Distortion calibration method, system and device for lens module and storage medium

A distortion calibration and lens module technology, applied in image analysis, instrumentation, computing, etc., can solve the problem of not being able to take into account the needs of large-scale mass production and high efficiency and high precision, and achieve the effect of taking into account the effect of distortion correction and production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

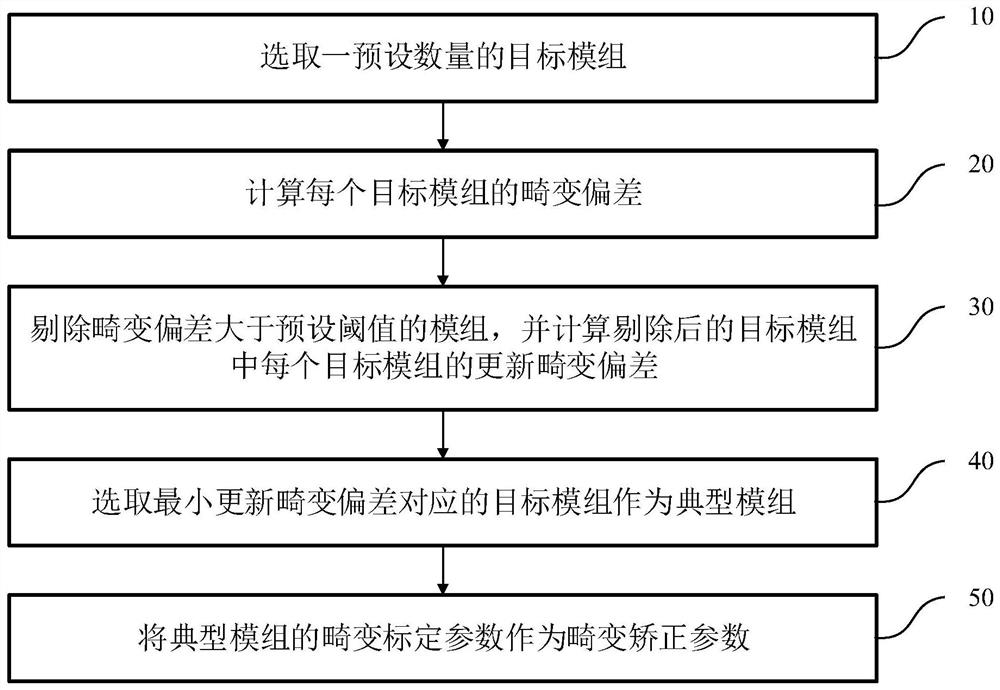

[0056] A method for calibrating distortion of a lens module, such as figure 1 As shown, the distortion calibration method includes:

[0057] Step 10. Select a preset number of target modules; in practical applications, in order to ensure more accurate calibration parameters, the selected number of target modules is generally not less than 200.

[0058] Step 20, calculate the distortion deviation of each target module, and then perform step 30; the distortion deviation is used to characterize the deviation between the distortion correction mapping grid of each target module and the average distortion correction mapping grid of all target modules ;

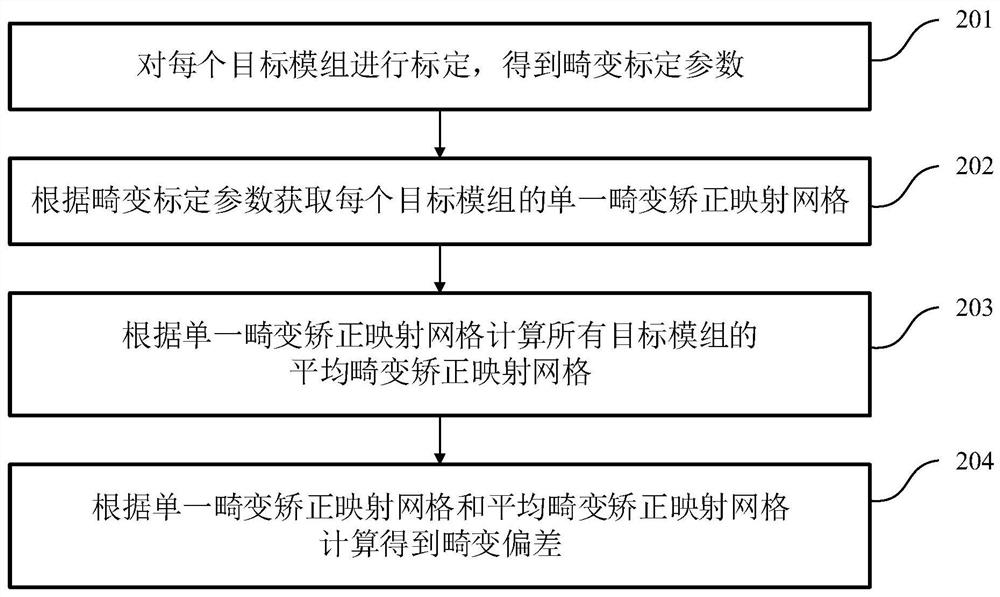

[0059] Among them, such as figure 2 As shown, step 20 specifically includes:

[0060] Step 201, calibrate each target module to obtain distortion calibration parameters;

[0061] In this embodiment, the calibration result of the ultra-wide-angle module includes: the camera internal parameter matrix and the distortion coefficient:...

Embodiment 2

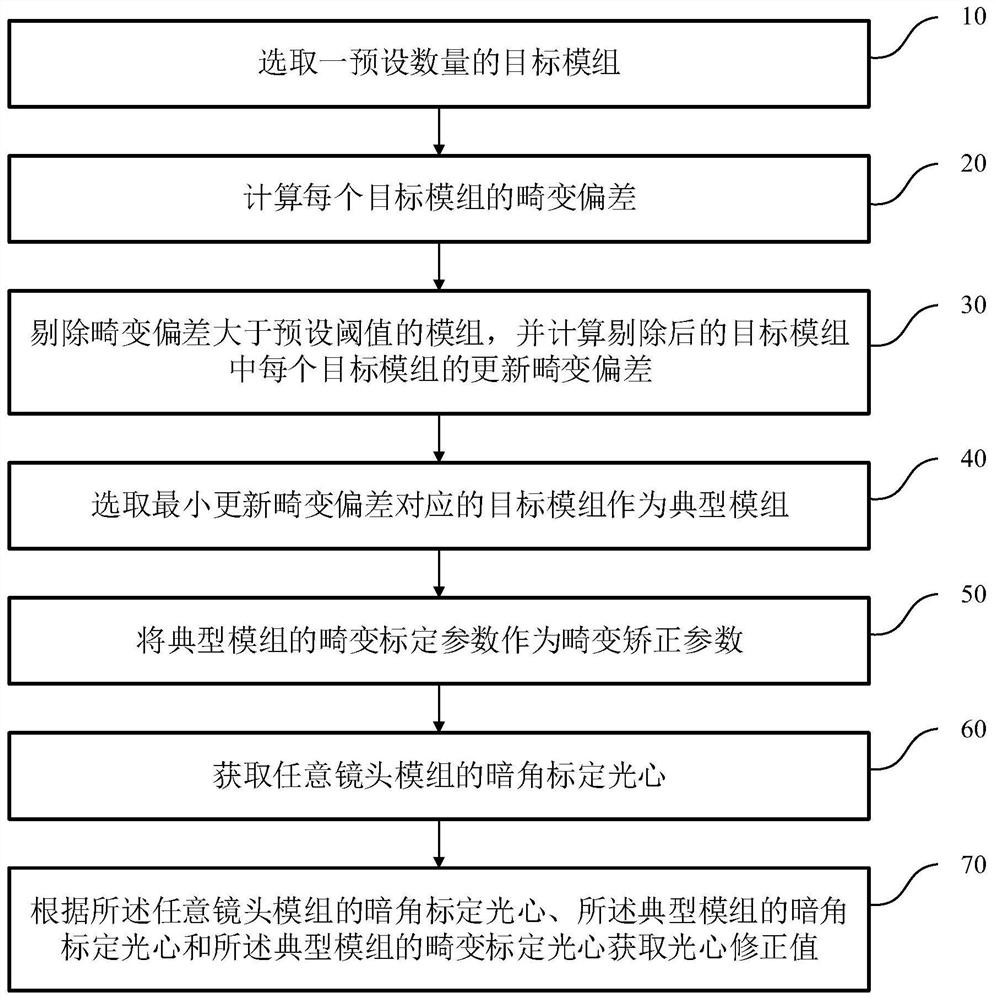

[0086] This embodiment is a further improvement on the basis of Embodiment 1. The radial distortion is caused by the design of the optical lens. Its characteristic is that the optical center is the circle point and the distortion becomes more and more serious along the radial direction, while the tangential distortion coefficient is Due to the manufacturing process, such distortion is usually small for modules with better quality. It can be seen that whether the position of the optical center is accurate has a significant impact on the distortion correction effect. If the position of the optical center is inaccurate, establish a The coordinate mapping of will no longer be accurate. When applying distortion correction parameters to any other module for distortion correction, in order to obtain a more ideal distortion correction effect, it is necessary to correct the deviation of the optical center.

[0087] In this embodiment, the distortion calibration parameters of each target...

Embodiment 3

[0097] A distortion calibration system for lens modules, such as Figure 5 As shown, the distortion calibration system includes:

[0098] The target selection module 1 is used to select a preset number of target modules; in practical applications, in order to ensure more accurate calibration parameters, the selected number of target modules is generally not less than 200.

[0099]The distortion deviation calculation module 2 is used to calculate the distortion deviation of each target module, and the distortion deviation is used to characterize the deviation between the distortion correction mapping grid of each target module and the average distortion correction mapping grid of all target modules ;

[0100] The elimination module 3 is used to eliminate the modules whose distortion deviation is greater than the preset threshold, and call the distortion deviation calculation module 2 to calculate the update distortion deviation of each target module in the eliminated target mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com