Mold for vertical pouring of organic glass and method for vertically pouring organic glass by the mold

A technology of plexiglass and casting molds, which is applied in the field of forming and pouring devices, can solve the problems of unfavorable batch production, cumbersome clamping operation, high clamping requirements, etc., and achieve the effects of convenient pouring, convenient operation, high product precision and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

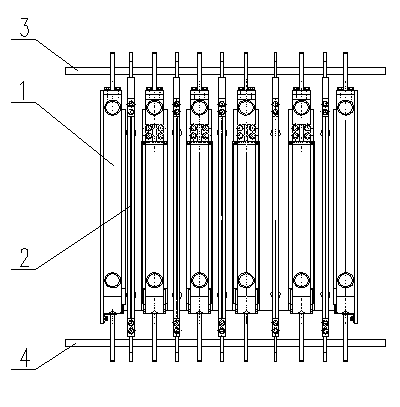

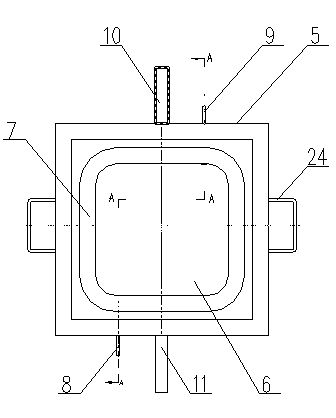

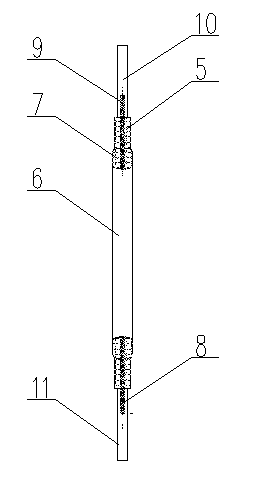

[0021] Figure 1-4 As shown, a plexiglass vertical casting mold includes a water tank 1, a strip frame 2, an upper boom 3 and a lower boom 4. The rubber strip frame 2 includes a mold frame 5, a rubber strip 7, a feed pipe 8, an air outlet pipe 9, a hook 10 on the rubber strip frame and a hook 11 under the rubber strip frame. The mold cavity 6 on the end face, the mold frame 5 on the wall of the mold cavity 6 is embedded with a rubber strip 7, the rubber strip 7 exceeds the front and rear end faces of the mold frame 5, and the lower part of the mold frame 5 is provided with a mold frame and a rubber strip connected to the mold cavity. The upper part of the mold frame 5 is provided with an air outlet pipe 9 passing through the mold frame and the rubber strip to communicate with the mold cavity, the two sides of the mold frame 5 are provided with handles, and the upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com