Nanometer-modified fiber reinforced plastic reinforcement sea sand concrete fence board and preparation method thereof

A nano-modification, concrete technology, applied in the field of water conservancy engineering, can solve the problems of reducing the service life of the overall structure, the steel bars in the fence panel are easy to corrode, and the promotion and application are inconvenient, achieving good resistance, good corrosion resistance, and promoting ecological environment protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

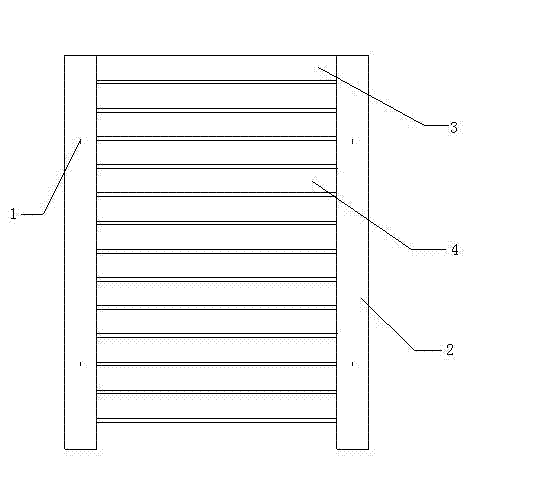

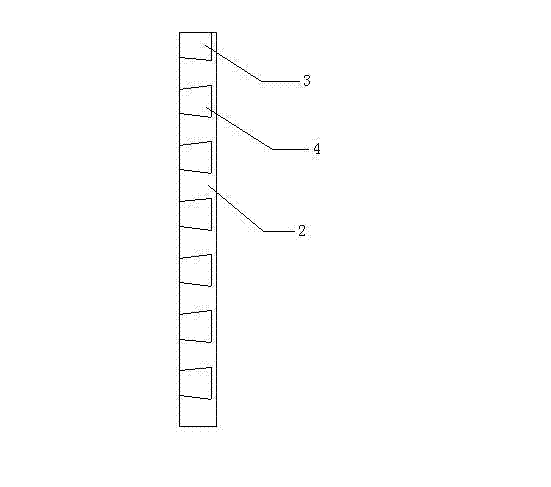

Image

Examples

Embodiment 1

[0026] Embodiment 1: A kind of nano-modified FRP bar strengthens the sea sand concrete fence board, comprises the following components by mass percentage: glass fiber 70%, epoxy resin (bisphenol A type) 25.5%, nanoclay 0.6%, Accelerator (2-benzyl-4-methylimidazole) 0.45%, inhibitor 0.05%, curing agent (ethylenediamine) 0.4%, ethylene glycol 3%. The strength grade of sea sand concrete is designed to be C40.

[0027] The preparation process specifically includes the following steps:

[0028] 1) Select the raw materials of nano-modified FRP bars, weigh them according to the mass percentage of each raw material, and set aside;

[0029] 2) Disperse the nano-clay in the ethylene glycol solvent, and ultrasonically disperse the nano-clay while mechanically stirring; then stir the dispersed nano-clay and resin evenly to obtain a modified resin, and then impregnate the glass fiber into the added In the resin containing curing agent, accelerator, etc., it is cured by heating; finally, ...

Embodiment 2

[0033] Embodiment 2: A kind of nano-modified FRP bar strengthens the sea sand concrete fence board, comprises the following components by mass percentage: glass fiber 65%, vinyl unsaturated polyester 29.5%, carbon nanotube 0.06%, accelerator (2-benzyl-4-methylimidazole) 0.3%, polymerization inhibitor 0.04%, curing agent (ethylenediamine) 0.6%, ethylene glycol 4.5%. The strength grade of sea sand concrete is designed to be C60.

[0034] The preparation method is the same as in Example 1.

Embodiment 3

[0035] Example 3: A nano-modified FRP bar reinforced sea sand concrete fence, including the following components by mass percentage: glass fiber 75%, epoxy resin (bisphenol A type) 21.5%, carbon nanotube 0.045% , accelerator (2-benzyl-4-methylimidazole) 0.15%, polymerization inhibitor 0.045%, curing agent (ethylenediamine) 0.3%, ethylene glycol 2.96%. The strength grade of sea sand concrete is designed to be C30.

[0036] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com