Polyphenylene sulfide composite material, preparation method and molding method thereof

A technology of polyphenylene sulfide and composite materials, which is applied in the field of polyphenylene sulfide composite materials and its preparation, can solve problems such as labor consumption and time-consuming annealing process, and achieve the goals of reducing production costs, improving market competitiveness, and speeding up the cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

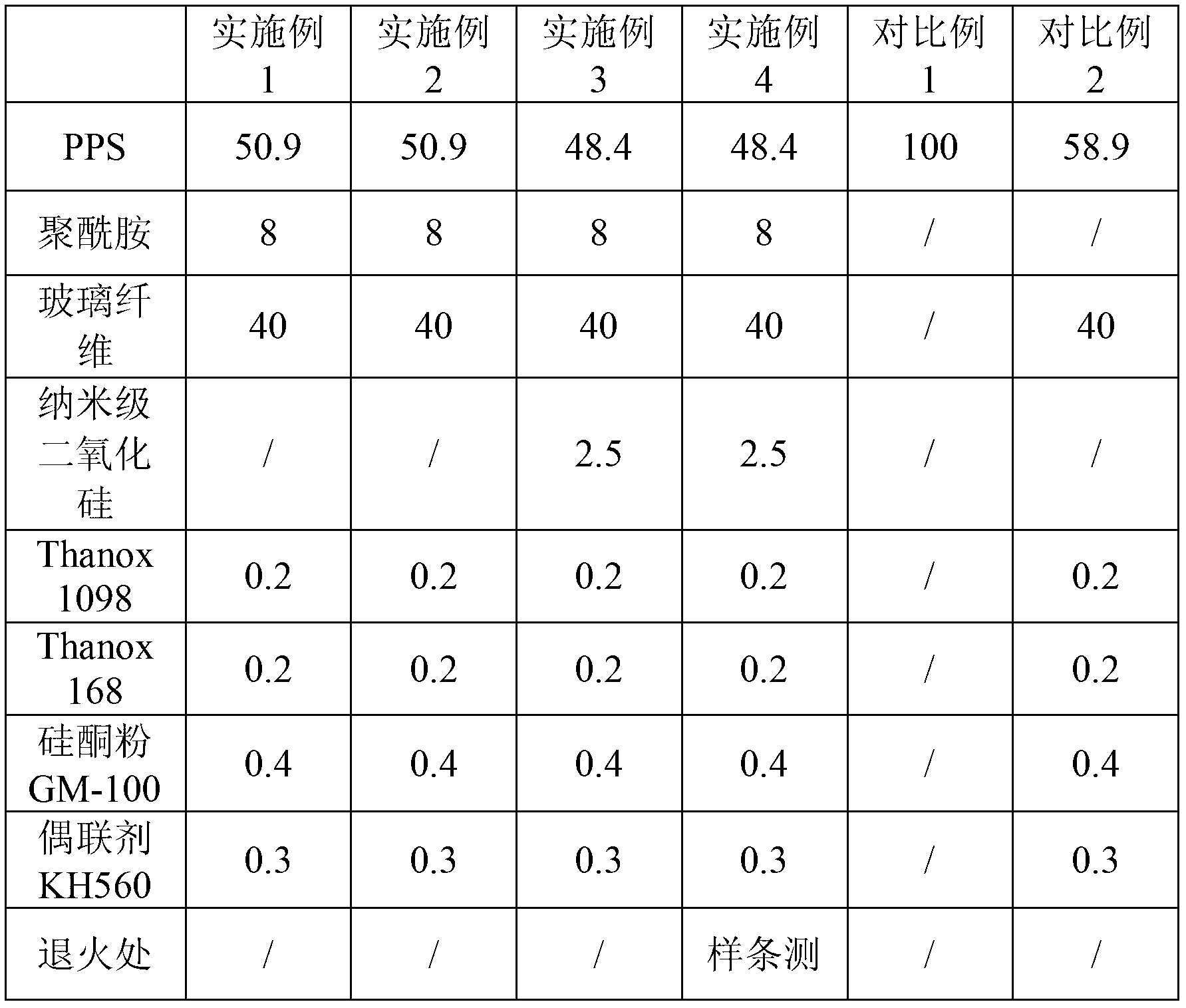

Embodiment 1

[0061] Accurately weigh the pre-dried polyphenylene sulfide and polyamide, antioxidant, lubricant and coupling agent according to the ratio of the components shown in Example 1 shown in the following table 1, wherein the polyamide is PA66 , the antioxidant is a mixture of Thanox1098 and Thanox168, the coupling agent is KH560, and the lubricant is silicone powder GM-100. Then stir in a high-speed mixer at a speed of 700rpm / min for 3 minutes to mix the components evenly, and then add them to the main feeding port of the twin-screw extruder; add the glass fiber to the extruder from the side feeding port of the twin-screw extruder In the discharge machine, polyphenylene sulfide composite material pellets are obtained through melt blending, extrusion, cooling and granulation. The temperature of the twin-screw extruder is set at 280-295°C, the speed of the main engine is 400rpm / min, and the length-to-diameter ratio of the screw is 40:1.

Embodiment 2

[0063] According to the ratio of the components shown in Example 2 shown in Table 1 below, accurately weigh the pre-dried polyphenylene sulfide and polyamide, antioxidant, lubricant and coupling agent, wherein polyamide is resistant to High-temperature nylon PA6T, the antioxidant is a mixture of Thanox1098 and Thanox168, the coupling agent is KH560, and the lubricant is silicone powder GM-100. Then stir in a high-speed mixer at a speed of 700rpm / min for 3 minutes to mix the components evenly, and then add them to the main feeding port of the twin-screw extruder; add the glass fiber to the extruder from the side feeding port of the twin-screw extruder In the discharge machine, polyphenylene sulfide composite material pellets are obtained through melt blending, extrusion, cooling and granulation. The temperature of the twin-screw extruder is set at 285-300°C, the speed of the main engine is 400rpm / min, and the length-to-diameter ratio of the screw is 40:1.

Embodiment 3

[0065] Accurately weigh the pre-dried polyphenylene sulfide and polyamide, antioxidant, lubricant, nucleating agent and coupling agent according to the ratio of the components shown in Example 3 shown in Table 1 below, wherein, The polyamide is high temperature resistant nylon PA6T, the antioxidant is a mixture of Thanox1098 and Thanox168, the nucleating agent is nano-scale silicon dioxide, the coupling agent is KH560, and the lubricant is silicone powder GM-100. Then stir in a high-speed mixer at a speed of 700rpm / min for 3 minutes to mix the components evenly, and then add them to the main feeding port of the twin-screw extruder; add the glass fiber to the extruder from the side feeding port of the twin-screw extruder In the discharge machine, polyphenylene sulfide composite material pellets are obtained through melt blending, extrusion, cooling and granulation. The temperature of the twin-screw extruder is set at 285-305°C, the speed of the main engine is 400rpm / min, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com