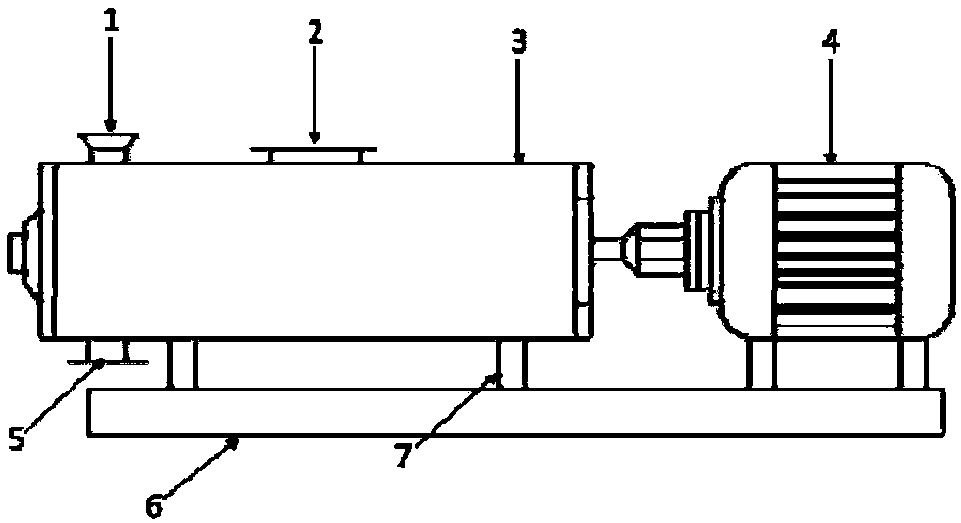

Stirring device and horizontal double-shaft self-cleaning reactor

A technology of stirring device and stirring plate, which is applied in mixers with rotating stirring devices, chemical/physical/physical-chemical stationary reactors, mixer accessories, etc. , heavy and other problems, to achieve the effect of enhanced shearing ability, good self-cleaning effect, and enhanced stirring and mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

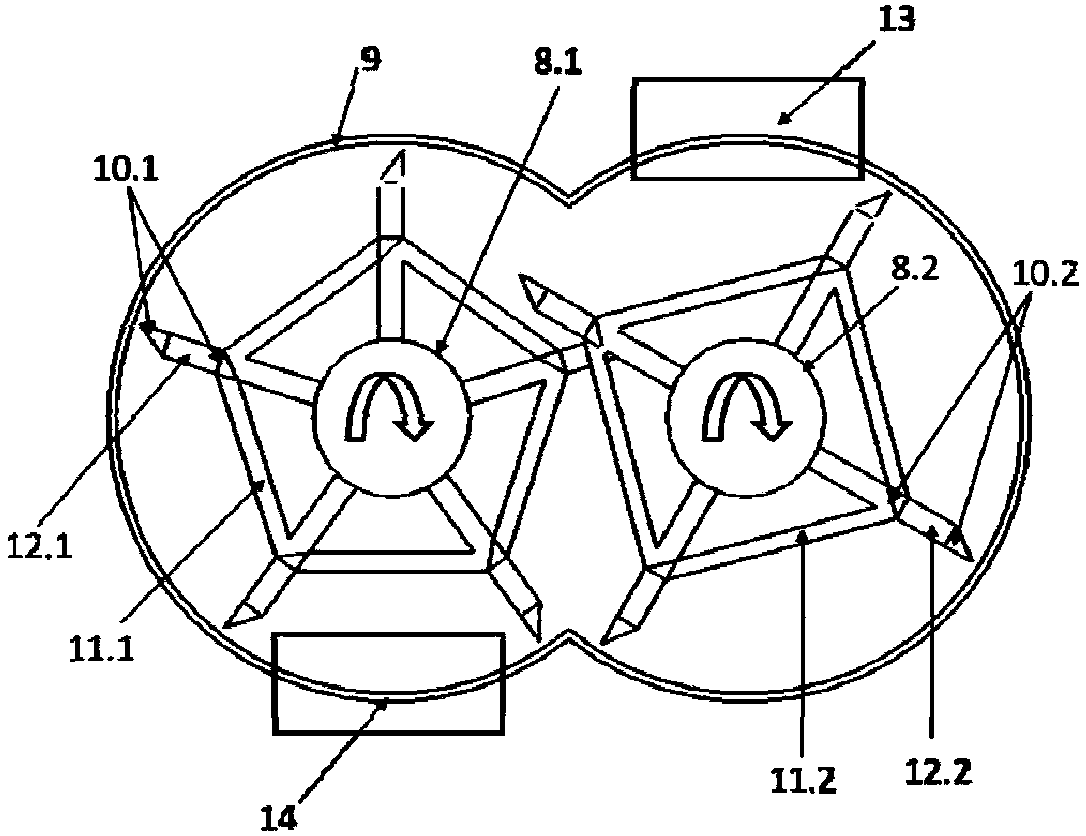

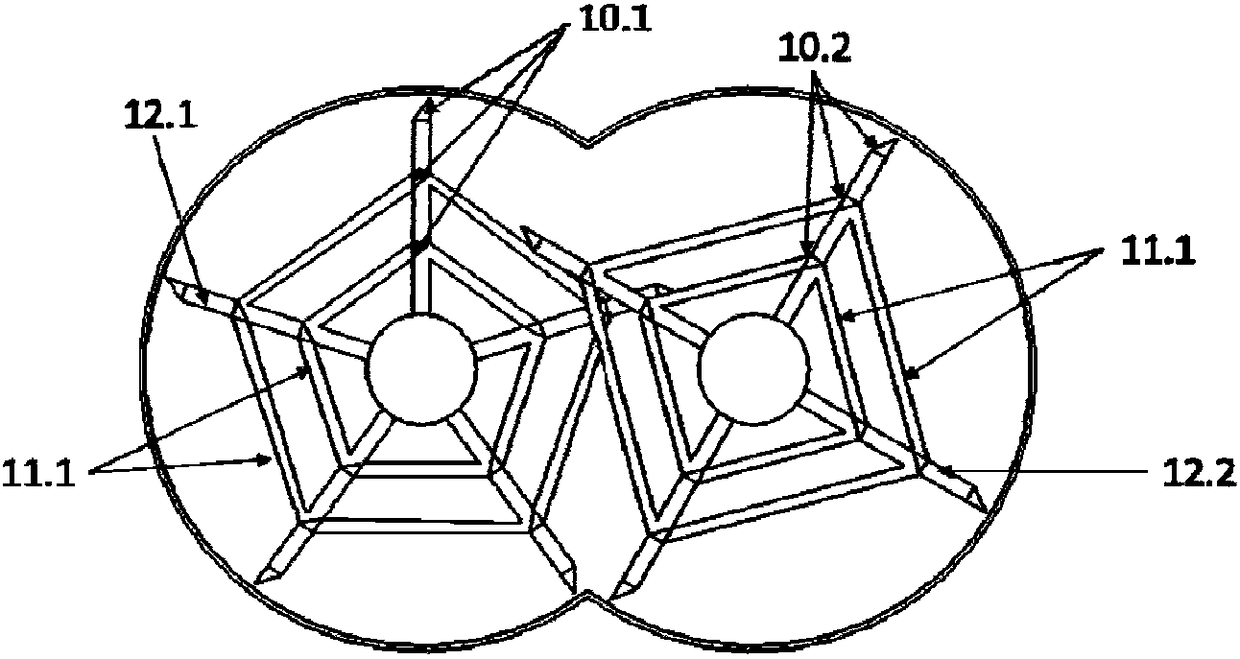

[0037] Example 1: Self-cleaning process of a biaxial reactor

[0038] The structure and principle of the reactor are as mentioned above, the ratio of the rotational speed of the two rotating shafts is 4:5, and the ratio of the supporting rods of the rotating shaft stirring plate is 5:4. Comparing the reactor described in Chinese patent (CN201210186362.5, 2012) with the horizontal double-shaft self-cleaning reactor with double-layer and three-layer stirring blades distributed radially, the stirring blades on the second rotating shaft are obtained Schematic diagram of the relative motion trajectory relative to the first rotation axis. Compared with the traditional single-layer horizontal double-shaft self-cleaning stirring reactor, the horizontal double-shaft self-cleaning reactor with radially distributed double-layer stirring blades has more blades and is distributed up and down in multiple layers. When rotating around the rotating shaft, it can self-clean the entire space of...

Embodiment 2

[0039] Embodiment 2: the final polycondensation process of poly-p-phenylene terephthalamide

[0040] In the later stage of the polymerization process of poly-p-phenylene terephthalamide, the viscosity of the reaction system is very high, and it is difficult for the traditional reactor to reach the product target. The structure and principle of the reactor are as described above, and the structural parameters of some reactors are as follows: the length of the stirring blades on the first rotating shaft and the second rotating shaft is 40-80 mm, and the stirring blades on the two shafts are arranged at intervals, and the distance between the stirring discs of the rotating shafts is 30 mm. -80mm, the distance between the stirring paddles distributed radially on the rotating shaft is 30-80mm. Due to the use of double-layer blades, when the two blades in the middle of the kettle intersect each other, the shear rate reaches the maximum, and the fluid in the flow field can experience...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com