False tooth and manufacturing method thereof

A manufacturing method and denture technology, applied in the field of dentures, can solve problems such as weak dentures, and achieve the effects of high strength, high melting point and accurate parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

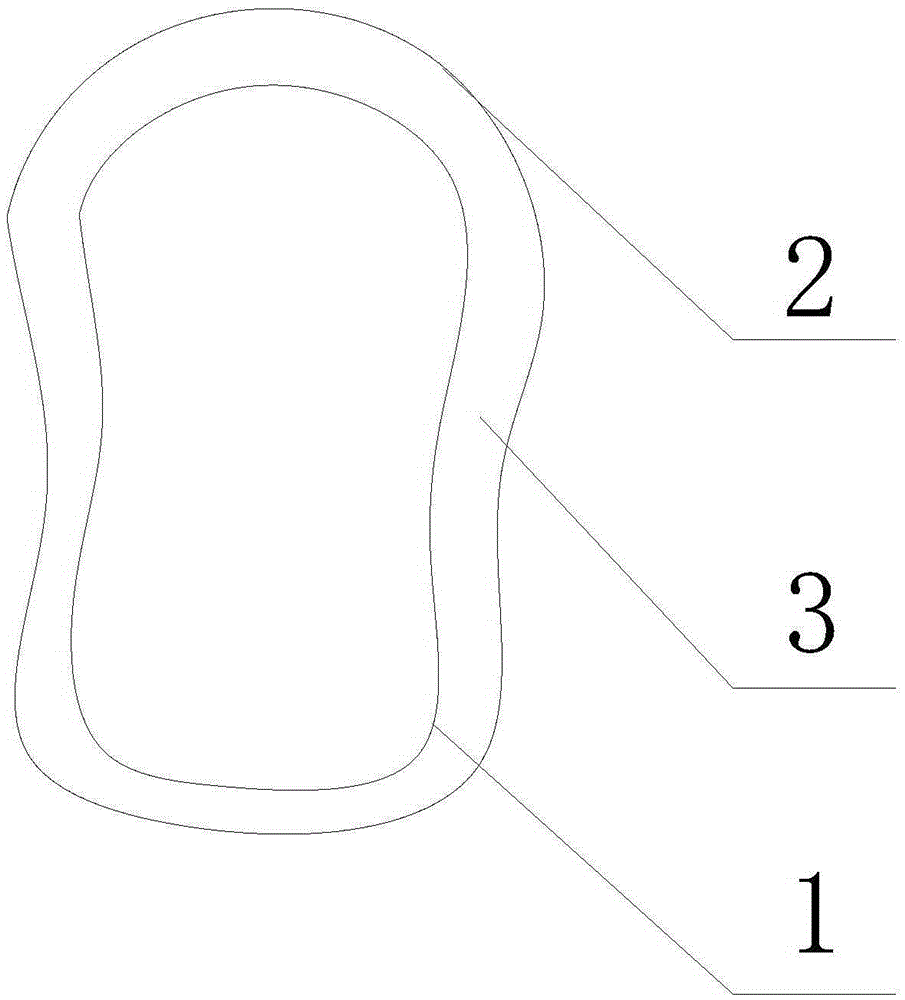

[0028] a denture such as figure 1 As shown, the inner crown 1 is included. The inner crown 1 is used as a basic bracket, and the basic structure of the denture is formed by 3D printing. The outermost side of the inner crown 1 is covered with a body porcelain layer 2. The body porcelain layer 2 is made of porcelain powder The outer surface of the inner crown 1 is made of zirconia material after cutting, grinding and sintering, and a paste 3 is provided between the body porcelain layer 2 and the inner crown, and the paste 3 is used to fill the body porcelain layer 2 and the inner crown 1 the gap between. The function of paste 3 is to fix the body porcelain layer and the inner crown, more precisely, to make the body porcelain layer and the inner crown more stable, so that the two are not easy to deform or deviate. Sometimes, due to the excessive occlusal force of the teeth, it is easy to cause the denture to be out of alignment, and the function of the paste is to make the posit...

Embodiment 2

[0033] A method for making teeth, comprising the steps of:

[0034] Step 1, collect and correct the data of three-dimensional parameters of the teeth that need to be made into dentures, and restore the simulated tooth model;

[0035] Step 2, production of the inner crown 1: According to the simulated tooth model obtained in the above step 1, a basic bracket of the tooth is produced by using 3D printing technology;

[0036] Step 3, production of body porcelain layer 2: according to the structure of the inner crown 1 obtained in step 2, a body porcelain layer is made on its outer layer. The volume of the body porcelain layer 2 is larger than that of the inner crown 1. The body porcelain layer is cut and ground The device performs numerical control cutting on the zirconia material to form the zirconia ceramic layer 2 structure;

[0037] Step 4, filling of paste body 3: filling the mixture of resin and ceramic between the body porcelain layer and the inner crown, and then sinteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com