Manufacturing method of vacuum cooking and packaging bag for food

A production method and packaging bag technology are applied to the production field of food vacuum cooking packaging bags, which can solve the problems of short shelf life, delamination, and staleness, and achieve the effects of improving toughness strength and peel strength, good air flow, and prolonging shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

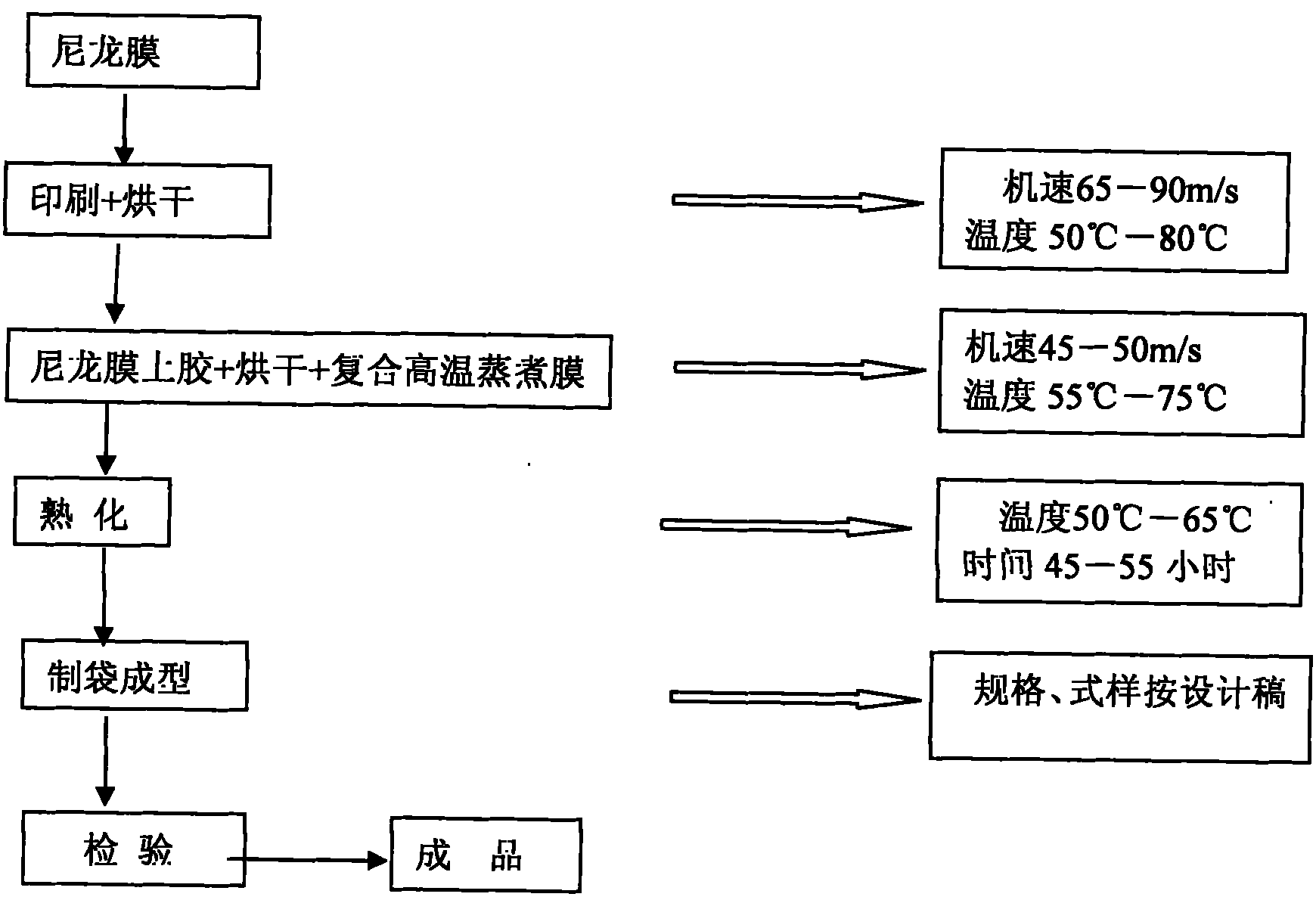

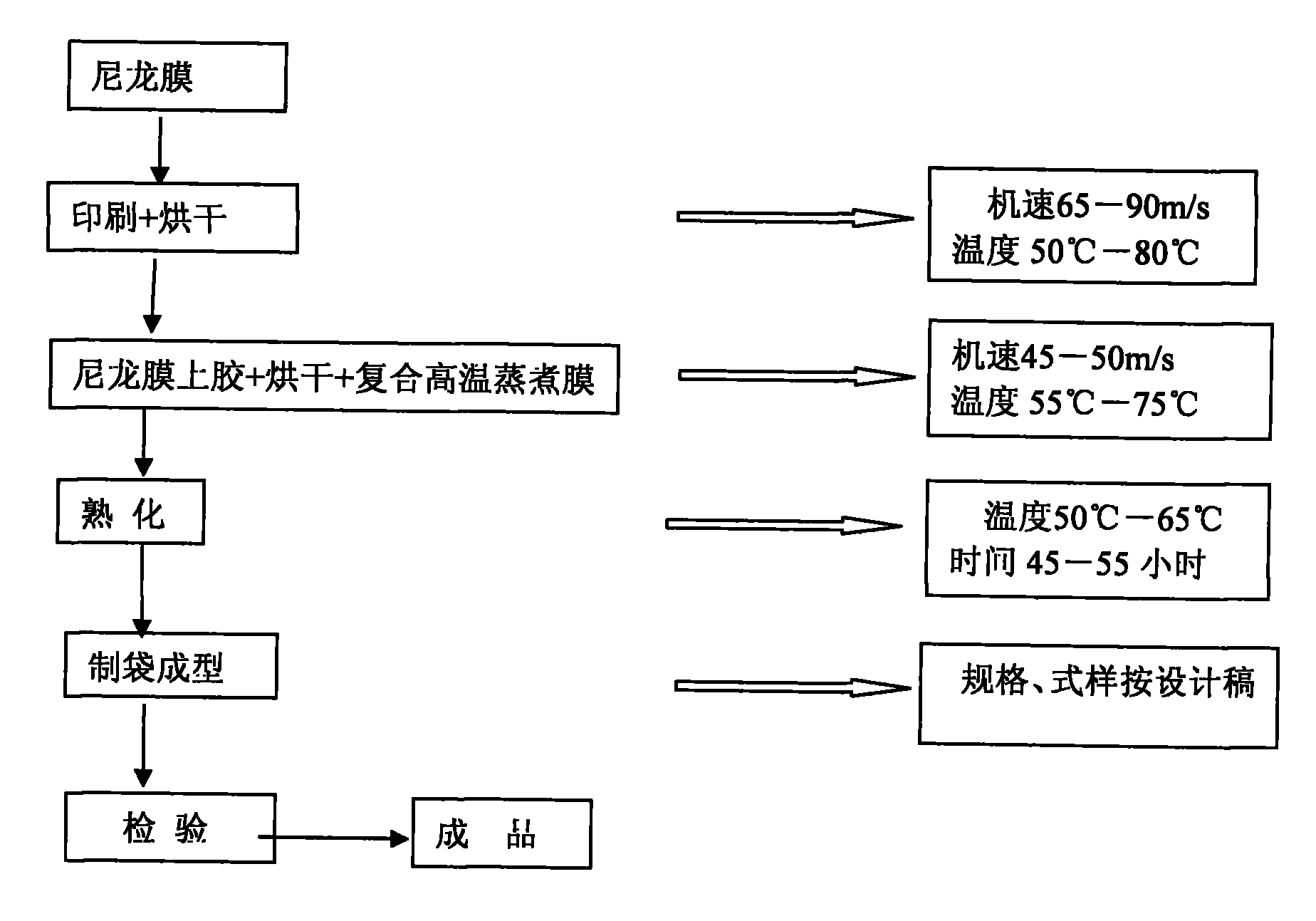

Image

Examples

Embodiment 1

[0009] The production method of high temperature resistant food vacuum cooking packaging color printing bag is to use nylon film (BOPA) with good printing performance, high temperature resistance (up to 280°C), gas barrier and air tightness and excellent toughness, and print it with 135°C high temperature cooking ink Finally, it is compounded with retort film (RCPP) which has good transparency, strong bag-making heat sealability, certain gas barrier property, and can withstand high temperature of 135°C. According to its weight ratio: nylon film (BOPA) 18-33%, ink With glue 5-10%, high temperature resistant cooking film (RCPP) 60-75%, first send the printed nylon film (BOPA) into the composite process, use polyurethane glue and solvent according to the weight of 1:1.1-1.3 Stir evenly and apply glue to the nylon film (BOPA), heat through the drying tunnel, the temperature of the drying tunnel reaches 55-75°C, so that the air will convect in the drying tunnel (the compound machine...

Embodiment 2

[0011] The method of making high-temperature-resistant vacuum cooking packaging bags first uses nylon film (BOPA) with good printing performance, high temperature resistance (up to 280 ° C), gas barrier and air tightness, and excellent toughness, and has good transparency and bag heat sealing. Retort film (RCPP) compound with strong resistance, certain gas barrier property, and high temperature resistance of 135°C, according to its weight ratio: nylon film (BOPA) 18-33%, ink and glue 5-10%, high temperature resistant retort film (RCPP) 60-75%, first send the printed nylon film (BOPA) into the composite process, use polyurethane glue and solvent according to the weight ratio of 1:1.1-1.3, stir evenly to glue the nylon film (BOPA) ), heating through the drying tunnel, the temperature of the drying tunnel reaches 55-75°C, so that the air is convected in the drying tunnel (the composite machine has an air inlet and an air exhaust outlet), and the residual solvent is discharged out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com