High volume stability marine concrete and its preparation method

A technology for marine concrete and stability, applied in the field of marine concrete and its preparation, can solve the problems of concrete performance deterioration, shortening the service life of the structure, etc., and achieve the effects of improving compactness, reducing heat of hydration, and improving erosion ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

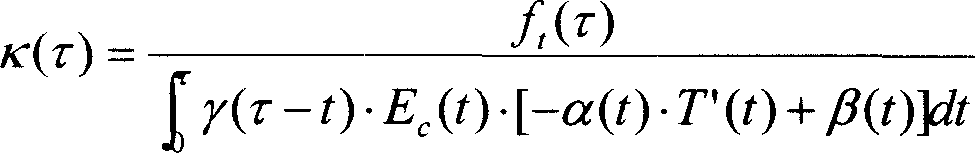

Image

Examples

Embodiment 1~5

[0039] Weigh the raw materials and mixing water according to the concrete mix ratio requirements in Table 1, pour them into the mixer and mix for 30-60 seconds until uniform. The strength grade of cement is 52.5, C 3 A content is less than 8%. The ground slag reaches the grade of S95 and above. The particle size of silica fume is 0.01~0.1μm, SiO 2 content greater than 90%. The maximum particle size of limestone or granite is less than 25mm. The length of the synthetic fiber is 4-6 mm, the diameter is less than 50 microns, the elongation is greater than 14%, and the tensile strength is greater than 300 MPa. The water reduction rate of the plasticizer is higher than 30%. The volume content of the aggregate in the marine concrete prepared in each embodiment is above 68%.

[0040] The main performance parameters of the marine concrete prepared in each embodiment are shown in Table 2.

[0041] Component

[0042] performance parameters

[0043] As can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com