Automatic production line task scheduling method

A technology for automated production lines and task scheduling, applied in electric/hybrid power, control/regulation systems, comprehensive factory control, etc. Easy to set up, easy to expand, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

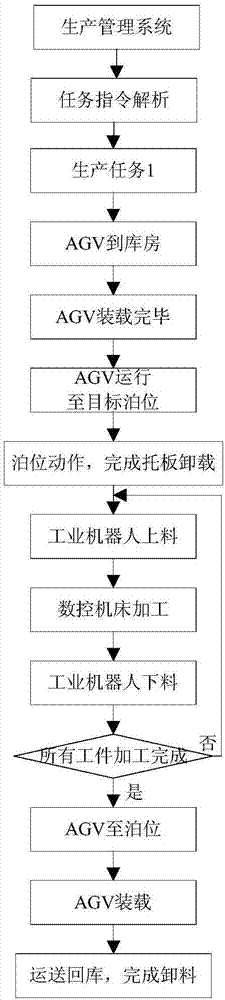

[0026] The purpose of this method is to schedule the production tasks issued by the production management system, including CNC machine tools, AGVs, and industrial robots, for automatic production, and complete the production tasks from raw material delivery to product storage.

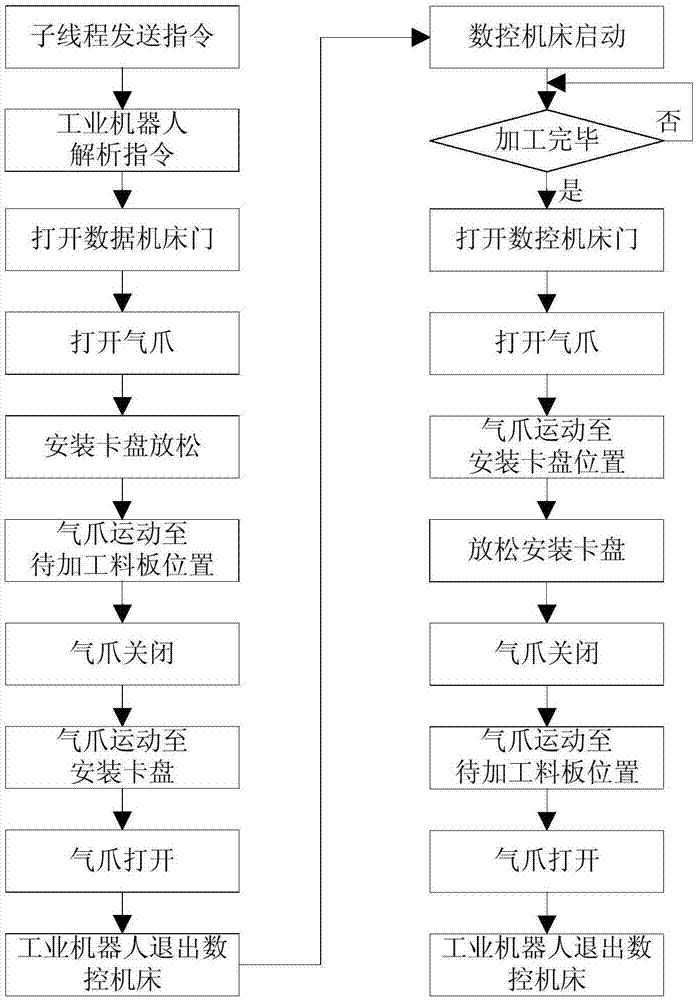

[0027] The present invention is an automatic production line scheduling method based on CNC machine tools, AGVs and industrial robots, and the specific implementation steps are as follows:

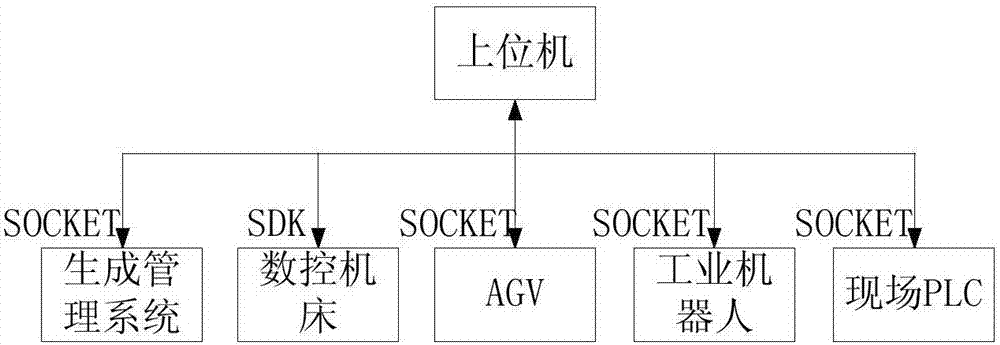

[0028] Step S1: Establish a main thread in the host computer based on the windows platform using C#, using the TCP / IP protocol, and establish a connection with the production management system in the main thread through the IP address and port number of the production manag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com