Method for making avocado salad sauce and water-phase premixing device

A production method and avocado technology, which are applied in chemical instruments and methods, mixers with rotary stirring devices, mixers, etc., can solve problems such as intolerance to baking, improve mixing and mixing effects, reduce cleaning labor, and are easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

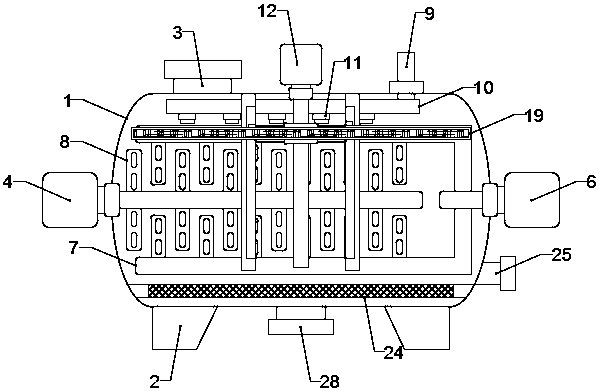

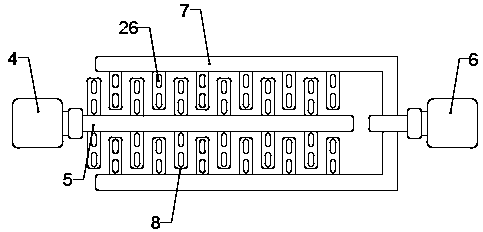

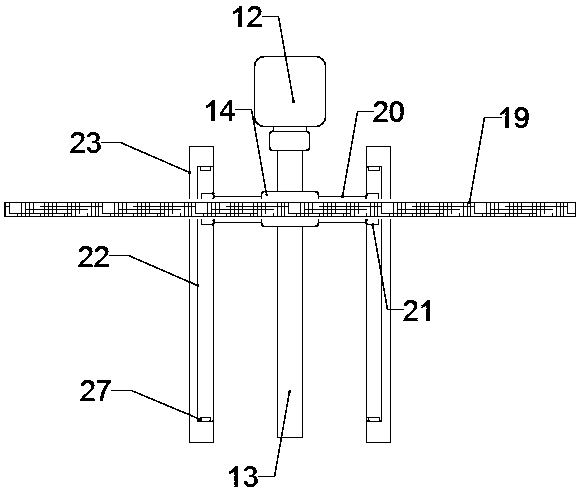

Method used

Image

Examples

Embodiment 1

[0028] Step 1: After the frozen egg liquid with heat-stable egg yolk liquid is out of the warehouse, remove the outer packaging and put it in a special box for egg thawing, and place it in a closed refrigerator at 1-8°C for 48 hours to thaw;

[0029] Step 2, prepare drinking water with a water temperature of 15°C, soybean oil with an oil temperature of 15°C, heat-stable egg yolk liquid with an egg liquid temperature of 1°C, and control the room temperature to 15°C;

[0030] Step 3: Add drinking water to the water phase premix tank, start stirring, then add white sugar, heat-stable egg yolk liquid, brilliant blue, lemon yellow, β-carotene, citric acid, avocado puree, EDTA in sequence Disodium, edible salt, steviol glycoside and sucralose are stirred and dissolved;

[0031] Step 4, add soybean oil into the oil phase premix tank, start stirring, then add xanthan gum to disperse evenly;

[0032] Step 5: Turn on the vacuum of the emulsifier to 500 bar, open the bottom valve of the...

Embodiment 2

[0039] Step 1: After the frozen egg liquid with heat-stable egg yolk liquid is out of the warehouse, remove the outer packaging and put it in a special box for egg thawing, and place it in a closed refrigerator at 1-8°C for 48 hours to thaw;

[0040] Step 2, prepare drinking water with a water temperature of 20°C, soybean oil with an oil temperature of 20°C, heat-stable egg yolk liquid with an egg liquid temperature of 8°C, and control the room temperature to 25°C;

[0041] Step 3: Add drinking water to the water phase premix tank, start stirring, then add white sugar, heat-stable egg yolk liquid, brilliant blue, lemon yellow, β-carotene, citric acid, avocado puree, EDTA in sequence Disodium, edible salt, steviol glycoside and sucralose are stirred and dissolved;

[0042] Step 4, add soybean oil into the oil phase premix tank, start stirring, then add xanthan gum to disperse evenly;

[0043] Step 5: Turn on the vacuum of the emulsifier to 500 bar, open the bottom valve of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com