Slip form lifting frame

A technology of lifting frame and sliding form, which is applied in the fields of formwork/template/work frame, on-site preparation of building components, construction, etc. problems, to achieve the effect of fast construction progress, practicality and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

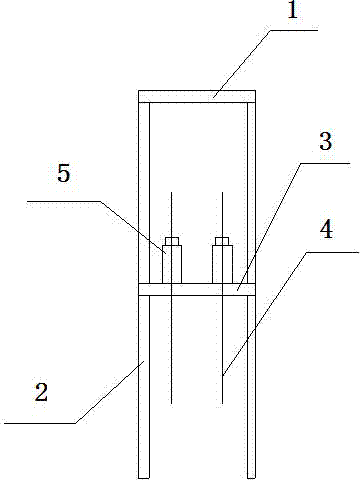

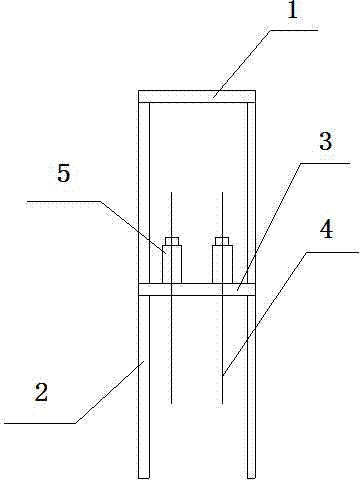

[0008] As an embodiment of the present invention, such as figure 1 As shown, a sliding form lifting frame includes a "open" shaped lifting frame body, and the lifting frame body is composed of a horizontally arranged top beam 1, a support beam 3 parallel to the top beam, and two vertical columns 2 Composition, the height of the column 2 is 450mm, the length of the top beam 1 and the support beam 3 is 150mm, the vertical distance between the top beam 1 and the support beam 3 is 250mm, the top beam 1 and the support beam 3 are made of No. 12 channel steel As a result, in this embodiment, as a preference, the column 2 is made of No. 18 channel steel. The upper surface of the support beam 3 is provided with a jack 5, and there are two jacks 5, and a support rod 4 is arranged on the jack 5, and the support rod 4 is made of ф48×3.5mm welded steel pipe. In this embodiment, as a preference, two jacks 5 are provided on the upper surface of the support beam 3; the surfaces of the top b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com