Flowing water breeding tank lifting system

A lifting system and culture tank technology, applied in the field of running water culture tank lifting system, can solve the problems of increasing the difficulty and labor intensity of fishing operations, unfavorable breeding production efficiency, and affecting breeding production efficiency, so as to achieve both breeding production efficiency and pressure reduction The water carrying capacity and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

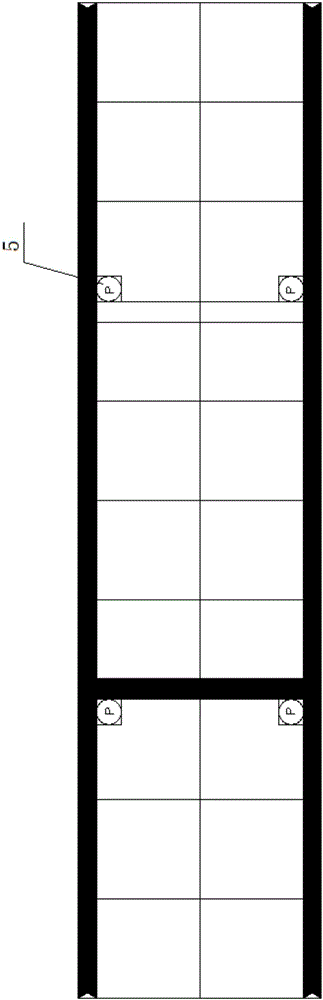

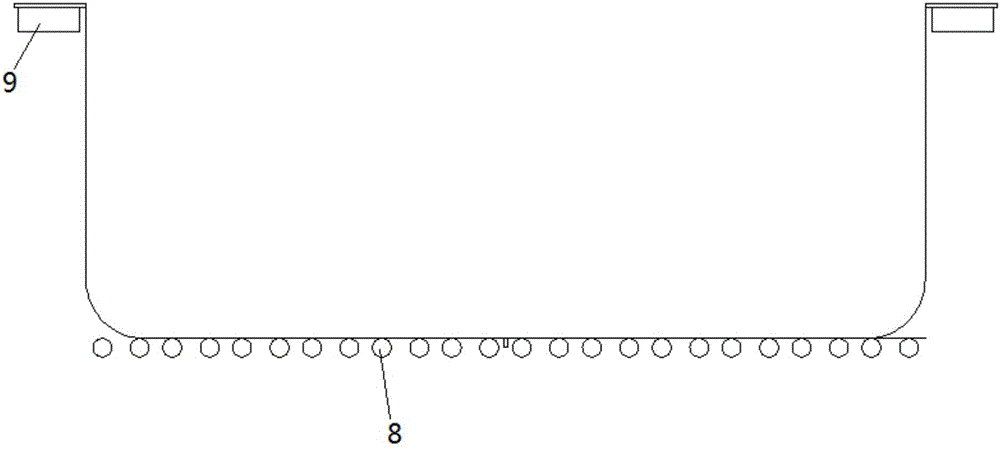

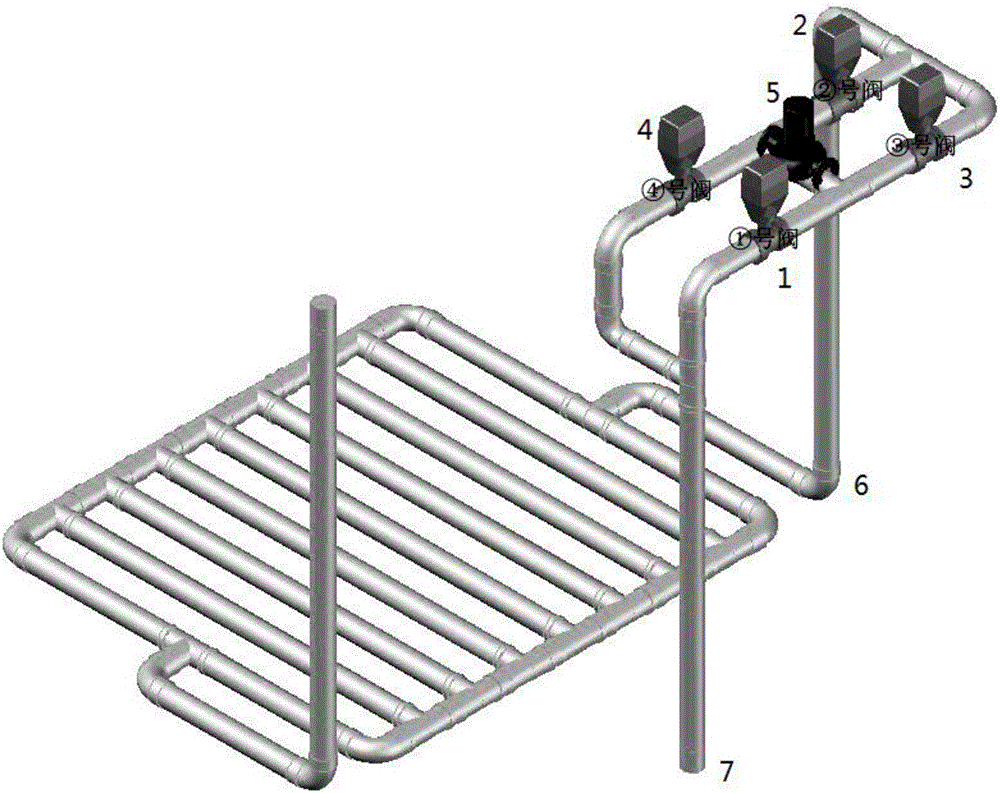

[0025] see Figure 1-Figure 4 , a lifting system for a flowing water aquaculture tank, the two ends of the flowing water aquaculture tank are made of permeable mesh material, and the inside is used for aquaculture; the bottom of the flowing water aquaculture tank is provided with a first buoyancy pad 8, and the self gravity of the flowing water aquaculture tank is greater than The buoyancy provided by the first buoyancy pad 8; a number of ballast water pipe devices are evenly arranged on the symmetrical side of the center of gravity at the bottom of the running water culture tank, and the ballast water pipe devices include a water pump 5 and a four-way reversing pipeline; the four-way There are four valves 1, 2, 3, and 4 on the reversing pipeline, and the ballast coil connection end 6 connected to the ballast coil at the bottom of the tank is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com