Cleaning process and production line of PET (polyethylene terephthalate) bottle sheets

A bottle flake and process technology, applied in the field of PET bottle flake cleaning process and its production line, can solve the problem of difficult removal of pollutant sources, and achieve the effects of improving energy utilization rate, reducing processing cost and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

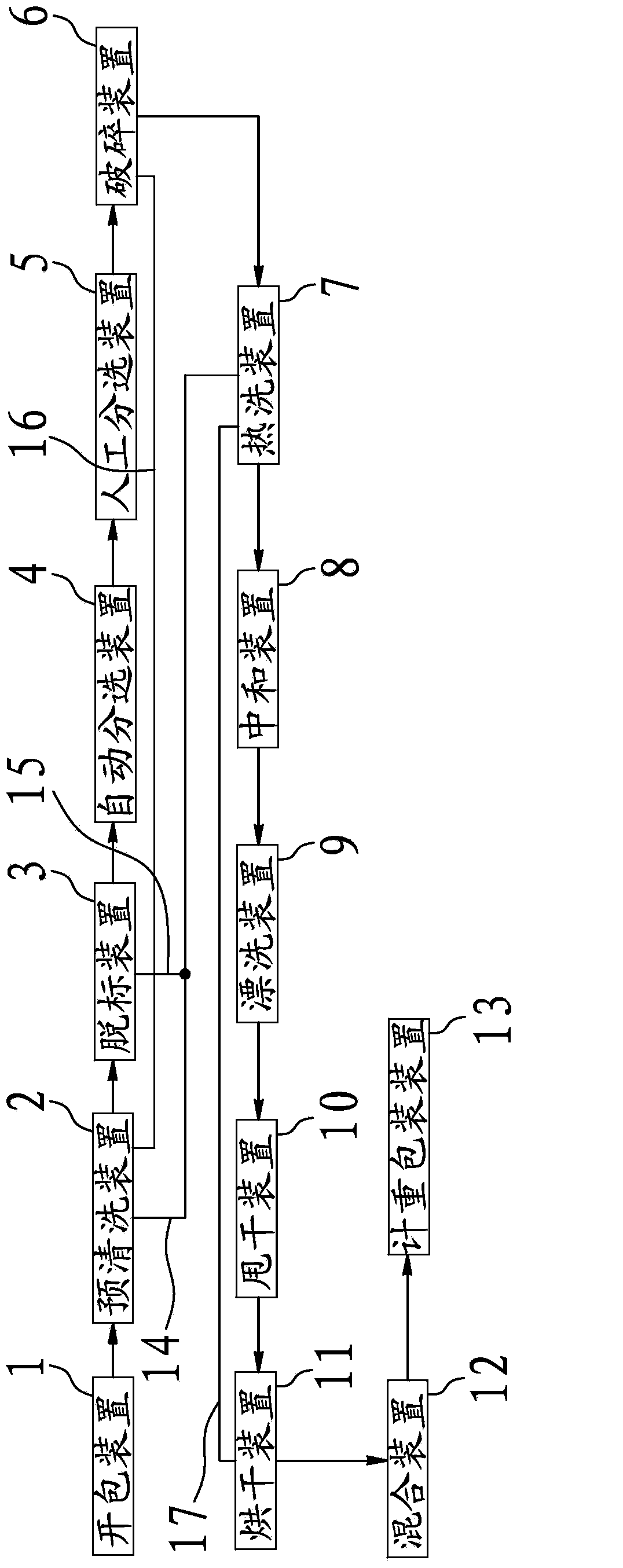

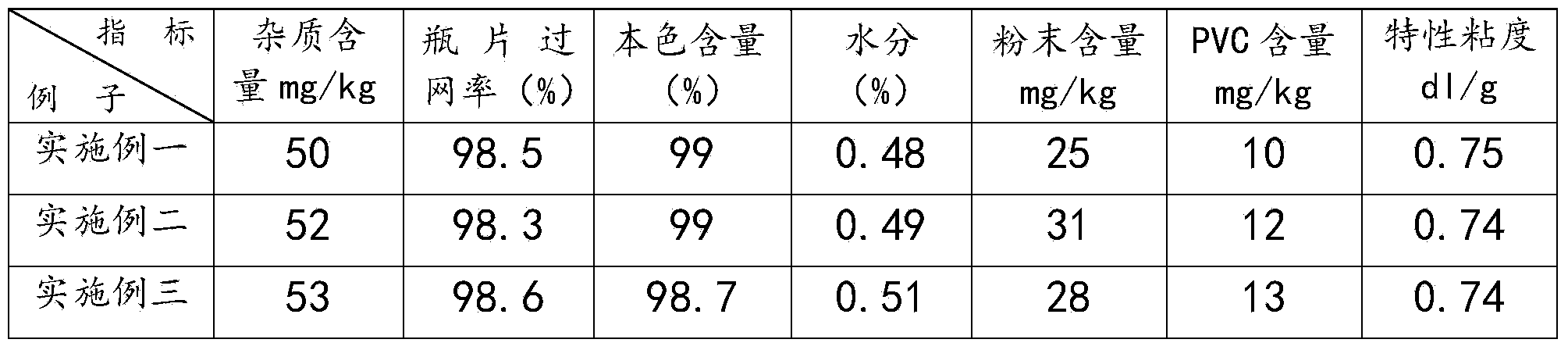

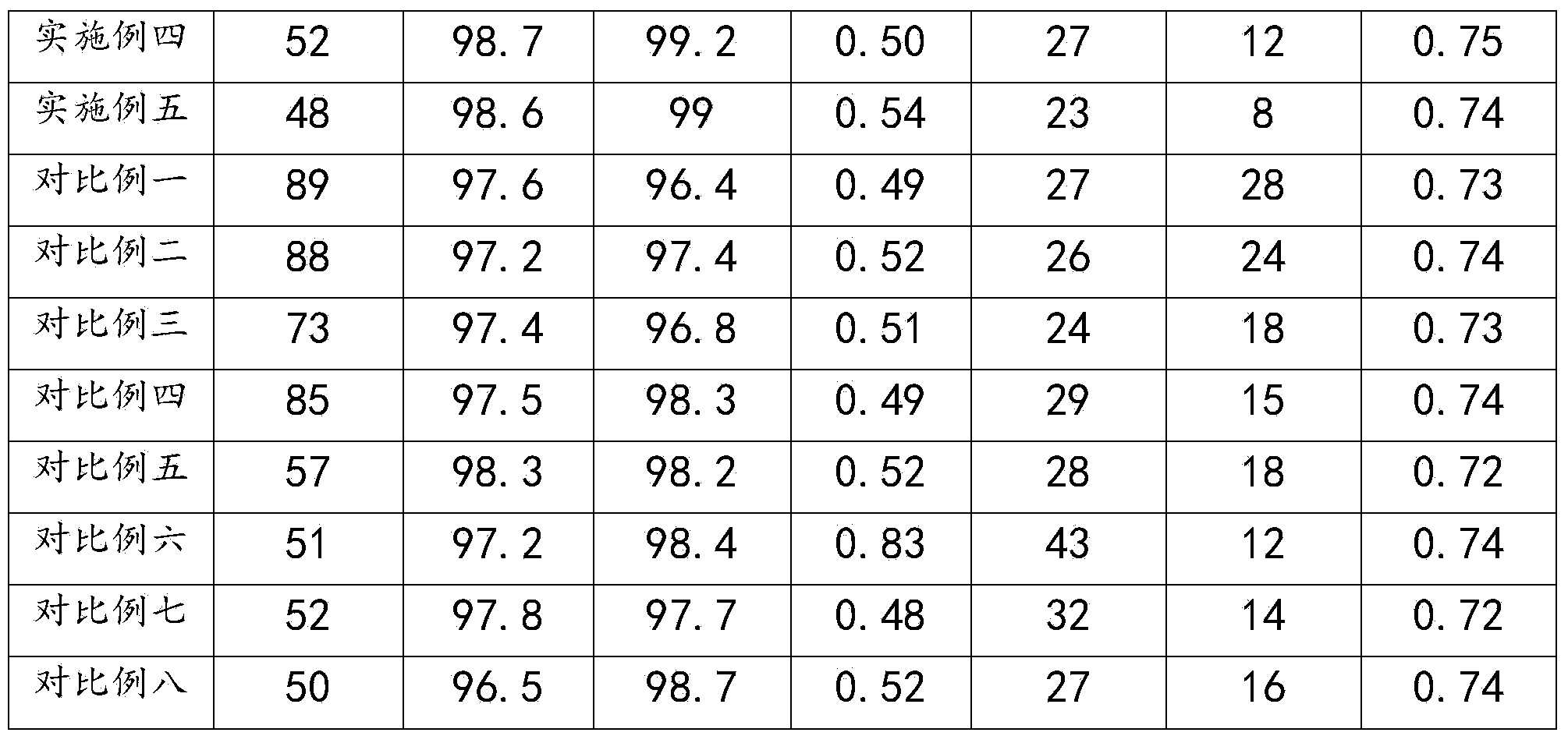

[0043] The invention relates to a cleaning process for PET bottle flakes. After the PET bottle is opened, the whole bottle pre-cleaning device initially removes impurities, the label-removing device removes the label, the sorting device removes bottles of different colors and non-PET material bottles, and the manual sorting platform Manual sorting, crushing by crushing device, hot washing in hot cooking pot, neutralization in neutralization tank, rinsing by rinsing device, spin-drying, drum drying, mixing, weighing and packaging.

[0044] It should be noted that the water used for the initial impurity removal of the whole bottle pre-cleaning device involved in the present invention comes from the water after hot washing in the hot cooking pot at a temperature of 60-80°C after being diluted and adjusted to a pH of 8-9. Alkaline water; the purpose of choosing alkaline water with a pH of 8-9 after the temperature of 60-80°C after hot washing in the hot cooking pot is to ensure wat...

Embodiment 2

[0062] The invention relates to a cleaning process for PET bottle flakes. After the PET bottle is opened, the whole bottle pre-cleaning device initially removes impurities, the label-removing device removes the label, the sorting device removes bottles of different colors and non-PET material bottles, and the manual sorting platform Manual sorting, crushing by crushing device, hot washing in hot cooking pot, neutralization in neutralization tank, rinsing by rinsing device, spin-drying, drum drying, mixing, weighing, and packaging.

[0063] It should be noted that the water used for the initial impurity removal of the whole bottle pre-cleaning device involved in the present invention comes from the water after hot washing in the hot cooking pot at a temperature of 60-80°C after being diluted and adjusted to a pH of 8-9. Alkaline water; the purpose of choosing alkaline water with a pH of 8-9 after the temperature of 60-80°C after hot washing in the hot cooking pot is to ensure wa...

Embodiment 3

[0081] The invention relates to a cleaning process for PET bottle flakes. After the PET bottle is opened, the whole bottle pre-cleaning device initially removes impurities, the label-removing device removes the label, the sorting device removes bottles of different colors and non-PET material bottles, and the manual sorting platform Manual sorting, crushing by crushing device, hot washing in hot cooking pot, neutralization in neutralization tank, rinsing by rinsing device, spin-drying, drum drying, mixing, weighing, and packaging.

[0082] It should be noted that the water used for the initial impurity removal of the whole bottle pre-cleaning device involved in the present invention comes from the water after hot washing in the hot cooking pot at a temperature of 60-80°C after being diluted and adjusted to a pH of 8-9. Alkaline water; the purpose of choosing alkaline water with a pH of 8-9 after the temperature of 60-80°C after hot washing in the hot cooking pot is to ensure wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com