Integrated rotary cavitating jet nozzle

A jet nozzle, centralized technology, applied in the field of centralized rotating cavitation jet nozzle, can solve the problems of water jet energy concentration, energy non-concentration, low energy concentration of cavitation water jet, etc. Shear action, effect of improving erosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

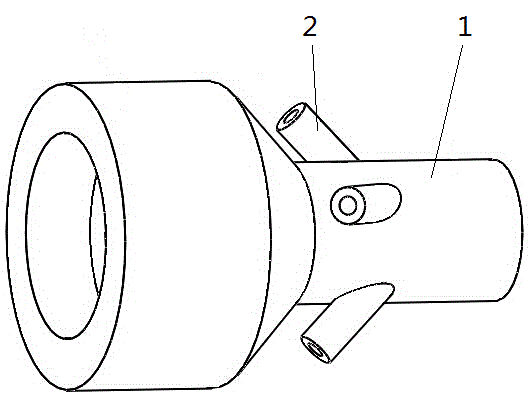

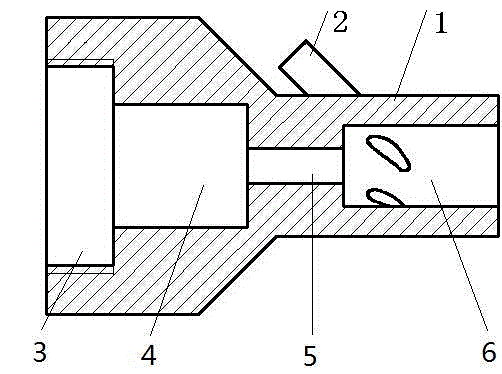

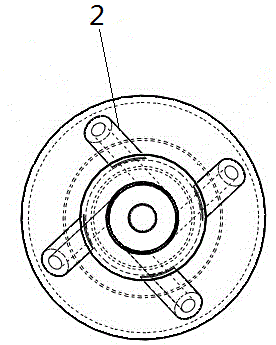

[0019] see figure 1 , figure 2 and image 3 , the centralized rotating cavitation jet nozzle is connected to the high-pressure water pipeline through the thread of the inlet section, and the inner flow channel of the nozzle consists of a cylindrical inlet section (3), a cylindrical resonant cavity (4), a cylindrical small hole (5) and a cylindrical outlet section (6), on the nozzle body (1) there are multiple inlet pipes (2) along the circumference, the inlet pipes (2) lead to compressed air, the inner hole of the inlet pipe (2) and the cylindrical outlet section (6 ) tangent to the inner hole, and the inner diameter of the air inlet pipe (2) is 1 / 2 of the difference between the inner diameter of the cylindrical outlet section (6) and the inner diameter of the cylindrical small hole (5).

[0020] see figure 2 , when water (or other fluid) enters from the cylindrical inlet section (3), it is ejected from the cylindrical hole (5) through the cylindrical resonant cavity (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com