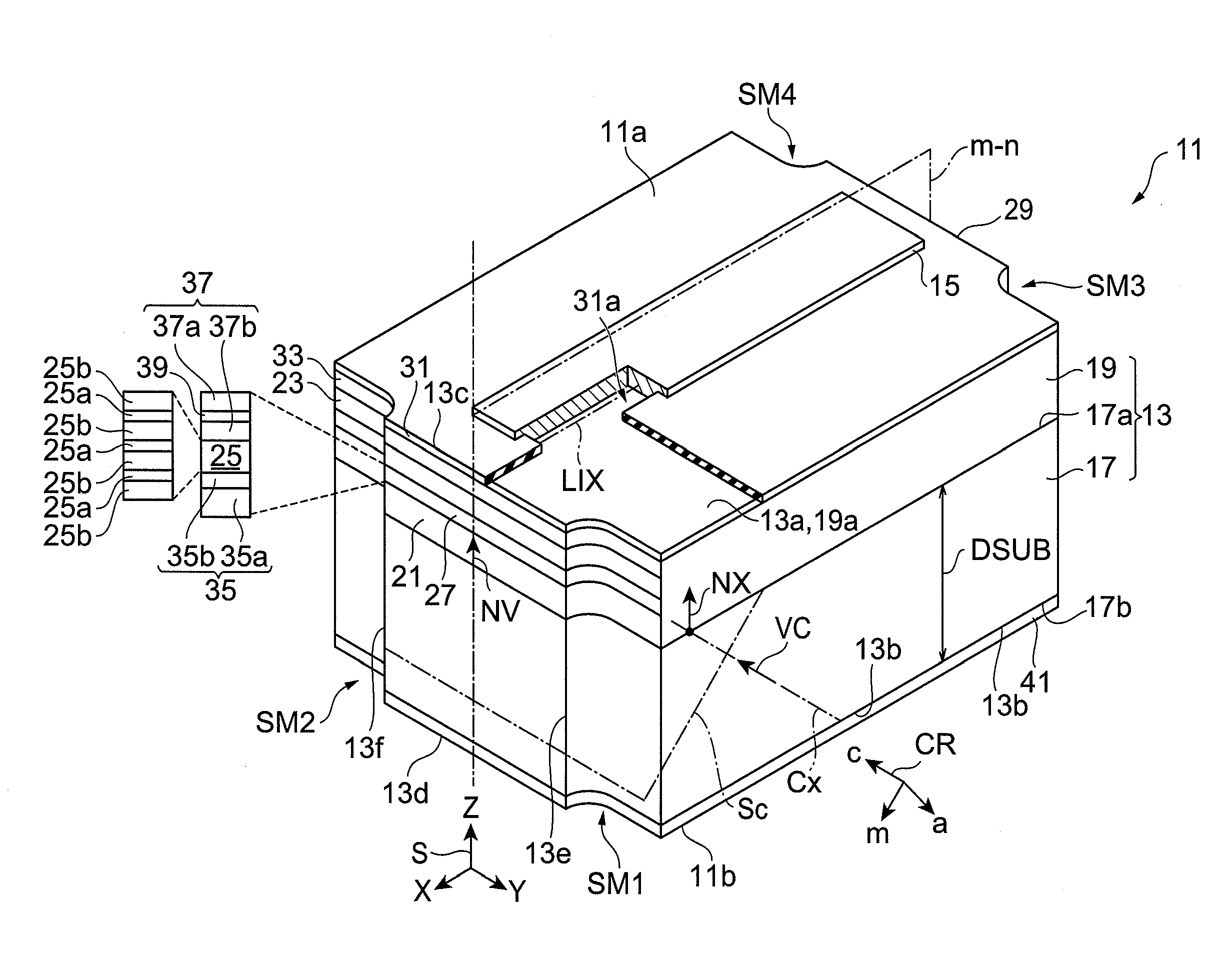

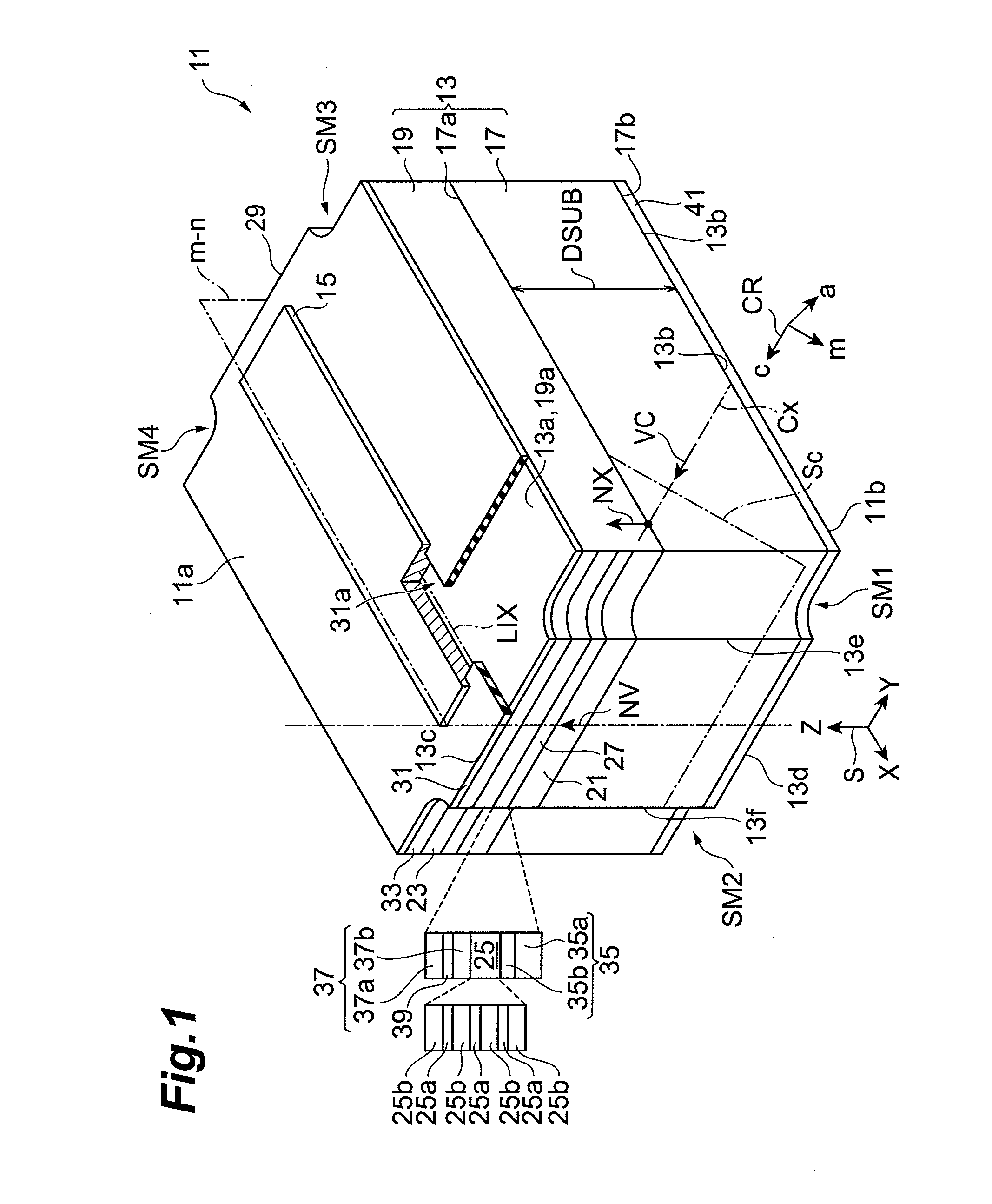

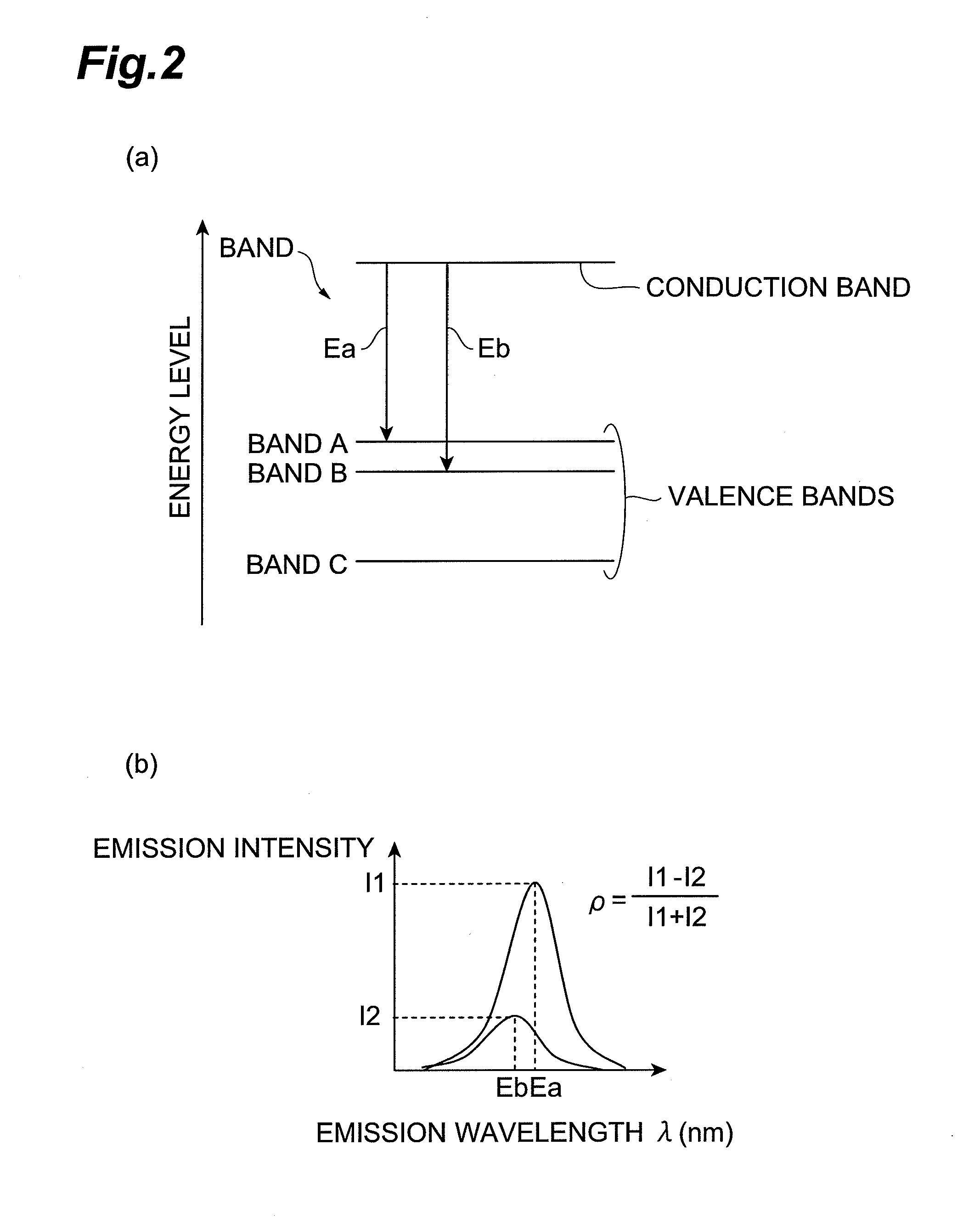

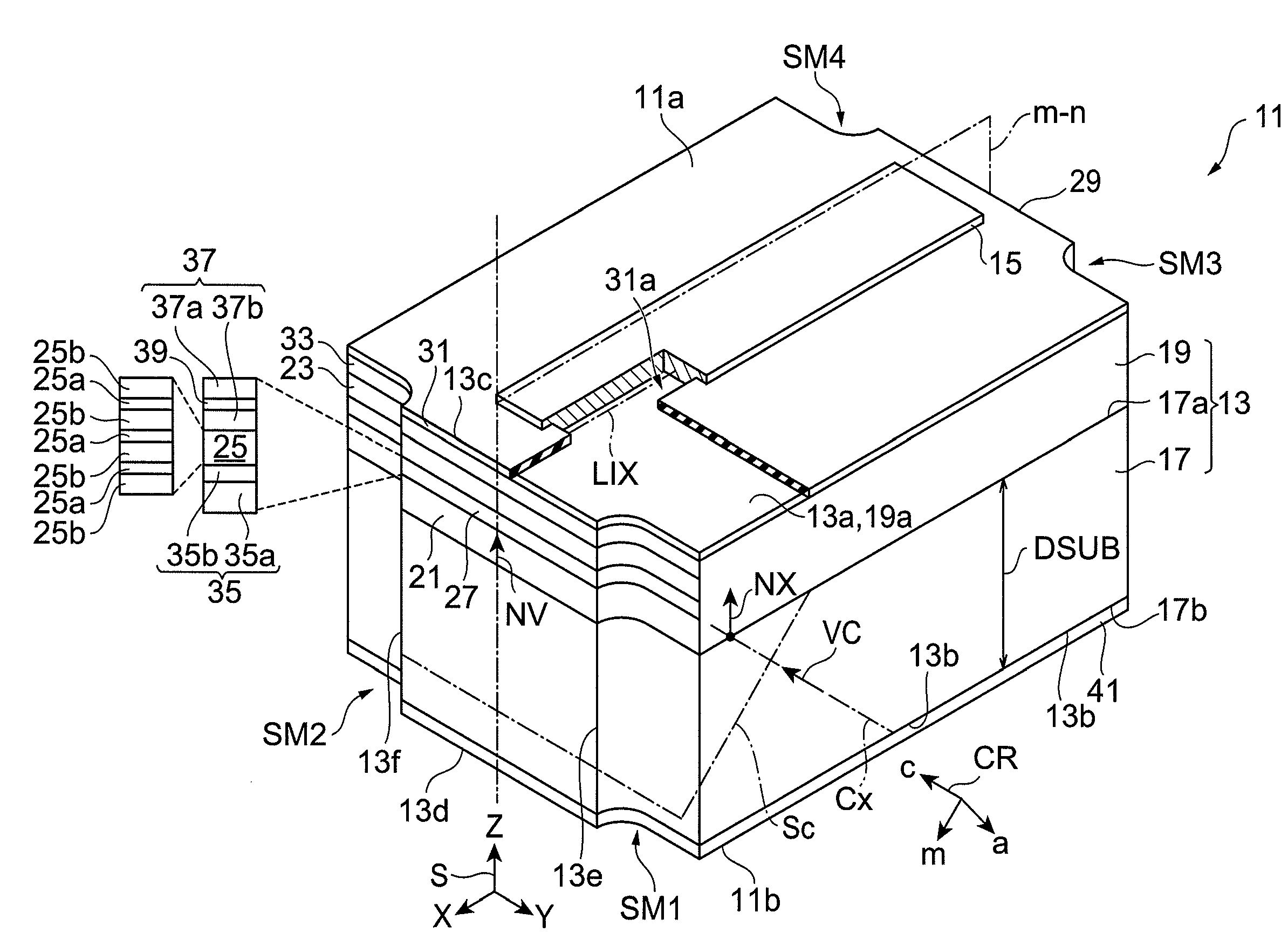

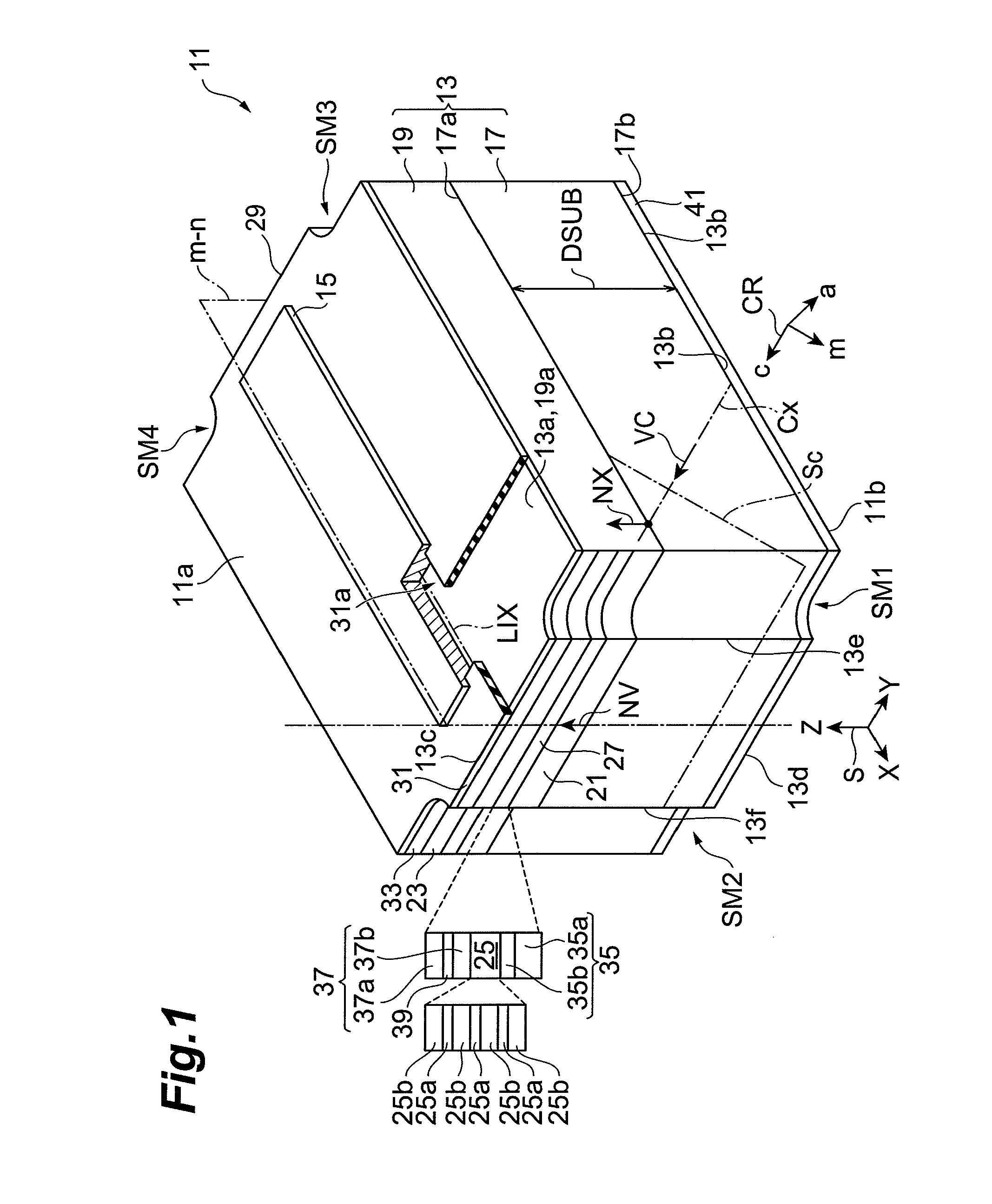

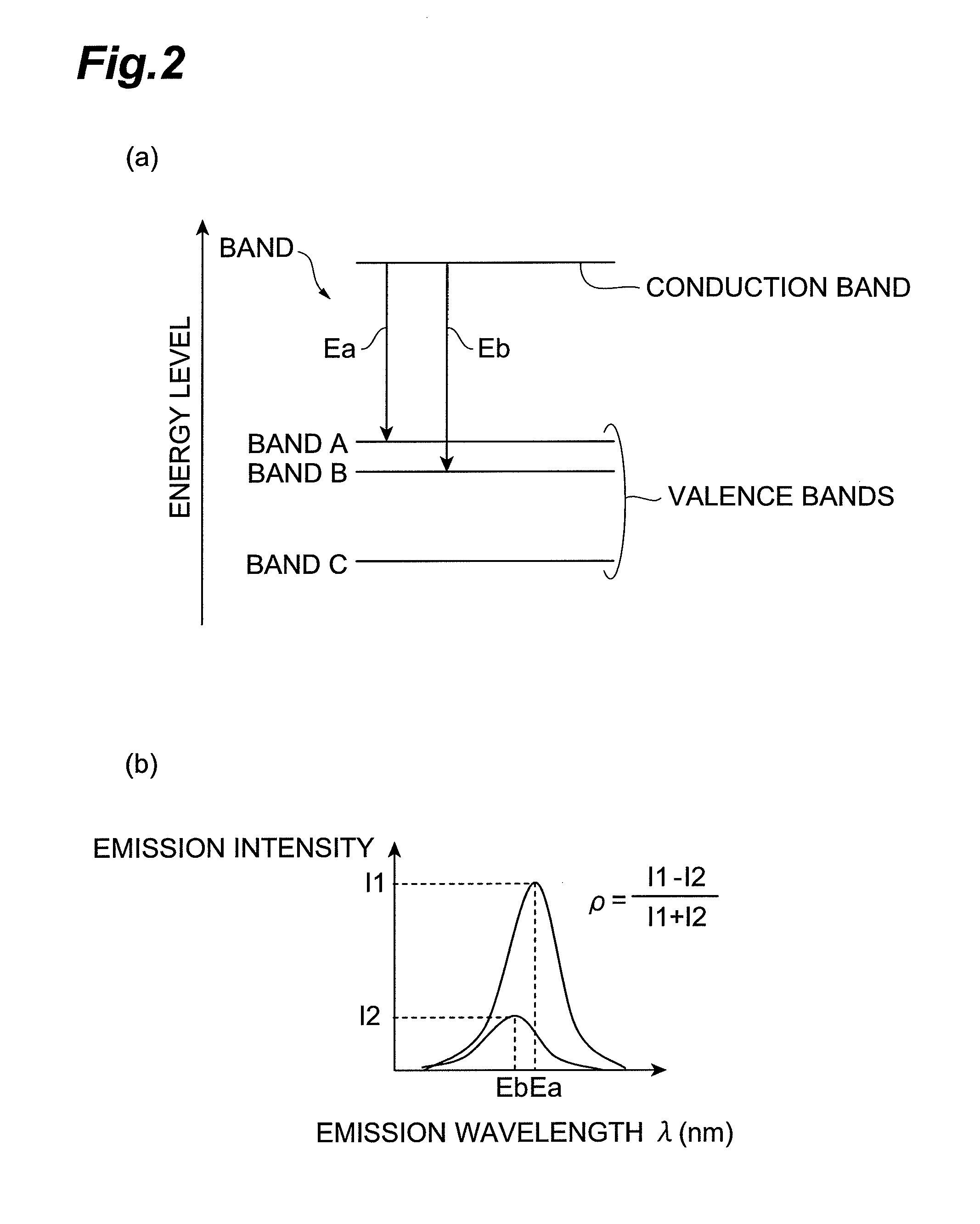

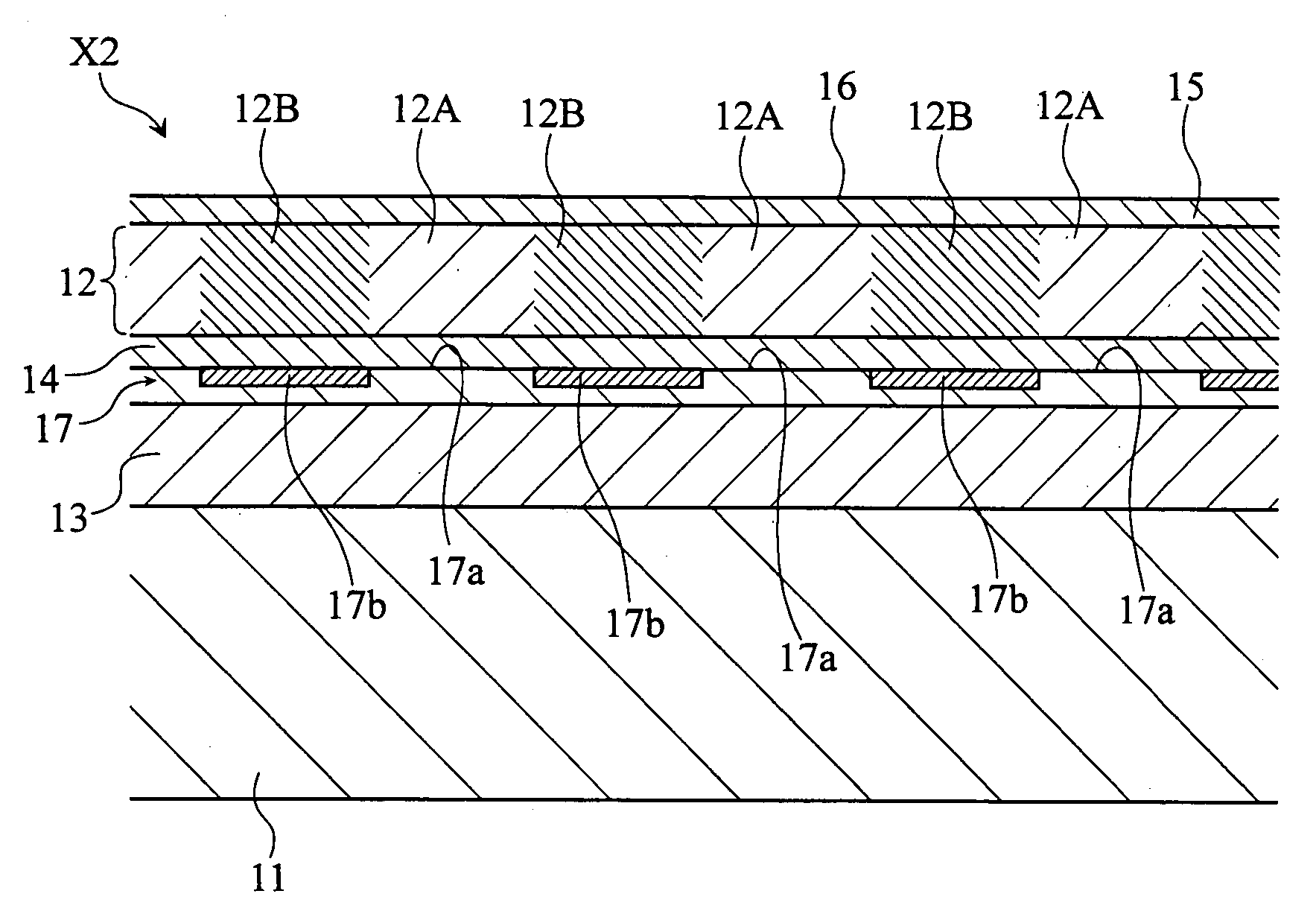

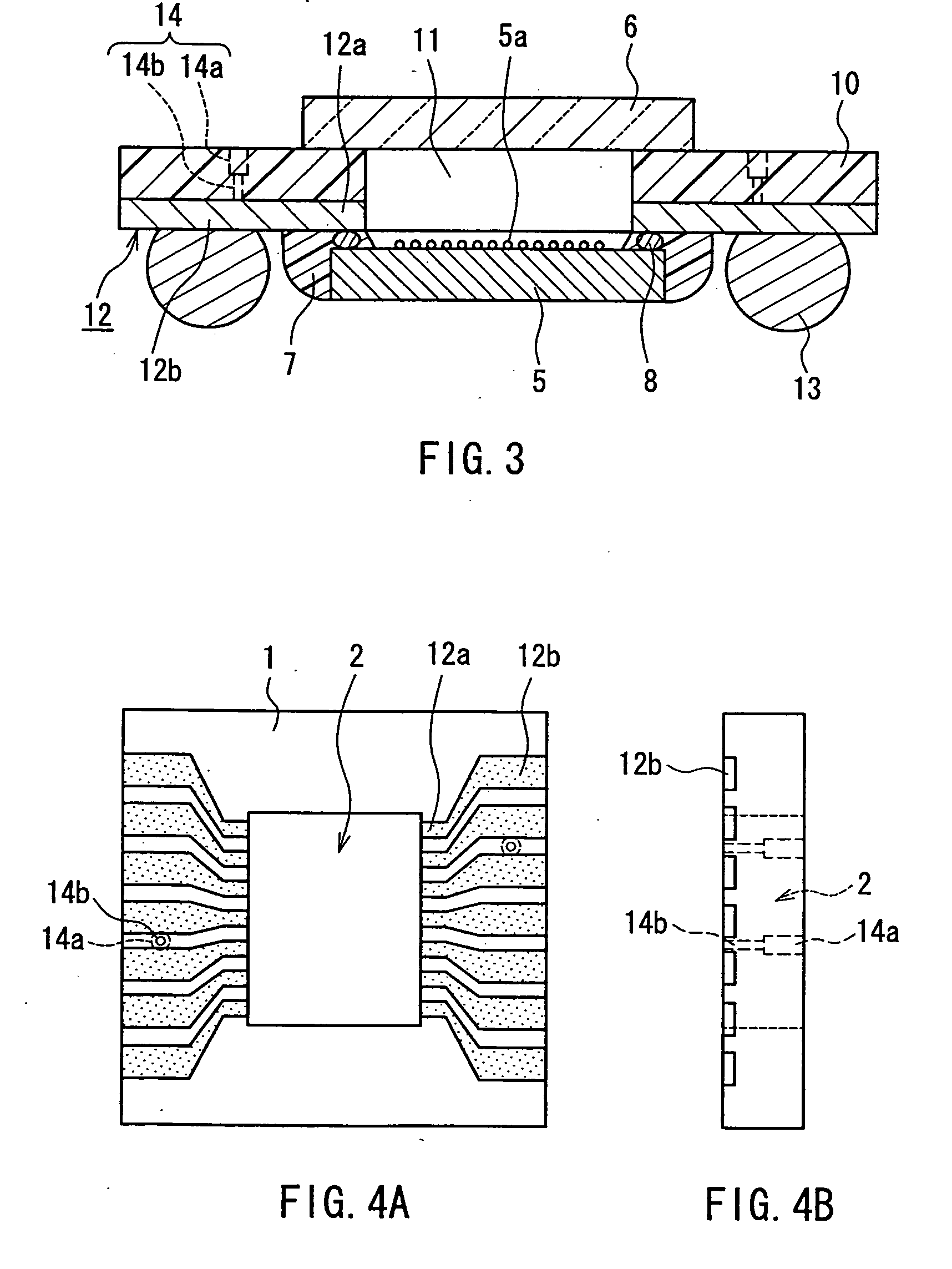

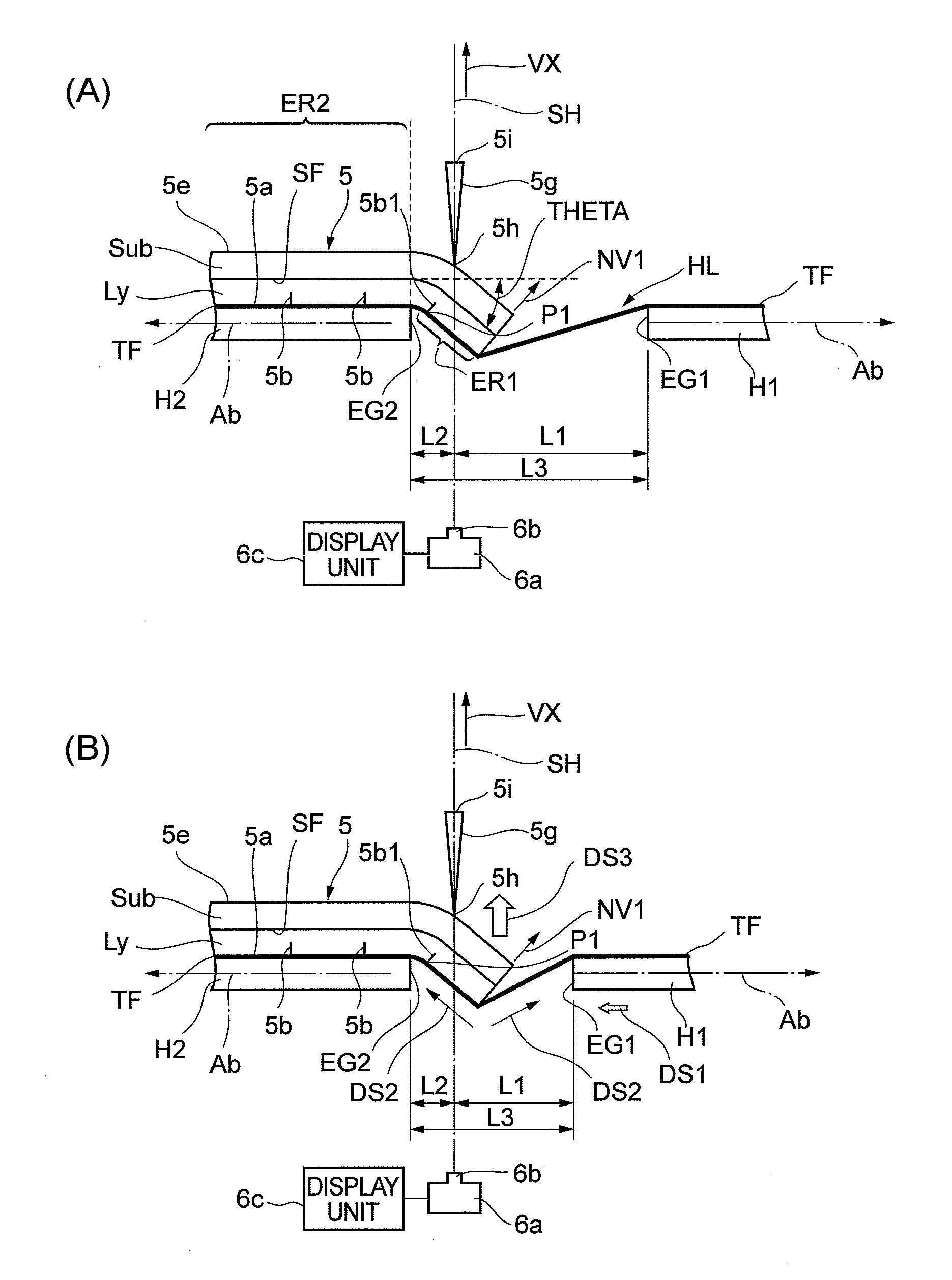

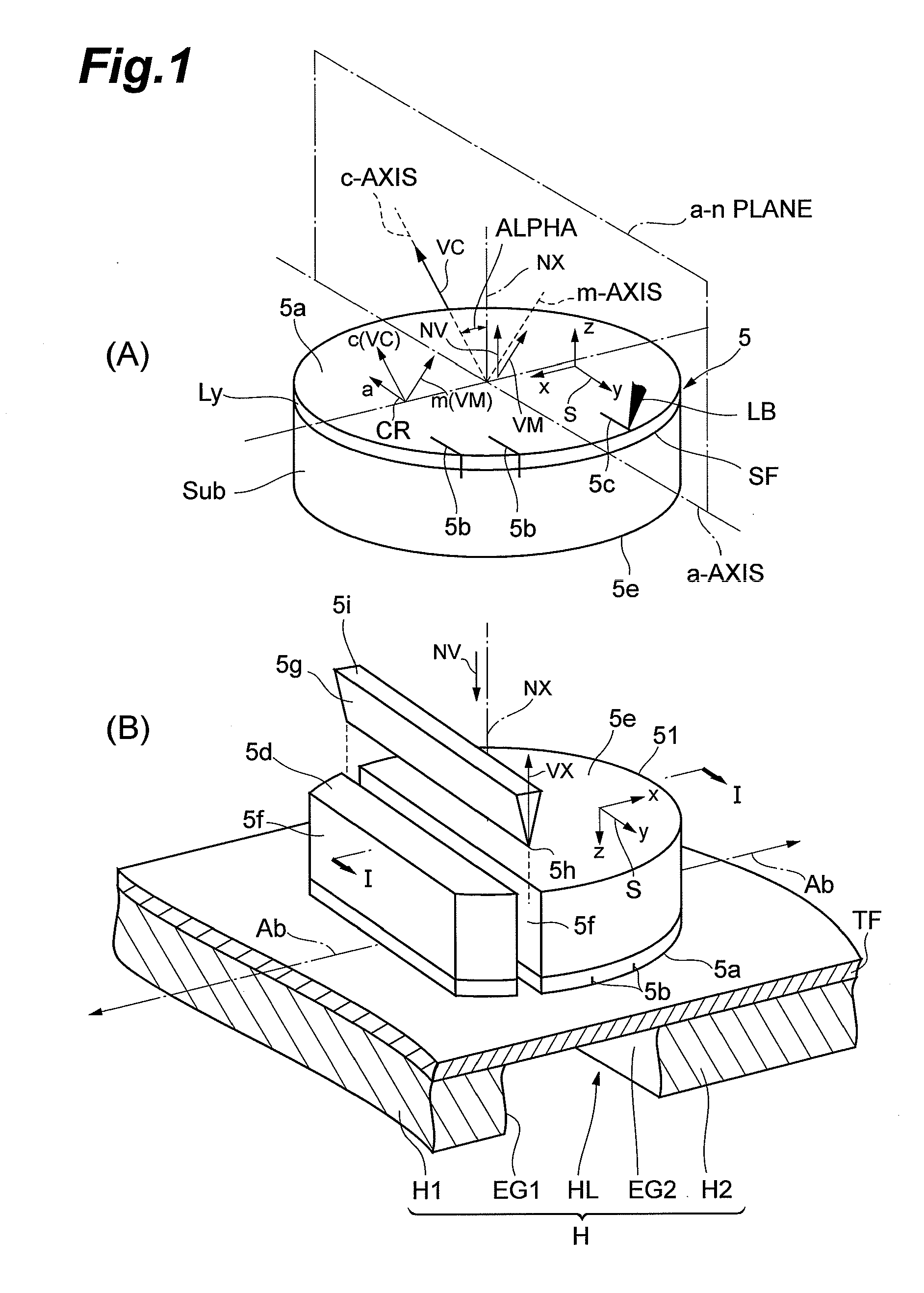

Group-iii nitride semiconductor laser device, and method for fabricating group-iii nitride semiconductor laser device

InactiveUS20110176569A1Reduce damageSufficient perpendicularityLaser detailsLaser optical resonator constructionLower thresholdDry etching

Provided is a group-III nitride semiconductor laser device with a laser cavity enabling a low threshold current, on a semipolar surface of a support base the c-axis of a hexagonal group-III nitride of which tilts toward the m-axis. In a laser structure 13, a first surface 13a is a surface opposite to a second surface 13b and first and second fractured faces 27, 29 extend each from an edge 13c of the first surface 13a to an edge 13d of the second surface 13b. A scribed mark SM1 extending from the edge 13c to the edge 13d is made, for example, at one end of the first fractured face 27, and the scribed mark SM1 or the like has a depressed shape extending from the edge 13c to the edge 13d. The fractured faces 27, 29 are not formed by dry etching and thus are different from the conventional cleaved facets such as c-planes, m-planes, or a-planes. It is feasible to use emission of a band transition enabling a low threshold current.

Owner:SUMITOMO ELECTRIC IND LTD

Group-III nitride semiconductor laser device, and method for fabricating group-III nitride semiconductor laser device

InactiveUS8071405B2Sufficient perpendicularitySufficient flatnessLaser optical resonator constructionLaser active region structureDry etchingNitride semiconductors

Provided is a group-III nitride semiconductor laser device with a laser cavity enabling a low threshold current, on a semipolar surface of a support base the c-axis of a hexagonal group-III nitride of which tilts toward the m-axis. In a laser structure 13, a first surface 13a is a surface opposite to a second surface 13b and first and second fractured faces 27, 29 extend each from an edge 13c of the first surface 13a to an edge 13d of the second surface 13b. A scribed mark SM1 extending from the edge 13c to the edge 13d is made, for example, at one end of the first fractured face 27, and the scribed mark SM1 or the like has a depressed shape extending from the edge 13c to the edge 13d. The fractured faces 27, 29 are not formed by dry etching and thus are different from the conventional cleaved facets such as c-planes, m-planes, or a-planes. It is feasible to use emission of a band transition enabling a low threshold current.

Owner:SUMITOMO ELECTRIC IND LTD

Magnetic recording medium and method of making the same

ActiveUS20070224455A1Suppress noiseSufficient flatnessRecord information storageCoatingsRecording layerRecording media

A magnetic recording medium includes a continuous recording layer, and a seed layer including a surface held in contact with the recording layer. The seed layer includes an oxidized region and a non-oxidized region in the surface held in contact with the recording layer. The recording layer includes a recording magnetic region and a non-recording magnetic region. The recording magnetic region corresponds in position to the non-oxidized region and has perpendicular magnetic anisotropy. The non-recording magnetic region corresponds in position to the oxidized region.

Owner:RESONAC CORP

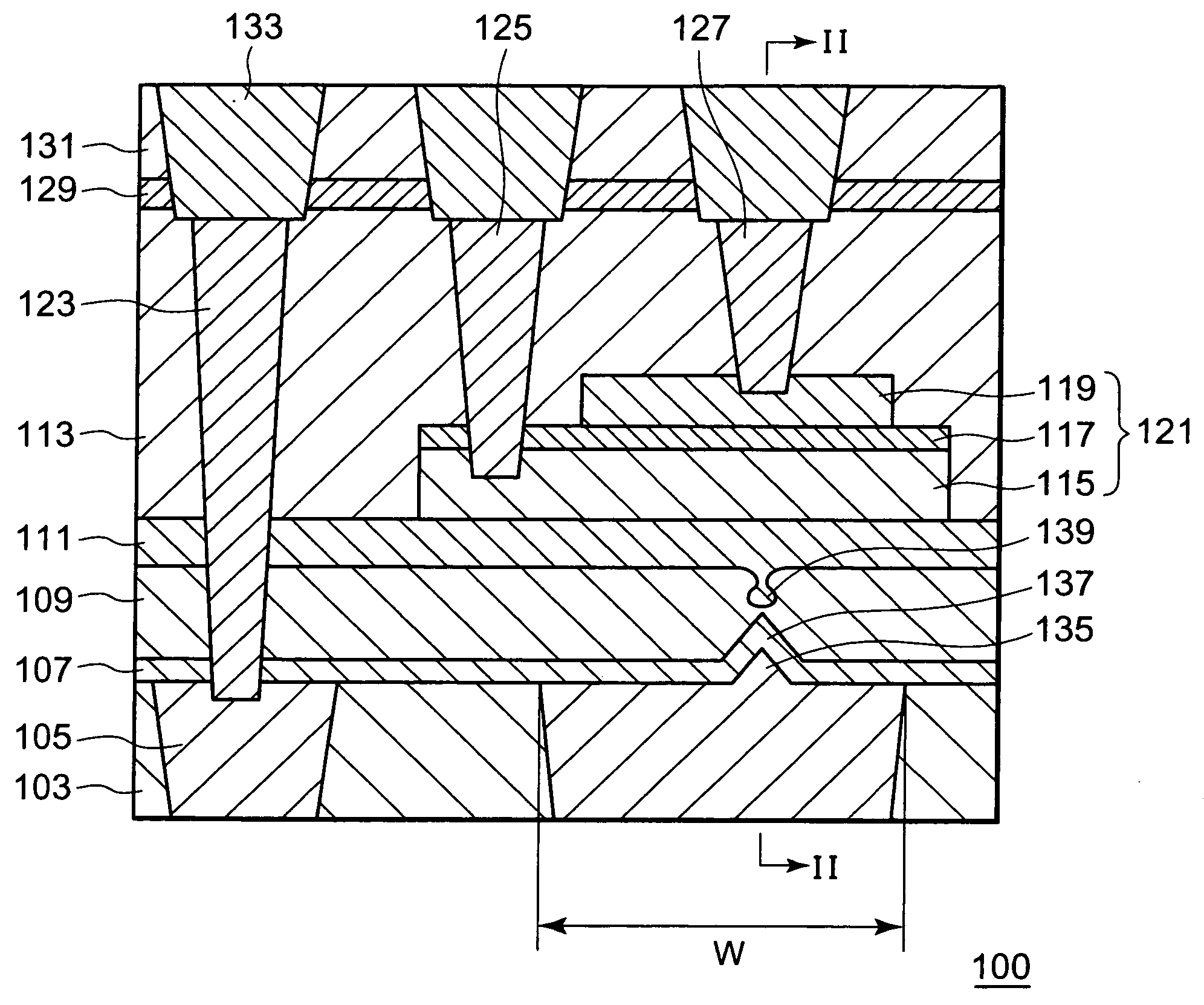

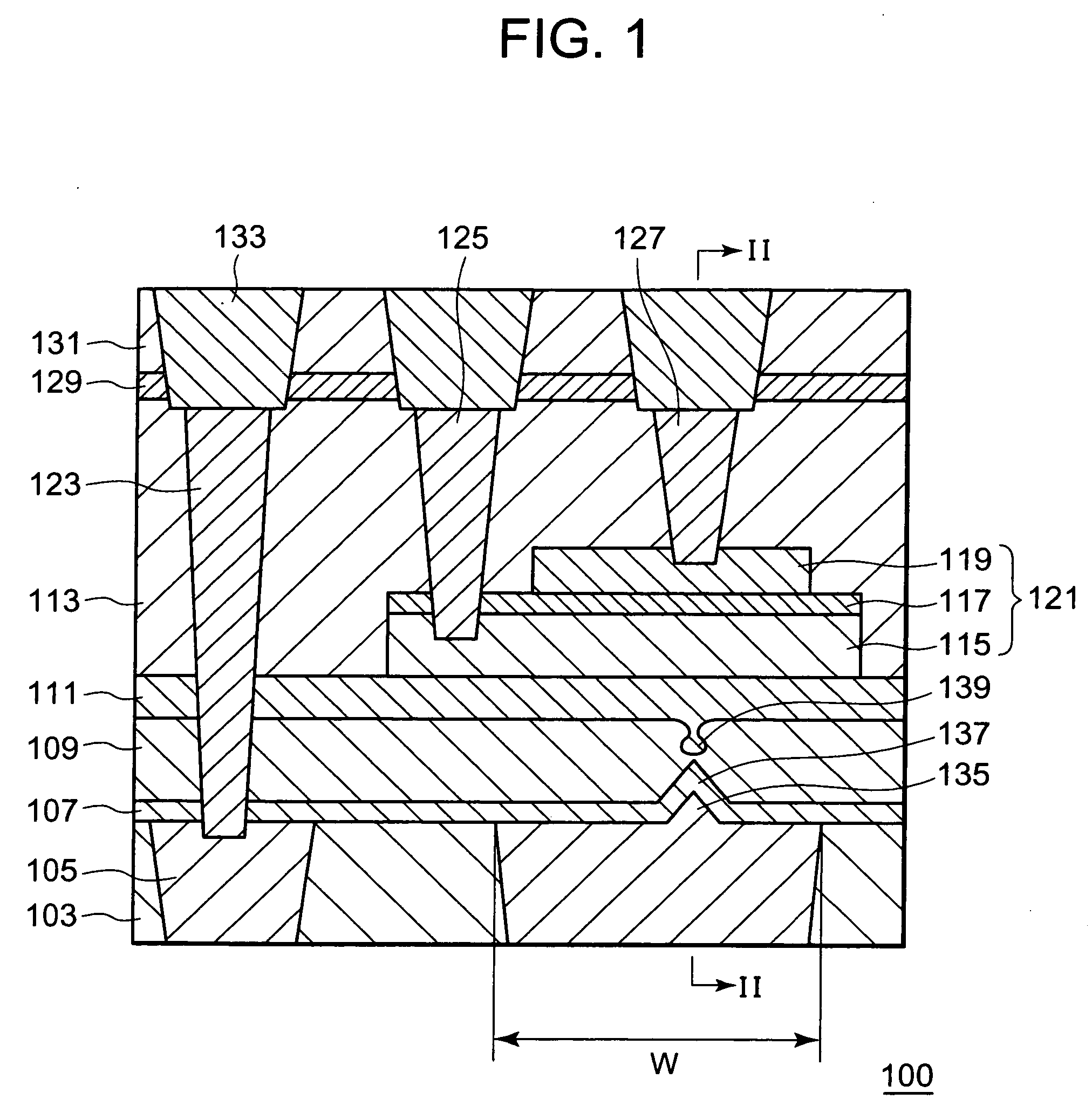

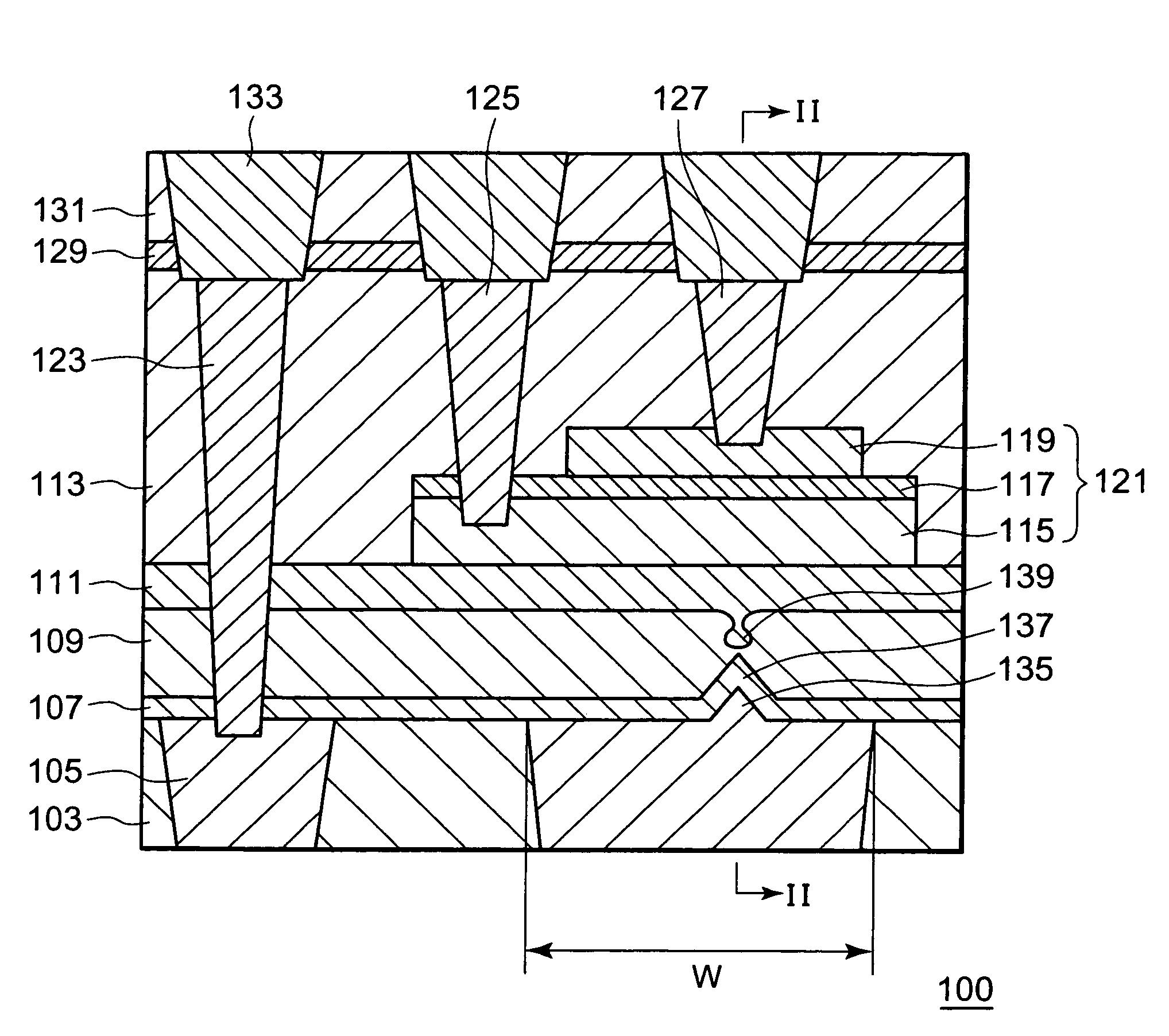

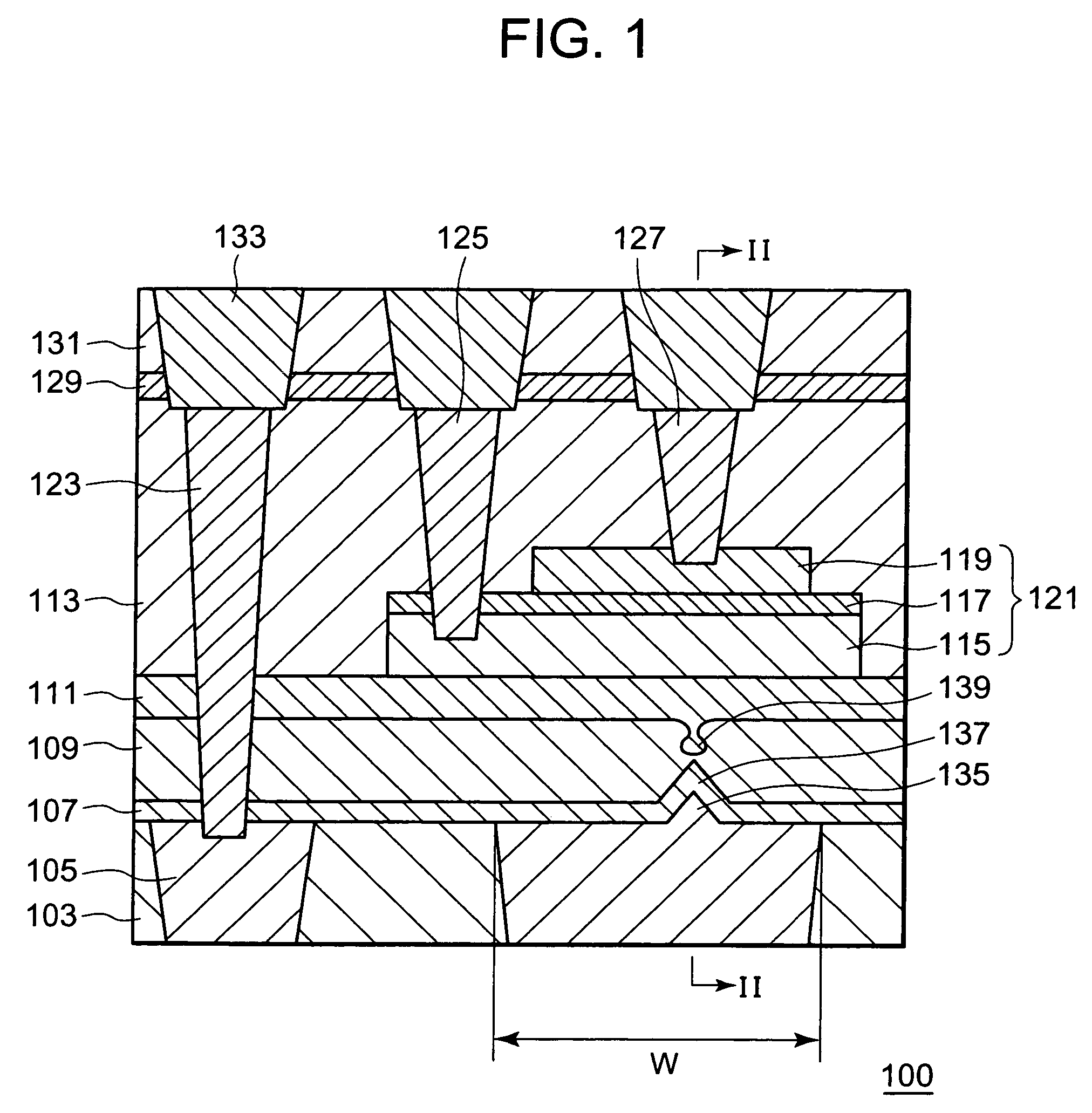

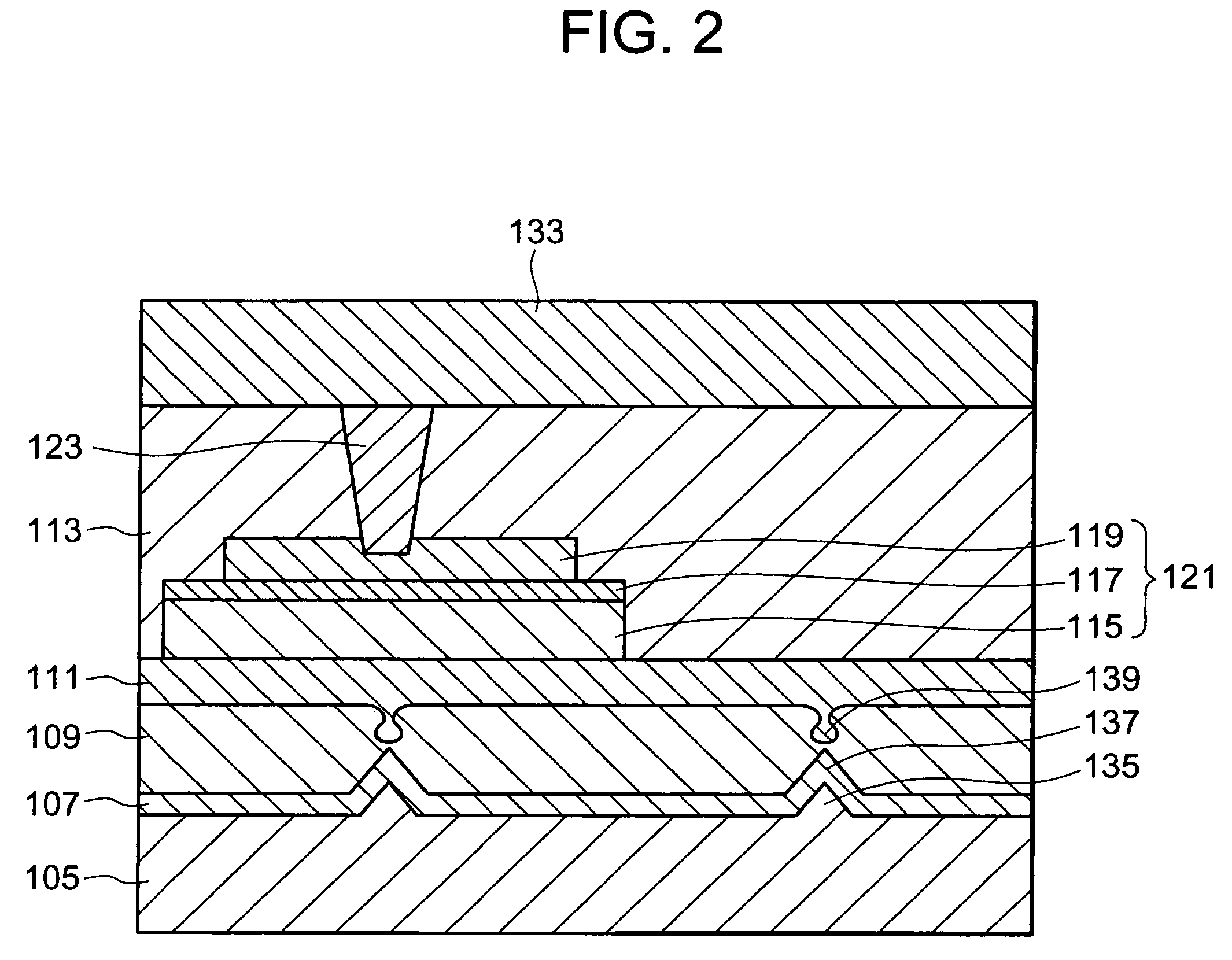

Semiconductor device including MIM element and method of manufacturing the same

ActiveUS20090014835A1Improve reliabilityHigh yieldSemiconductor/solid-state device detailsSolid-state devicesEngineeringCapacitor

A semiconductor device includes a first wiring layer which is provided above a semiconductor substrate and includes a first insulating film and a wiring buried in the first insulating film, a second insulating film provided above the first wiring layer, a third insulating film provided on the second insulating film, and a capacitor element provided on the third insulating film. The wiring includes an upper surface having a protruding portion. The capacitor element includes a lower electrode provided on the third insulating film, a capacitor insulating film provided on the lower electrode, and an upper electrode provided on the capacitor insulating film.

Owner:RENESAS ELECTRONICS CORP

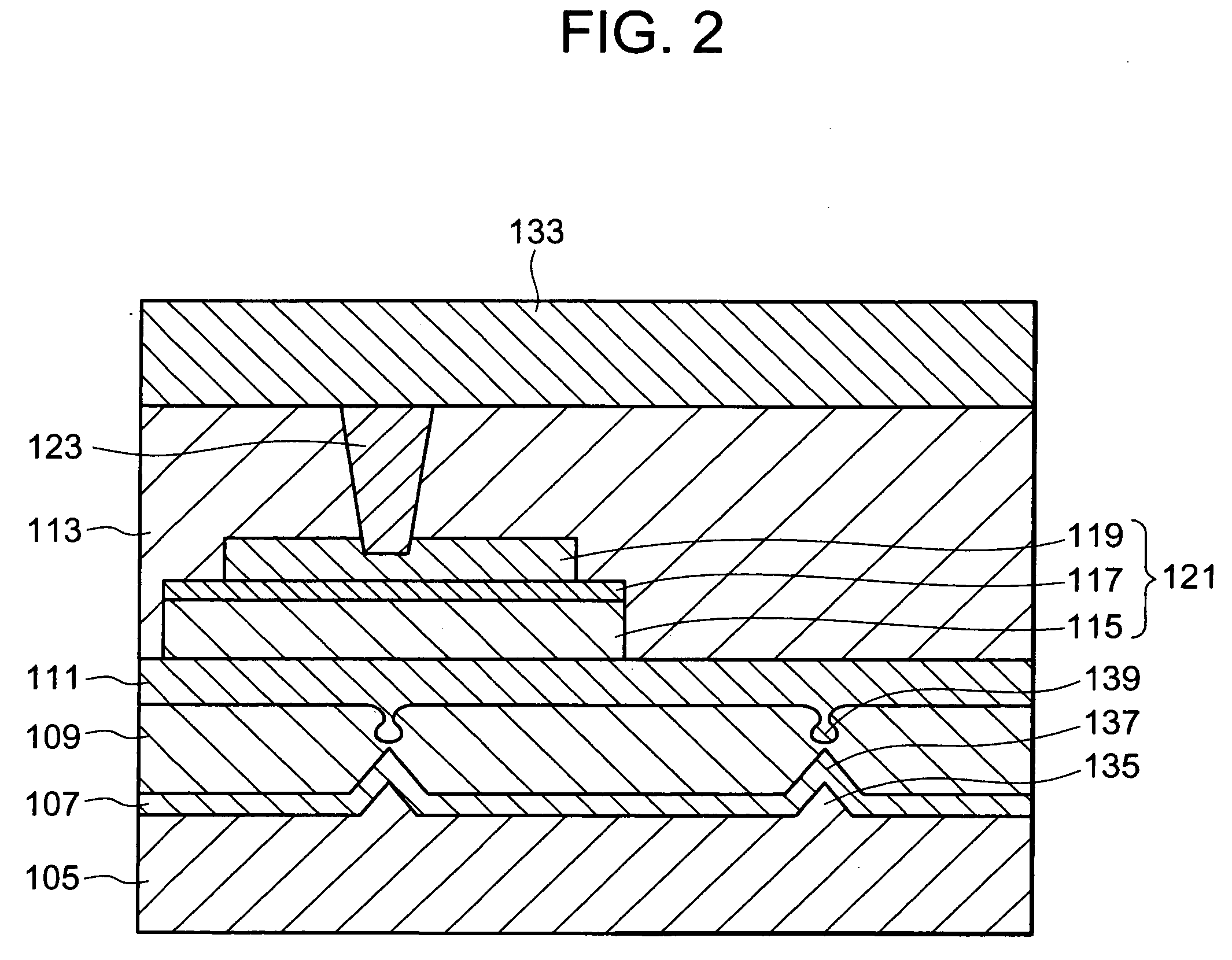

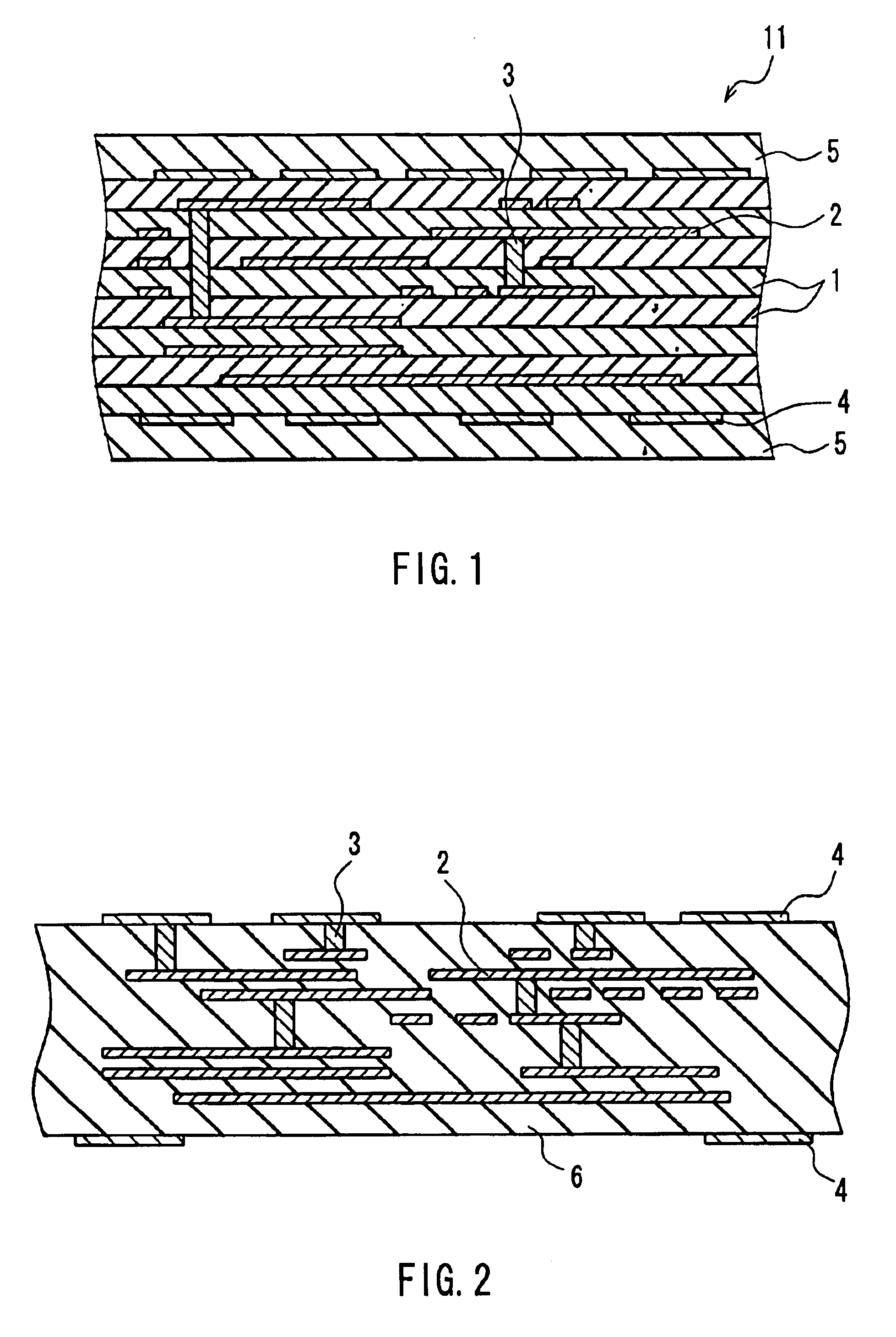

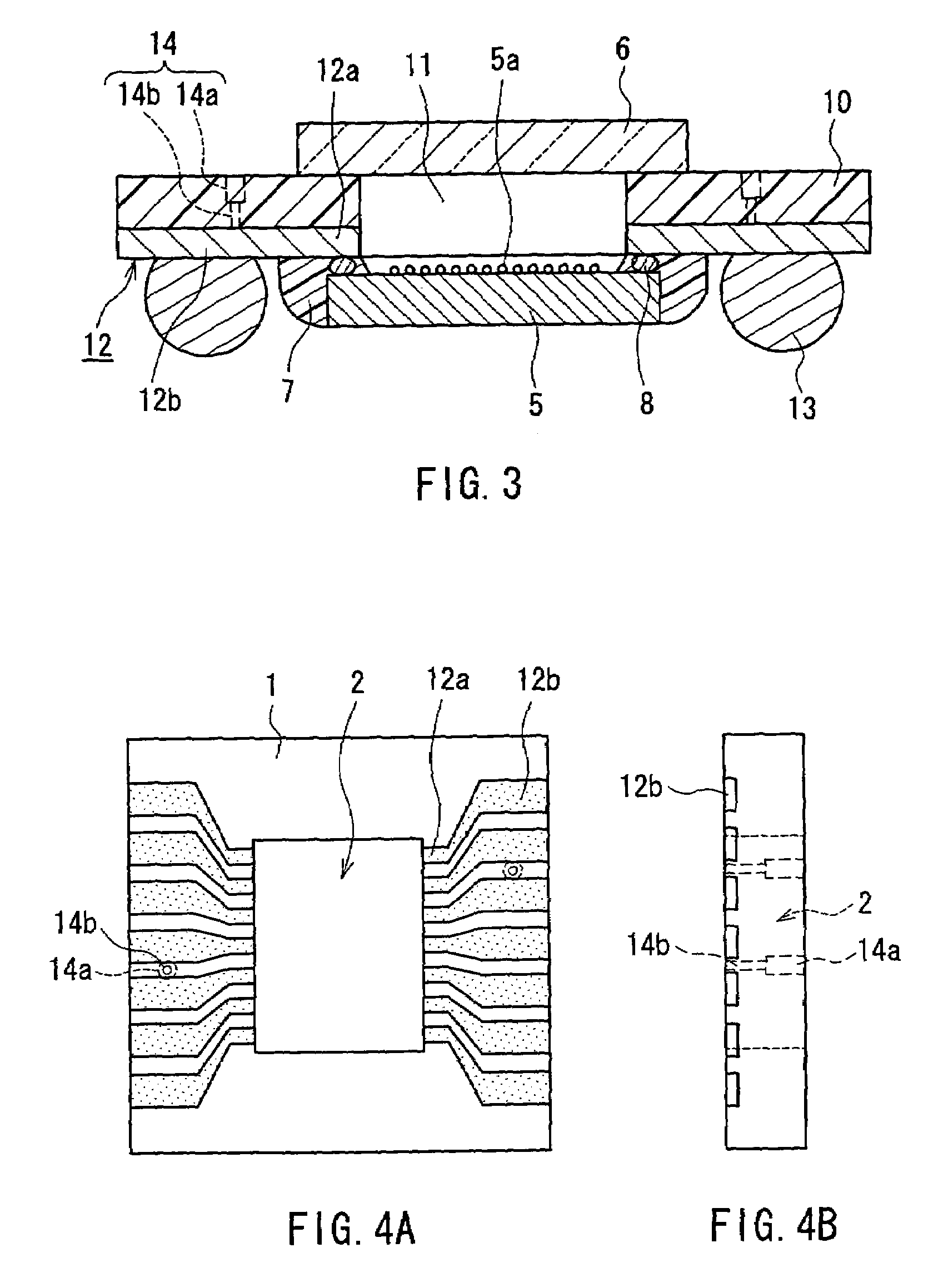

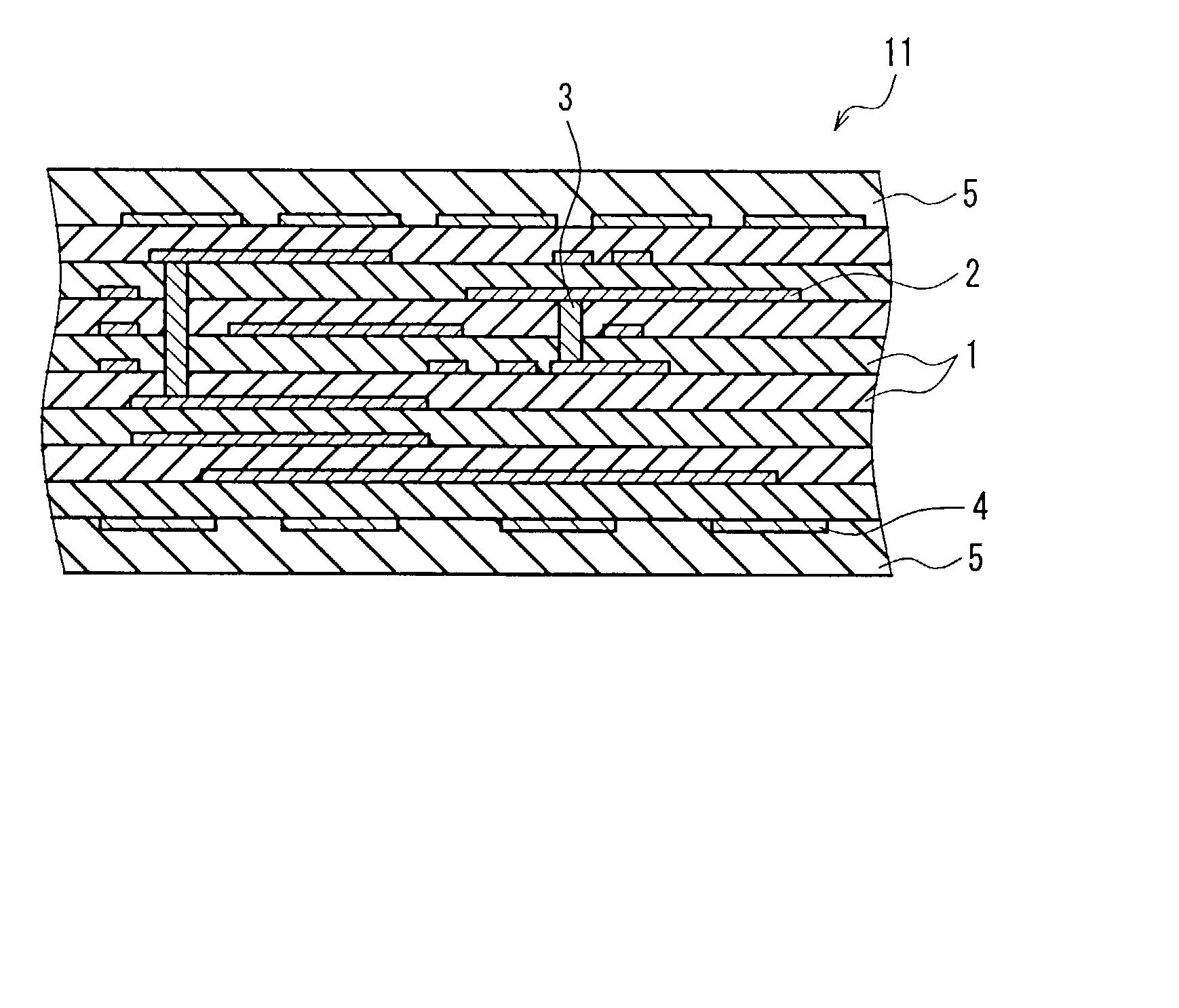

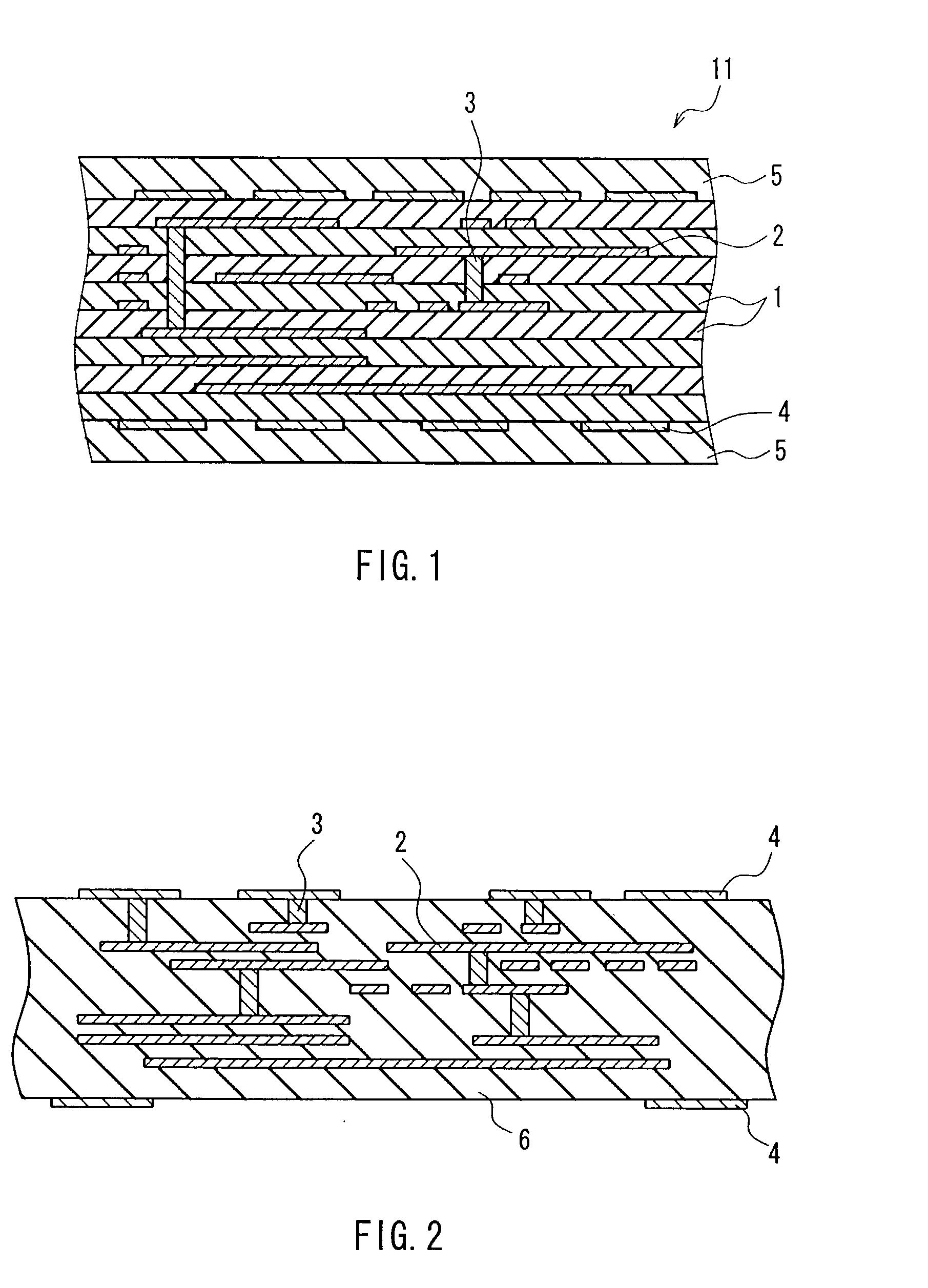

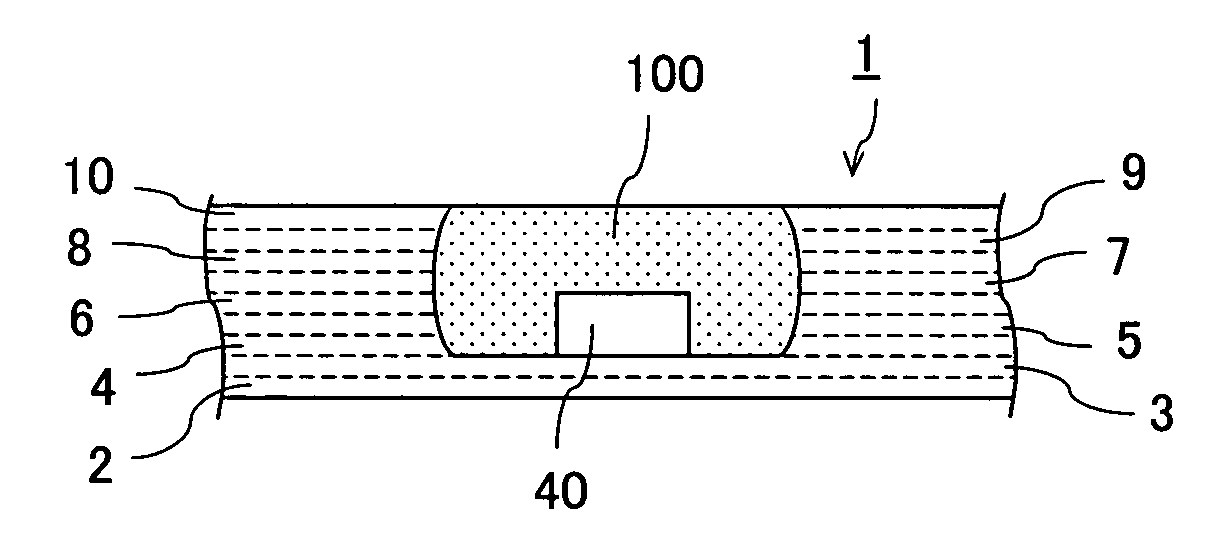

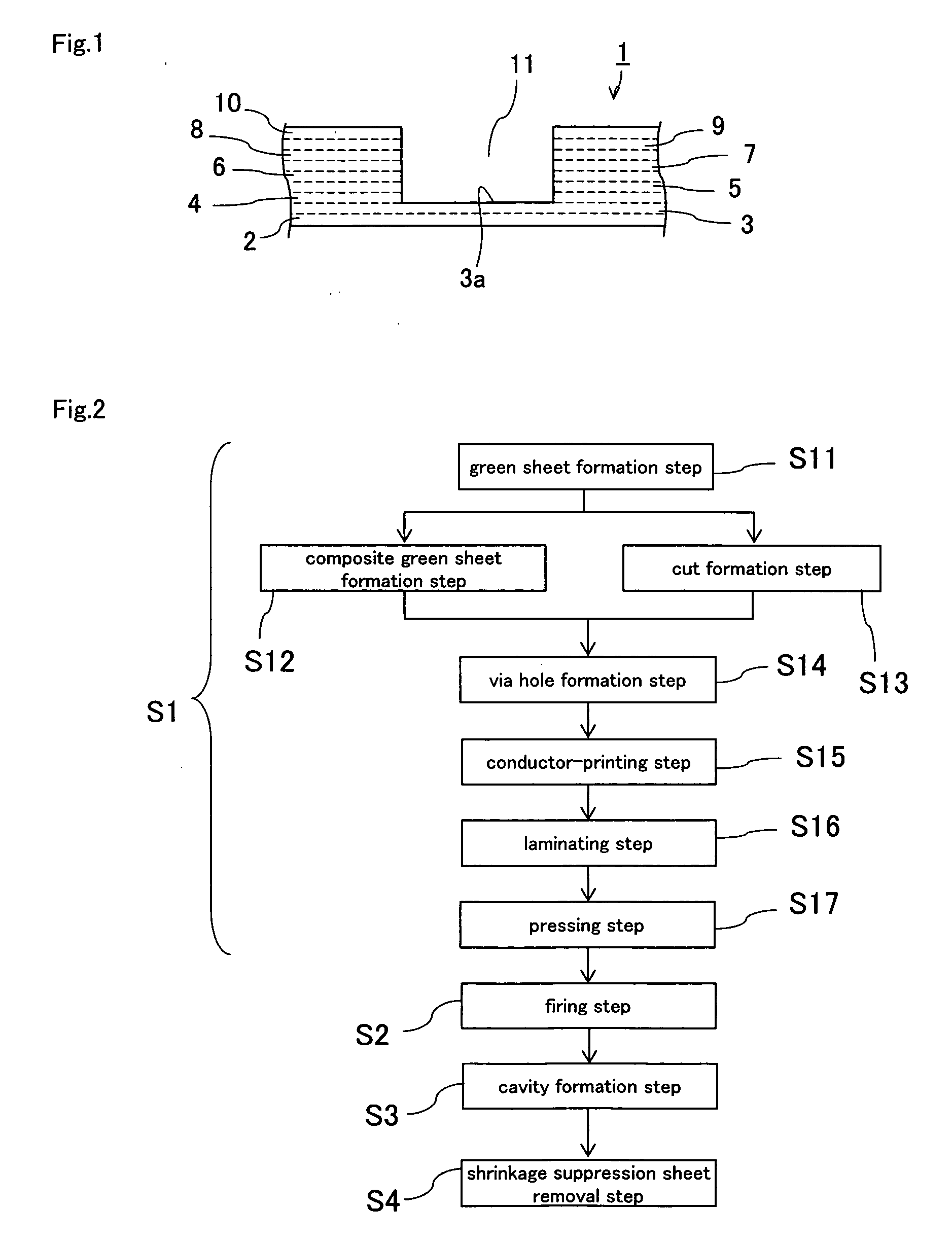

Multilayer ceramic substrate and method for manufacturing the same

InactiveUS6762369B2Sufficient flatnessPreventing defect in vicinitySemiconductor/solid-state device detailsSolid-state devicesConductive materialsHigh dimensional

A multilayer ceramic substrate includes a glass ceramic body, a conductive pattern, and a via conductor. The conductive pattern is formed in the glass ceramic body and on at least one principal surface of the glass ceramic body. The via conductor makes a connection between the predetermined conductive patterns. The via conductor includes a conductive material and a Mo compound or a Mo metal. The conductive material includes at least one selected from the group consisting of Ag, Au, Pt and Pd as a main component. The amount of Mo compound or Mo metal is in the range of 0.05 to 10 parts by weight in terms of Mo metal with respect to 100 parts by weight of the conductive material. This multilayer ceramic substrate can achieve sufficient flatness and high dimensional accuracy, while preventing defects that occurs in the vicinity of electrodes after firing.

Owner:PANASONIC CORP

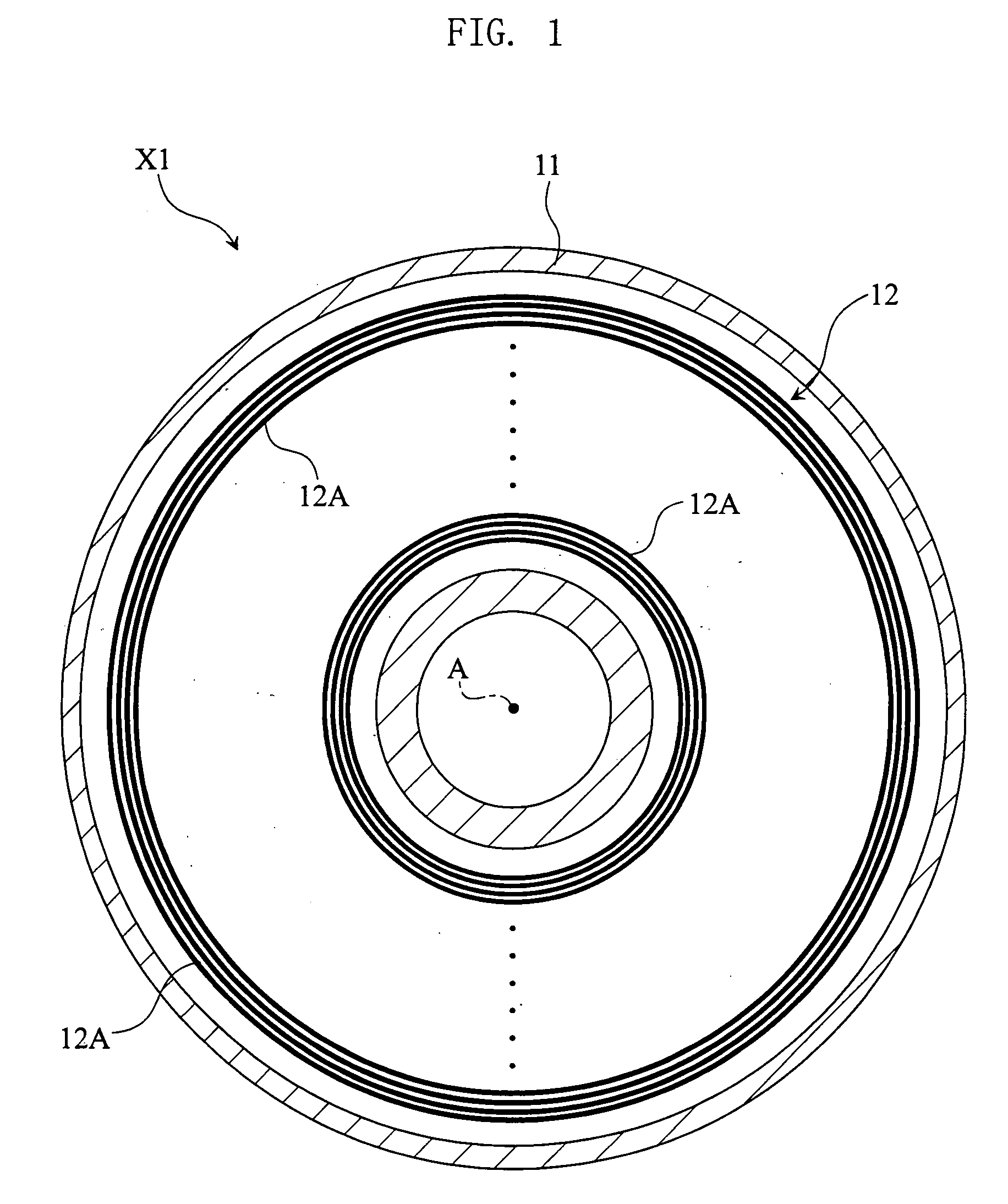

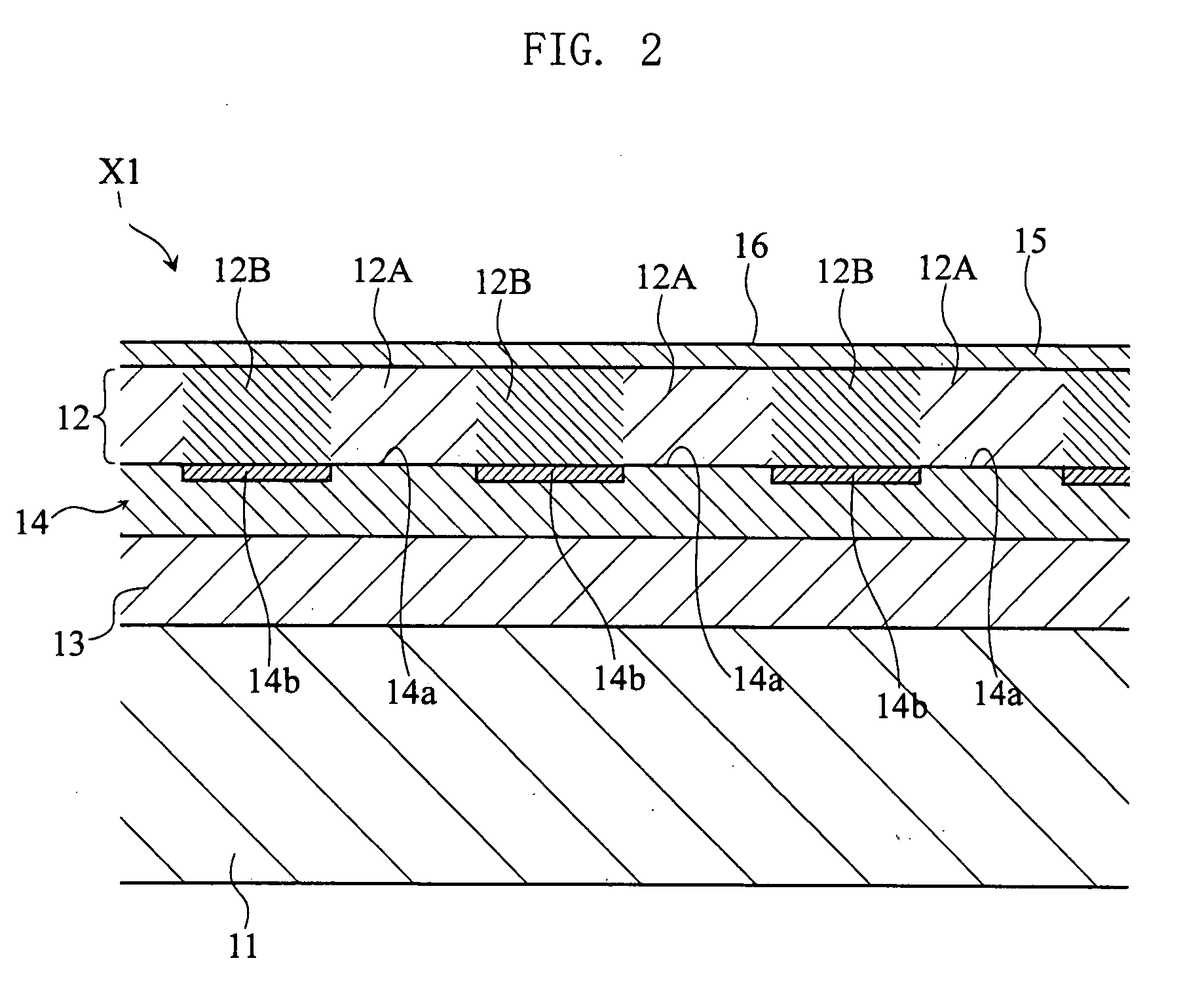

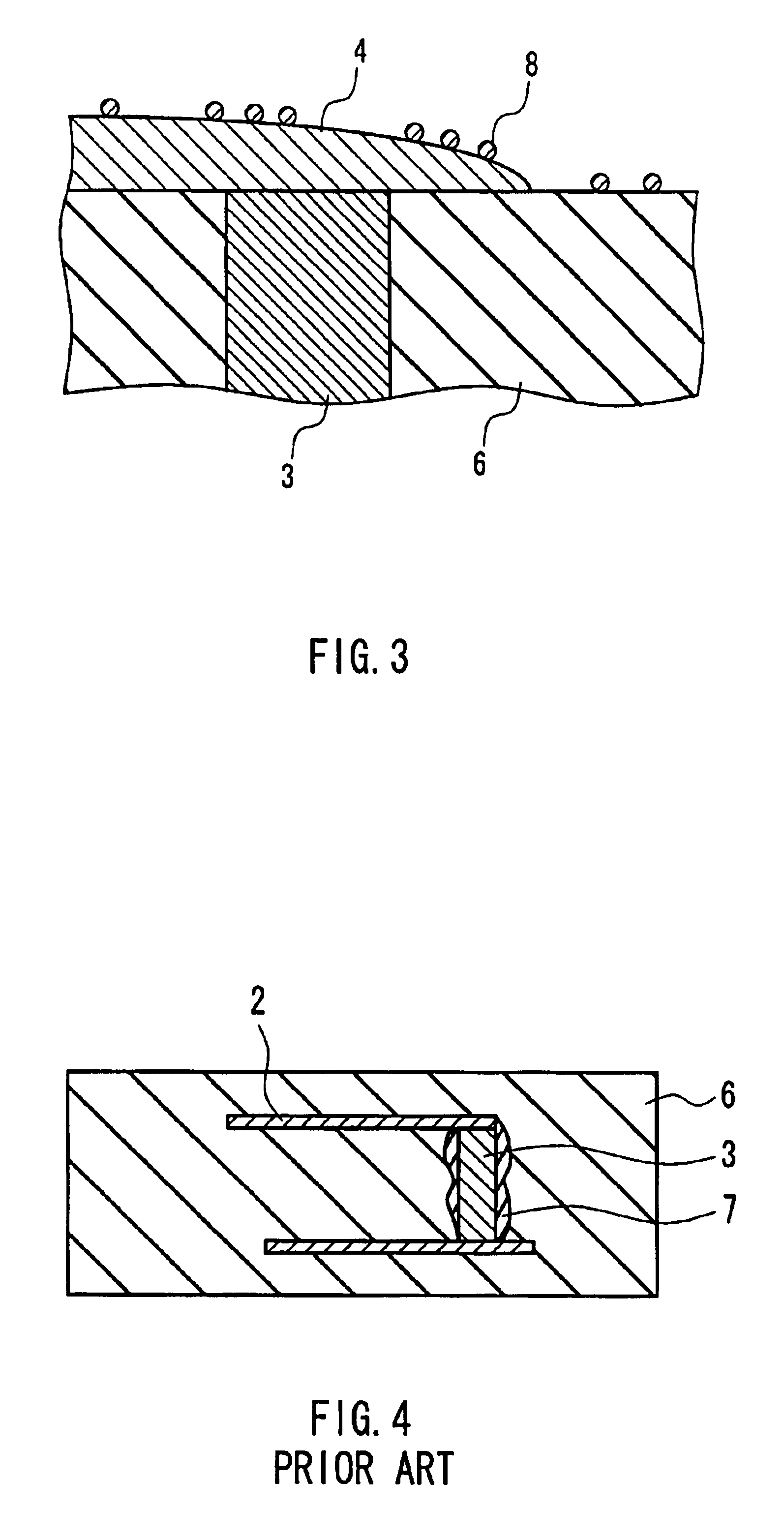

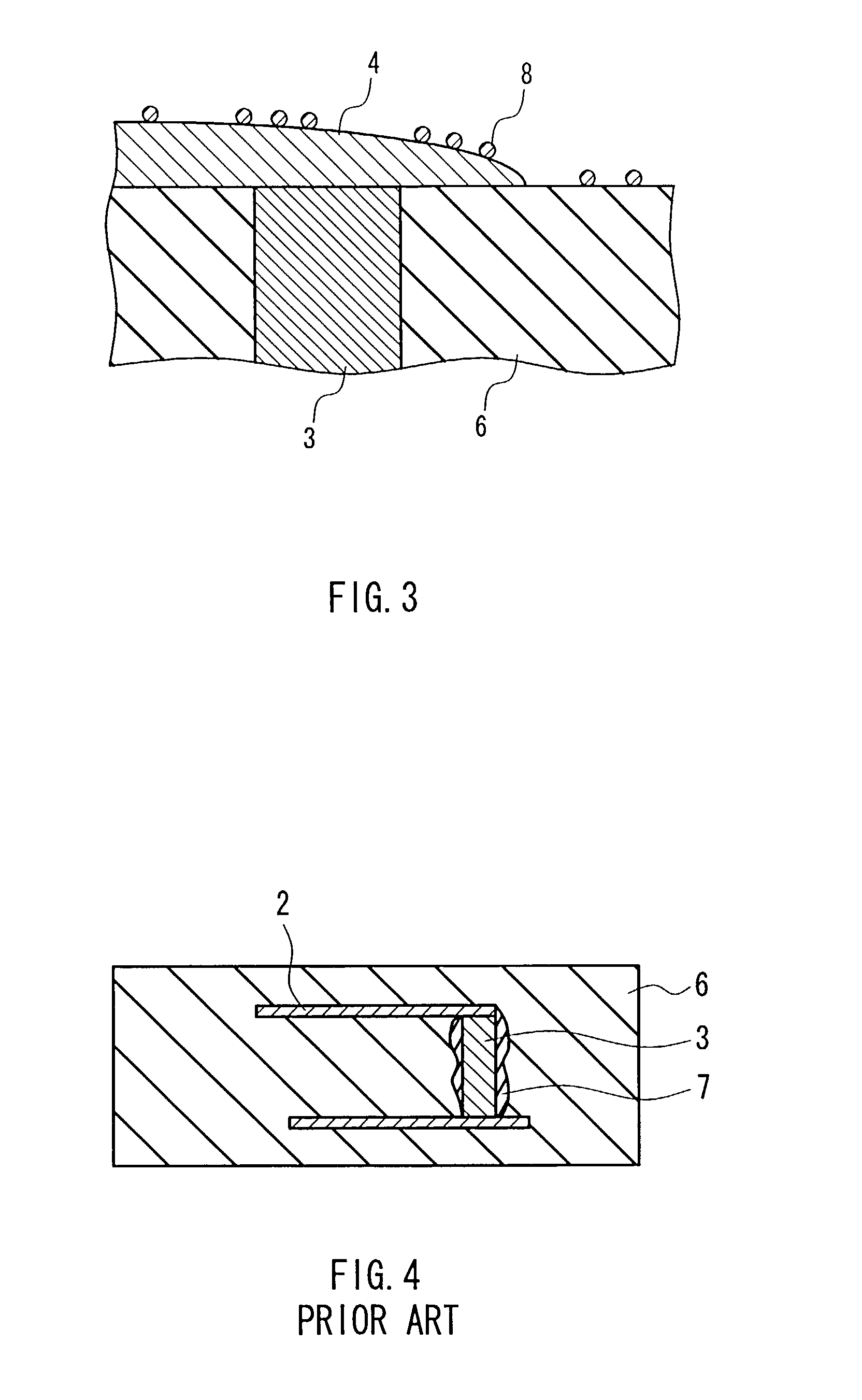

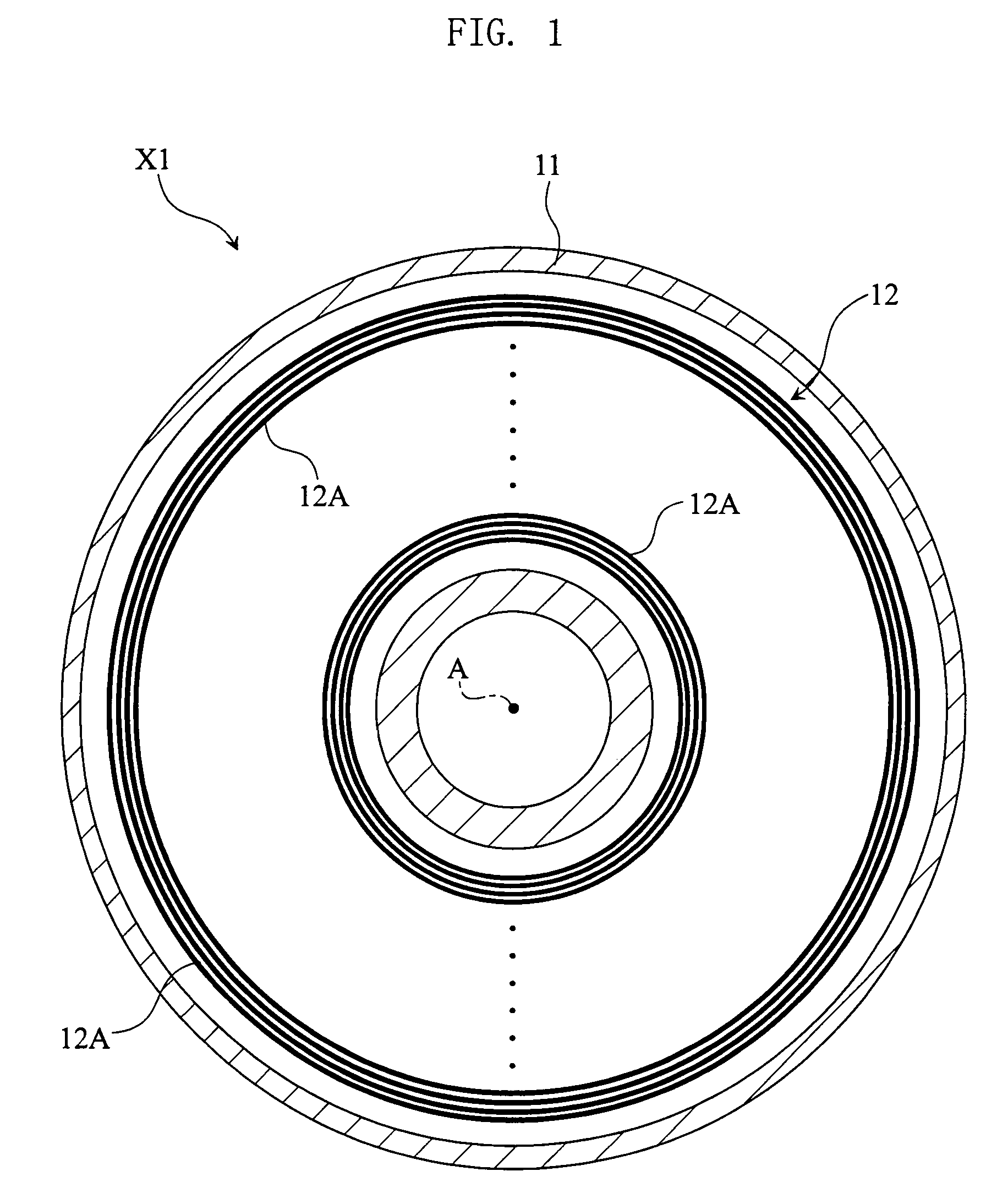

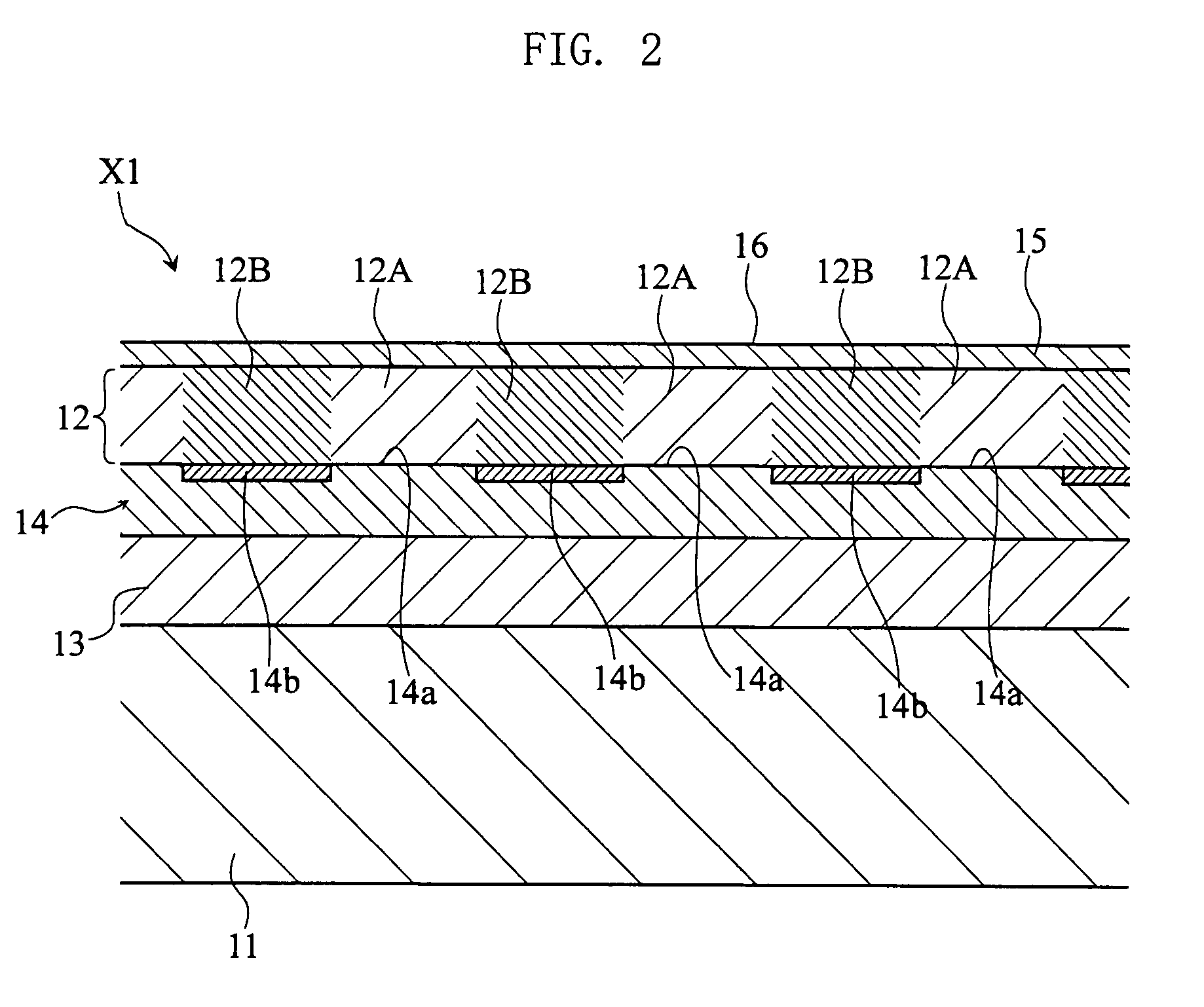

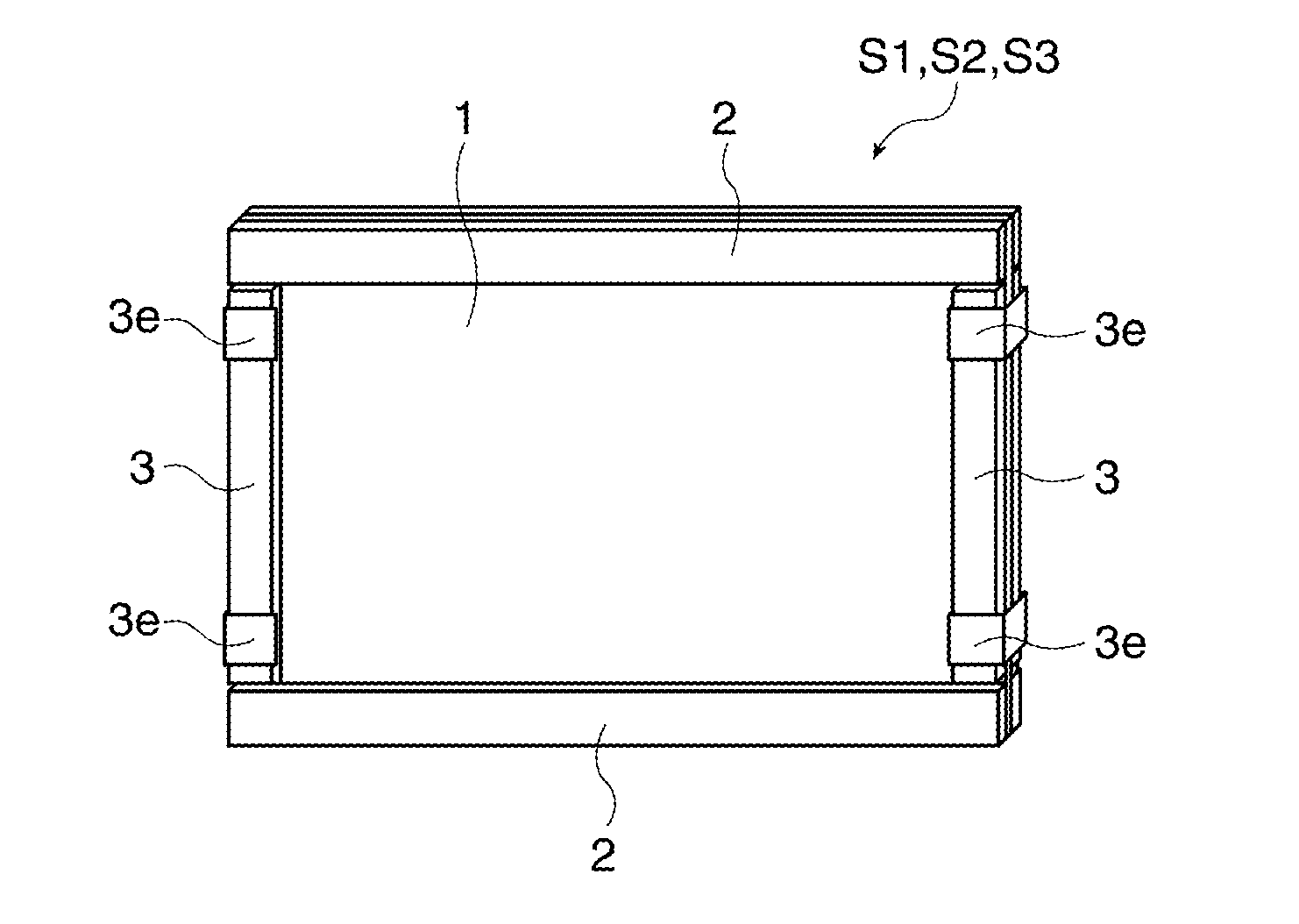

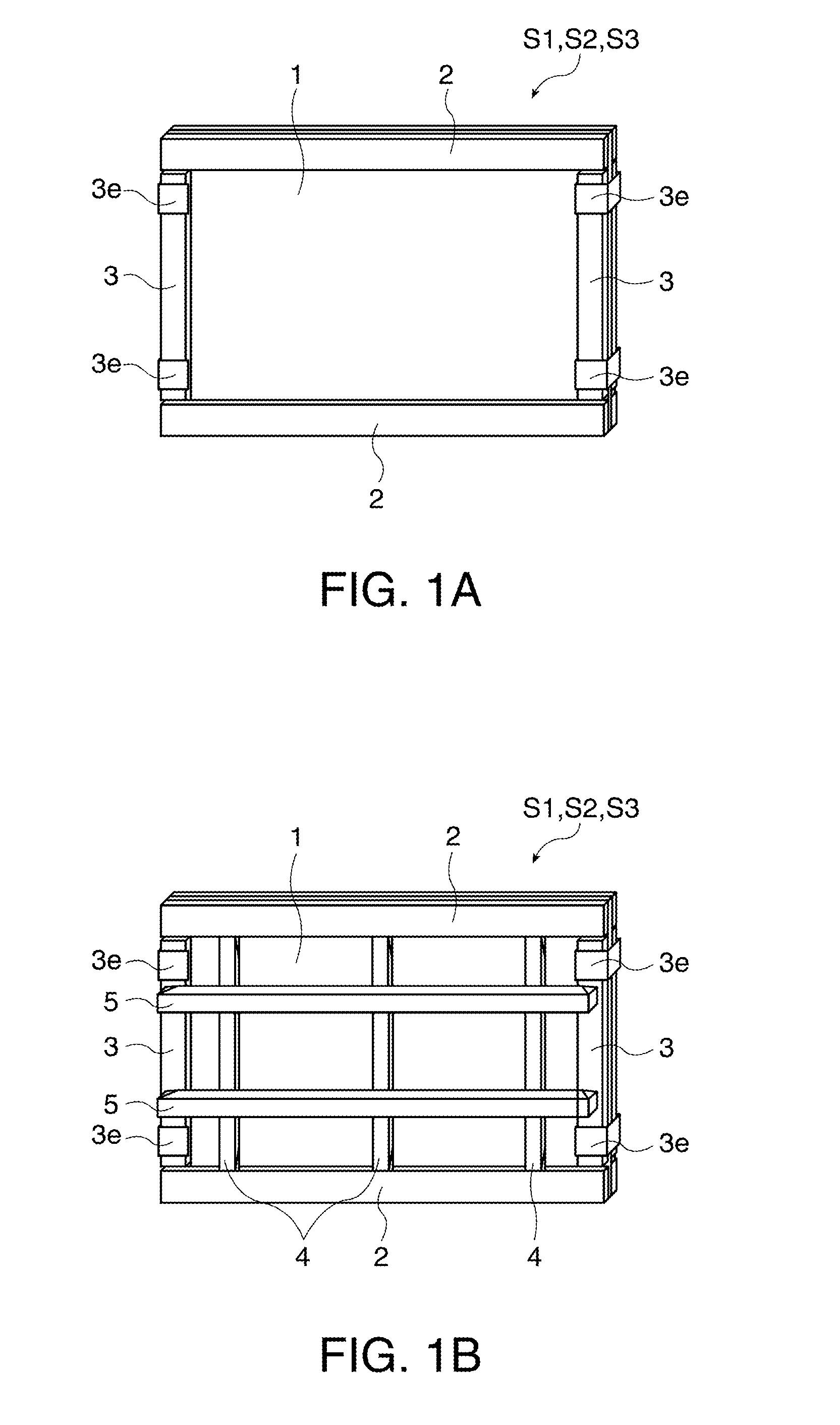

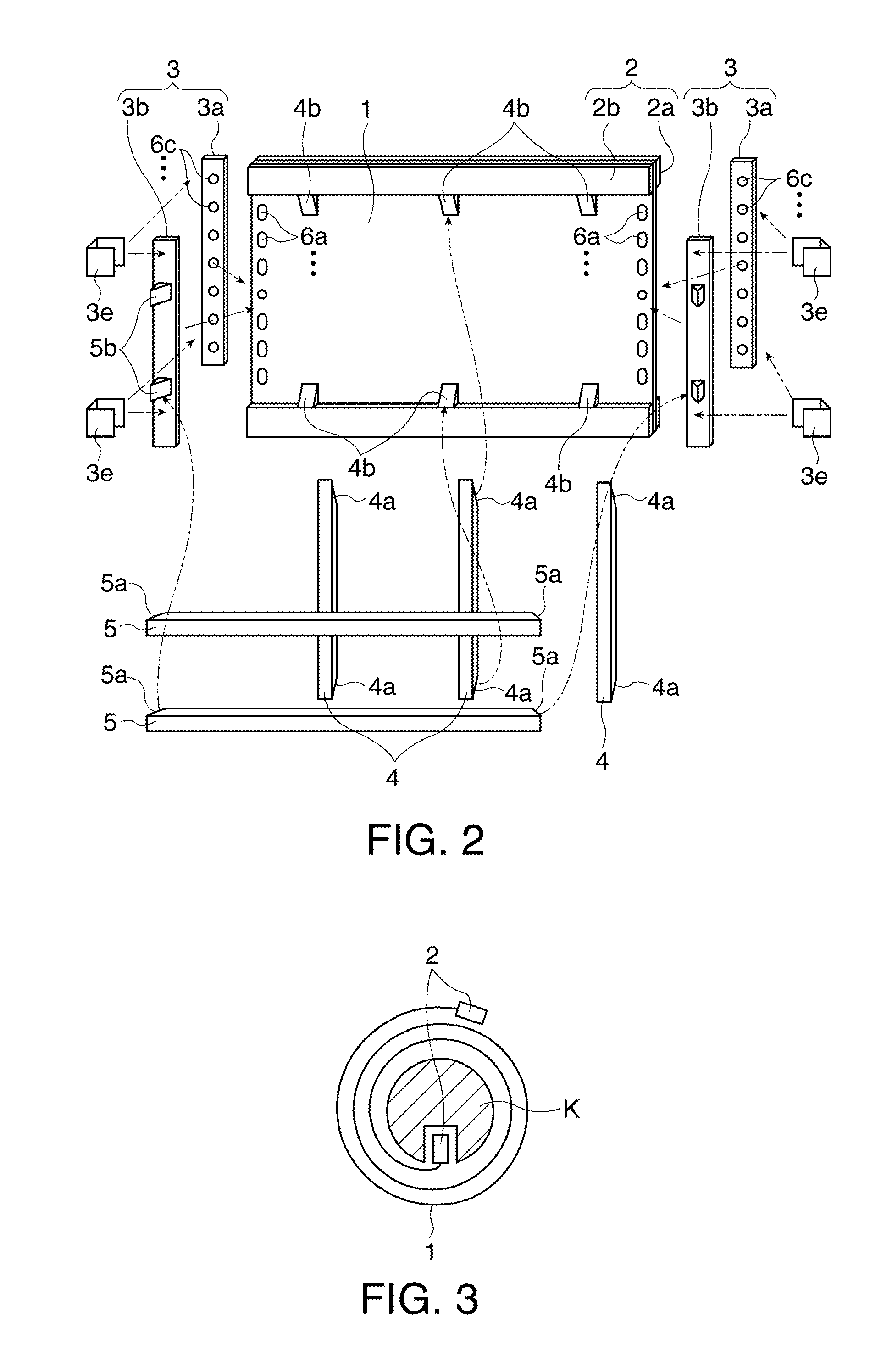

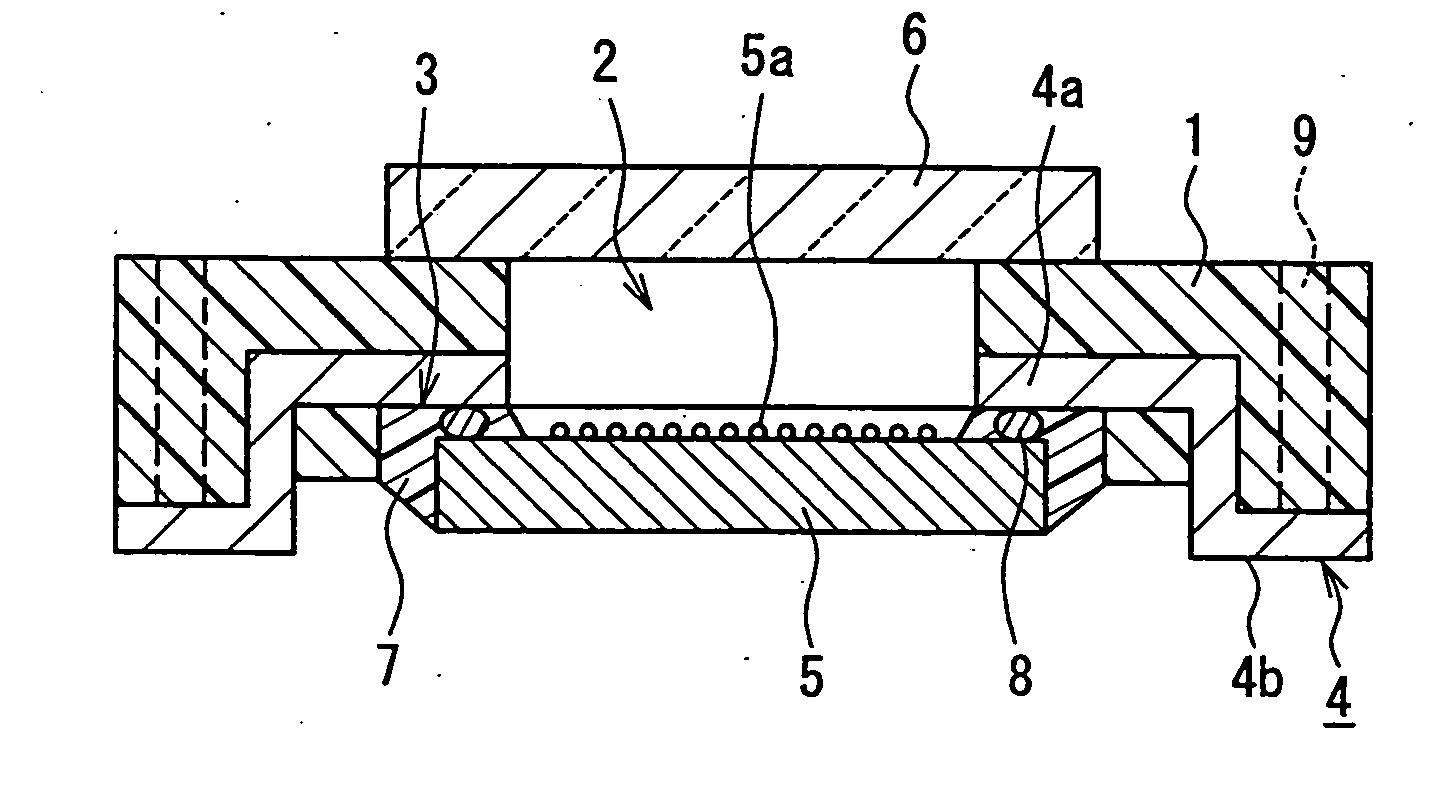

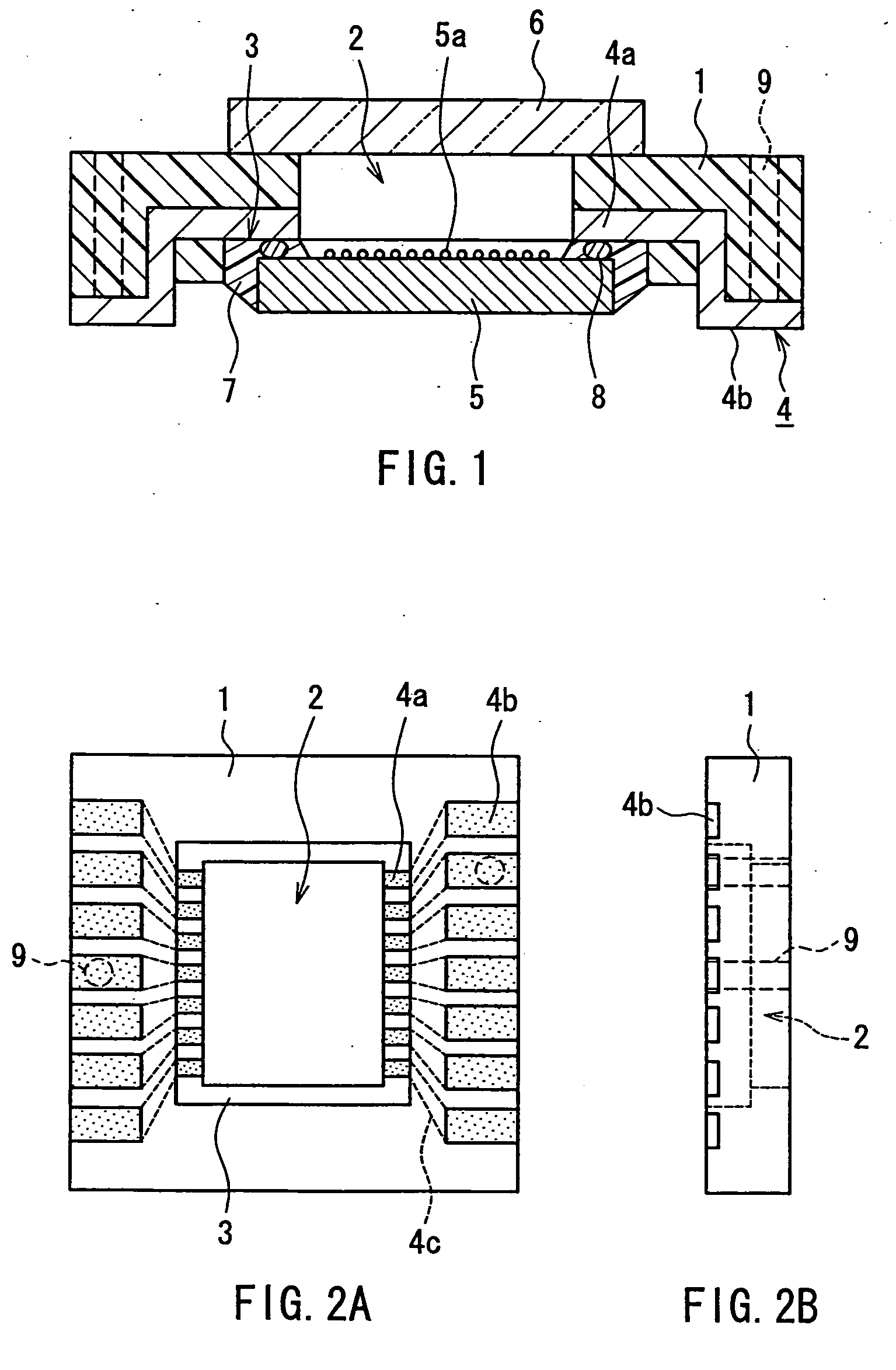

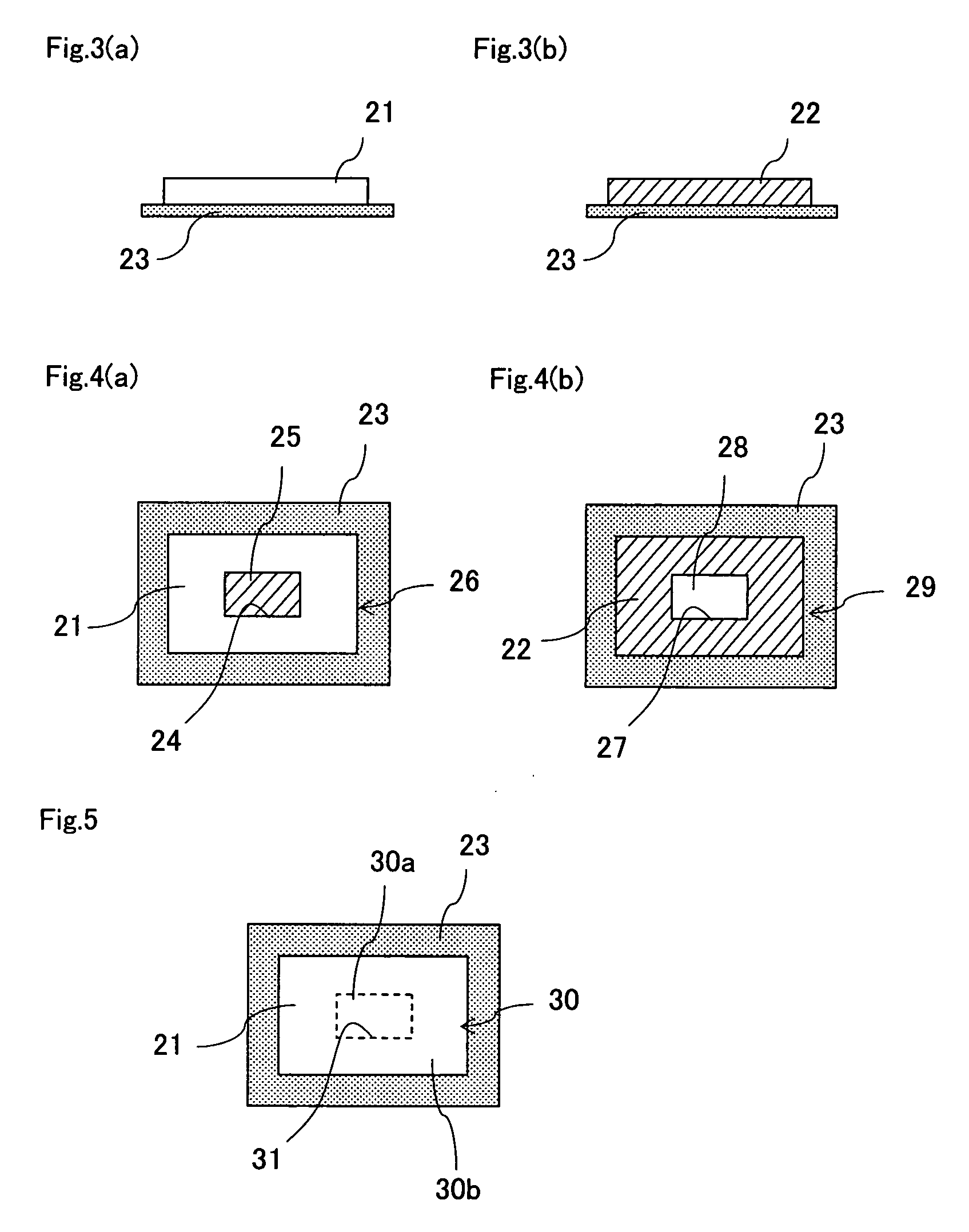

Solid-state imaging device and method for producing the same

ActiveUS7154156B2Sufficient flatnessReduce variation in dimensional accuracyTelevision system detailsSemiconductor/solid-state device detailsSolid-stateEngineering

A solid-state imaging device includes: a base made of an insulation material and having a frame form in planar shape with an aperture formed at an inner region; a plurality of wirings provided on one surface of the base and extending toward an outer periphery of the base from a region along the aperture; and an imaging element mounted on the surface of the base with wirings provided thereon so that a light-receptive region of the imaging element faces the aperture. An end portion on the aperture side of each of the plurality of wirings forms an internal terminal portion and an end portion on the outer peripheral side of each of the plurality of wirings forms an external terminal portion, the internal terminal portion of the wiring being connected electrically with an electrode of the imaging element. The wirings are made of thin metal plate leads, the base is made up of a resin molded member in which the thin metal plate leads are embedded, and at least a part of a side edge face of the thin metal plate leads is embedded in the base. The rigidity of the base is enhanced by the thin metal plate leads, thus reducing a curl and a warp of the base.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

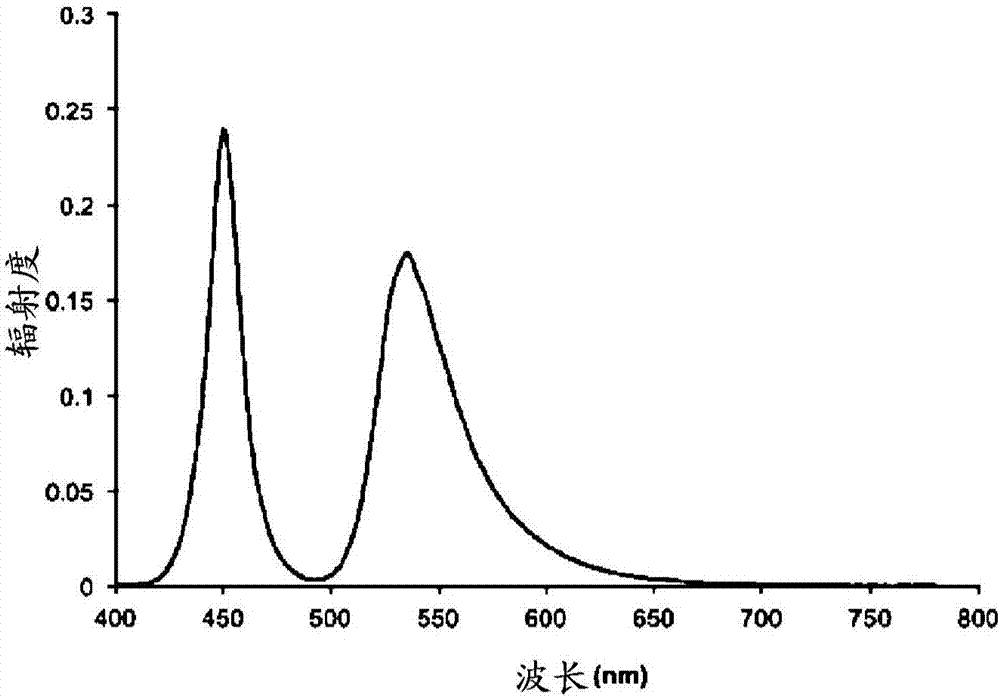

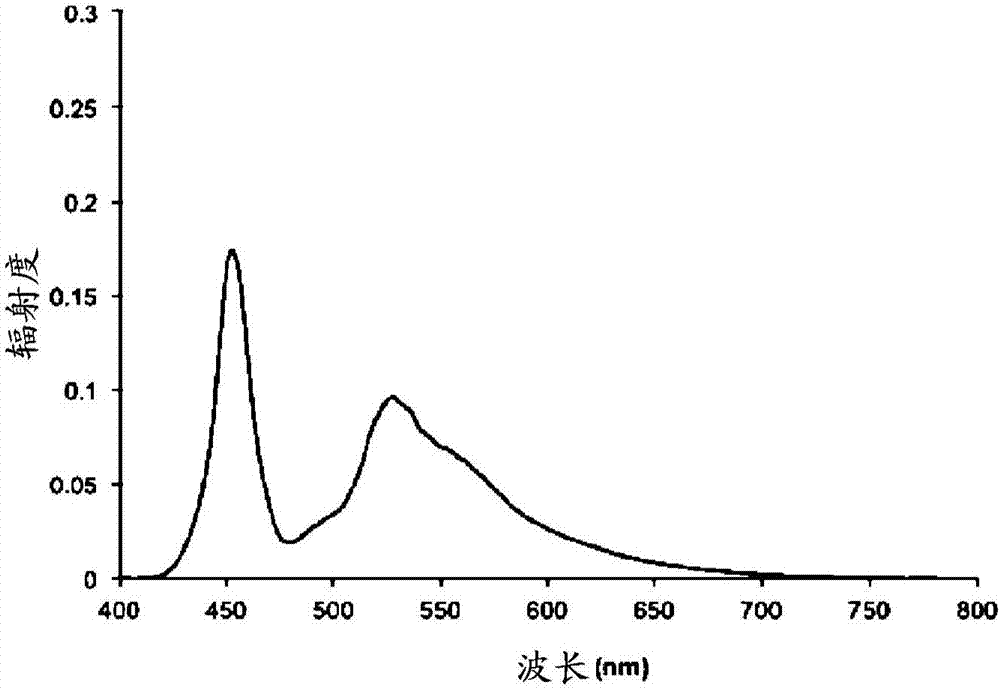

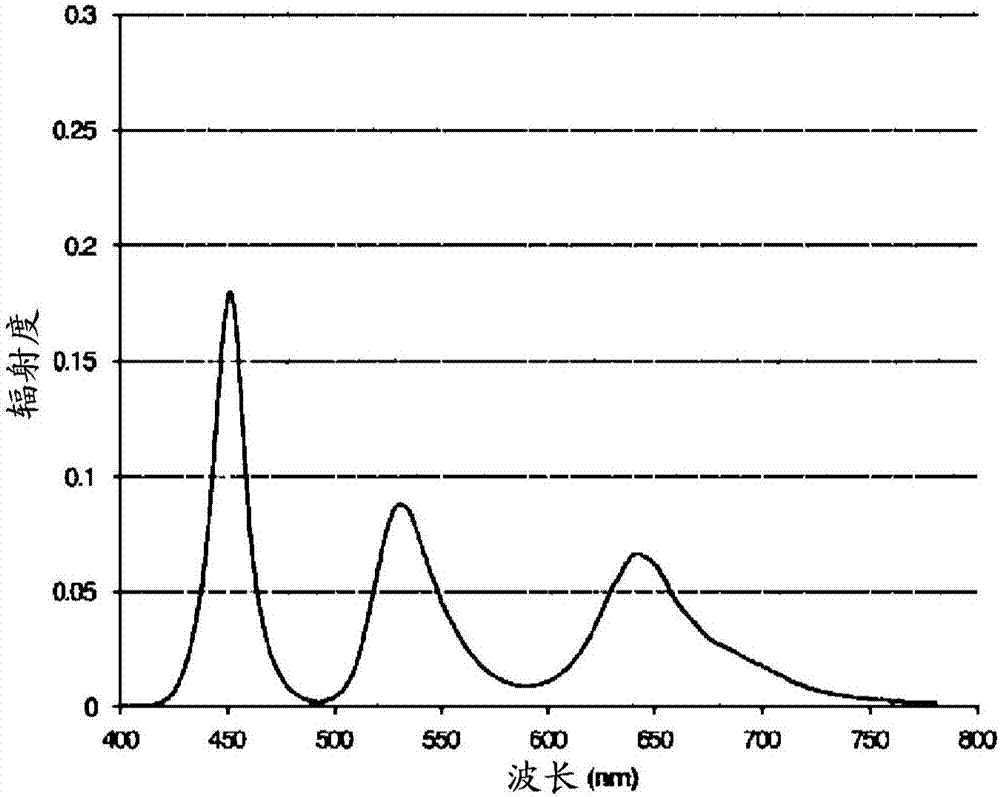

Color conversion film, method for producing same, back-light unit and display apparatus

ActiveCN107109021AGood environmental stabilityImprove quantum efficiencyOptical filtersLuminescent compositionsQuantum efficiencyLuminous intensity

The present invention relates to a color-conversion film, a method for producing same, and a back-light unit comprising the color-conversion film, the color-conversion film comprising: a resin matrix; and an organic fluorescent substance dispersed within the resin matrix and absorbing blue or green light to emit light of a different wavelength from the absorbed light, wherein the resin matrix comprises a thermoplastic resin, and the color-conversion film has: a light-emission peak at 450 nm; a half-width of 40 nm; a half-width of 60 nm or less at the light emission peak when irradiated with light having a mono-modal distribution of luminous intensity; a quantum efficiency of 80% or greater; and an absorption coefficient of 30,000 M-1cm-1 or greater at the maximum absorption wavelength.

Owner:LG CHEM LTD

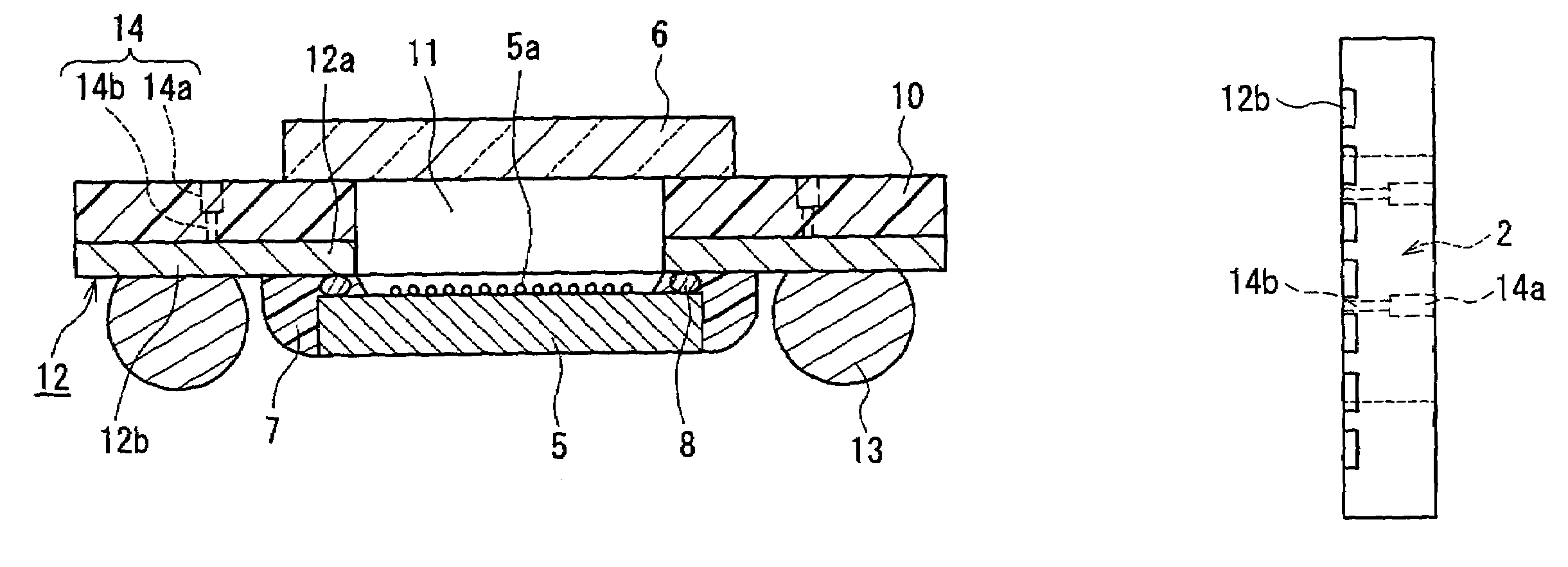

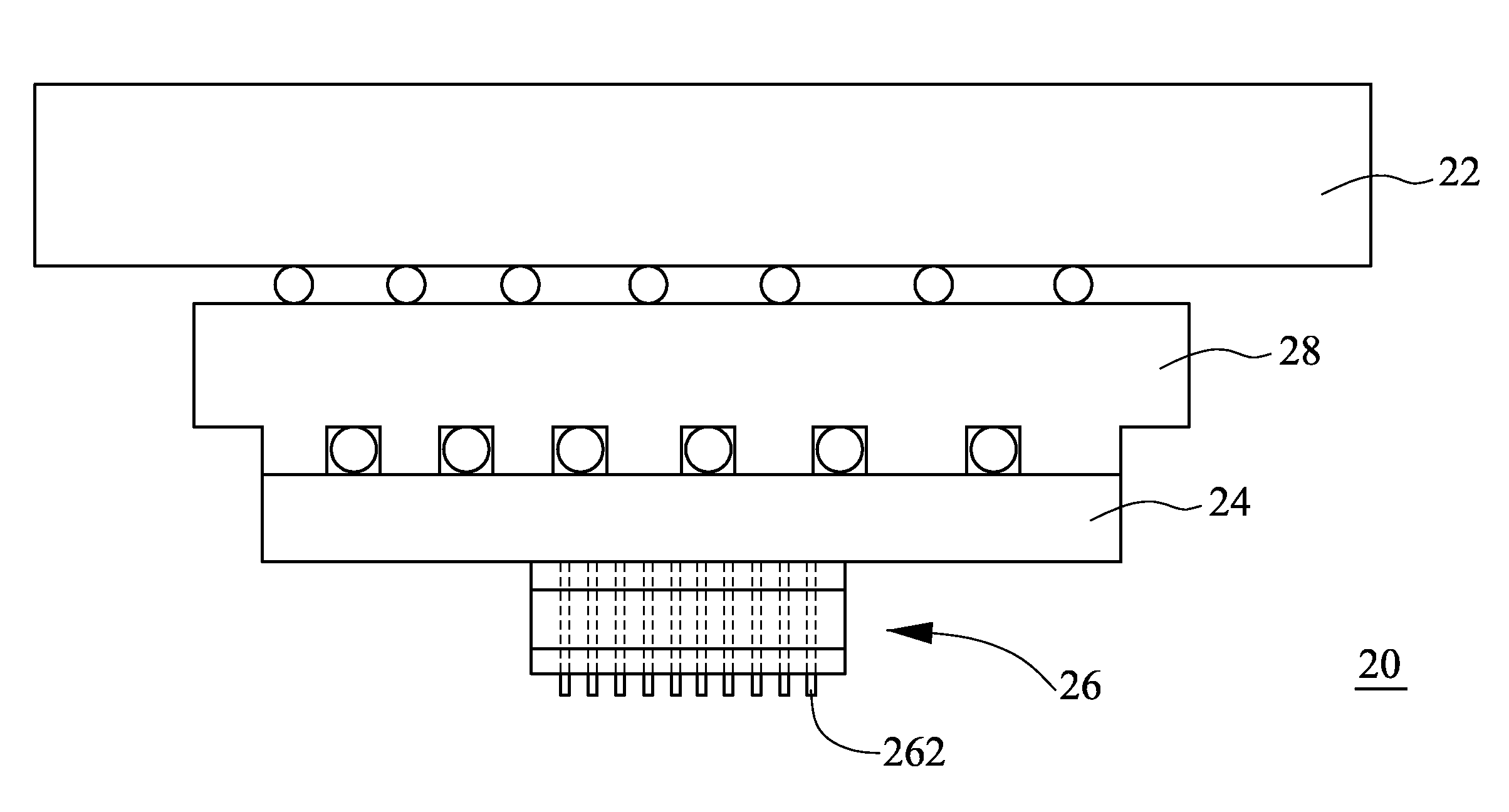

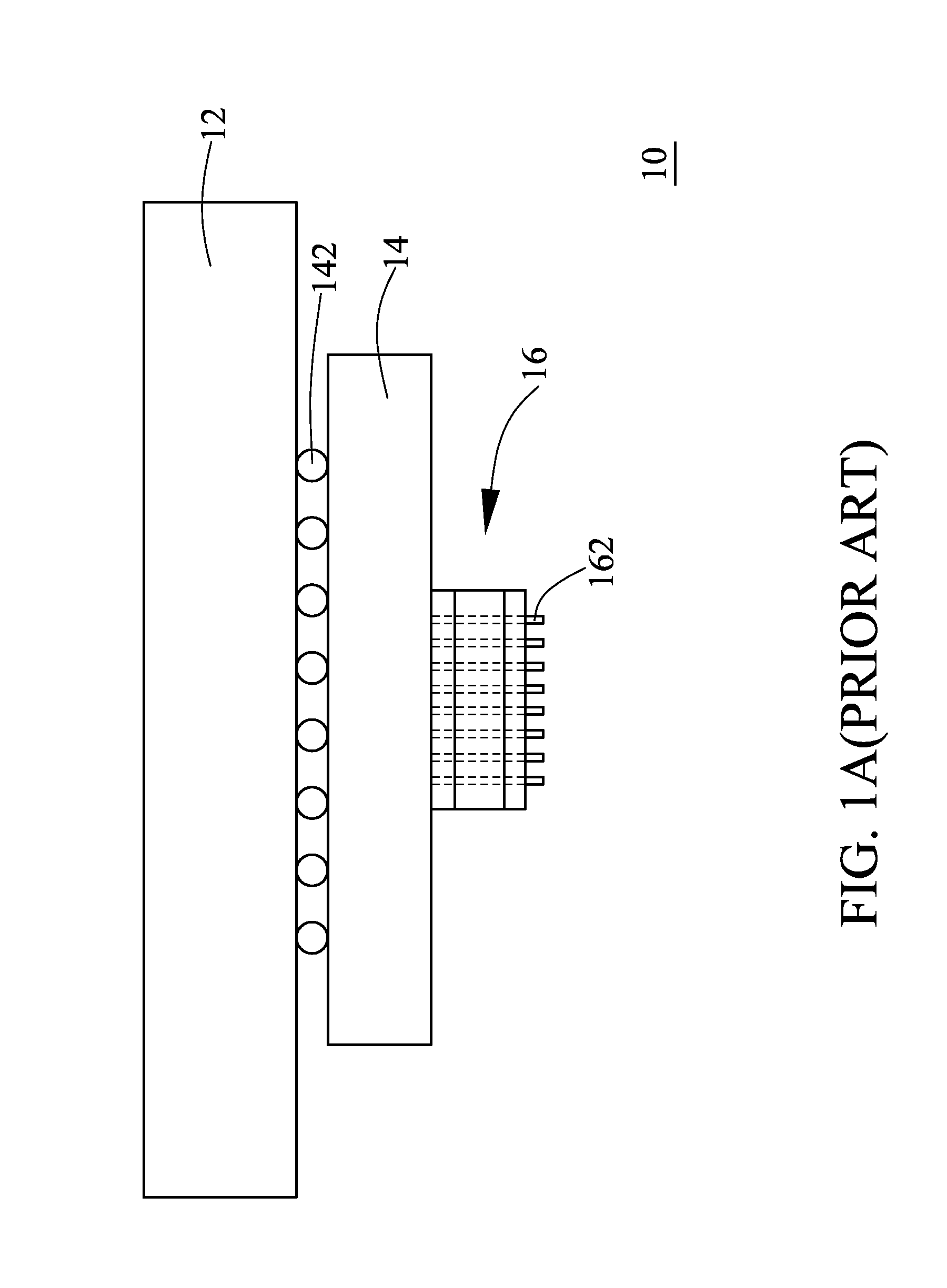

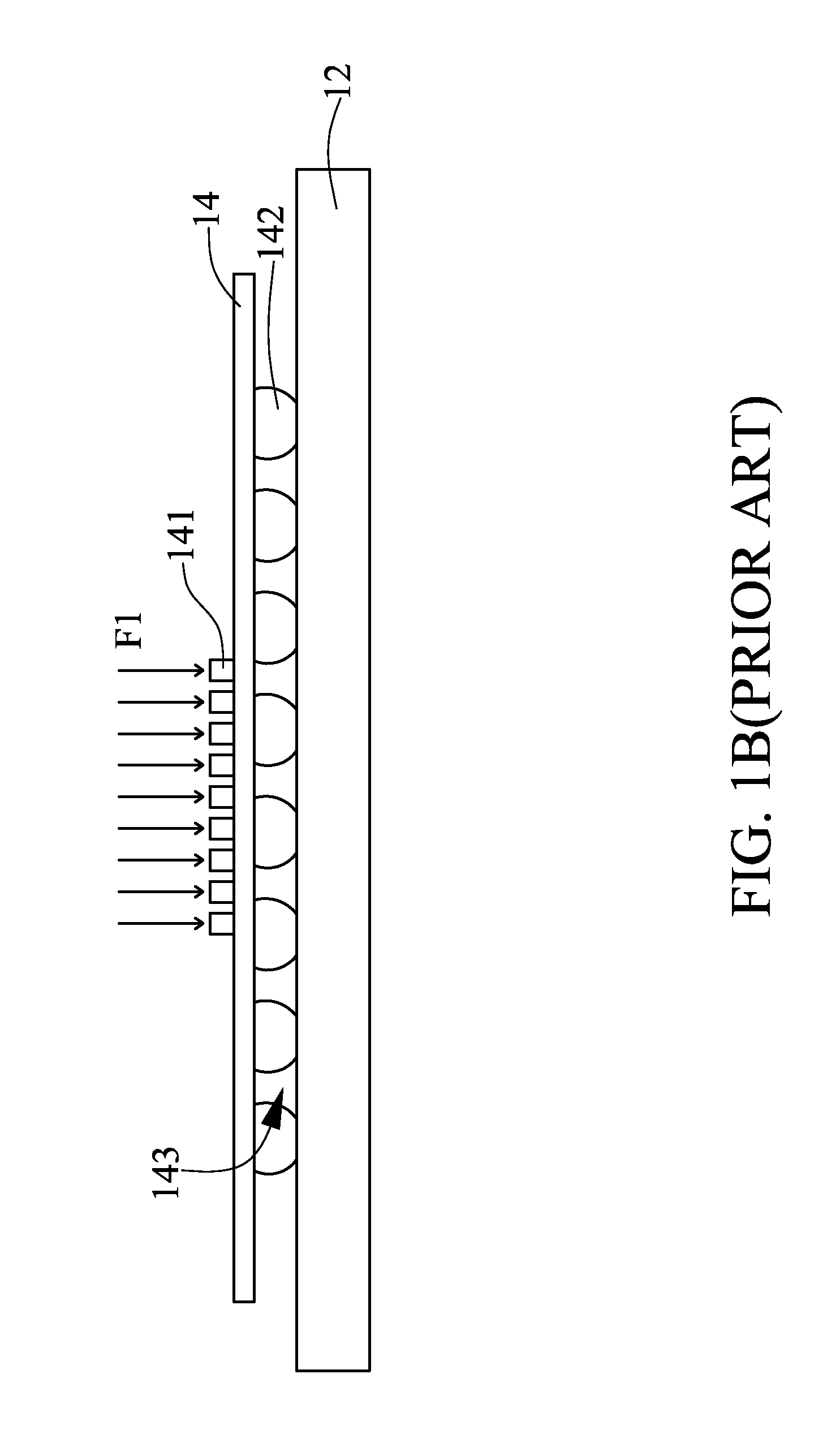

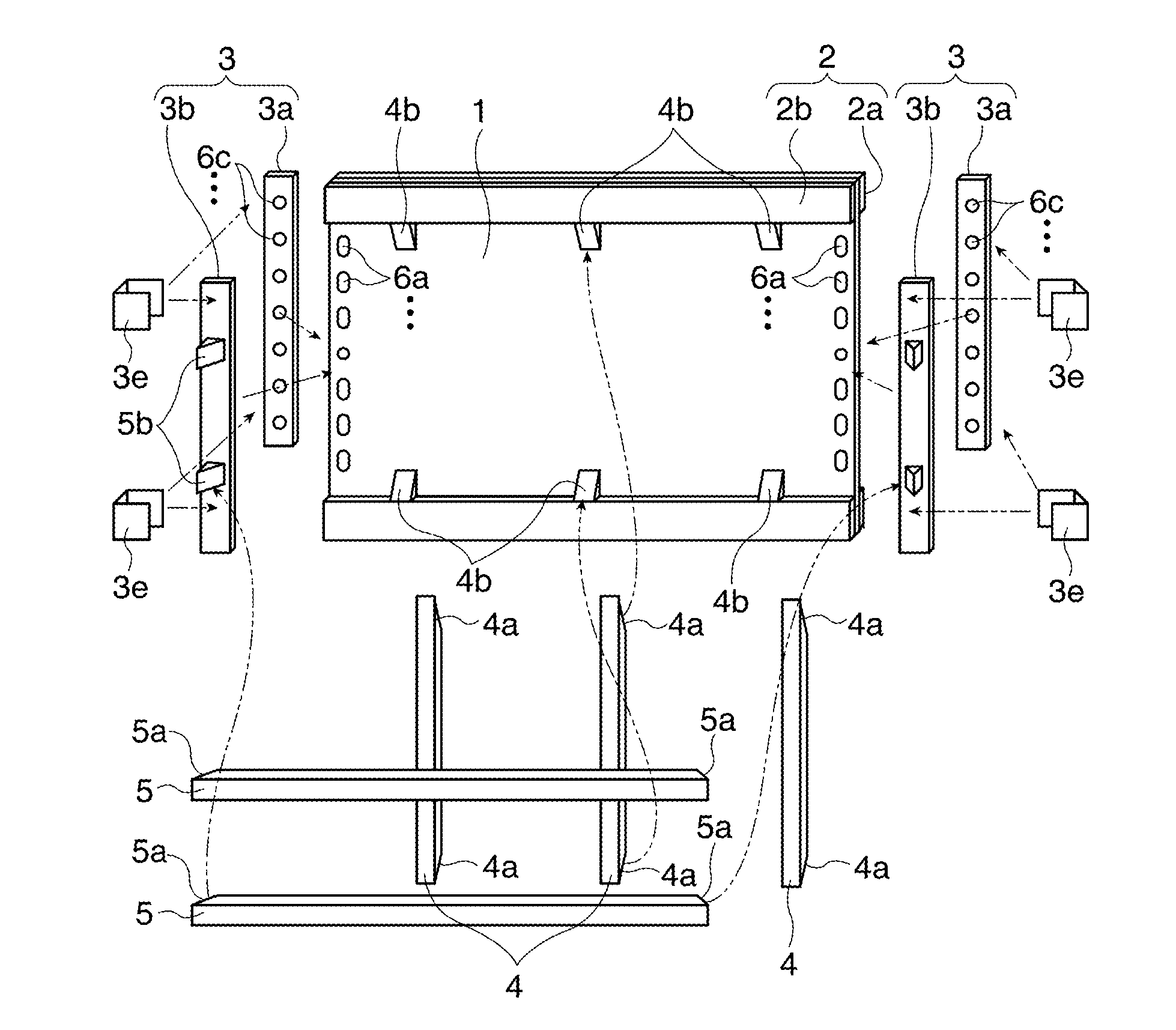

Probing device

ActiveUS20130033283A1Avoid deformationSufficient flatnessElectrical measurement instrument detailsElectrical testingElectricityTransformer

A probing device includes a circuit board, a reinforcing plate, at least one space transformer and at least one probe assembly. The reinforcing plate is disposed on the circuit board, and the reinforcing plate has a plurality of inner conductive wires electrically connecting to those of the circuit board. The reinforcing plate defines a plurality of receiving space therein. The space transformer is disposed on the reinforcing plate, and the space transformer has a plurality of inner conductive wires electrically connecting to those of the reinforcing plate via a plurality of first solder balls. The probe assembly is disposed on the space transformer, and the probe assembly includes a plurality of probes. The first solder balls are disposed in the receiving spaces, and the reinforcing plate abuts against the space transformer.

Owner:MICROELECTRONICS TECH INC

Multilayer ceramic substrate and method for manufacturing the same

InactiveUS20030094307A1Sufficient flatnessPreventing defect in vicinitySemiconductor/solid-state device detailsSolid-state devicesConductive materialsHigh dimensional

A multilayer ceramic substrate includes a glass ceramic body, a conductive pattern, and a via conductor. The conductive pattern is formed in the glass ceramic body and on at least one principal surface of the glass ceramic body. The via conductor makes a connection between the predetermined conductive patterns. The via conductor includes a conductive material and a Mo compound or a Mo metal. The conductive material includes at least one selected from the group consisting of Ag, Au, Pt and Pd as a main component. The amount of Mo compound or Mo metal is in the range of 0.05 to 10 parts by weight in terms of Mo metal with respect to 100 parts by weight of the conductive material. This multilayer ceramic substrate can achieve sufficient flatness and high dimensional accuracy, while preventing defects that occurs in the vicinity of electrodes after firing.

Owner:PANASONIC CORP

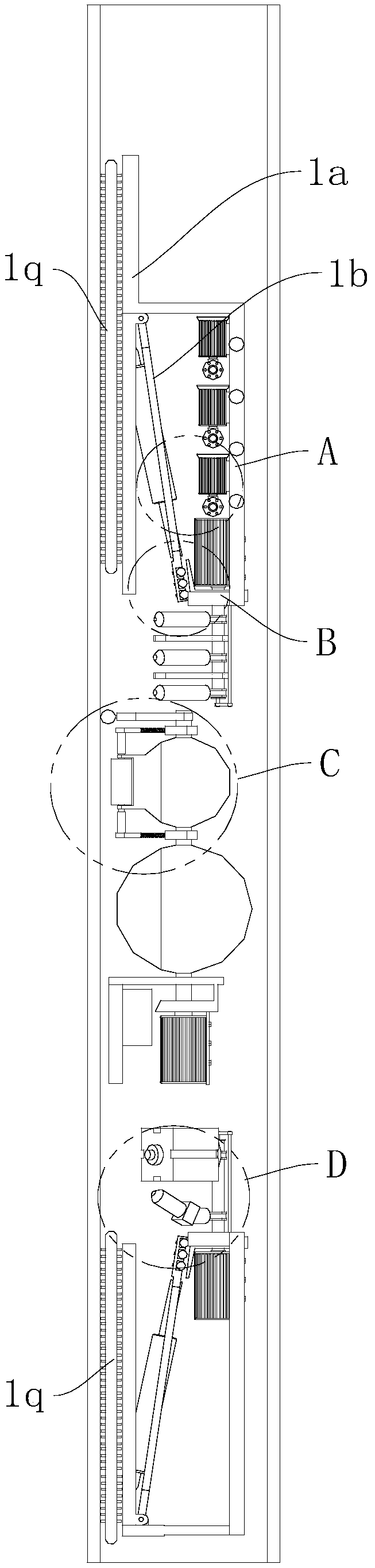

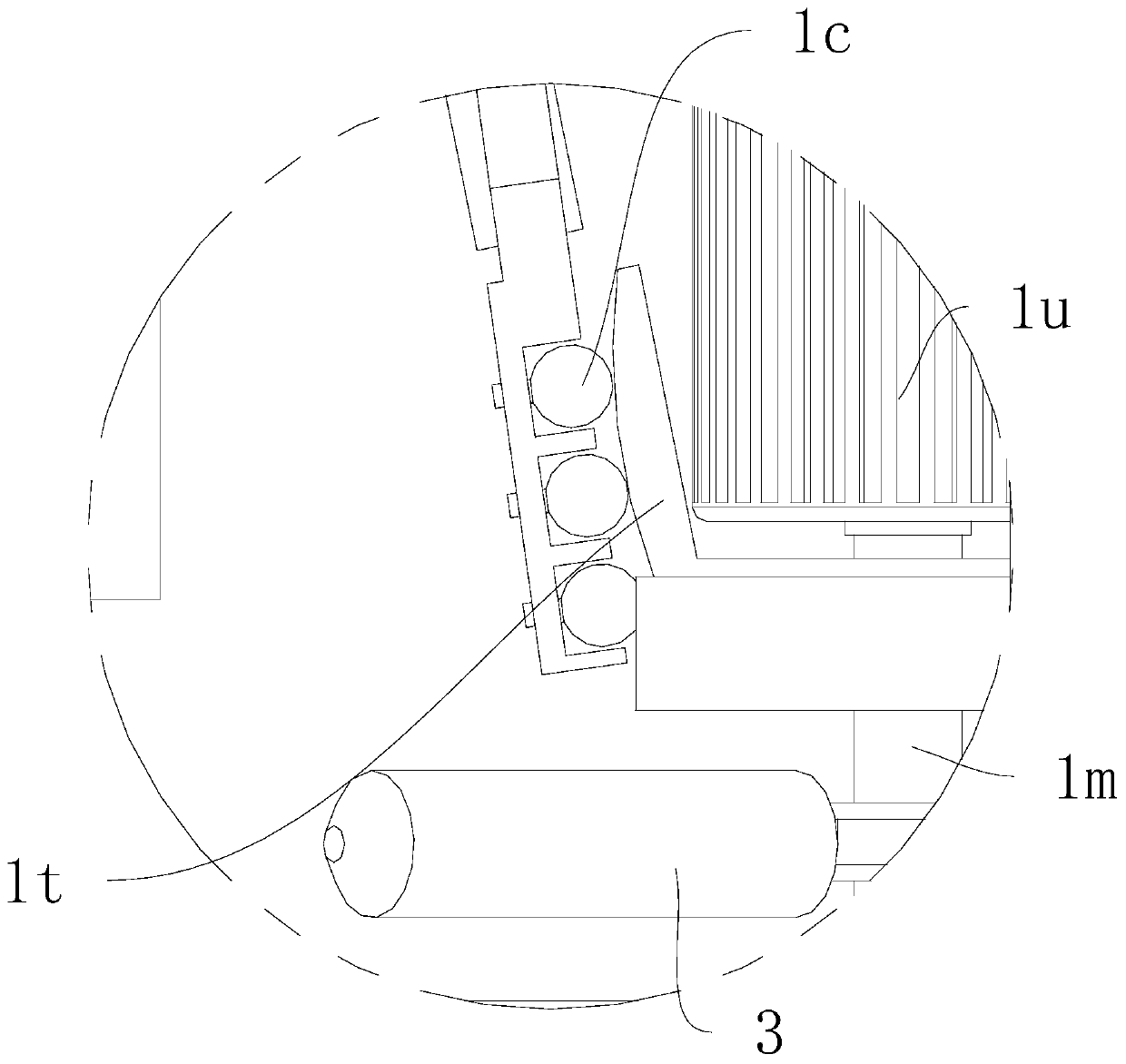

Remote pipe local annular repair equipment and method

ActiveCN110030459AFully hot-pressed trimming purposeFully hot-pressed trimming purpose to make it fast curingPigs/molesControl engineeringCcd camera

The invention relates to the technical field of pipe maintenance equipment, in particular, remote pipe local annular repair equipment and method. The remote pipe local annular repair equipment comprises a detection mechanism, a repair mechanism, an auxiliary mechanism and two small-size intelligent vehicles. The detection mechanism and the repair mechanism are each arranged on the corresponding small-size intelligent vehicle. Each small-size intelligent vehicle comprises a base plate, a lifting plate, an ascending-and-descending block and a small-size hydraulic rod. One end of each lifting plate is in shaft connection with one end of the corresponding base plate in a matched manner. Each small-size hydraulic rod is mounted at the outer side of the corresponding base plate and used for driving the other end of the corresponding lifting plate to move. A top beam bracket is arranged above each base plate in an erected manner. Each ascending-and-descending block is movably arranged at oneend of the corresponding top beam bracket. The bottom of each ascending-and-descending block is in transmission fit with the free end of the corresponding lifting plate. The detection mechanism comprises a CCD camera and a light supplementing device, wherein the CCD camera and the light supplementing device are mounted at the front sides of the ascending-and-descending blocks corresponding to theCCD camera and the light supplementing device. The repair mechanism comprises a first spray head, a second spray head and a third spray head, wherein the first spray head, the second spray head and the third spray head are mounted at the front sides of the ascending-and-descending blocks corresponding to the first spray head, the second spray head and the third spray head. The auxiliary mechanismcomprises a cleaning air bag and a compaction air bag. By means of the remote pipe local annular repair equipment and method, the repair quality can be greatly improved.

Owner:浙江蓝清市政建设集团有限公司

Magnetic recording medium and method of making the same

ActiveUS7588843B2Sufficient flatnessReduce the overall heightRecord information storageCoating part of support with magnetic layerRecording layerContinuous recording

A magnetic recording medium includes a continuous recording layer, and a seed layer including a surface held in contact with the recording layer. The seed layer includes an oxidized region and a non-oxidized region in the surface held in contact with the recording layer. The recording layer includes a recording magnetic region and a non-recording magnetic region. The recording magnetic region corresponds in position to the non-oxidized region and has perpendicular magnetic anisotropy. The non-recording magnetic region corresponds in position to the oxidized region.

Owner:RESONAC CORP

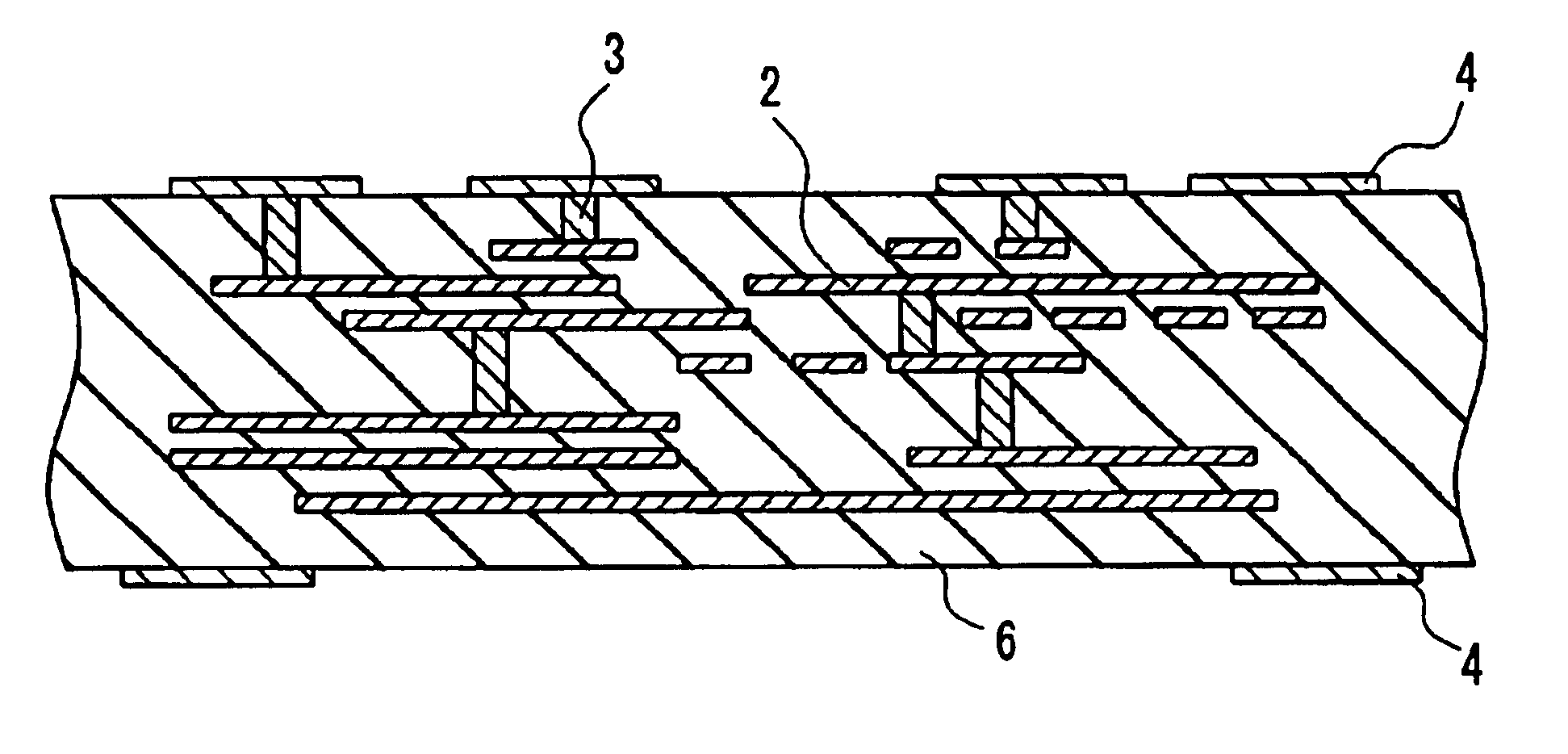

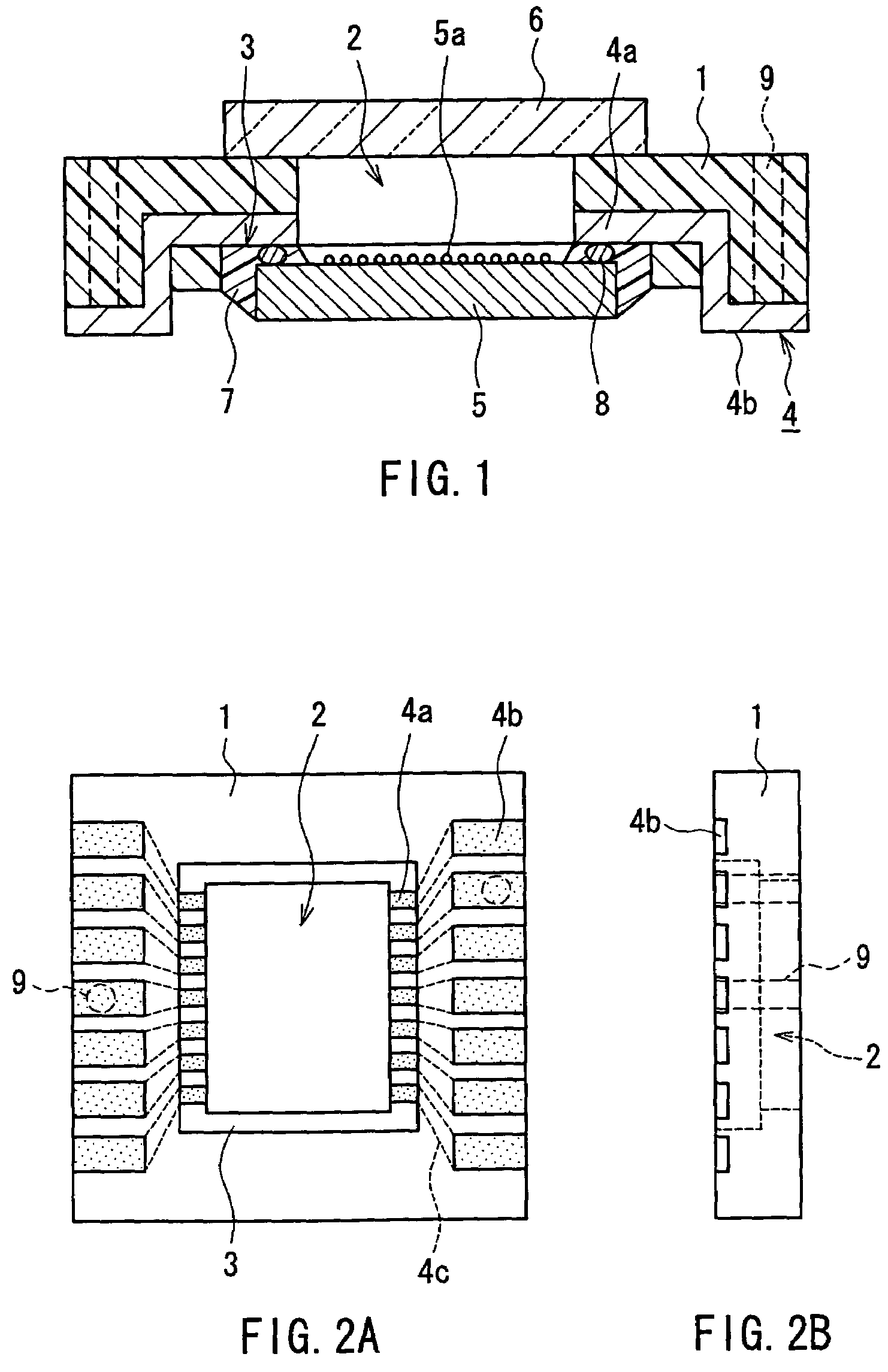

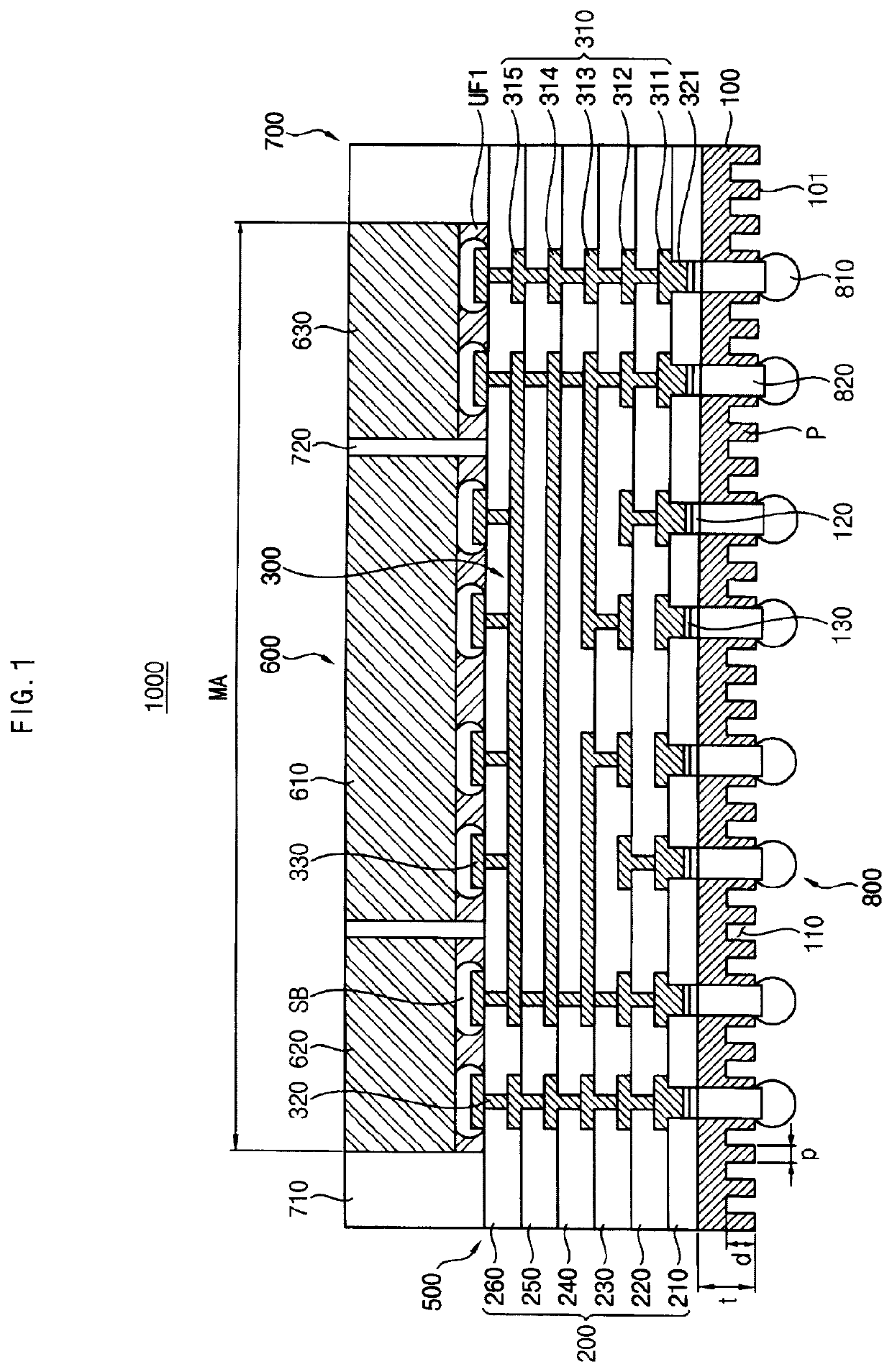

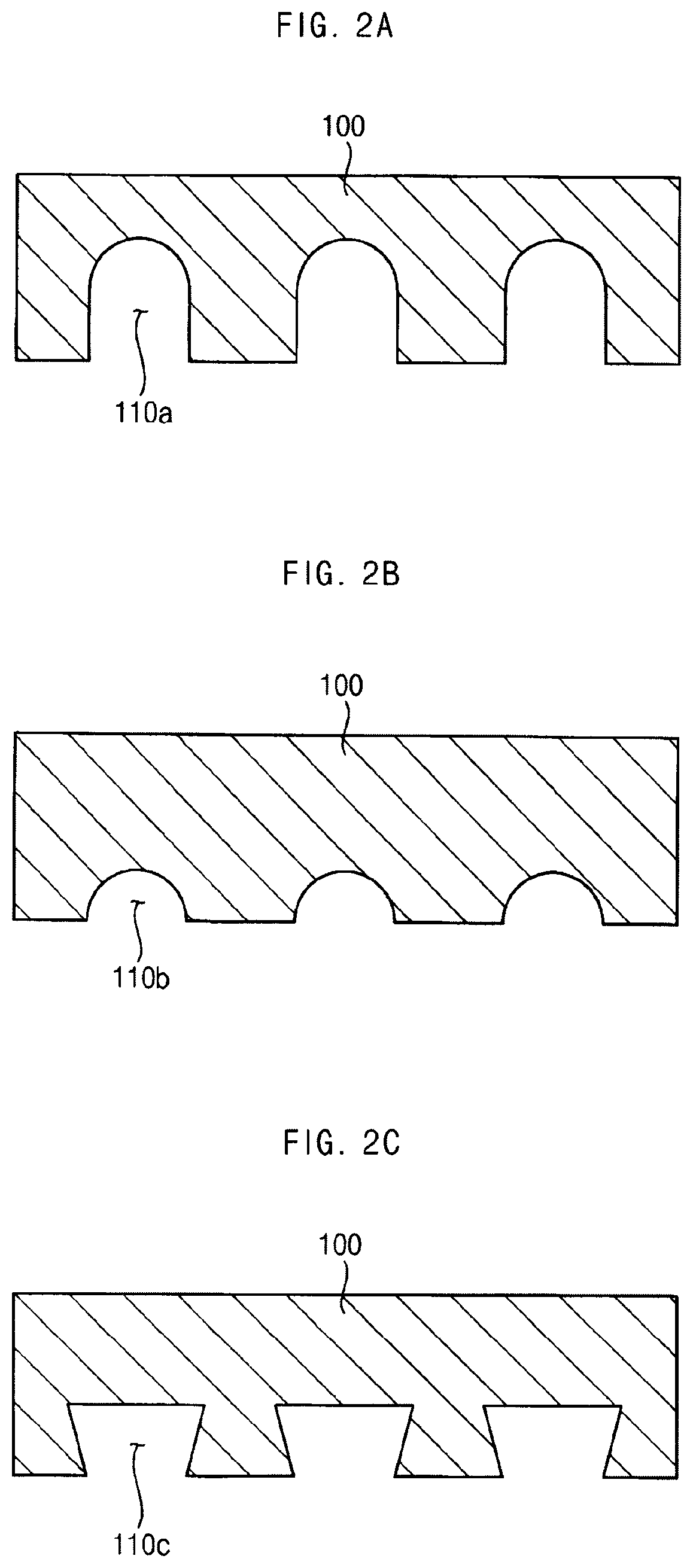

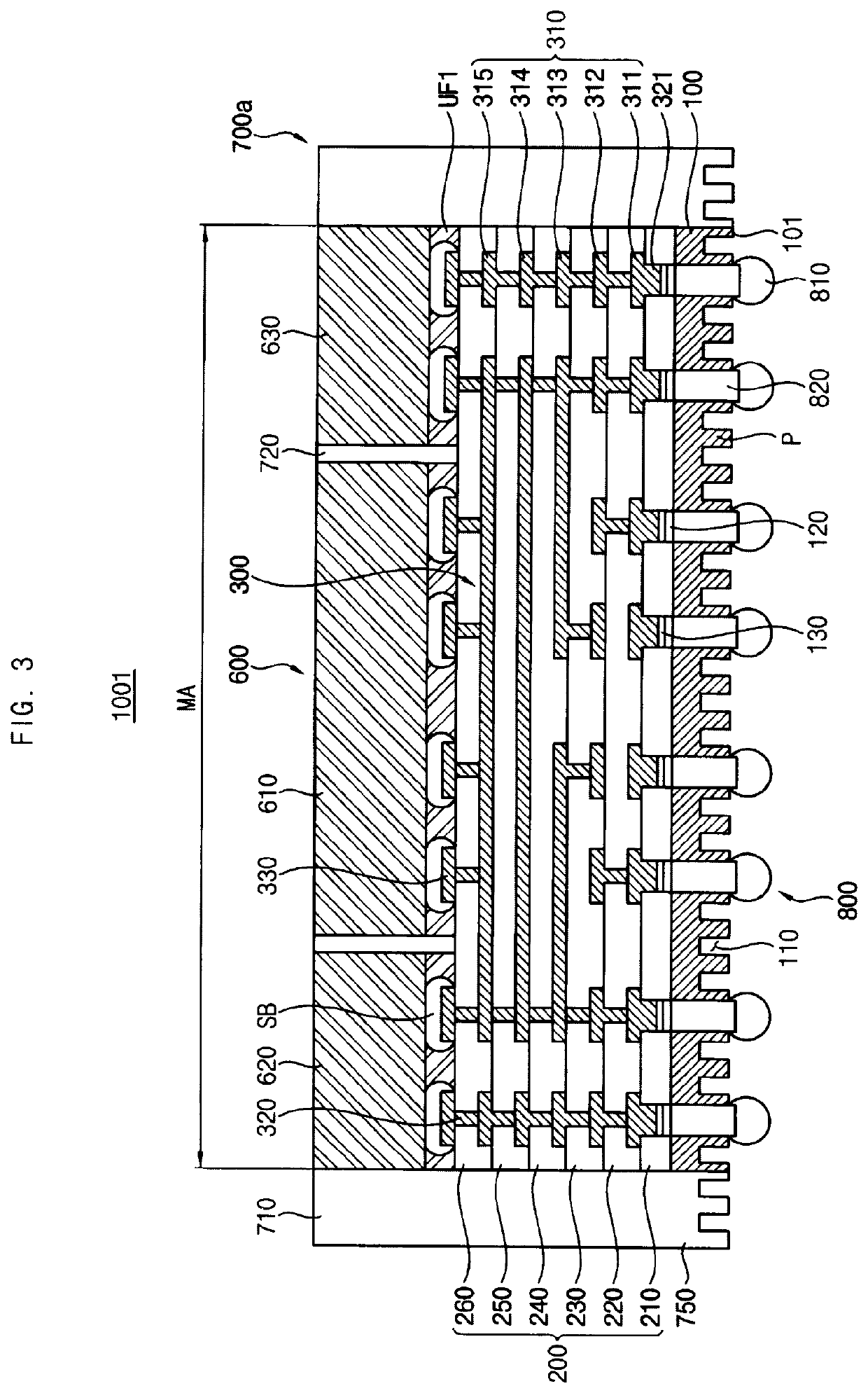

Semiconductor package, electronic apparatus and method of manufacturing the semiconductor package

ActiveUS20210210360A1Enhance combination forceIncrease forceSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor package

A semiconductor package includes an interposer having a separation layer on a rear surface of which a plurality of first recesses is arranged. A plurality of wiring structures is stacked on the separation layer alternately with a plurality of insulation interlayers. A plurality of semiconductor devices is arranged, side by side, on the interposer side and connected to a plurality of the wiring structures. A plurality of contact terminals on the rear surface of the separation layer is connected to the plurality of the wiring structures through the separation layer. A flatness deterioration of the interposer is minimized and the contact surface between the interposer and under fill resin is enlarged.

Owner:SAMSUNG ELECTRONICS CO LTD

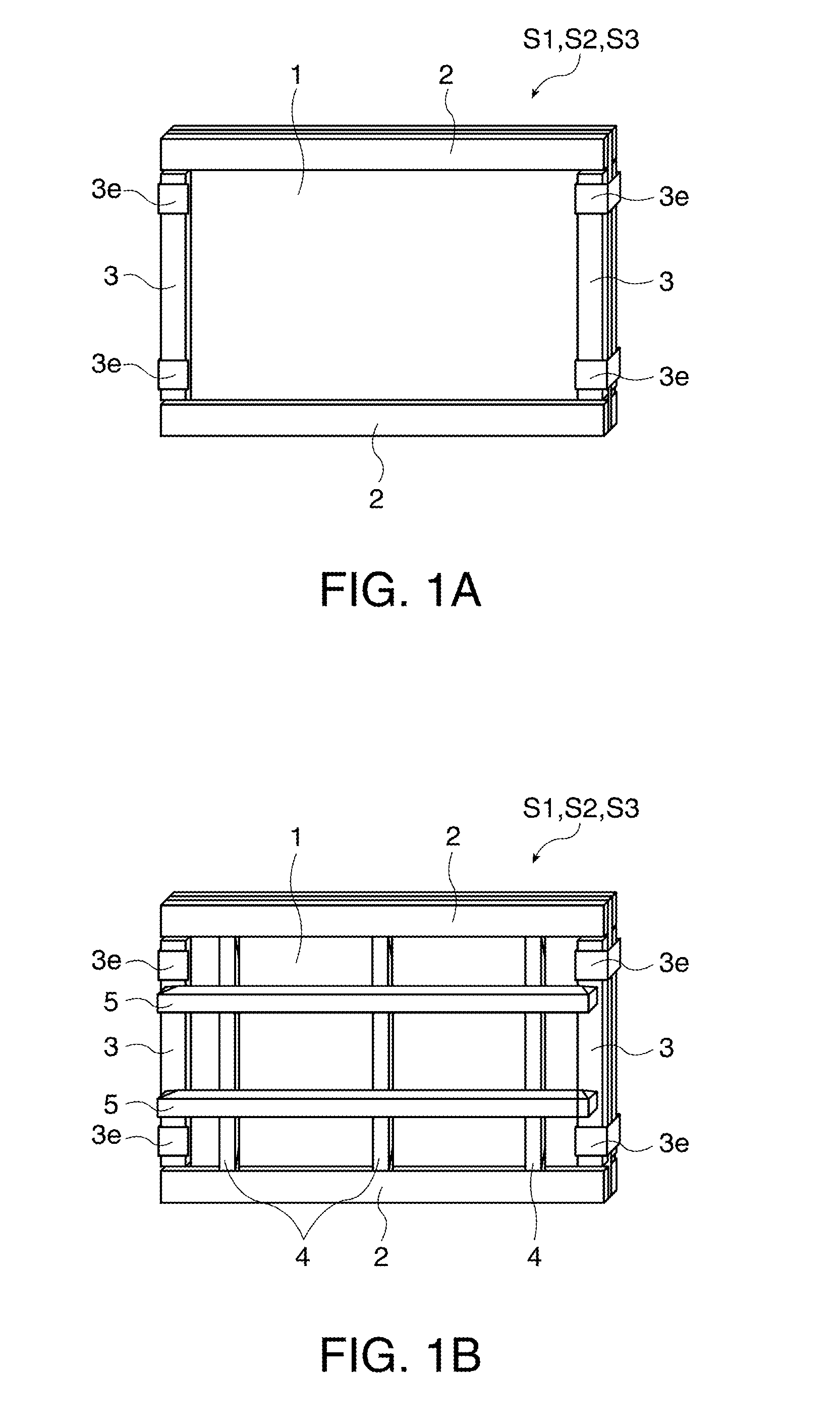

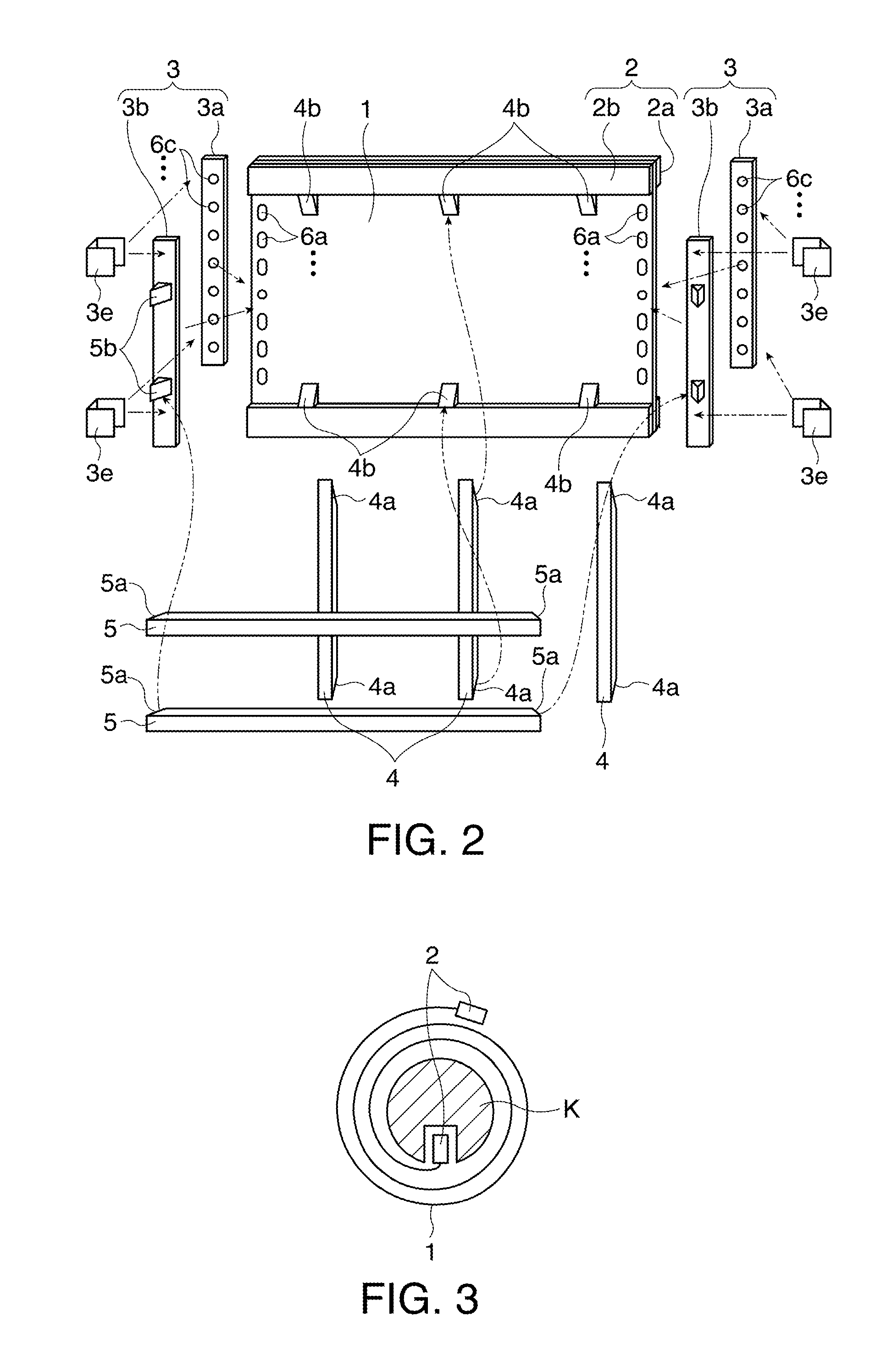

Screen unit

Owner:SEIKO EPSON CORP

Semiconductor device including capacitor element provided above wiring layer that includes wiring with an upper surface having protruding portion

ActiveUS8039924B2Reduction withstanding voltage can be suppressedImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesCapacitorSemiconductor

Owner:RENESAS ELECTRONICS CORP

Screen unit

Owner:SEIKO EPSON CORP

Solid-state imaging device and method for producing the same

InactiveUS20070069319A1Sufficient flatnessReduce variationTelevision system detailsContact member manufacturingThin metalEngineering

A solid-state imaging device includes: a base made of an insulation material and having a frame form in planar shape with an aperture formed at an inner region; a plurality of wirings provided on one surface of the base and extending toward an outer periphery of the base from a region along the aperture; and an imaging element mounted on the surface of the base with wirings provided thereon so that a light-receptive region of the imaging element faces the aperture. An end portion on the aperture side of each of the plurality of wirings forms an internal terminal portion and an end portion on the outer peripheral side of each of the plurality of wirings forms an external terminal portion, the internal terminal portion of the wiring being connected electrically with an electrode of the imaging element. The wirings are made of thin metal plate leads, the base is made up of a resin molded member in which the thin metal plate leads are embedded, and at least a part of a side edge face of the thin metal plate leads is embedded in the base. The rigidity of the base is enhanced by the thin metal plate leads, thus reducing a curl and a warp of the base.

Owner:PANASONIC CORP

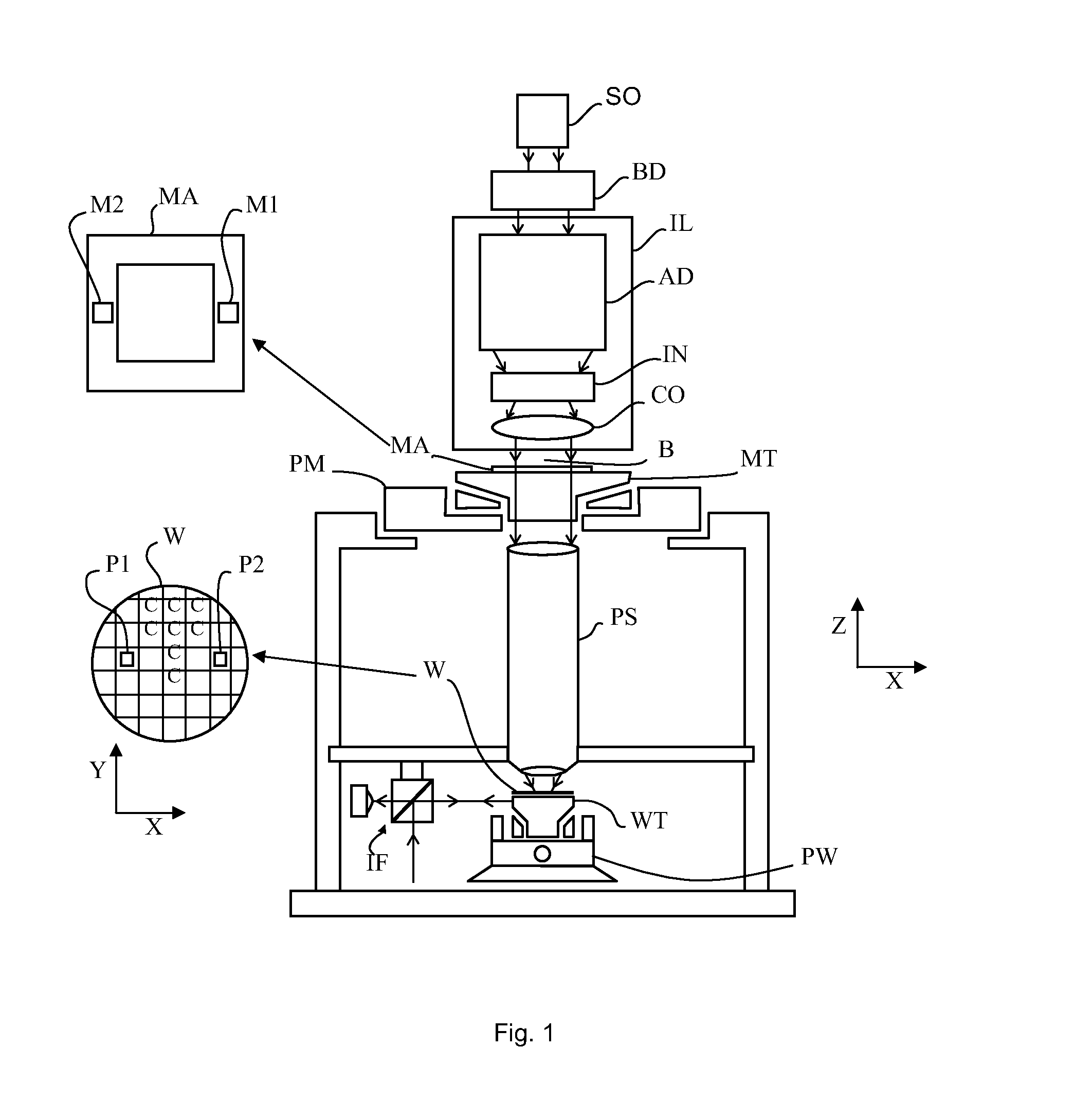

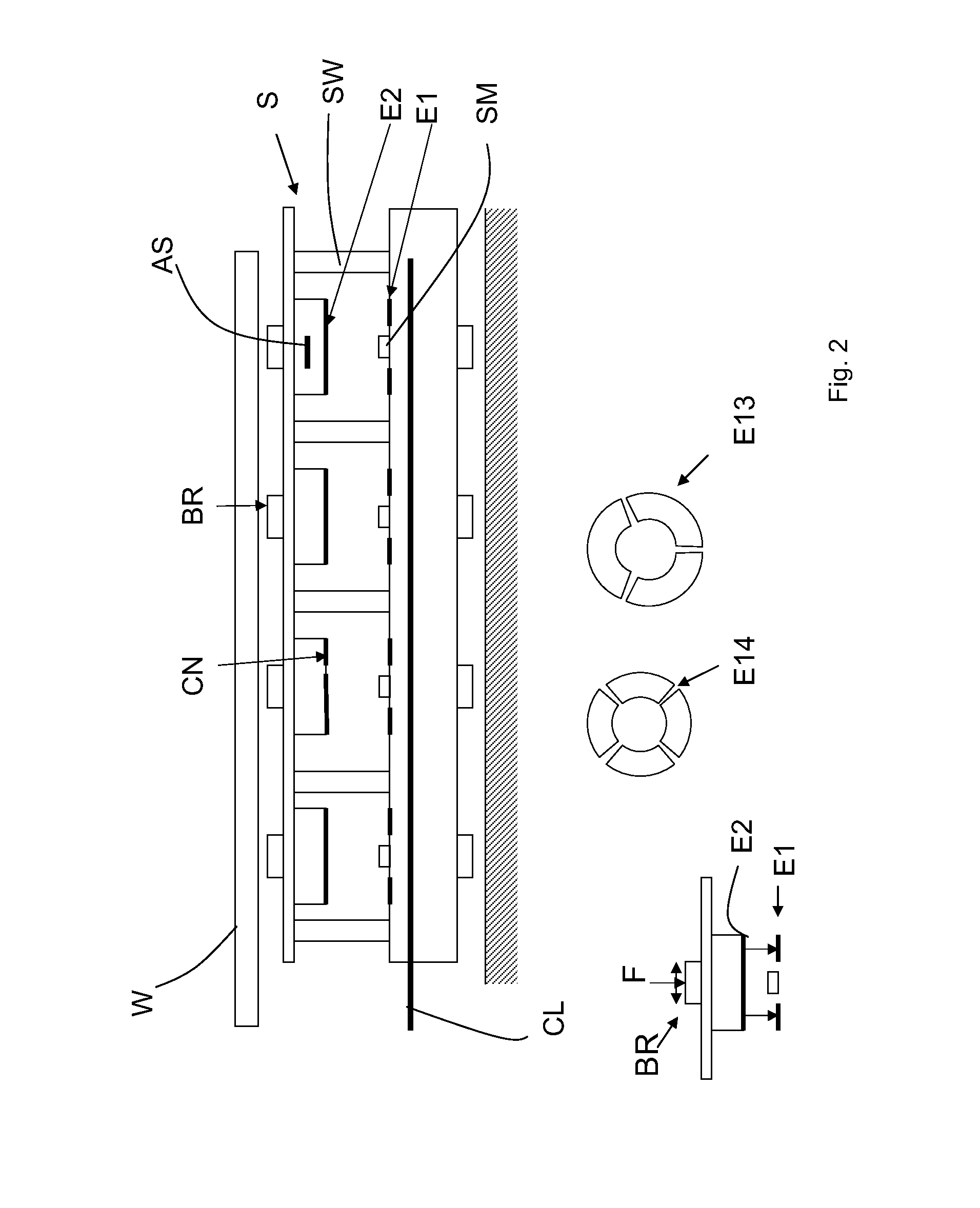

Lithographic Apparatus Comprising a Support for Holding an Object, and a Support for Use therein

ActiveUS20150002832A1Sufficient flatnessSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringMechanical engineering

Owner:ASML NETHERLANDS BV

Multilayer ceramic substrate

InactiveUS20080283281A1Dimensional accuracy is securedSufficient flatnessSemiconductor/solid-state device detailsSolid-state devicesMetallurgyCeramic substrate

Owner:TDK CORPARATION

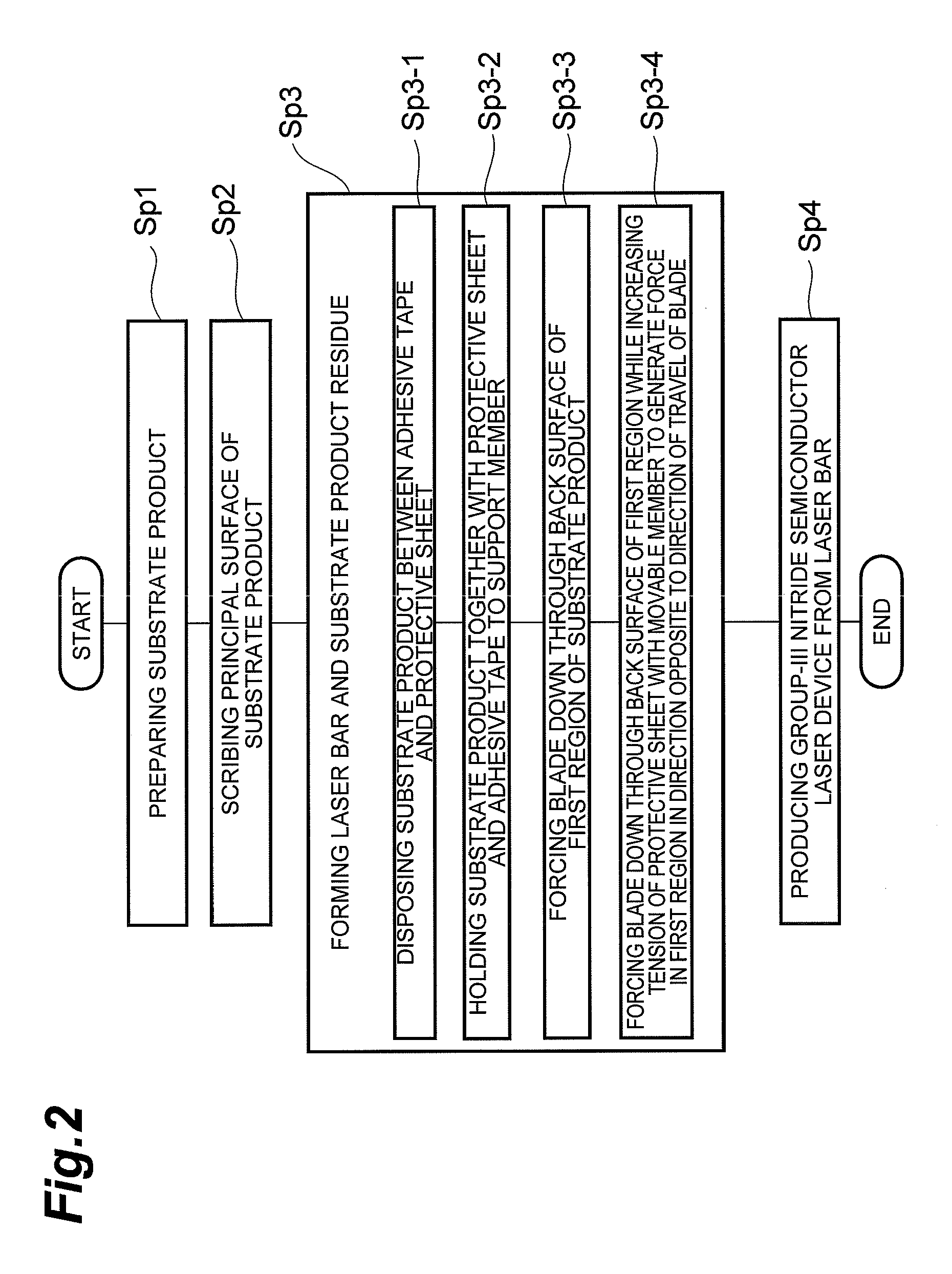

Method for fabricating group-iii nitride semiconductor laser device

InactiveUS20130065336A1Improve flatnessHigh perpendicularitySemiconductor/solid-state device manufacturingNanoopticsAngle alphaNitride semiconductors

A method for fabricating a group-III nitride semiconductor laser device stably supplies laser cavity mirrors having a low lasing threshold current through the use of a semi-polar plane. A blade 5g is forced down through a first region ER1 to keep the first region ER1 squeezed between a support member H2 and a movable member H1 together with a part of a protective sheet TF in contact with the first region ER1 while the tension generated in the area of the protective sheet TF in contact with the first region ER1 with the movable member H1 increases until the semi-polar principal surface SF at an end face EG1 of the first region ER1 tilts by a deflection angle THETA from the semi-polar principal surface SF of a second region ER2, and a force is thereby generated in the first region ER1 in a direction opposite to the direction of travel of the blade 5g toward the first region ER1. For example, an angle ALPHA is within the range of 71 degrees to 79 degrees, and the deflection angle THETA is within the range of 11 to 19.

Owner:SUMITOMO ELECTRIC IND LTD

Stainless steel, titanium, or titanium alloy solid polymer fuel cell separator and its method of production and method of evaluation of warp and twist of separator

ActiveUS7807281B2Small releaseLow costFuel cells groupingFinal product manufactureTitanium alloyContact resistance

The present invention releases a method of producing a metal separator for a solid polymer fuel cell by stainless steel, titanium, or titanium alloy during which securing lower cost and mass producibility by using a material having a high workability to form a complicated shape by a high productivity, then using an inexpensive blast process to drive a conductive substance into the surface of the metal separator member, that is, provides a stainless steel, titanium, or titanium alloy solid polymer fuel cell separator comprised of stainless steel, titanium, or titanium alloy in the surface of which a low ion release conductive substance is buried, having an arithmetic mean roughness (Ra) of the separator surface of 0.5 to 5.0 μm, having a 10-point mean roughness (Rz) of 3 to 20 μm, having an average spacing of surface relief shapes (Sm) of 300 μm or less, having values of a warp rate and twist rate of a separator of 0.1 or less, and having a contact resistance value with respect to carbon paper of 15 mΩcm2 or less at a surface pressure of 1 MPa.

Owner:SINTOKOGIO LTD

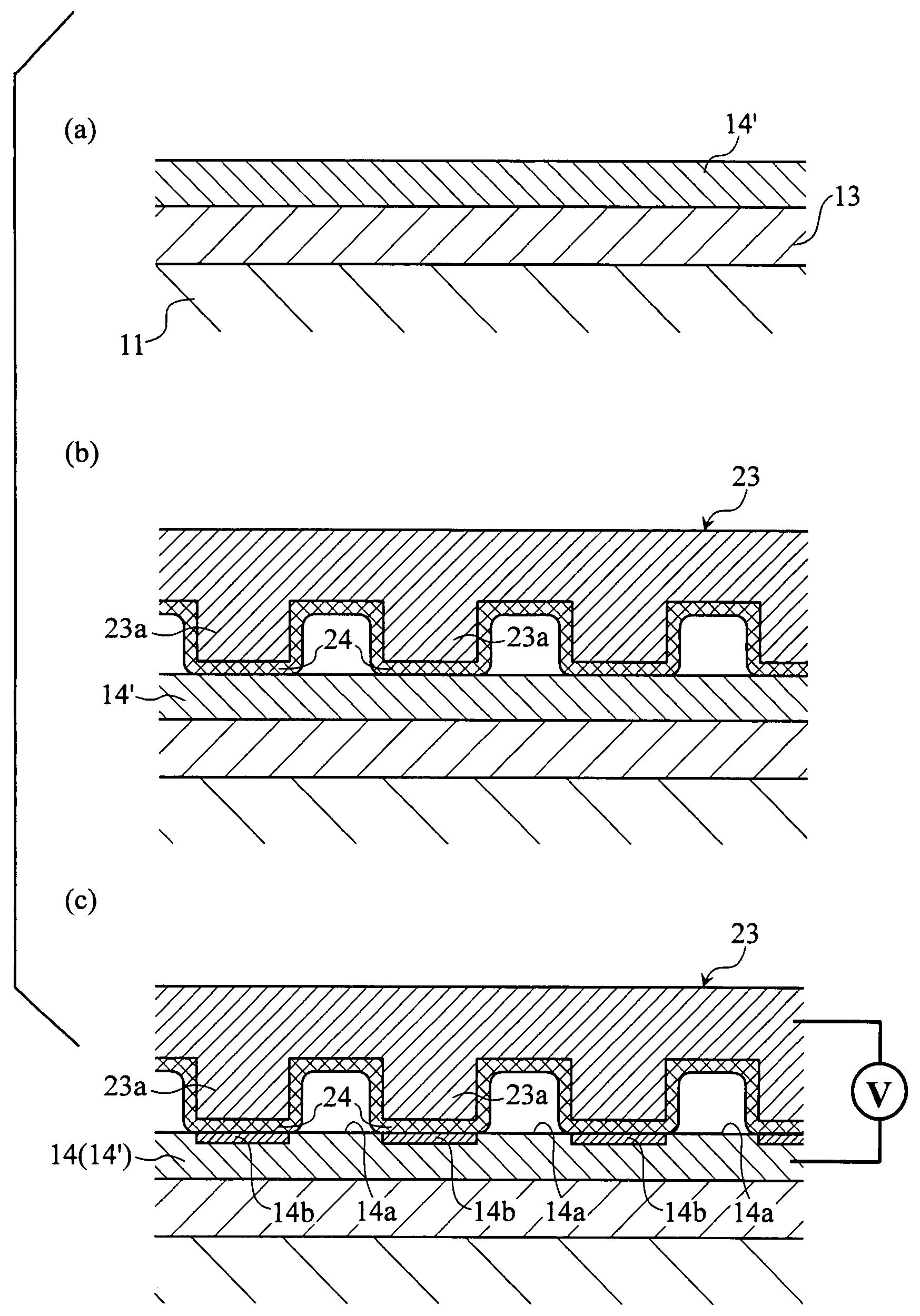

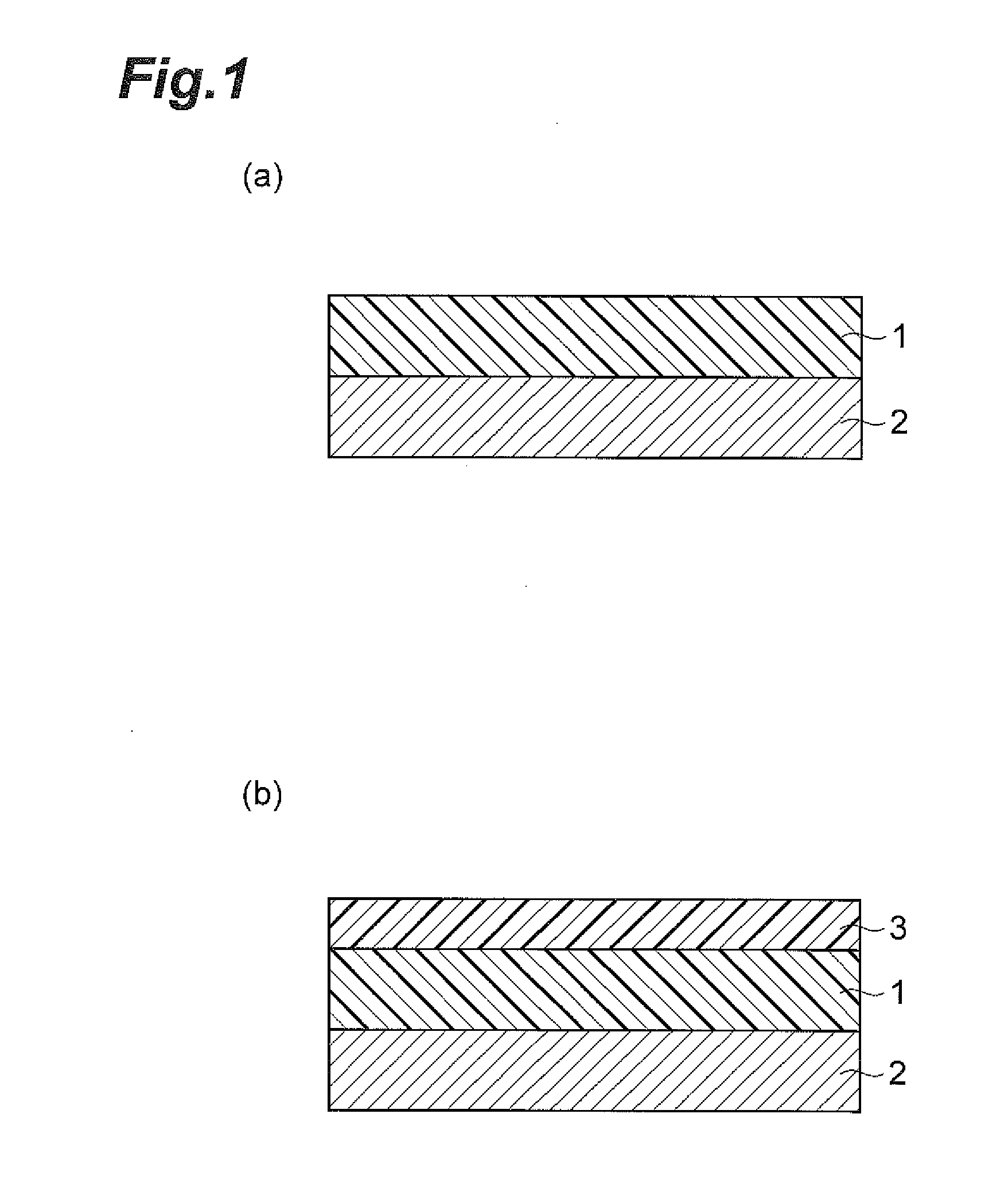

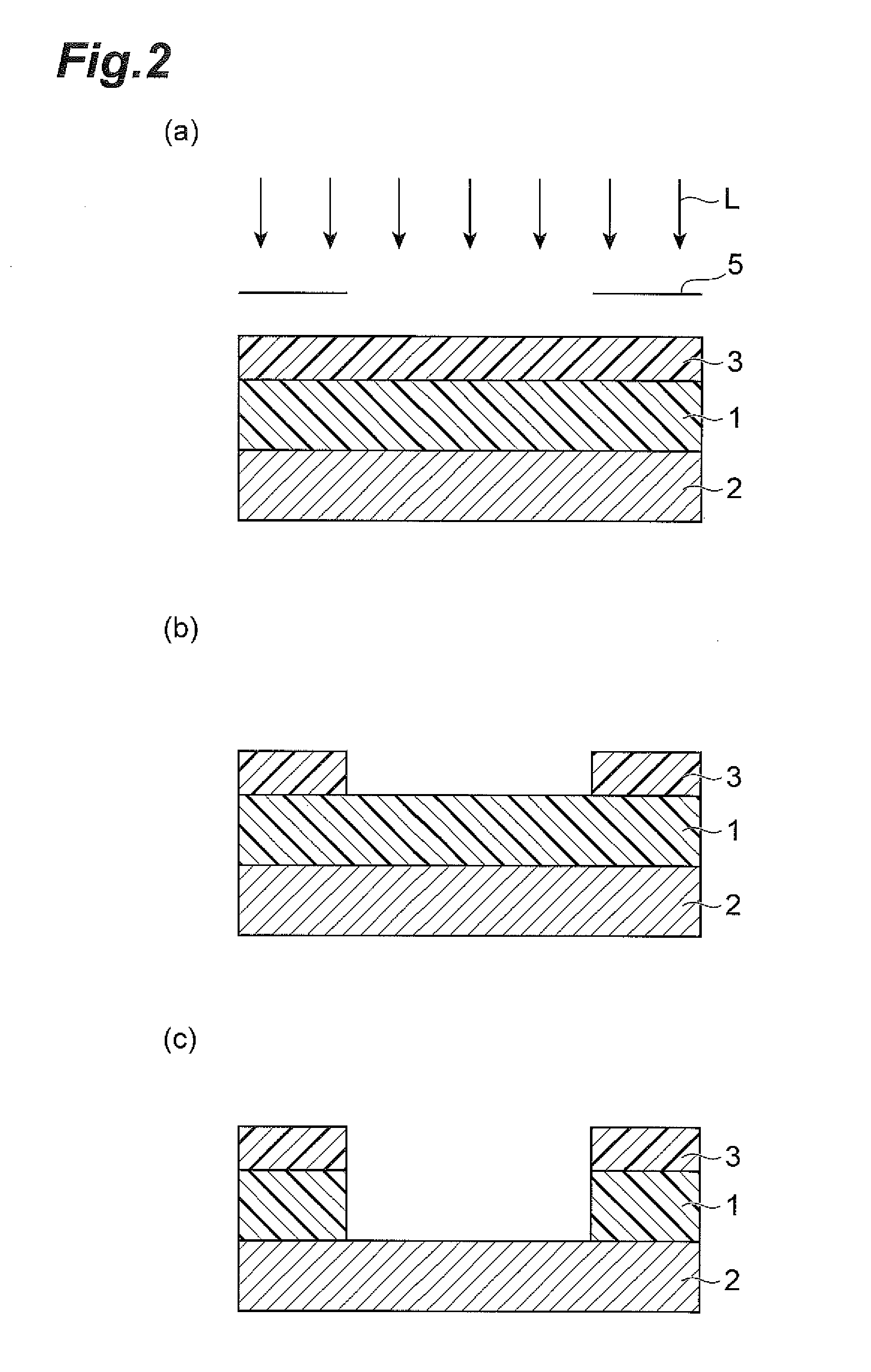

Method for manufacturing adhesion body, method for manufacturing substrate with adhesive pattern, and substrate with adhesive pattern

InactiveUS20120202015A1Sufficient flatnessInhibitionAdhesive processesLayered productsProtection layerChemistry

The method for manufacturing an adhesion body according to the present invention is a method for manufacturing an adhesion body in which a first adherend and a second adherend are bonded to each other via an adhesive pattern, comprising a step of providing an adhesive layer containing a thermosetting component on a first adherend; a step of forming an adhesive pattern by etching the adhesive layer in a state in which a protective layer for protecting a predetermined portion of the adhesive layer from etching is provided on a surface of the adhesive layer opposite to a surface in contact with the first adherend; and a step of bonding a second adherend to the adhesive pattern after the protective layer is removed.

Owner:HITACHI CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com