Carbon film laminate, method of manufacturing said laminate, and lubricant using said laminate

a technology of carbon film and lubricant, which is applied in the field of carbon film laminate, can solve the problems of deteriorated oil disposal, special environment, and inability to use oil-based liquid lubricants, and achieve the effects of low friction coefficient, high adhesiveness to the base material, and low wear ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0076]Hereinafter, the invention will be described in more detail with reference to examples and the like, but the invention is not limited to the examples and the like.

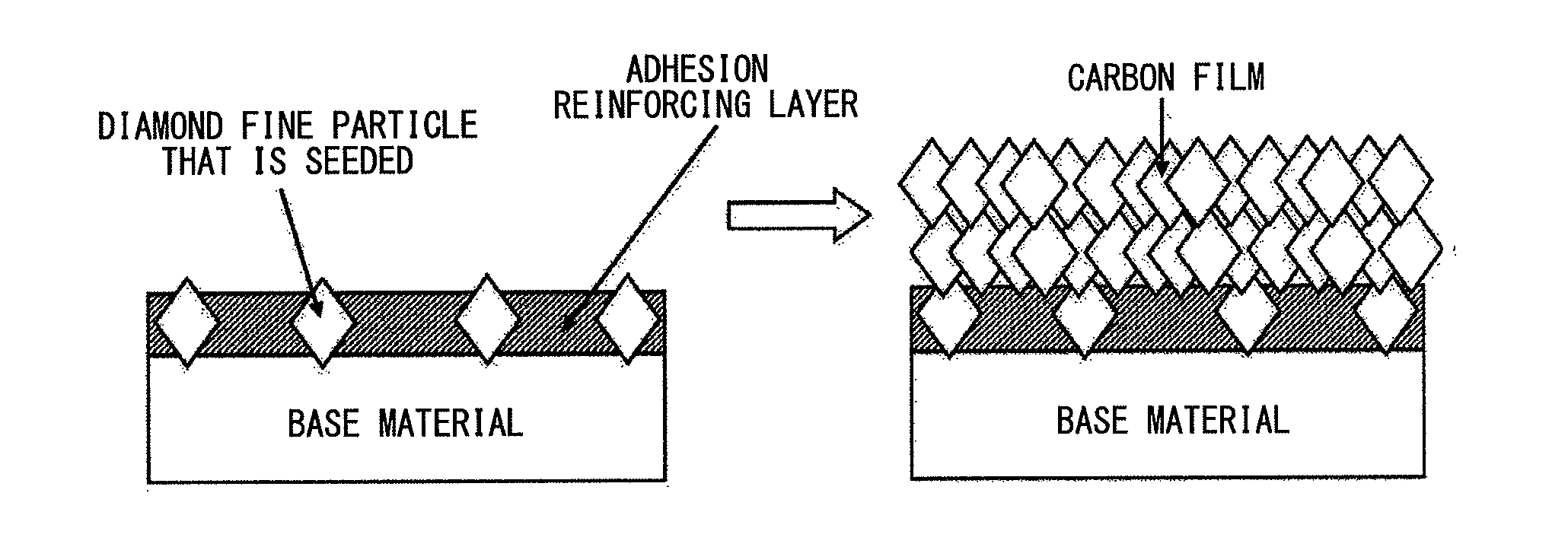

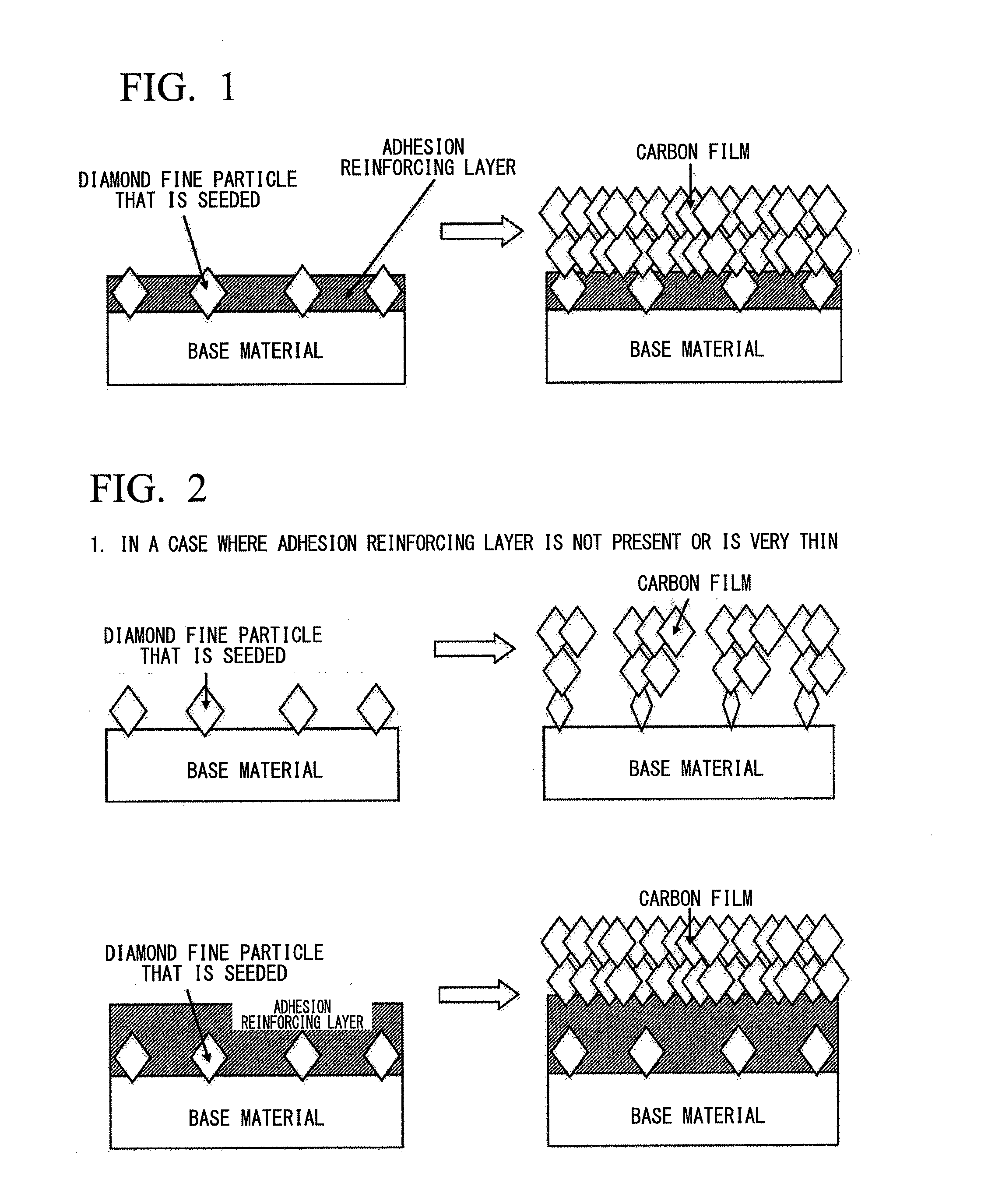

[0077]In the invention, a pre-treatment is carried out with respect to a base material, and then a plasma CVD treatment is carried out. As the pre-treatment, the base material was immersed in a dispersed solution of diamond ultrafine particles such as nanocrystal diamond particles, and then an ultrasonic treatment was carried out to allow the diamond ultrafine particles to adhere a surface of the base material. This method is known in the related art and is described in detail in PTL 2 and PTL 3.

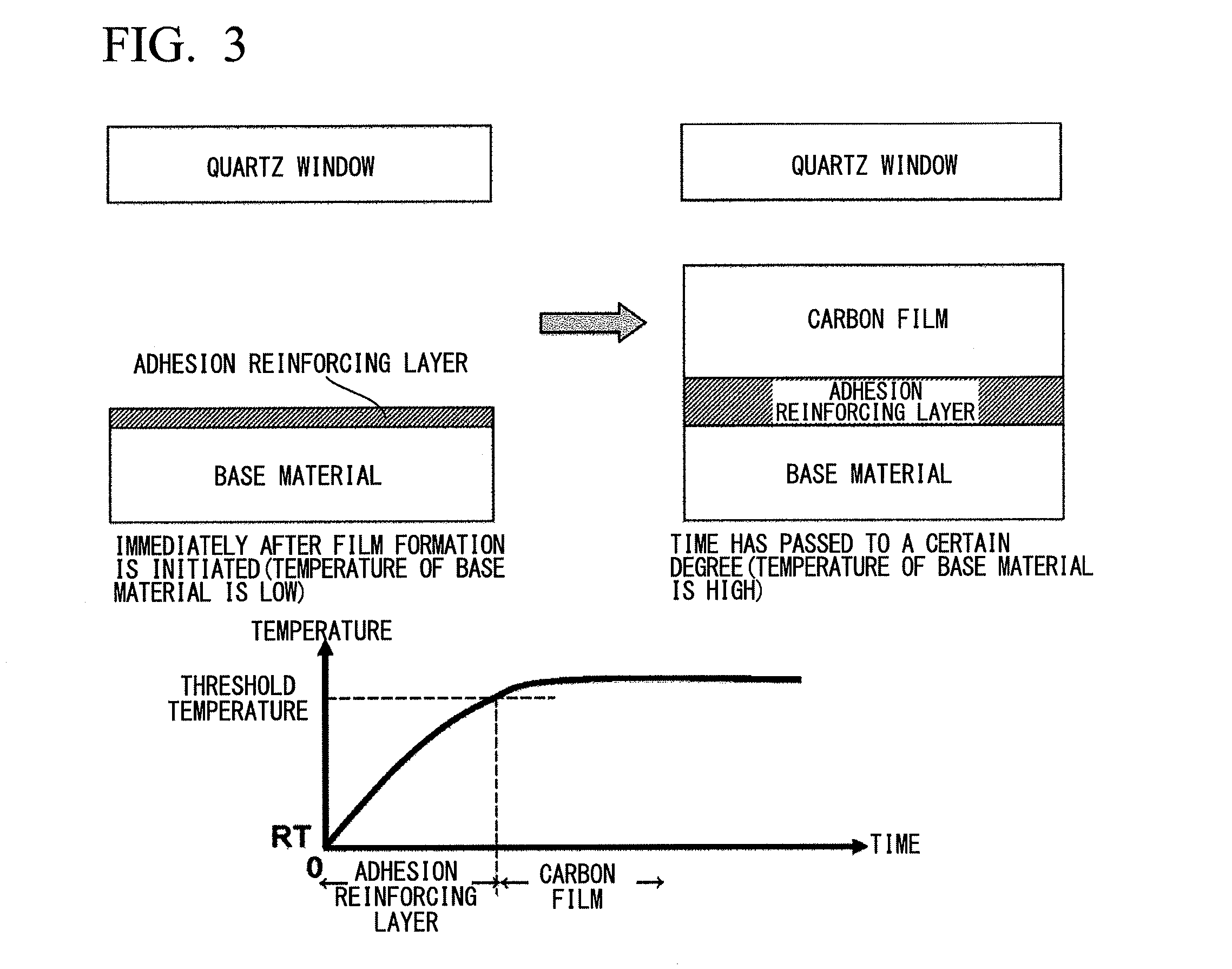

[0078]A plasma CVD treatment time is 1 to 20 hours. In addition, although being different depending on a base material, a treatment temperature is 100 to 500° C. If a temperature of the base material is increased, the damage to the base material due to plasma also increases. In addition, in an iron-based base material such as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| 2θ±0 | aaaaa | aaaaa |

| 2θ±0 | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com