Method for preparing konjac mannan oligosaccharide

A technology of mannan oligosaccharides and konjac grape, which is applied in the field of food and feed additives, can solve the problems of time-consuming enzyme utilization efficiency, low energy consumption, etc., and achieve the effects of improving efficacy and utilization efficiency, increasing contact area, and increasing contact probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Wash the fresh konjac, peel it, cut it into pieces, and preliminarily crush it with a juice extractor, add distilled water in the ratio of 1kg:1000kg according to the ratio of konjac and water, and cut it at 8000r / min with a high-shear mixing emulsifier. Cut and emulsify 3 times, each time for 10 minutes, then use an ultra-high pressure homogenizer to homogenize once at 200Mpa, and then homogenize twice at 500Mpa, let it stand, filter the supernatant liquid with a filter cloth, and put the filter residue at 80°C Dry for 24 hours to obtain konjac meal, and the order number is 60 orders.

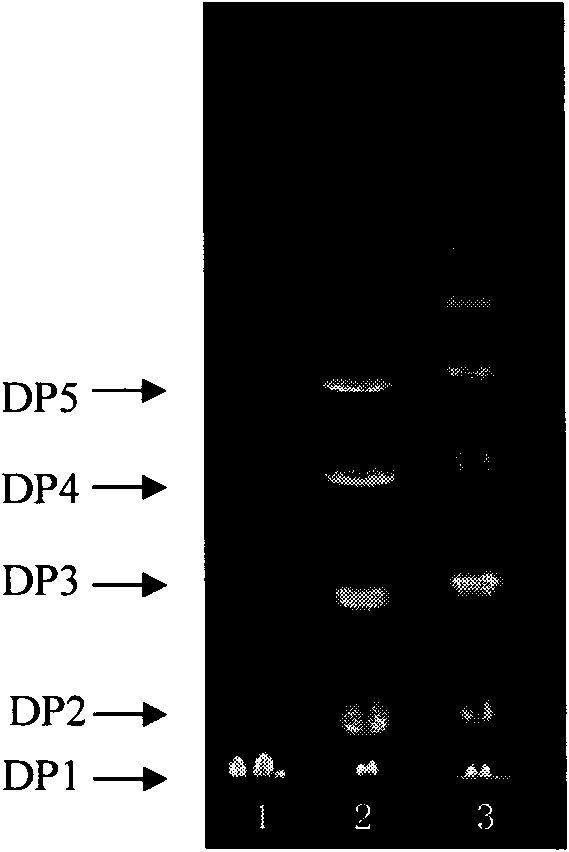

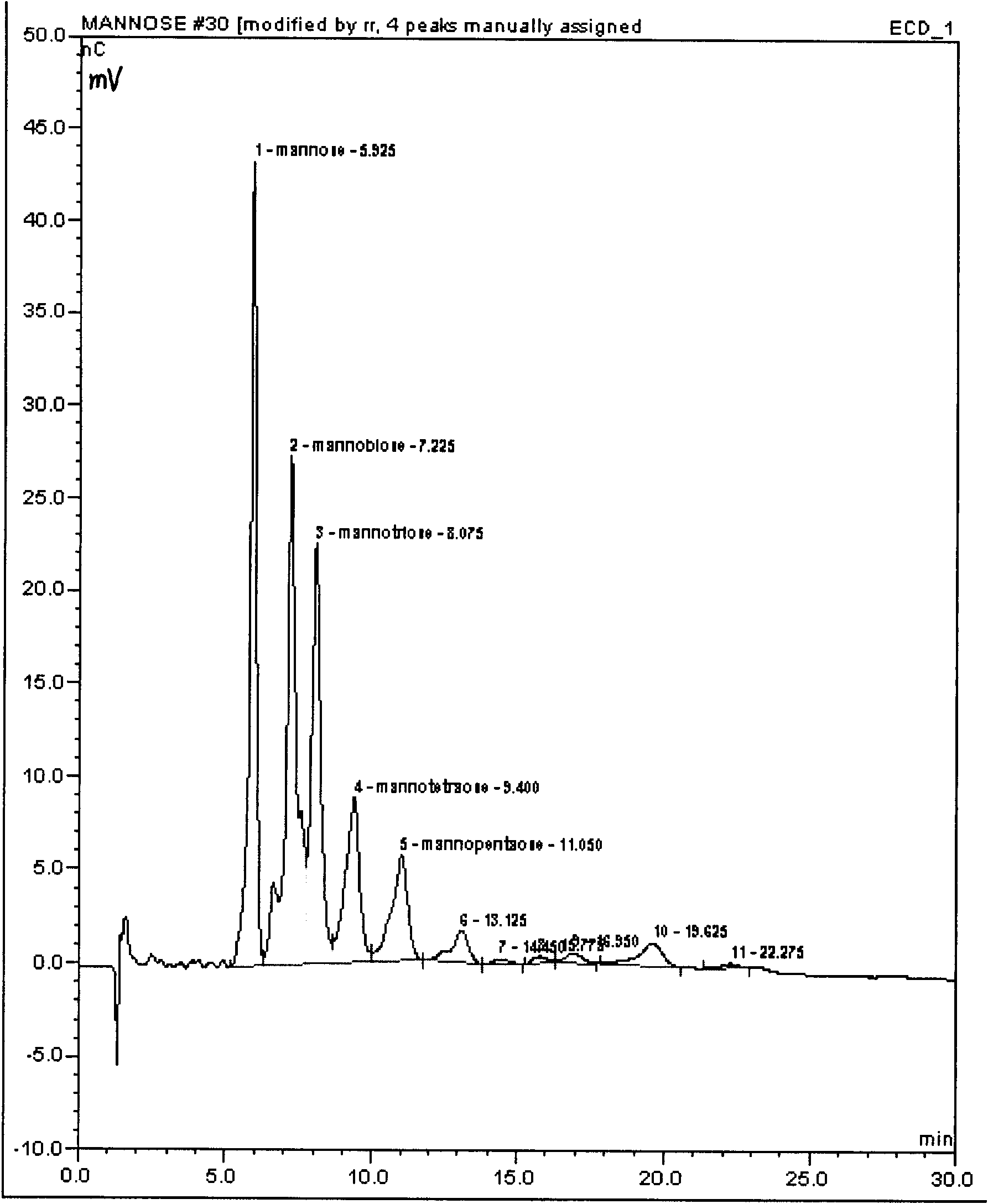

[0026] 2) Weigh 100 g of the 60-mesh konjac meal prepared in step 1), adjust it into a slurry of konjac meal with a concentration of 2% with water, and combine the slurry of the konjac meal with an endogenous enzyme activity of 190,000 U / g Type mannanase 40g carries out enzyme hydrolysis reaction, obtains the generation liquid of konjac glucomannan oligosaccharide, and constantly tak...

Embodiment 2

[0044] 1) Fresh konjac is washed, peeled, cut into pieces, preliminarily crushed with a juice extractor, added distilled water at a ratio of 1kg:600kg of konjac and water, and sheared at 10000r / min with a high-shear mixing emulsifier Emulsify twice, each time for 5 minutes, then use an ultra-high pressure homogenizer to homogenize once at 160MPa, and then homogenize three times at 650MPa, let it stand, filter the supernatant with a filter cloth, and dry the filter residue at 110°C for 10 Hour, obtain konjac meal, and order number is 80 orders.

[0045] 2) Weigh 100 g of the 80-mesh konjac meal prepared in step 1), adjust it into a slurry of 3.5% konjac meal with water, and combine the slurry of the konjac meal with an enzyme activity of 200,000 U / g Type mannanase 40g carries out enzyme hydrolysis reaction, obtains the generation liquid of konjac glucomannan oligosaccharide, and constantly takes out the generation liquid of described konjac glucomannan oligosaccharide, in this ...

Embodiment 3

[0049] 1) Fresh konjac is washed, peeled, cut into pieces, preliminarily crushed with a juice extractor, added with distilled water at a ratio of 1kg: 1200kg of konjac and water, and sheared at 6000r / min with a high-shear mixing emulsifier Emulsify 5 times, each time for 15 minutes, then use an ultra-high pressure homogenizer to homogenize once at 250MPa, and then homogenize three times at 450MPa, let it stand, filter the supernatant with a filter cloth, and dry the filter residue at 95°C for 20 Hour, obtain konjac meal, and order number is 40 orders.

[0050] 2) Weigh 100 g of the 40-mesh konjac meal prepared in step 1), adjust it into a slurry of konjac meal with a concentration of 1.5% with water, and combine the slurry of the konjac meal with an enzyme activity of 200,000 U / g Type mannanase 40g carries out enzyme hydrolysis reaction, obtains the generation liquid of konjac glucomannan oligosaccharide, and constantly takes out the generation liquid of described konjac gluco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com