Method for preparing glue reduction agent by amphiprotic polyester polycarboxylic acid compound

A technology of carboxylic acid compounds and adhesive reducers, which is applied in the field of amphoteric polyester polycarboxylic acid compounds to prepare adhesive reducers, can solve the problems of small molecular weight, single functional components of adhesive reducers, outstanding matching and adaptability, etc. Achieve the effects of improving dispersibility and workability, improving slump retention ability, and reducing competitive adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

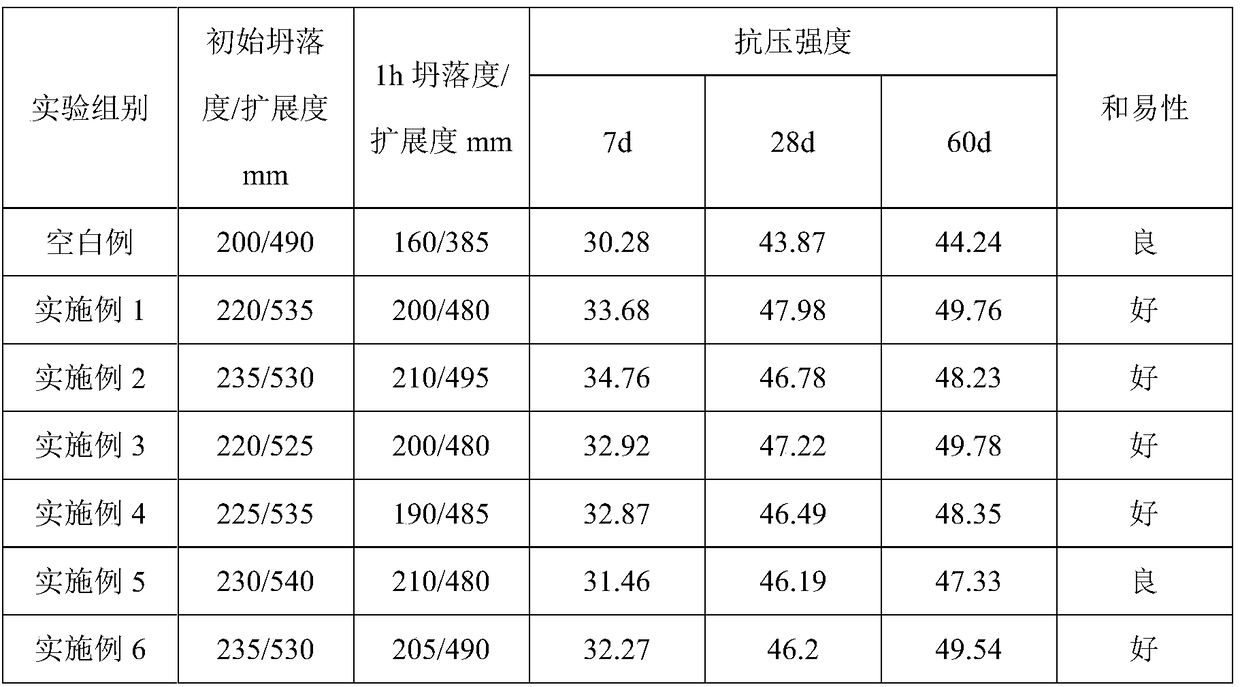

Embodiment 1

[0060] Embodiment 1 (each component consumption is parts by weight)

[0061] 1. Preparation of esterified polyether macromonomer: the preparation method is carried out in the following steps:

[0062] 1), put into the container 30 parts of 600 molecular weight methoxypolyethylene glycol monomethyl ether, 20 parts of acrylic acid, sodium thiosulfate loaded on zirconia, and bake at high temperature to obtain 0.5 part of solid superacid, p-tert-butyl-o- 0.1 parts of hydroquinone, 30 parts of benzene, fully stirred, sealed and vacuumized;

[0063] 2), raise the temperature to 110°C and keep it warm for 4 hours;

[0064] 3) After the heat preservation is over, stop heating, and when the temperature drops to 30°C, add 1 part of sodium hydroxide, separate the catalyst carrier and the water-carrying agent, and obtain an esterified polyether macromonomer with a molecular weight of 1200.

[0065] 2. Preparation of adhesive reducer: Amphoteric polyester polycarboxylate adhesive reducer...

Embodiment 2

[0070] Embodiment 2 (each component consumption is parts by weight)

[0071] 1. Preparation of esterified polyether macromonomer: the preparation method is carried out in the following steps:

[0072] 1), drop into container 32 parts of 600 molecular weight methoxypolyethylene glycol monomethyl ethers, 22 parts of methacrylic acid, the sodium thiosulfate loaded on ferric oxide and make 0.6 part of solid superacid, 1 part through high-temperature baking , 0.3 parts of 1-diphenyl-2-picrylhydrazine, 29 parts of toluene, fully stirred, sealed and vacuumized;

[0073] 2), raise the temperature to 115°C and keep it warm for 5 hours;

[0074] 3) After the heat preservation is over, stop heating, and when the temperature drops to 30°C, add 2 parts of sodium carbonate, separate the catalyst carrier and the water-carrying agent, and obtain an esterified polyether macromonomer with a molecular weight of 1200.

[0075] 2. Preparation of adhesive reducer: amphoteric polyester polycarboxy...

Embodiment 3

[0080] Embodiment 3 (each component consumption is parts by weight)

[0081] 1. Preparation of esterified polyether macromonomer: the preparation method is carried out in the following steps:

[0082] 1), in container, drop into 34 parts of 600 molecular weight methoxypolyethylene glycol monomethyl ethers, 24 parts of maleic acid, the sodium thiosulfate loaded on ferric oxide obtains 0.7 part of solid super acid, 4 parts through high temperature baking -0.4 parts of hydroxy-2,2,6,6-tetramethylpiperidine-1-oxyl radical, 28 parts of xylene, fully stirred, sealed and evacuated;

[0083] 2), raise the temperature to 118°C and keep it warm for 6 hours;

[0084] 3) After the heat preservation is over, stop heating, and when the temperature drops to 30°C, add 3.5 parts of ethanolamine, separate the catalyst carrier and the water-carrying agent, and obtain an esterified polyether macromonomer with a molecular weight of 1200.

[0085] 2. Preparation of adhesive reducer: amphoteric po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com