Anti-yellowing type matte wetting and unsmoothing waxy-feel treatment agent for synthetic leather and preparation method thereof

A treatment agent and synthetic leather technology, which is applied in fiber treatment, textiles and papermaking, etc. It can solve the problems that affect the appearance of synthetic leather and cannot satisfy consumers' aesthetic and hand feeling, and achieve good matte matting effect and good yellowing resistance effect. , Unique and comfortable touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

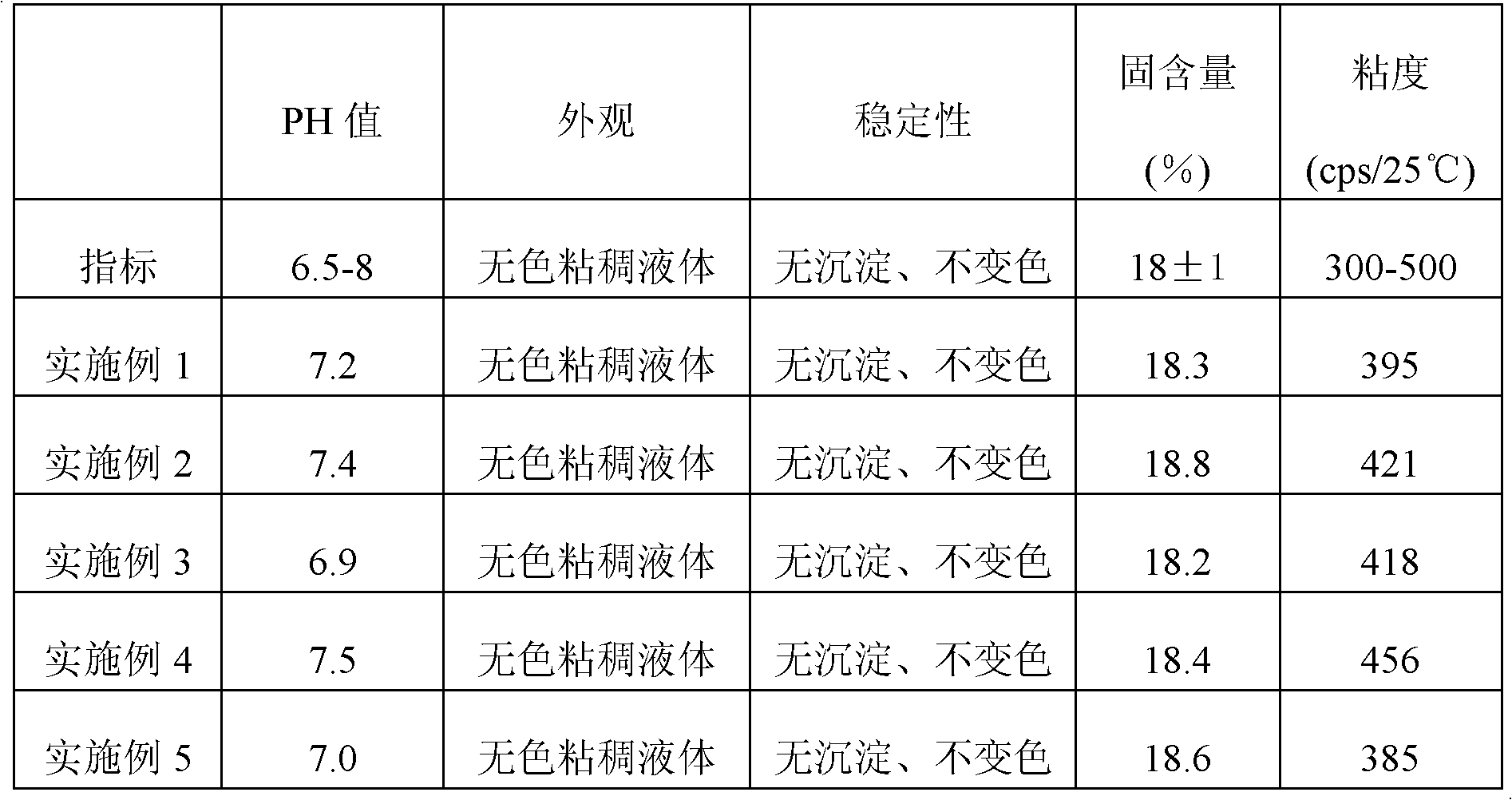

Embodiment 1

[0026] Under normal temperature and pressure, put 12 parts by weight of methyl ethyl ketone, 7 parts by weight of toluene, 4 parts by weight of silica matting powder, and 55 parts by weight of modified yellowing-resistant polyurethane resin into a 1L reactor, and fully stir at least at room temperature. After 30 minutes of grinding, filter and discard the filter residue; add 1 part by weight of polyether modified silicone oil and 1 part by weight of alkyl sulfonate to the resulting mixture, and stir uniformly at room temperature; then add the remaining modified yellowing resistant polyurethane After 20 parts by weight of the resin is uniformly stirred at room temperature for at least 30 minutes until the viscosity is stable, the finished product of the anti-yellowing type matte wet waxy feeling treatment agent for synthetic leather without precipitation and colorless viscous liquid is obtained. The performance indexes of the obtained anti-yellowing type matte wet waxy feeling tr...

Embodiment 2

[0029] Under normal temperature and pressure, put 15 parts by weight of methyl ethyl ketone, 10 parts by weight of toluene, 4 parts by weight of silica matting powder, and 50 parts by weight of modified yellowing-resistant polyurethane resin into a 1L reactor, and fully stir at least at room temperature. After 30 minutes of grinding, filter and discard the filter residue; add 0.5 parts by weight of polyether modified silicone oil and 0.5 parts by weight of alkyl sulfonate to the resulting mixture, and stir uniformly at room temperature; then add the remaining modified yellowing resistant polyurethane After 20 parts by weight of the resin is uniformly stirred at room temperature for at least 30 minutes until the viscosity is stable, the finished product of the anti-yellowing type matte wet waxy feeling treatment agent for synthetic leather without precipitation and colorless viscous liquid is obtained. The performance indexes of the obtained anti-yellowing type matte wet waxy fee...

Embodiment 3

[0032] Under normal temperature and pressure, put 14 parts by weight of methyl ethyl ketone, 8 parts by weight of toluene, 4.5 parts by weight of silica matting powder, and 50 parts by weight of modified yellowing-resistant polyurethane resin into a 1L reactor, and fully stir at least at room temperature. After 30 minutes of grinding, filter and discard the filter residue; add 0.8 parts by weight of polyether modified silicone oil and 0.7 parts by weight of alkyl sulfonate to the resulting mixture, and stir uniformly at room temperature; then add the remaining modified yellowing resistant polyurethane After 22 parts by weight of resin, uniformly stirred at room temperature for at least 30 minutes until the viscosity is stable, the finished product of anti-yellowing type matte wet waxy feeling treatment agent for synthetic leather without precipitation and colorless viscous liquid is obtained. The performance indexes of the obtained anti-yellowing type matte wet waxy feeling trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com