Solid-state imaging device and method for producing the same

a solid-state imaging and imaging device technology, applied in the direction of contact member manufacturing, television system, radioation controlled devices, etc., can solve the problems of high cost, inability to obtain a sufficient flatness of the base b>31, lens barrel not being aligned accurately with respect to the light-receptive region, etc., to achieve low cost, reduce variation in dimensional accuracy, and sufficient flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

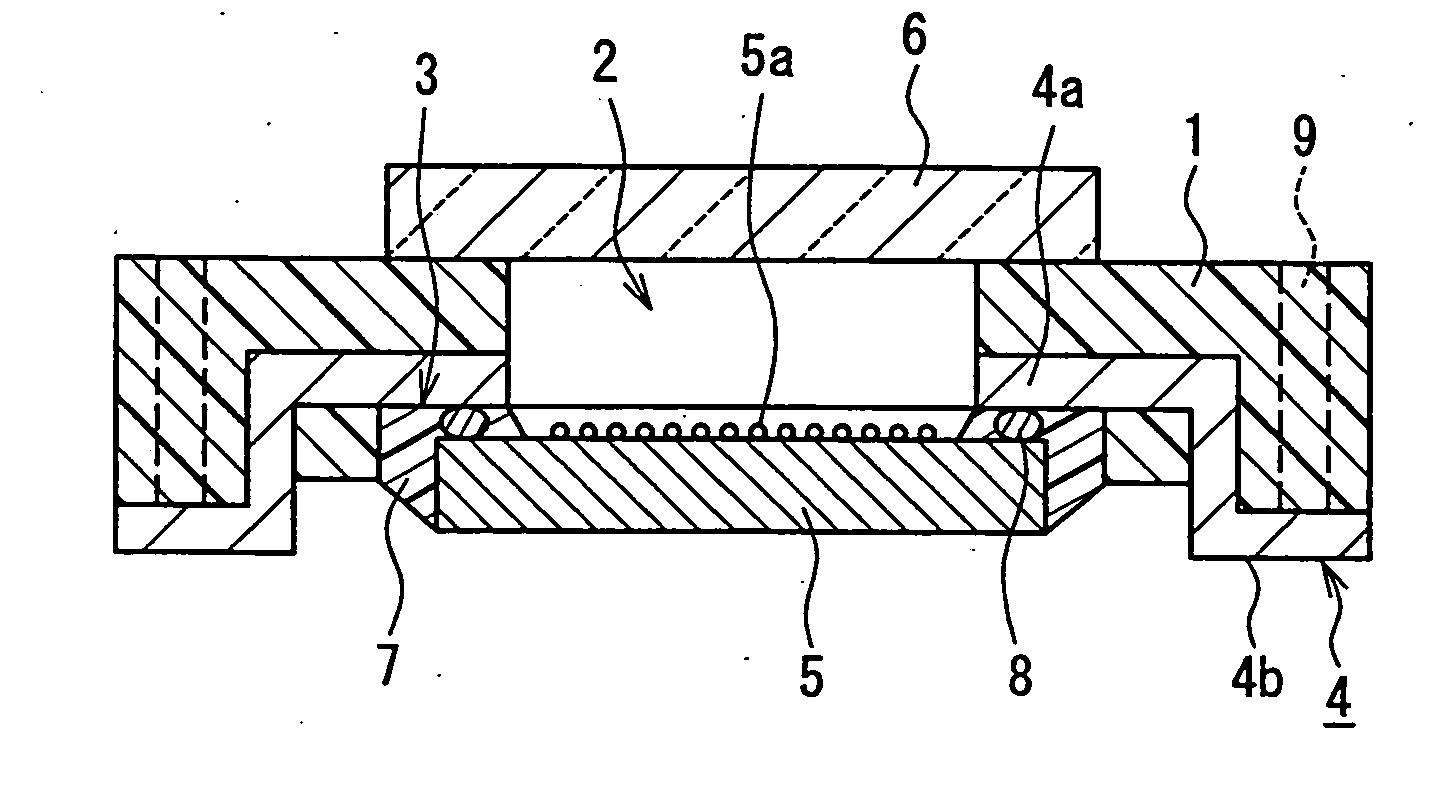

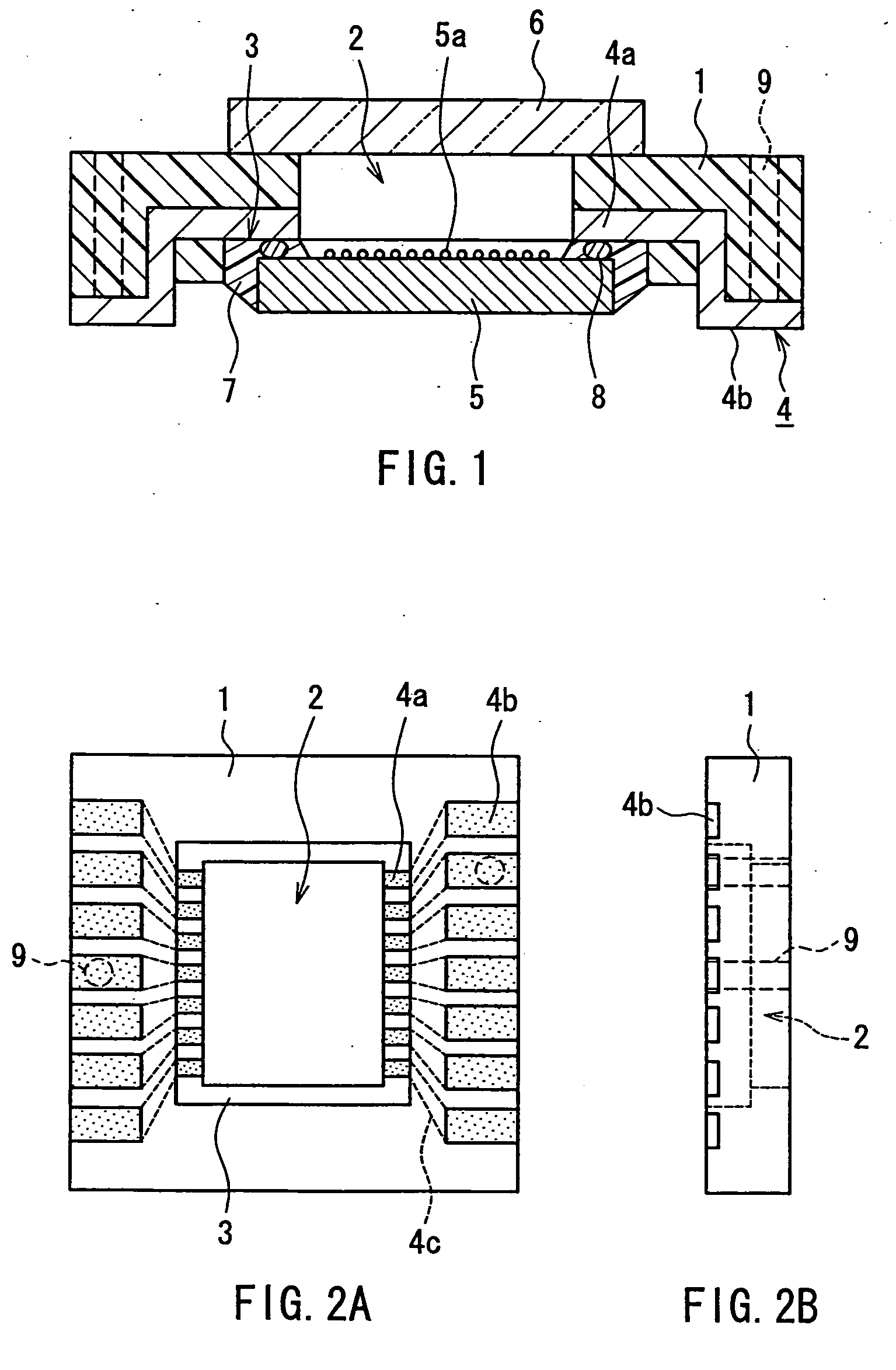

[0030] A solid-state imaging device of Embodiment 1 will be described below, with reference to FIGS. 1 and 2. A base 1 is made of a plastic resin such as an epoxy resin and has a rectangular frame form in planar shape having a rectangular aperture 2 in its center portion. A bottom face of the base 1 is recessed at a region along a periphery of the aperture 2 so as to form a rectangular recess 3 that surrounds the aperture 2. The bottom face of the base 1 is provided with a plurality of wirings 4 made of thin metal plate leads, which extend from the vicinity of the aperture 2 to an outer peripheral end face of the base 1. As the thin metal plate leads, Cu alloy, 42 alloy (Fe—Ni 42 alloy) and the like, which are similar to the materials used for a normal lead frame, are used. Thickness thereof usually ranges approximately from 2 to 3 μm.

[0031] On the surface of the recess 3 with the wirings 4 formed thereon, an imaging element 5 such as a CCD and the like formed on a Si base is mount...

embodiment 2

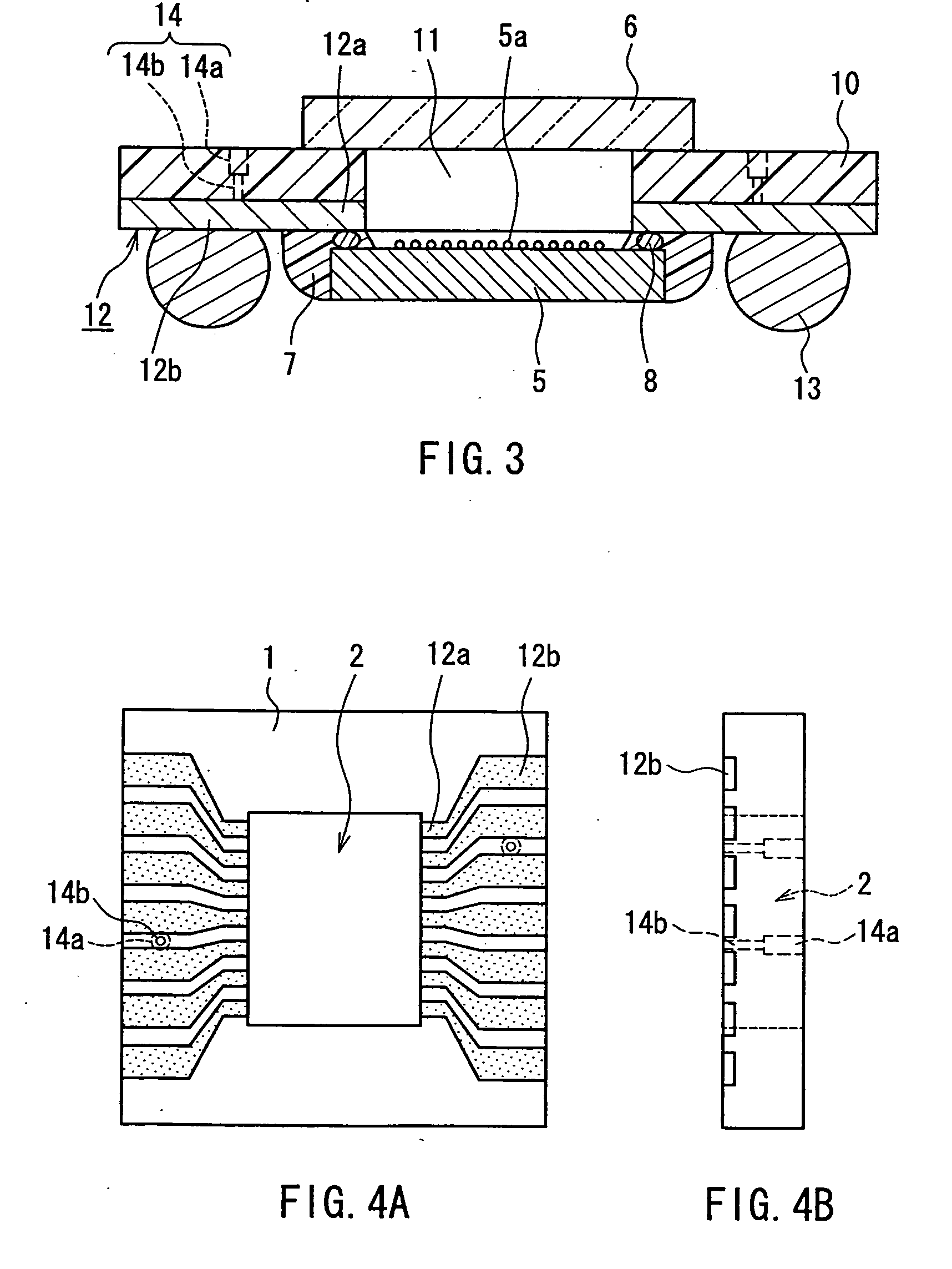

[0039] A solid-state imaging device according to Embodiment 2 will be described below, with reference to FIGS. 3 and 4. The same reference numerals will be assigned to the same elements as in Embodiment 1 so as to simplify their explanations. This embodiment is different from Embodiment 1 in the configuration of a base 10. The base 10 with a rectangular planar shape has a flat plate form having a uniform thickness as the whole in its cross-sectional shape, and does not have a recess as in Embodiment 1. An aperture 11 is formed in the central portion of the plate form base 10, and an imaging element 5 is mounted thereon with its light-receptive region 5a facing the aperture 11.

[0040] On the bottom face of the base 10, a plurality of wirings 12 made of thin metal plate leads are disposed, which extend from the edge of the aperture 11 to an outer peripheral end face of the base 10. On an electrode pad (not illustrated) disposed on the same surface of the imaging element 5 as the light...

embodiment 3

[0044] A method for producing the solid-state imaging device having the above-described configurations will be described below, with reference to FIGS. 5 and 6. In the following description, a case where the manufacturing method of this embodiment is applied for manufacturing the solid-state imaging device having the configuration of FIGS. 1 and 2, will be exemplified. FIGS. 5A to 5C show only a process of molding a base. FIG. 6 is a plan view of the base at a stage of FIG. 5B.

[0045] Firstly, a lower mold 20 and an upper mold 21 shown in FIG. 5A are prepared as molds for resin molding. The lower mold 21 has a recess 20aformed therein. This recess is filled with a resin so as to mold the base 1 of FIG. 1. Note here that FIG. 5A shows the base 1 being molded by turning the state of FIG. 1 upside down. In the central portion of the lower mold 20, a lower protrusion 20b also is formed. The upper mold 21 has an upper protrusion 21a formed in its central portion. When the lower mold 20 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shape | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com