Patents

Literature

48results about How to "Lower condensation point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Agricultural combination solvent and application thereof

InactiveCN102524246AImprove solubilityGood compatibilityBiocidePlant growth regulatorsGrowth plantSolvent

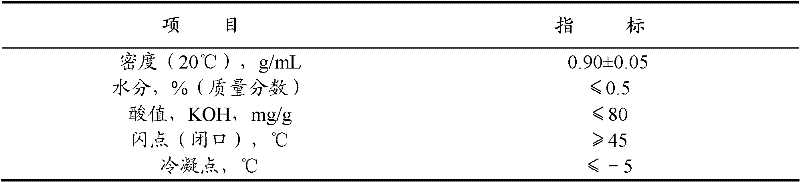

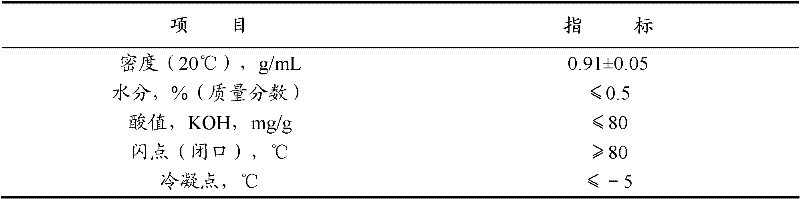

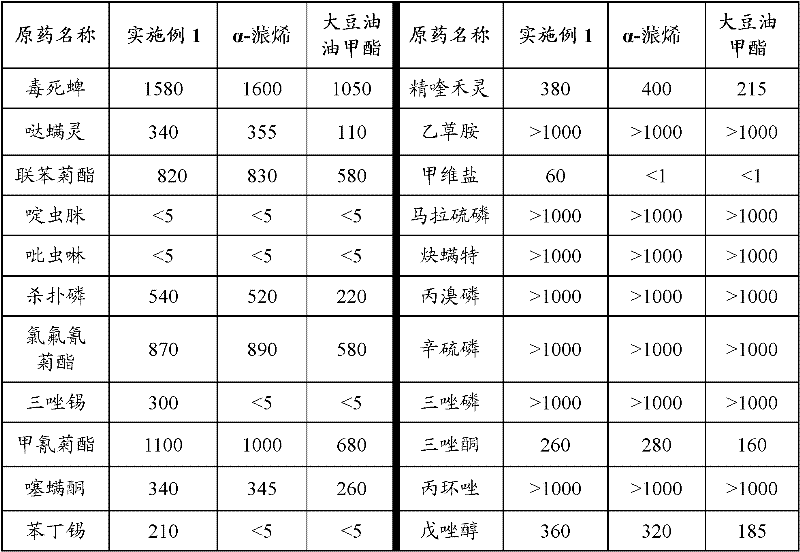

The invention provides an agricultural combination solvent which comprises a terpenoid and C8-C18 fatty acid esters. The agricultural combination solvent has good compatibility with pesticides, is safe and environment-friendly, has good biodegradation, has no pollution, has low freezing point and high flash point, and is safe and reliable in production, storage, transportation and use. The agricultural combination solvent can be applied in insecticides, herbicides or / and plant growth regulators.

Owner:FUJIAN NUODE BIOTECH

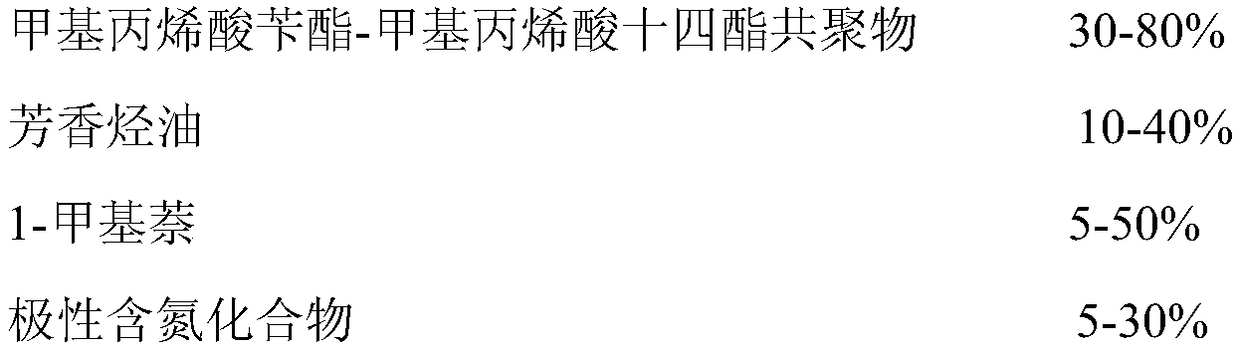

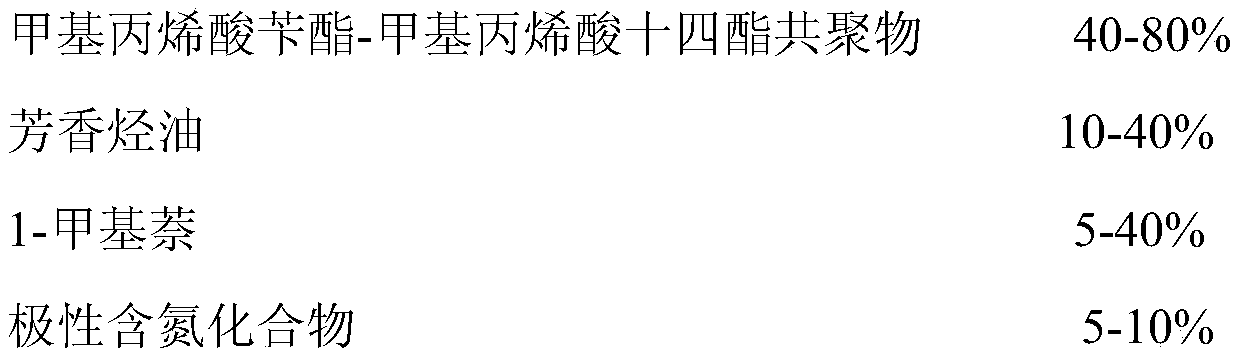

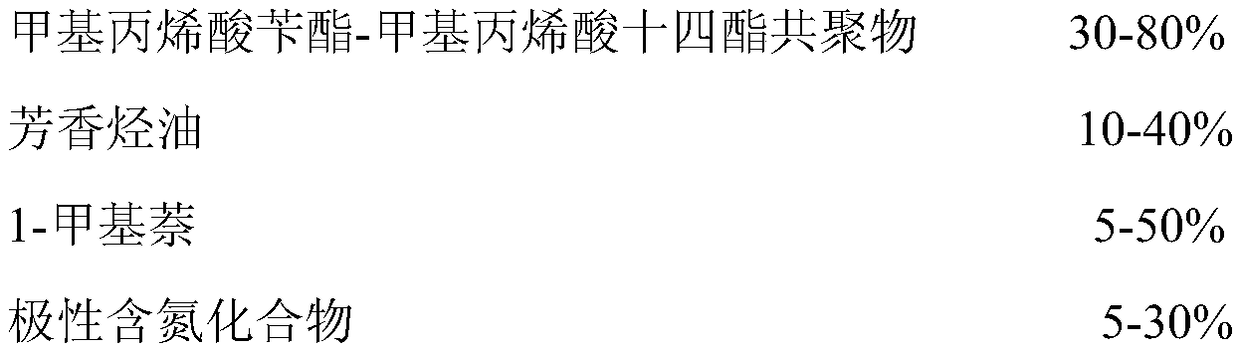

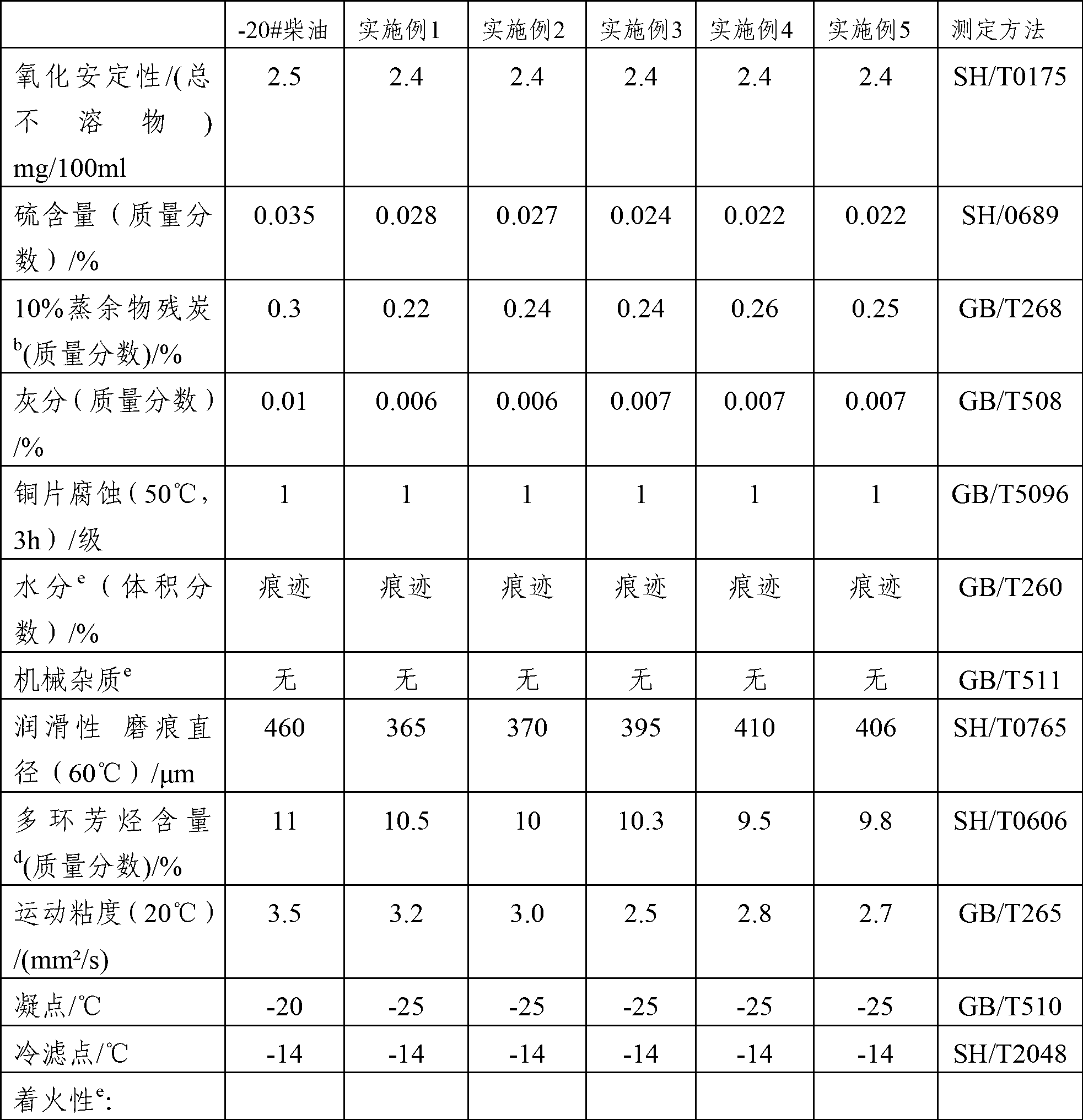

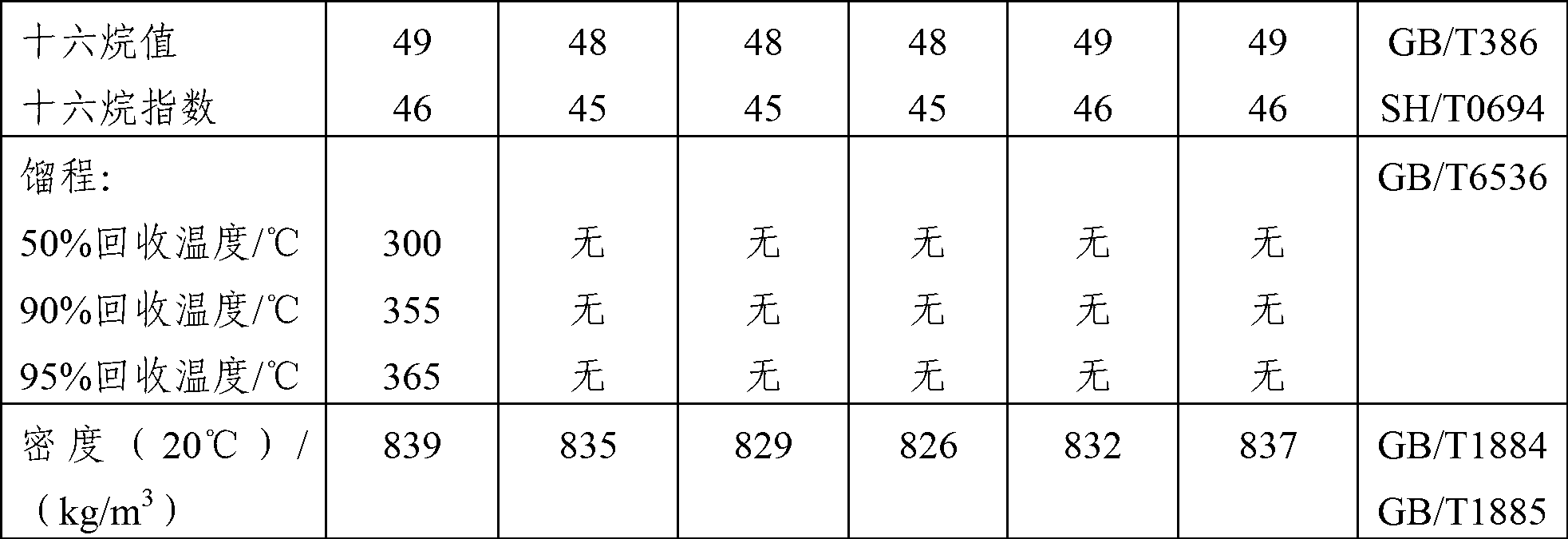

Wide-spectrum diesel pour point depressant composition, preparation method thereof and application of composition

InactiveCN109135846AIncrease polarityImprove solubilityLiquid carbonaceous fuelsFuel additivesPolymer scienceNitrogen

The invention discloses a wide-spectrum diesel pour point depressant composition, a preparation method thereof and an application of the composition. The pour point depressant composition comprises, in weight percent, 30-80% of benzyl methacrylate-methacrylic acid tetradecyl ester copolymers, 10-40% of arene oil, 5-50% of 1-methylnaphthalene and 5-30% of polar nitrogen-containing compounds. The raw materials are uniformly mixed according to predetermined weight percent to obtain the composition. The diesel pour point depressant composition can be rapidly dissolved in diesel oil, is high in spectrum and has remarkable pour point declining effect when being applied to different diesel, and a condensation point and a cold filter plugging point are reduced by 21-26 DEG C and 8-12 DEG C.

Owner:SHANGHAI INST OF TECH

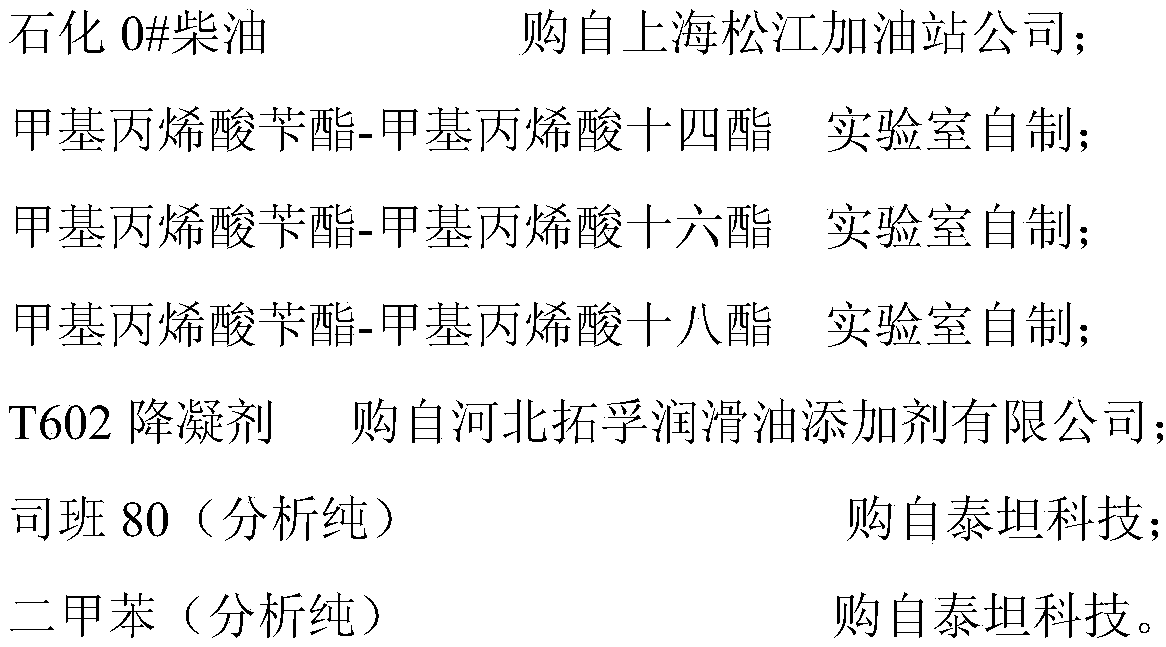

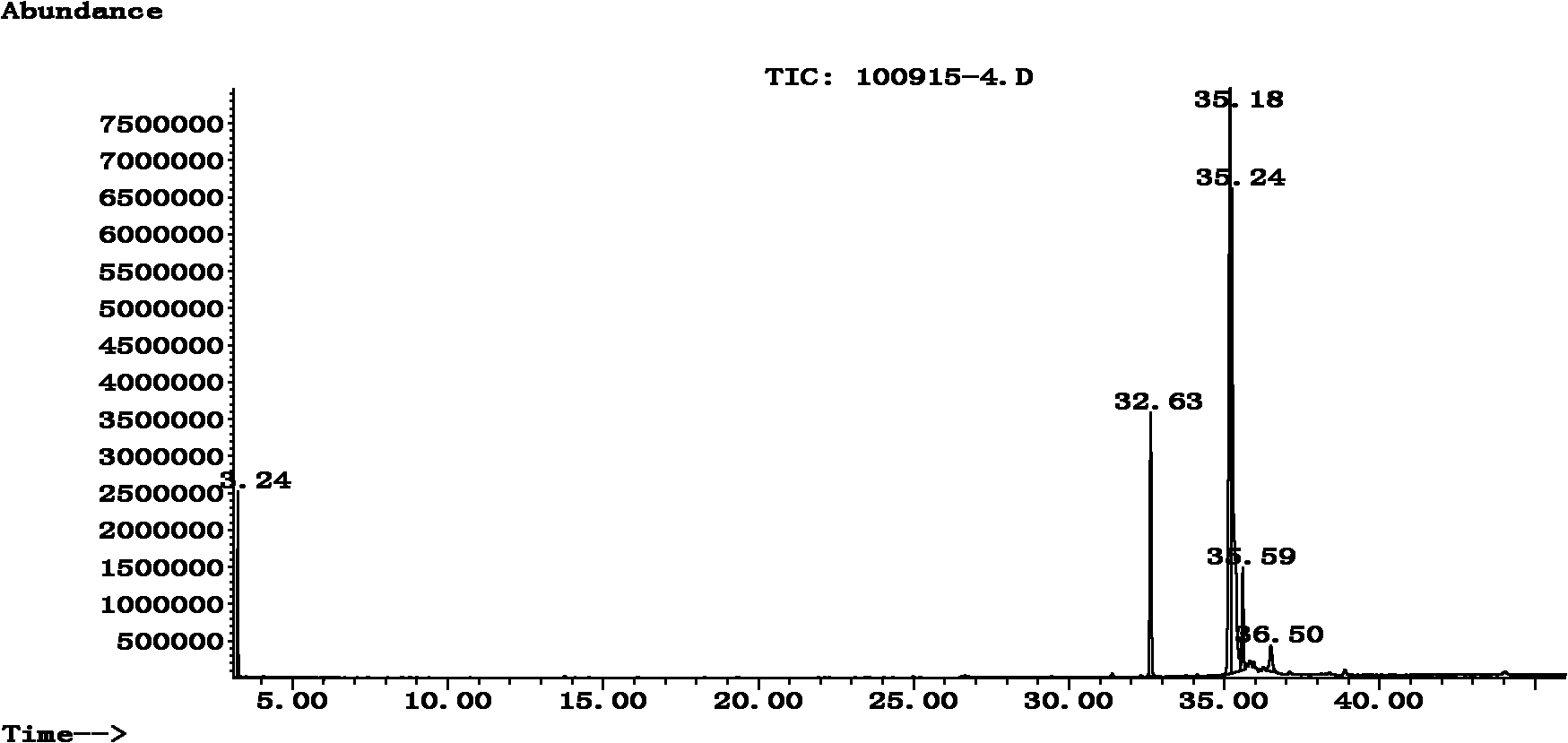

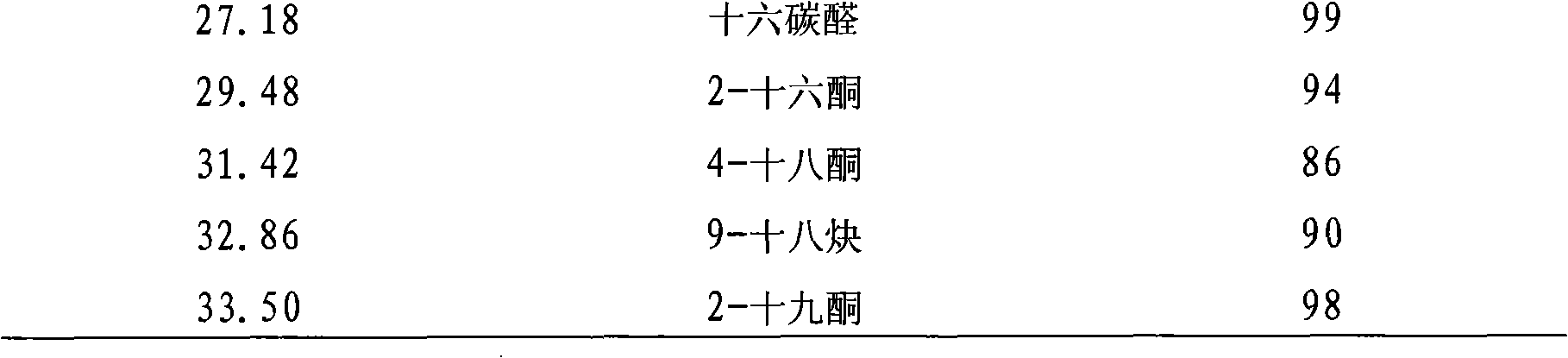

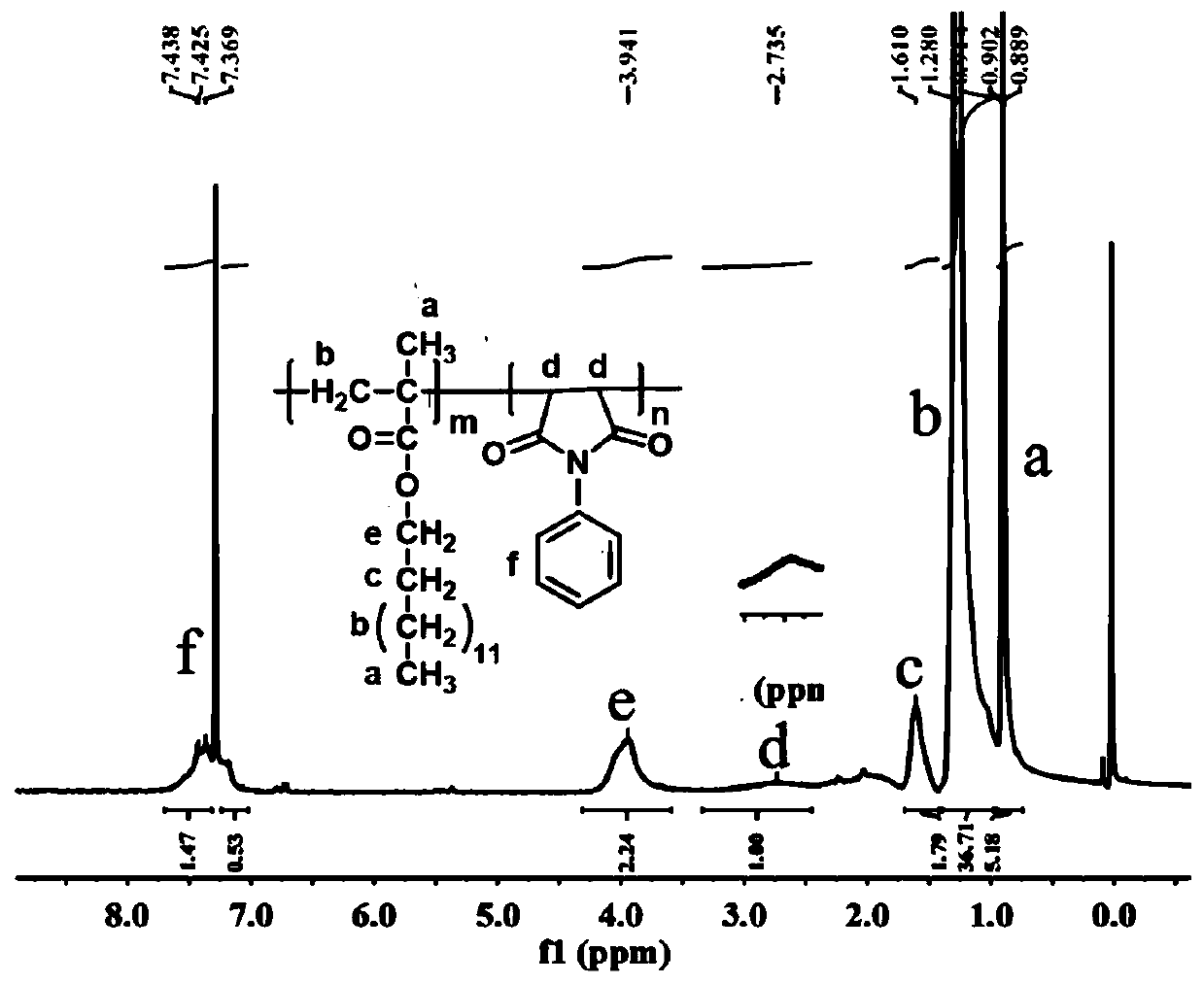

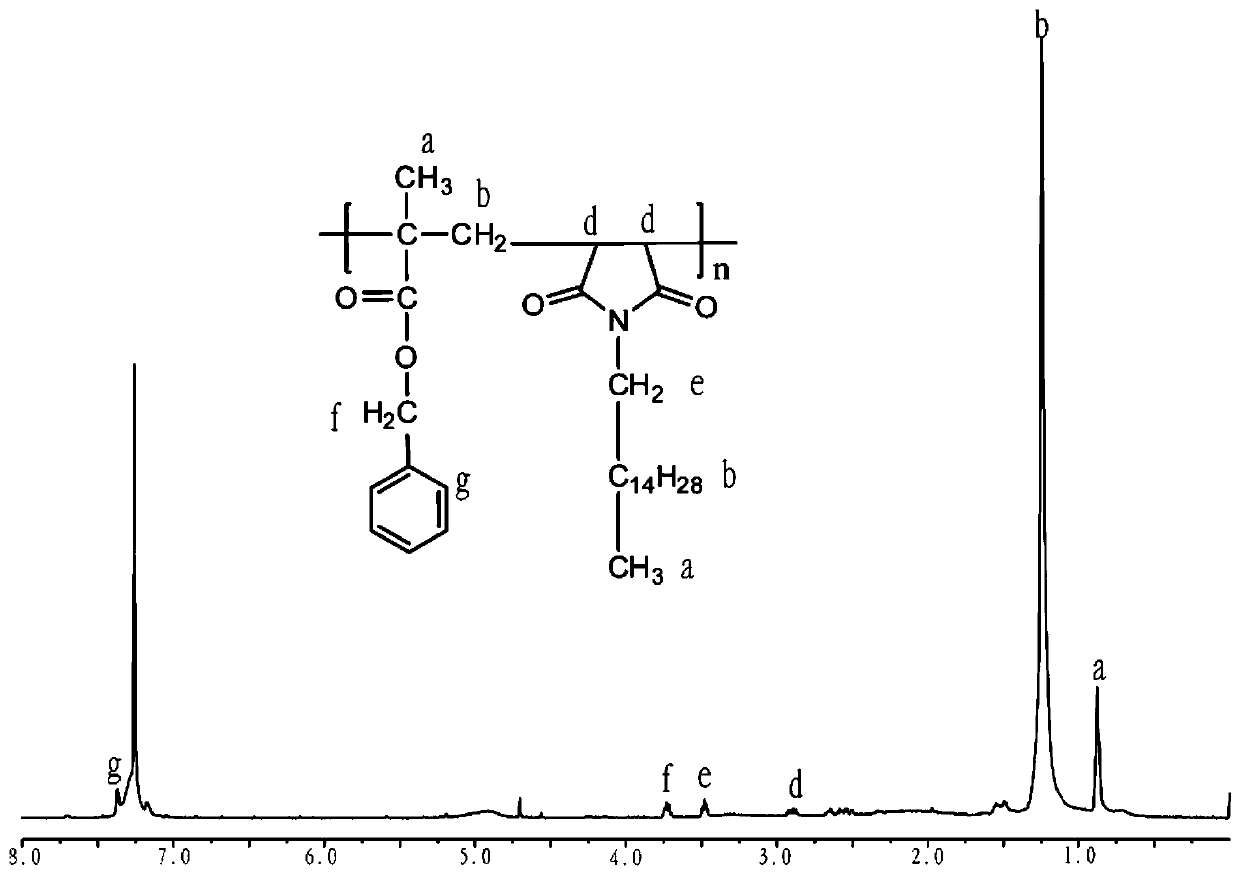

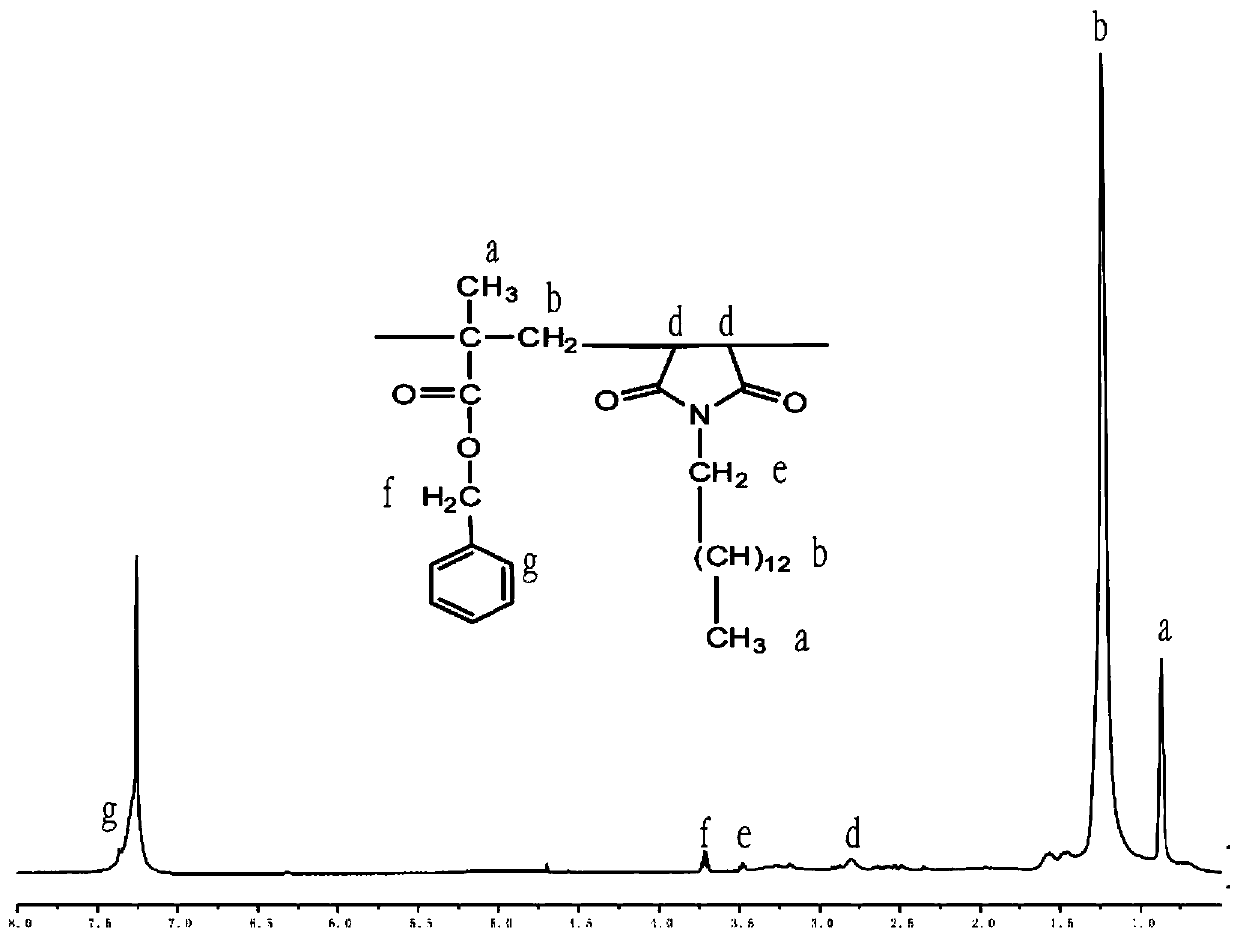

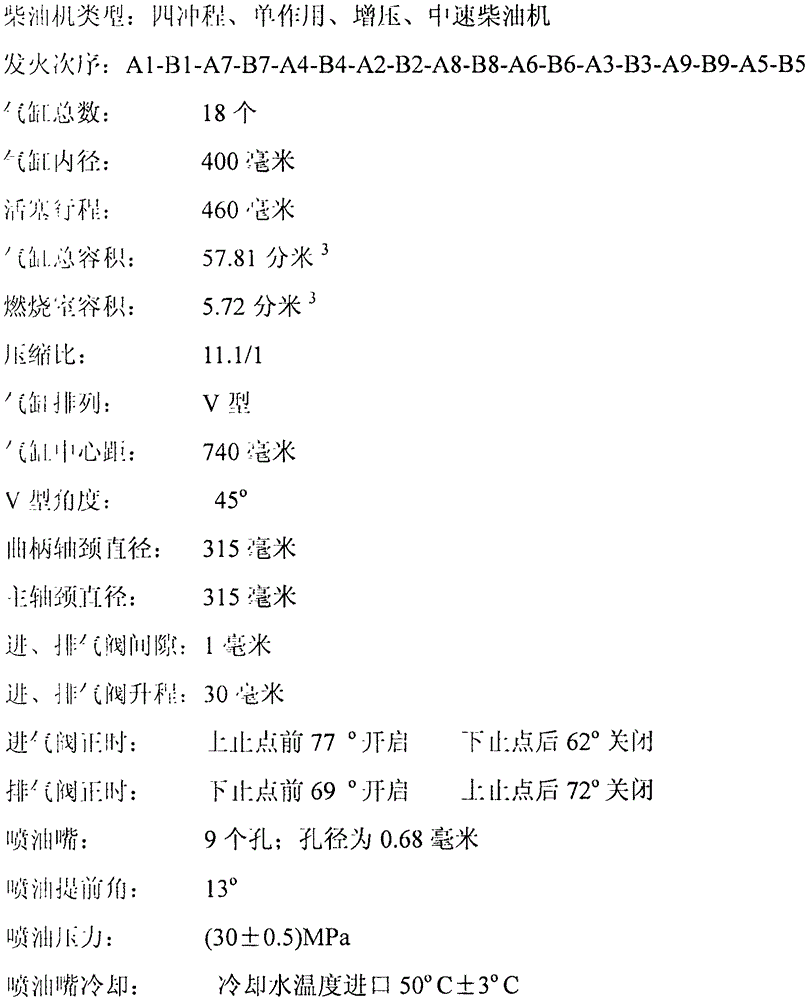

Preparation method of diesel oil pour point depressant

InactiveCN106279514ALower condensation pointImprove low temperature fluidityLiquid carbonaceous fuelsFuel additivesMaleic anhydrideSolvent

The invention discloses a preparation method of a diesel oil pour point depressant. The method includes the following steps of firstly, weighing high alcohols, catalyst, polymerization inhibitor and solvent to be sequentially added into a reactor and stirred till solids are completely dissolved, then adding methacrylic acid, and conducting reduced pressure distillation, alkali washing and water washing on the product after reaction ends to obtain methylacrylic acid high-carbon ester; secondly, weighing methylacrylic acid high-carbon ester, maleic anhydride, initiator and solvent to be evenly mixed, conducting reacting at a certain reaction temperature under the protection of nitrogen, adding aromatic amine and catalyst after reaction, changing the reaction temperature for reaction for a certain period of time, conducting reduced pressure distillation on the reaction liquid after reaction ends, then adding an excessive amount of methyl alcohol to generate white precipitates, removing supernate, and conducting washing and vacuum drying on the obtained white precipitates through methyl alcohol to obtain the diesel oil pour point depressant. The prepared diesel oil pour point depressant can remarkably reduce the condensation point of diesel oil and improve the low-temperature flowability of diesel oil; the raw materials are easy to obtain, the synthesis method is simple, and the additive dosage is small.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

Methanol diesel oil and preparation method thereof

InactiveCN103013590APromote mutual solubilityEnhancement of miscible propertiesLiquid carbonaceous fuelsZinc peroxideSolvent

The invention relates to methanol diesel oil which comprises methanol, diesel oil, fatty acid, petroleum acid, cosolvent, aviation kerosene, a cetane number improver and zinc peroxide. The invention further relates to a preparation method of the methanol diesel oil. According to the methanol diesel oil, the content of methanol in a system is greater, the methanol diesel oil has better mutual solubility with fossil diesel oil, the performance of the methanol diesel oil is improved obviously, and the methanol diesel oil can serve as -20# diesel oil for use, and is safe, environment-friendly and low in raw materials cost. The preparation method is simple in step, mild in condition and suitable for large-scale industrial production.

Owner:BEIJING QINGYANLIHUA GASOLINEEUM CHEM

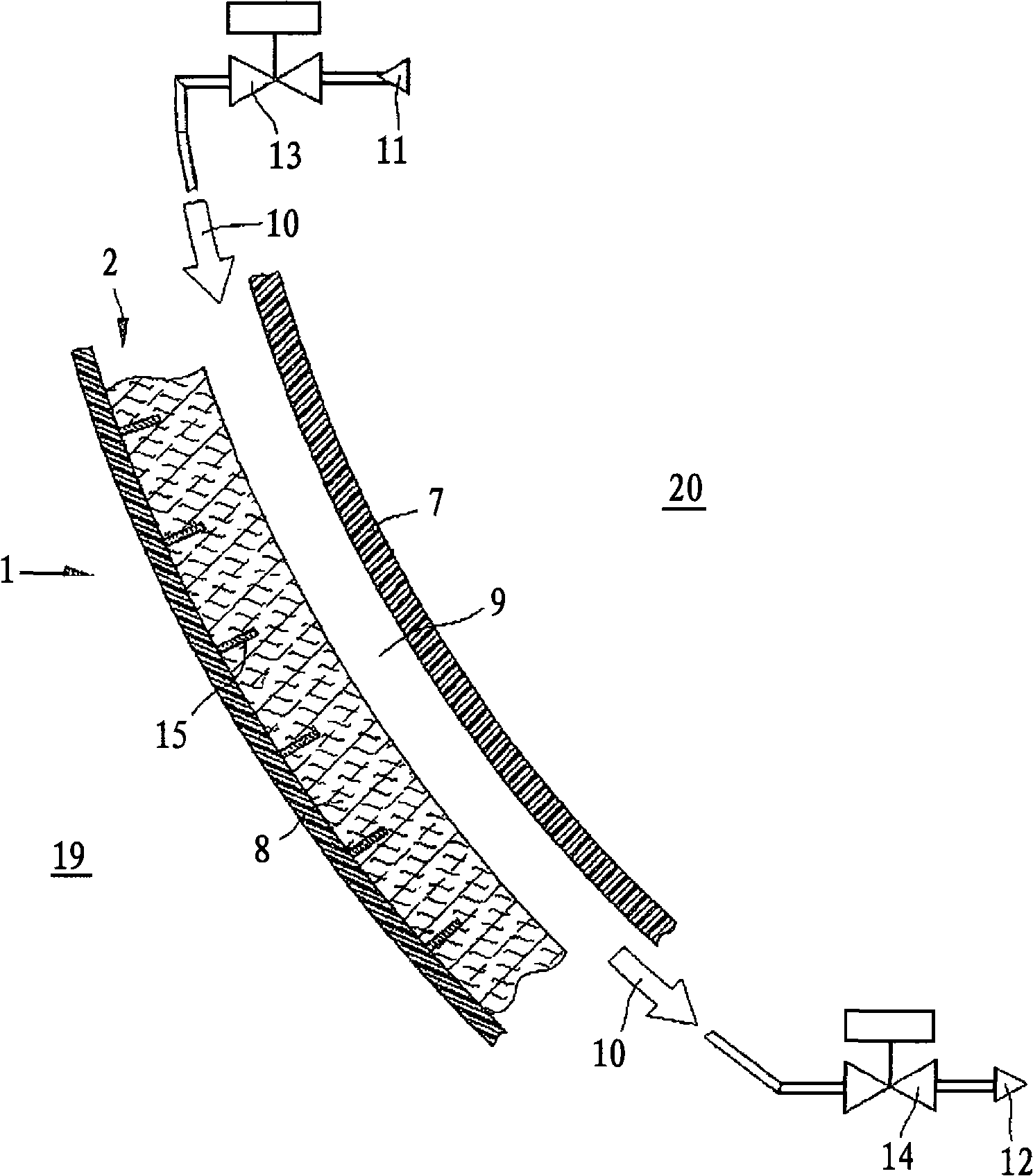

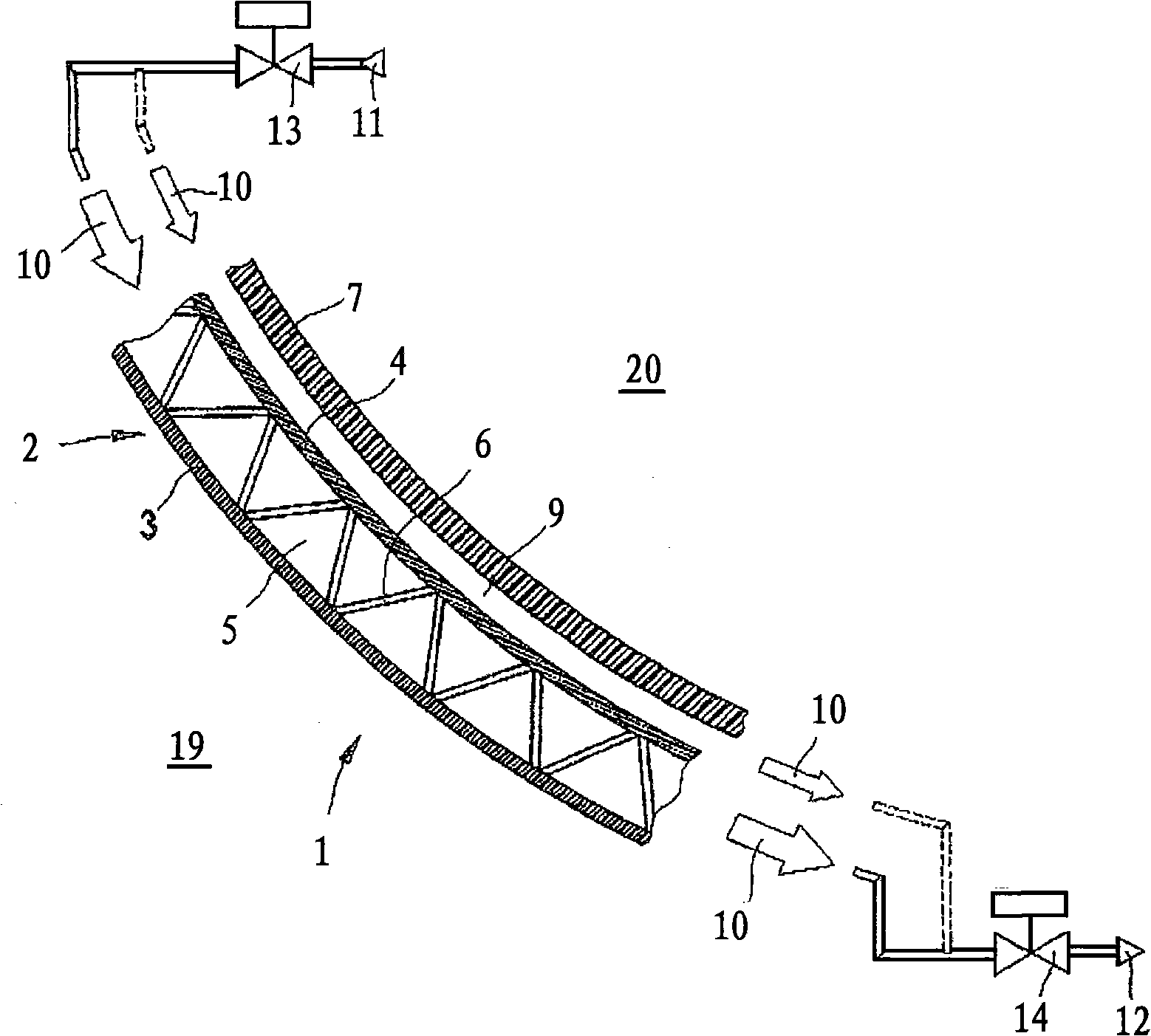

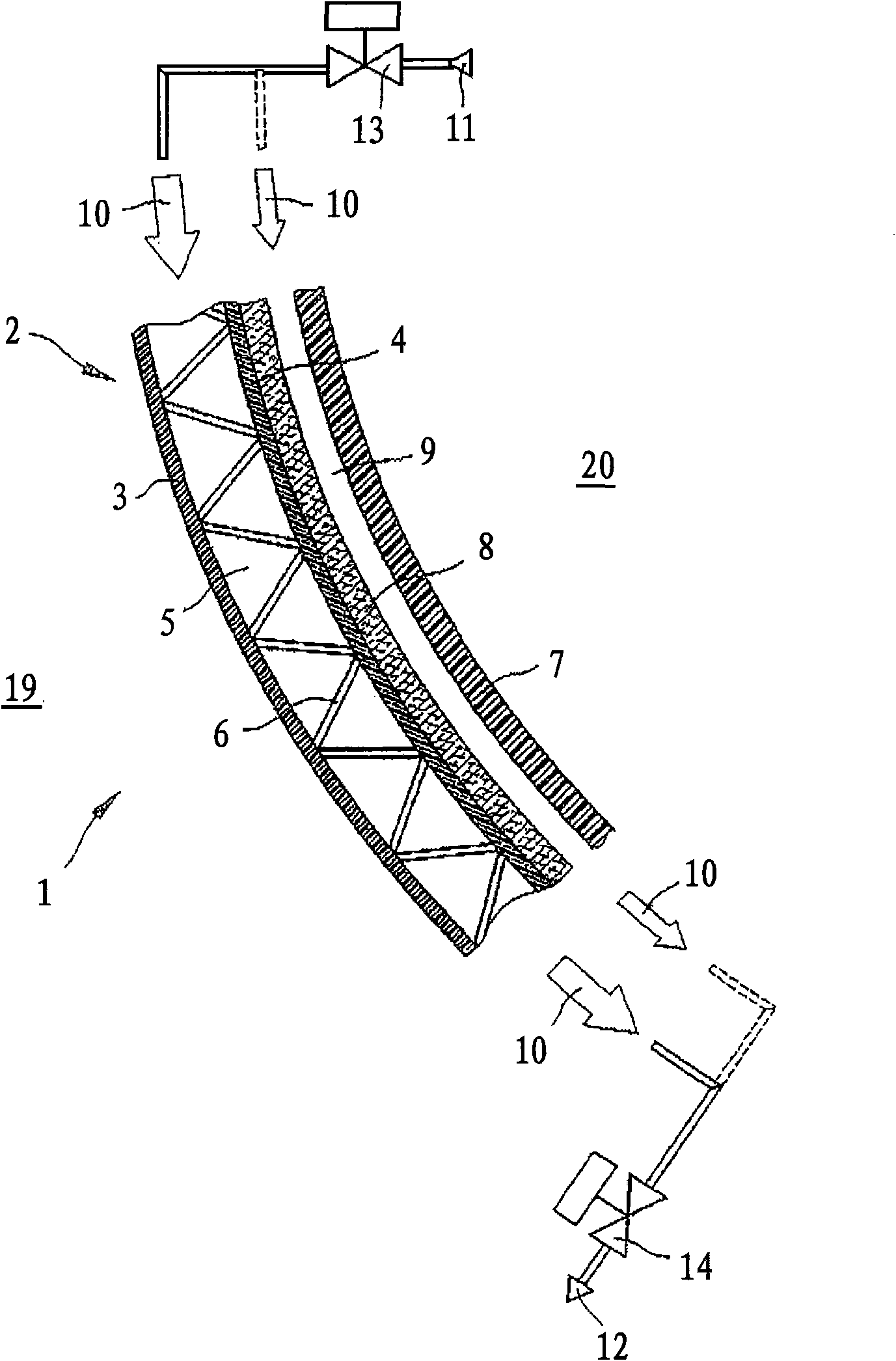

Fuselage of an aircraft or spacecraft and method of activelyinsulating such a fuselage

InactiveCN101636314ASave spaceReduce weightFuselage framesAir-treatment apparatus arrangementsInterior spaceStructural element

The present invention relates to a fuselage (1) of an aircraft or spacecraft, with at least one shell element (2) and a structural element (7). An interspace (5; 9) to which air can be admitted by an air stream (10) is provided between the at least one shell element (2) and the structural element (7). The fuselage is distinguished by the fact that, to form the air-admitting air stream (10) as an outgoing / incoming air stream of a pressurized interior space (20) of the fuselage (1), the interspace (5; 9) is connected to a corresponding outgoing / incoming air connection of the interior space (20). The invention also relates to a corresponding aircraft or spacecraft and to a method of actively insulating such a fuselage (1).

Owner:AIRBUS OPERATIONS GMBH

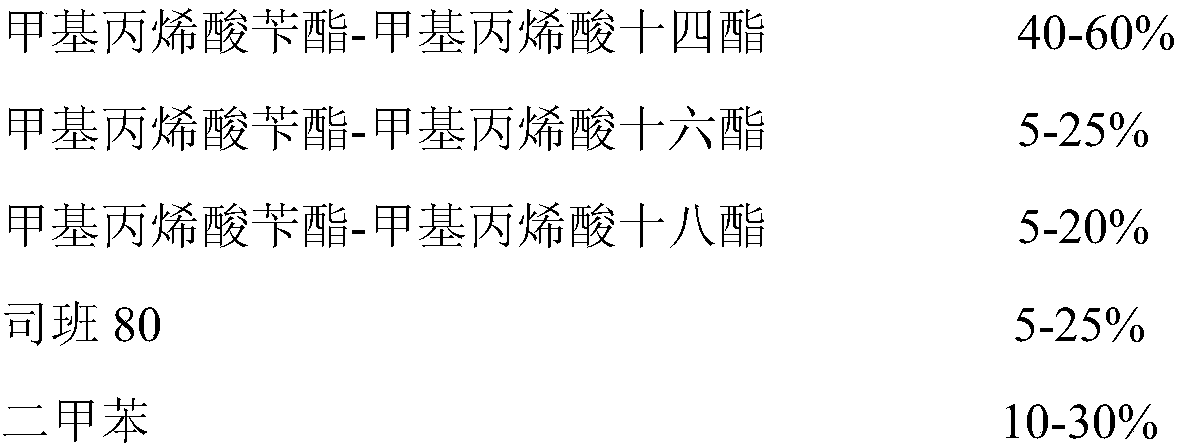

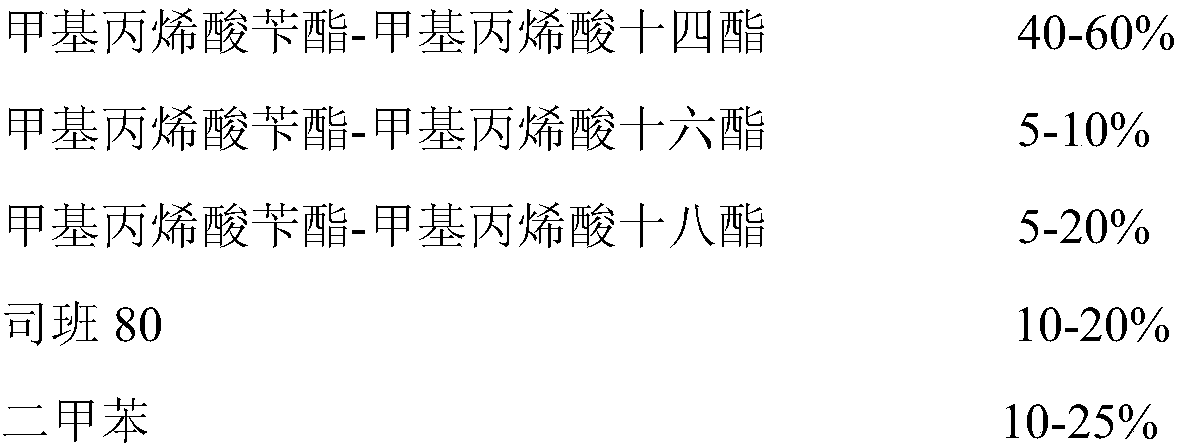

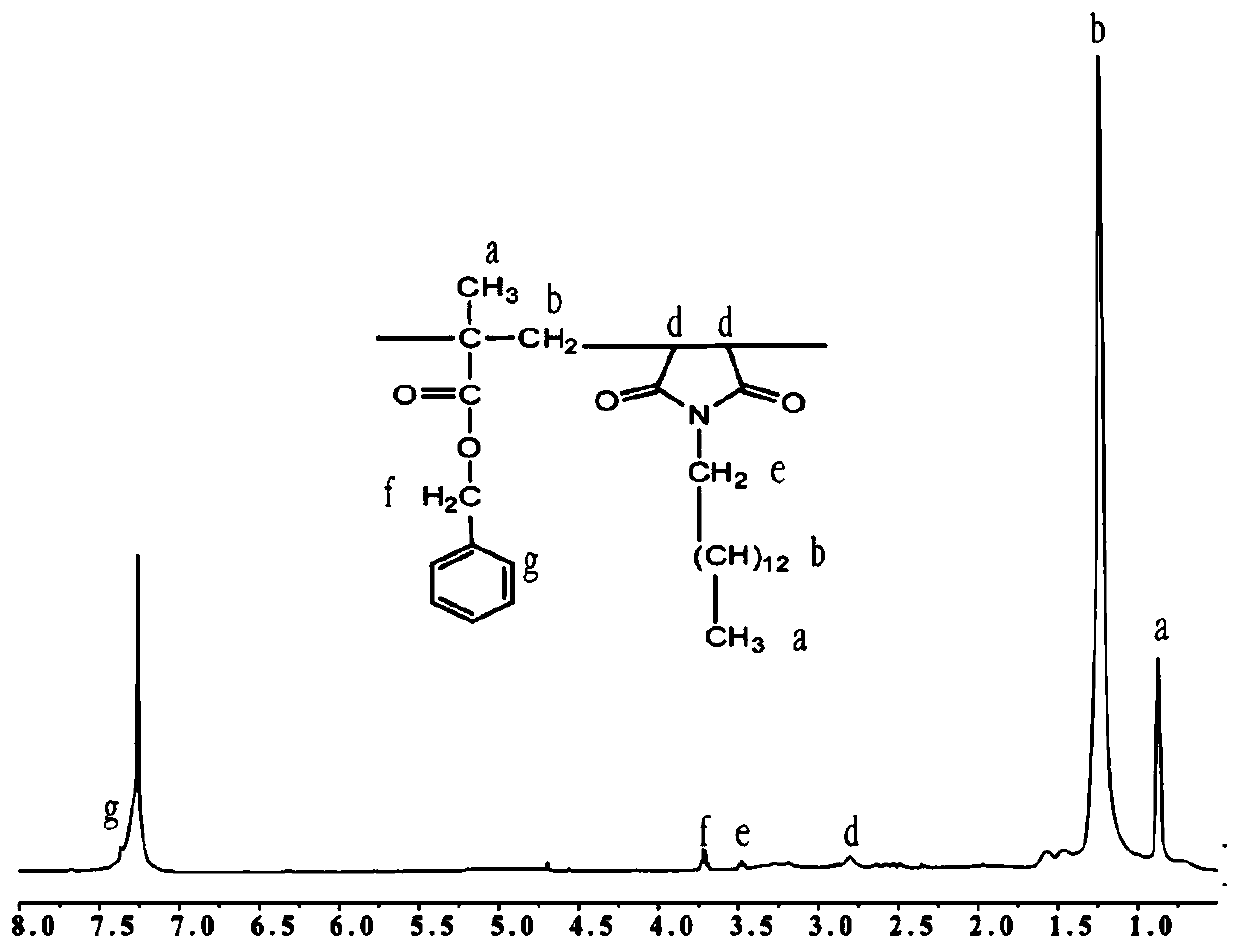

Diesel oil pour point depressant composition as well as preparation method and application thereof

ActiveCN109053951AEvenly dispersedImprove solubilityLiquid carbonaceous fuelsFuel additivesSolubilityNational standard

The invention discloses a diesel oil pour point depressant composition as well as a preparation method and application thereof. The diesel oil pour point depressant composition is prepared from the following components by mass percent: 40-60% of benzyl methacrylate-tetradecyl methacrylate, 5-25% of benzyl methacrylate-hexadecyl methacrylate, 5-20% of benzyl methacrylate-octadecyl methacrylate, 5-25% of span 80 and 10-30% of xylene. The diesel oil pour point depressant composition provided by the invention not only can effectively enhance the solubility of a pour point depressant in diesel oil,but also can effectively improve the low temperature flow performance of the diesel oil. After the obtained diesel pour point depressant composition is added into the commercially available diesel oil with model 0, the condensation point and cold filter point of the diesel oil with model 0 are respectively lowered by 22-26 DEG C and 8-11 DEG C, and the other properties of the diesel oil with model 0 can reach the national standards; the diesel oil pour point depressant composition can meet the requirement that various diesel-powered motor vehicles work normally at the low temperature.

Owner:湖南浩润科技有限公司

Method for preparing low temperature epoxy fatty acid branched-chain alcohol ester improver for biodiesel and application thereof

The invention discloses a method for preparing a low temperature epoxy fatty acid branched-chain alcohol ester improver for biodiesel and application thereof. The method comprises the steps of taking natural oil and branched-chain alcohol as raw materials to react in the presence of a catalyst, and carrying out distilling, standing and layering on the product to obtain supernatant fatty acid branched-chain alcohol ester; and then mixing the fatty acid branched-chain alcohol ester with formic acid, adding an epoxidation catalyst, reacting while dropwise adding hydrogen peroxide, and carrying out standing, layering, neutralizing and dewatering on the product to obtain epoxy fatty acid branched-chain alcohol ester. The invention develops an epoxy fatty acid branched-chain alcohol ester improver aiming at the characteristics of biodiesel. The method has the following beneficial effects: by branching bonds of fatty acid ester and introducing a polar group onto the interior double bond structure of the fatty acid ester, the improver can be easily mixed with the biodiesel to form uniform solution, thus being beneficial to blocking further growth of solid crystals; and after different oil-based biodiesels and the improver are mixed, the low temperature fluidity of the biodiesels can be obviously improved, the condensation point and cold filter point can be reduced by 5-15 DEG C, the calorific value can be improved, and the viscosity can be reduced.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

Polymethacrylate/graphene nano composite polymer pour point reducer and preparation method thereof

ActiveCN106978225AImprove low temperature performanceIncreased sensitivityLiquid carbonaceous fuelsFuel additivesAfter treatmentOrganic solvent

The invention discloses a polymethacrylate / graphene nano composite polymer pour point reducer and a preparation method thereof. The method comprises the following steps: (1) ultrasonically dispersing graphene oxide in an organic solvent to obtain a suspension; then adding methacrylate and an initiator into the suspension, and performing a polymerization reaction at 70 to 90 DEG C in an inert atmosphere to obtain a viscous material; and (2) adding a reducing agent into the viscous material to reduce the graphene oxide, and after the reaction is ended, performing the after-treatment to obtain the polymethacrylate / graphene nano composite polymer pour point reducer. The preparation method is simple and feasible, easy in operation, and high in safety; the obtained pour point reducer is stable in performance and excellent in pour point reduction effect; and moreover, the graphene has flammability, does not block a filter screen of an engine, and is not deposited at the bottom of the engine. The polymethacrylate / graphene nano composite polymer pour point reducer is applied to Number-0 diesel, and a cold filter plugging point and a condensation point of the number-0 diesel can be respectively decreased by 6 to 15 DEG C and 12 to 23 DEG C.

Owner:SHANGHAI INST OF TECH

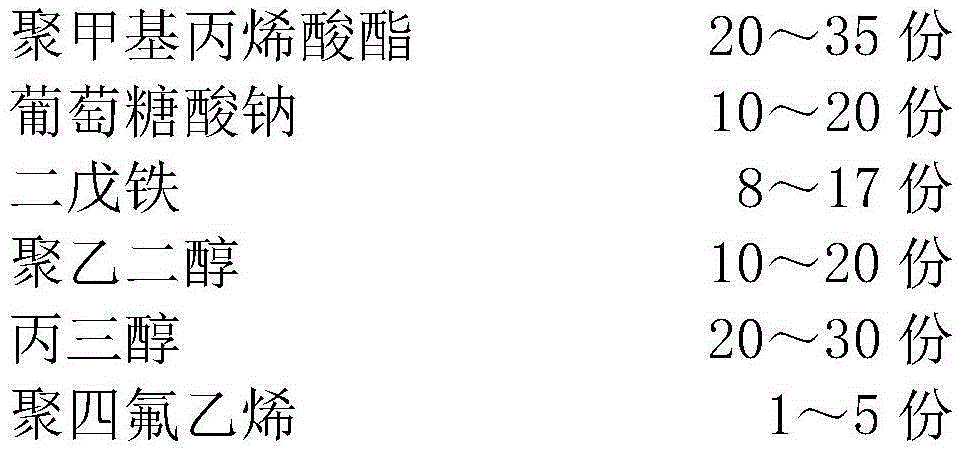

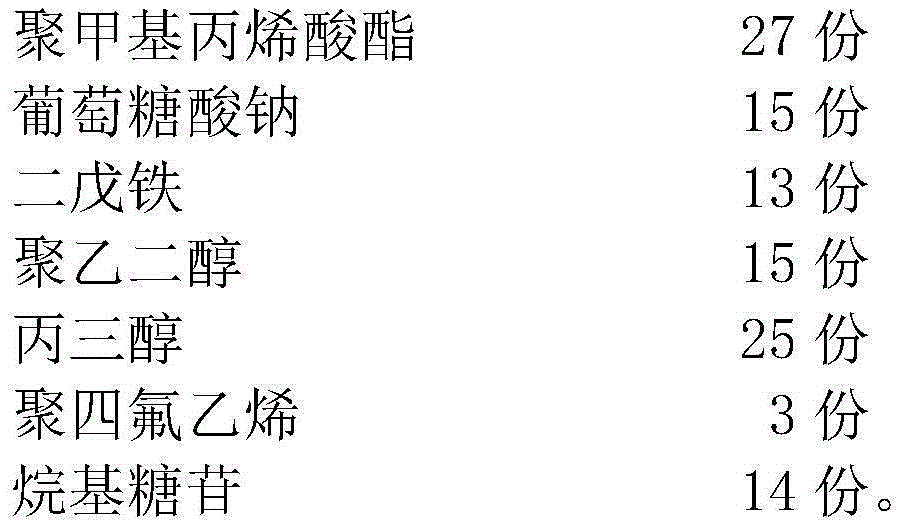

Smoke-eliminating antifreezing agent for diesel oil

InactiveCN104910978ANot easy to grow upInhibit growthLiquid carbonaceous fuelsFuel additivesPolyethylene glycolGlycerol

The invention relates to the technical field of petrochemical engineering, and particularly relates to a smoke-eliminating antifreezing agent for diesel oil. The antifreezing agent is prepared from the following raw materials in parts by weight: 20-35 parts of polymethacrylate, 10-20 parts of sodium gluconate, 8-17 parts of Fe(C5H5)2, 10-20 parts of polyethylene glycol, 20-30 parts of glycerol, 1-5 parts of polytetrafluoroethylene, and 10-18 parts of alkyl glycoside. The smoke-eliminating antifreezing agent for diesel oil disclosed by the invention can keep continuously supplemental firing, and can significantly reduce the condensation point and cold filter plugging point of diesel oil, prevent the diesel oil from being frozen at low temperature, clean parts, improve the effect of smoke elimination, and reduce the emission of exhaust gas.

Owner:ZHONGZHOU UNIV

Marine biological fuel oil and preparation method thereof

InactiveCN104789276AHigh calorific valueIncrease oxygen contentLiquid carbonaceous fuelsExhaust gas emissionsWaste oil

The invention discloses marine biological fuel oil which is prepared from the following ingredients in percentage by weight: 30-50 percent of waste plant oil residue, 5-10 percent of waste fusel, 30-50 percent of absorber oil, 15-30 percent of waste oil and 0.5-2 percent of an additive. The marine biological fuel oil makes full use of parts of waste resources and renewable energy sources, can remit the exploitation and consumption of oil resources, and is wide in raw material source, low in cost and good in economic benefit. The marine biological fuel oil is rich in oxygen, good in combustion performance, complete in combustion, high in thermal efficiency, less in exhaust gas emission pollutant and low in sulfur content, reduces mechanical corrosivity and sulfide emission, can be widely applied to the application fields of boilers and ships using petrochemical heavy oil burners, remits the shortage of oil resource, and reduces the pollution of waste oil on social environment.

Owner:舟山冉升能源科技有限公司

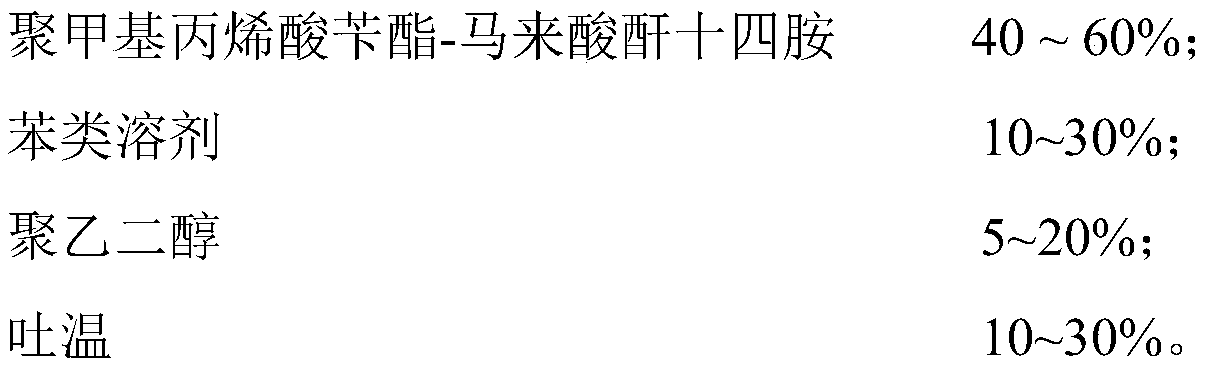

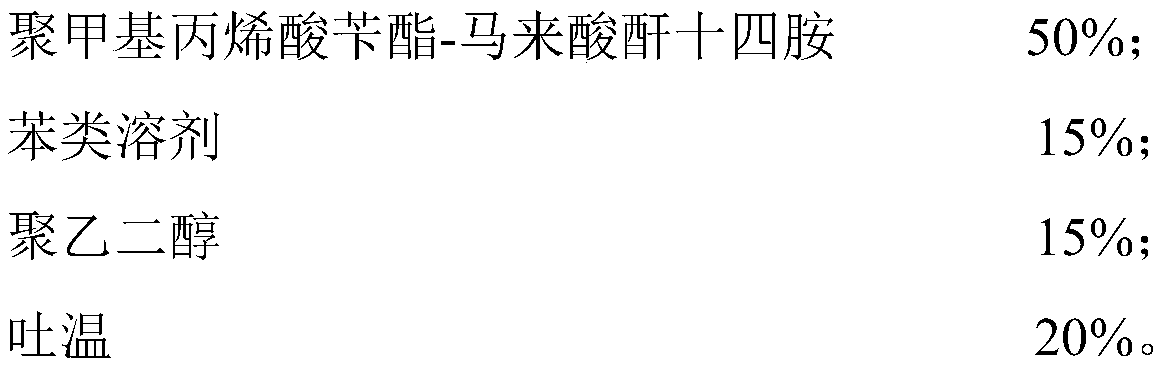

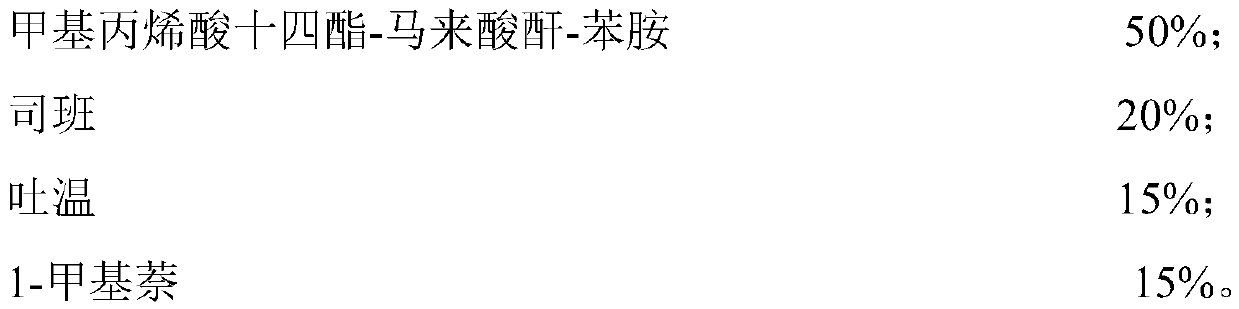

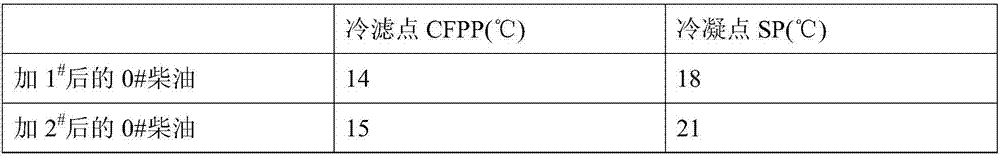

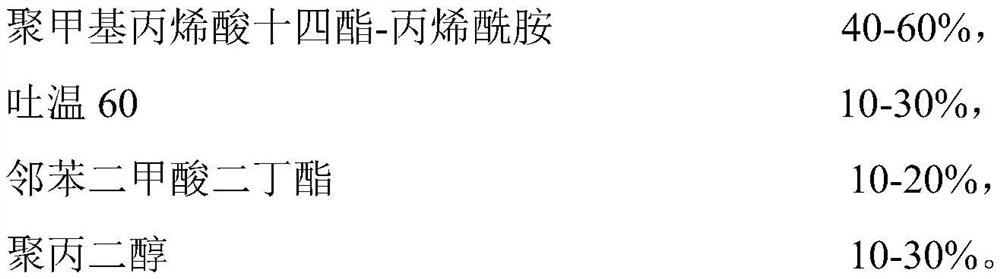

Diesel oil pour point depressant composition and preparation method and application thereof

InactiveCN110257116AAct as a diluentLowering the freezing pointLiquid carbonaceous fuelsFuel additivesDispersityPolyethylene glycol

The invention relates to a diesel oil pour point depressant composition. The diesel oil pour point depressant composition comprises, by mass, 40-60% of benzyl methacrylate-maleic anhydride tetradecylamine, 10-30% of benzene solvent, 5-20% of polyethylene glycol, 10-30% of Tween. A preparation method of the diesel oil pour point depressant composition includes: S1, evenly mixing the ingredients by stirring at a temperature of 25-40 DEG C to obtain a primary mixed solution; S2, dispersing the primary mixed solution with an ultrasonic generator to obtain the diesel oil pour point depressant composition. Compared with the prior art, the diesel oil pour point depressant composition has the advantages of wide application range and can be applied to all diesel oil in the current market, dispersity of the pour point depressant in 0# diesel oil sold in the market can be improved, a condensation point of the 0# diesel oil can be lowered by 20-25 DEG C, and a cold filter plugging point of the 0# diesel oil can be lowered by 6-11 DEG C.

Owner:SHANGHAI INST OF TECH

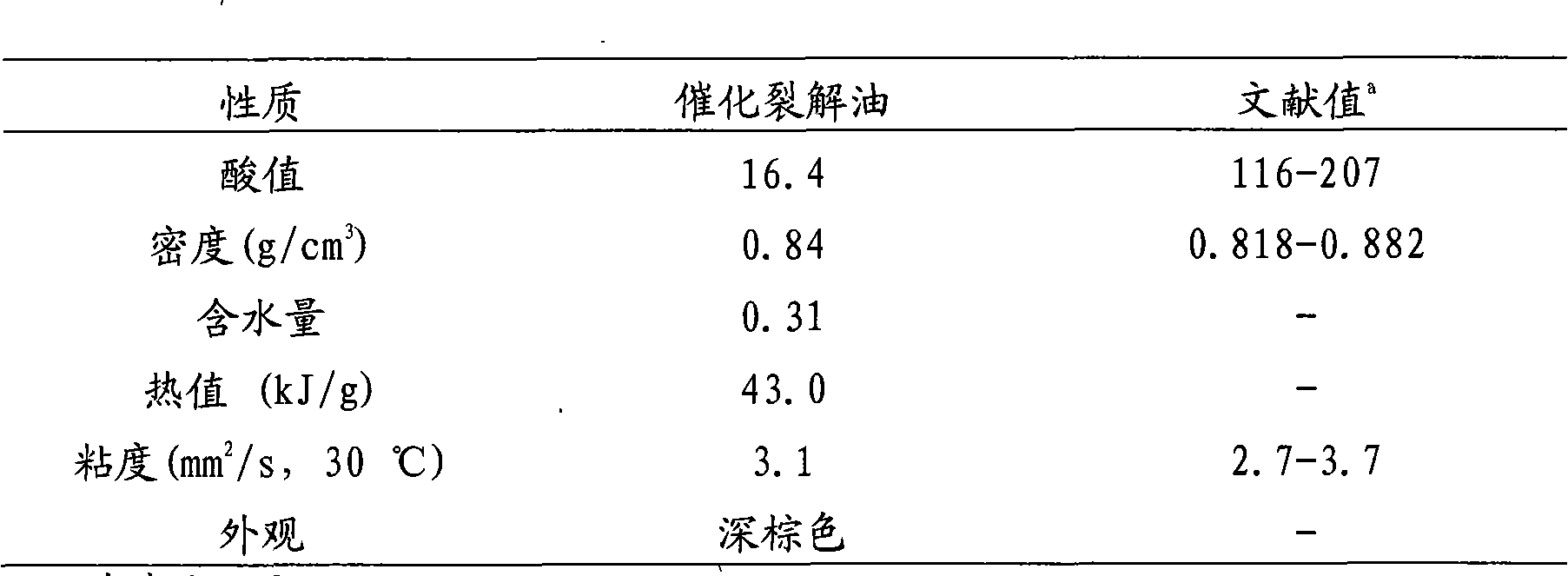

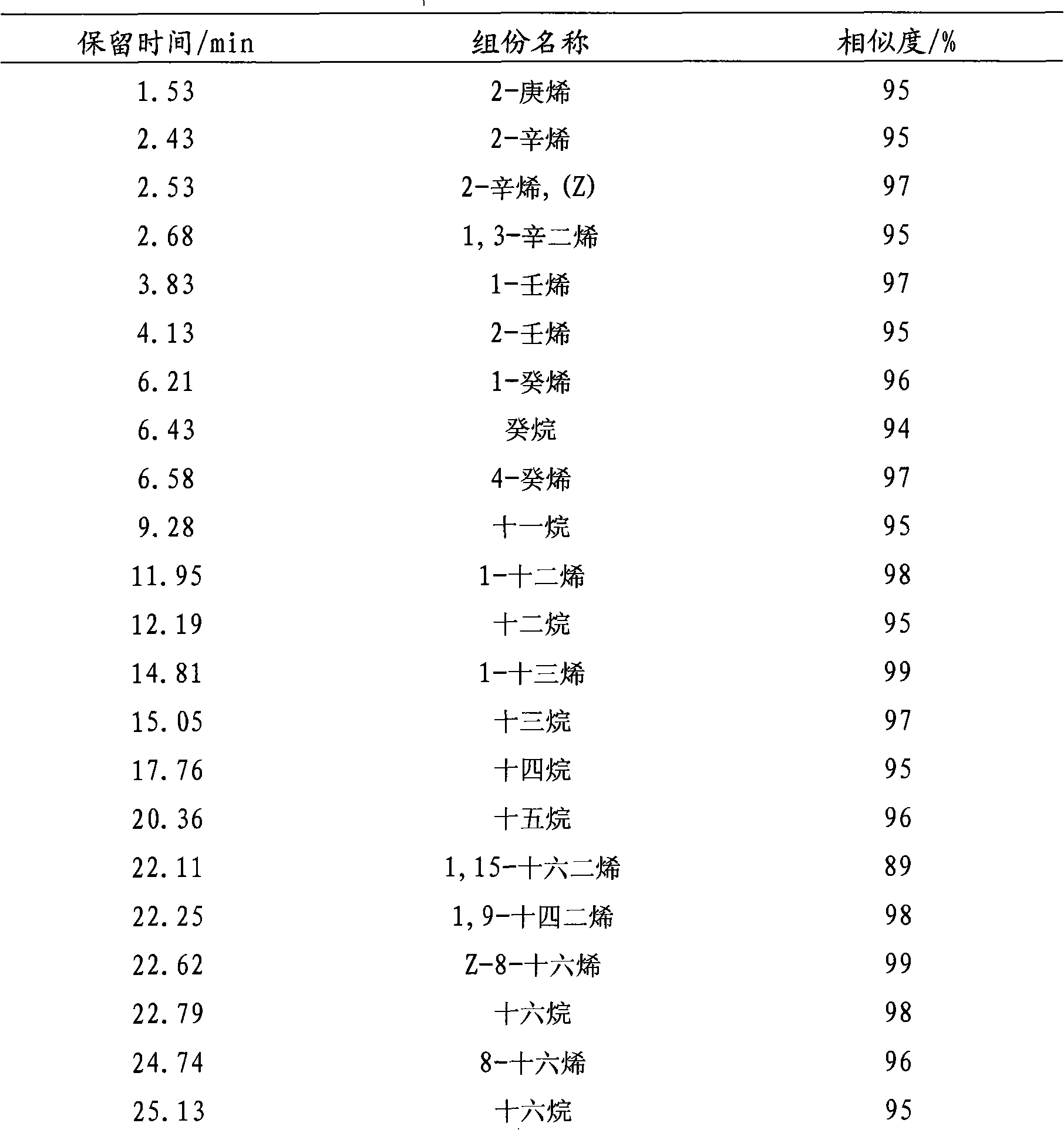

Method for preparing liquid fuel oil by catalyzing and cracking triglyceride

InactiveCN101531920BLess carboxyl contentLow acid valueCatalytic crackingLiquid hydrocarbon mixture productionGramAcid value

The invention discloses a method for preparing liquid fuel oil by catalyzing and cracking triglyceride, which comprises: a first step, according to a proportion of the triglyceride to a catalyst by mass being 100:1-10, weighing the triglyceride and the catalyst, and adding 5 to 30 percent of the triglyceride and the catalyst into a reaction kettle simultaneously; and a second step, heating the reaction kettle to between 350 and 500 DEG C, dropwise adding the rest 70 to 95 percent of the triglyceride into the reaction kettle, and condensing the generated vapor to obtain dark brown liquid, wherein the acid value is 16.4 mg KOH / g, the density is 0.84 g / cm3, the water content is 0.31 percent, the thermal value is 43.0 kilojoules per gram, and the viscosity is 3.1 mm2 / s.

Owner:JIANGSU QIANGLIN BIO ENERGY +1

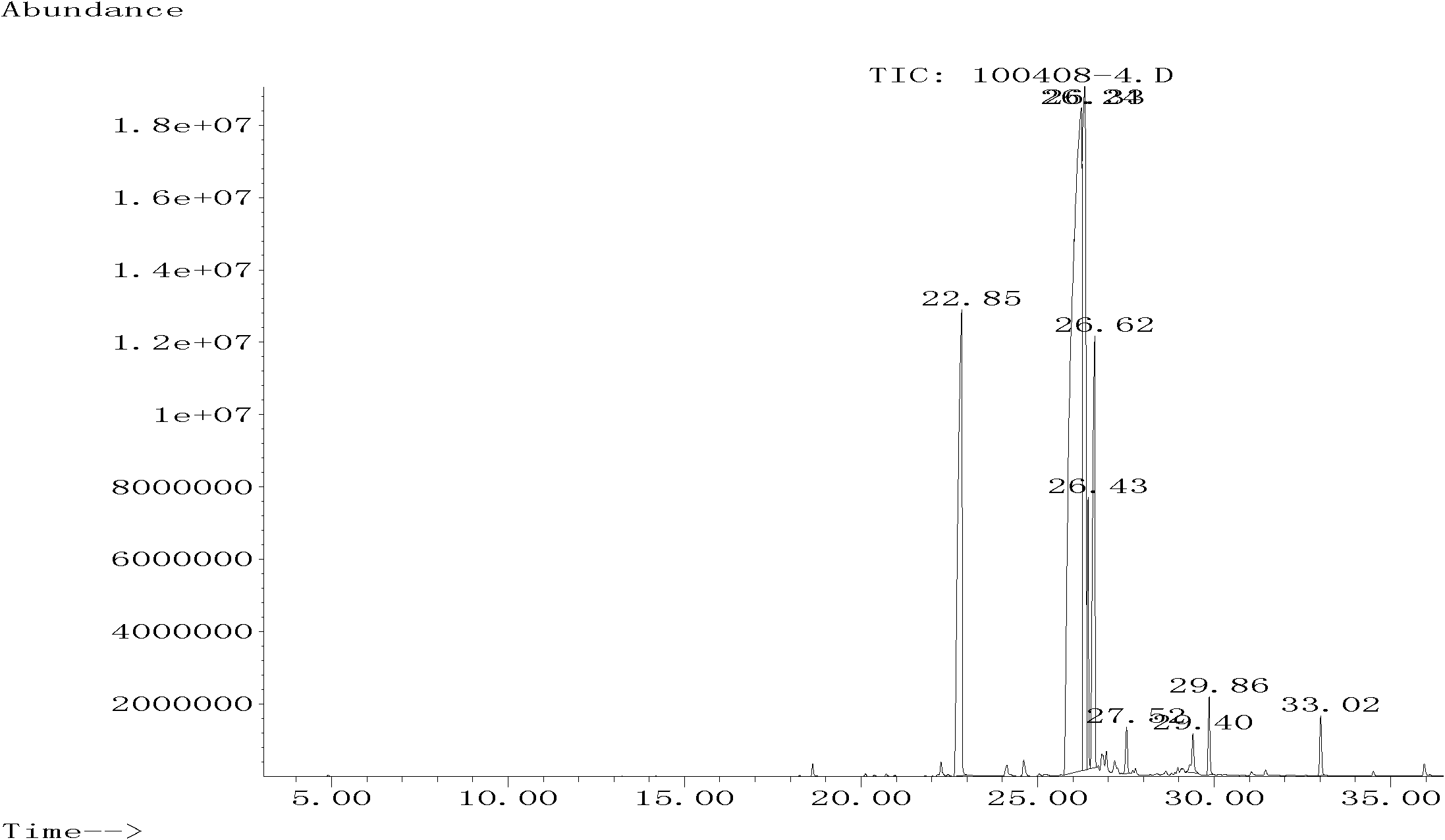

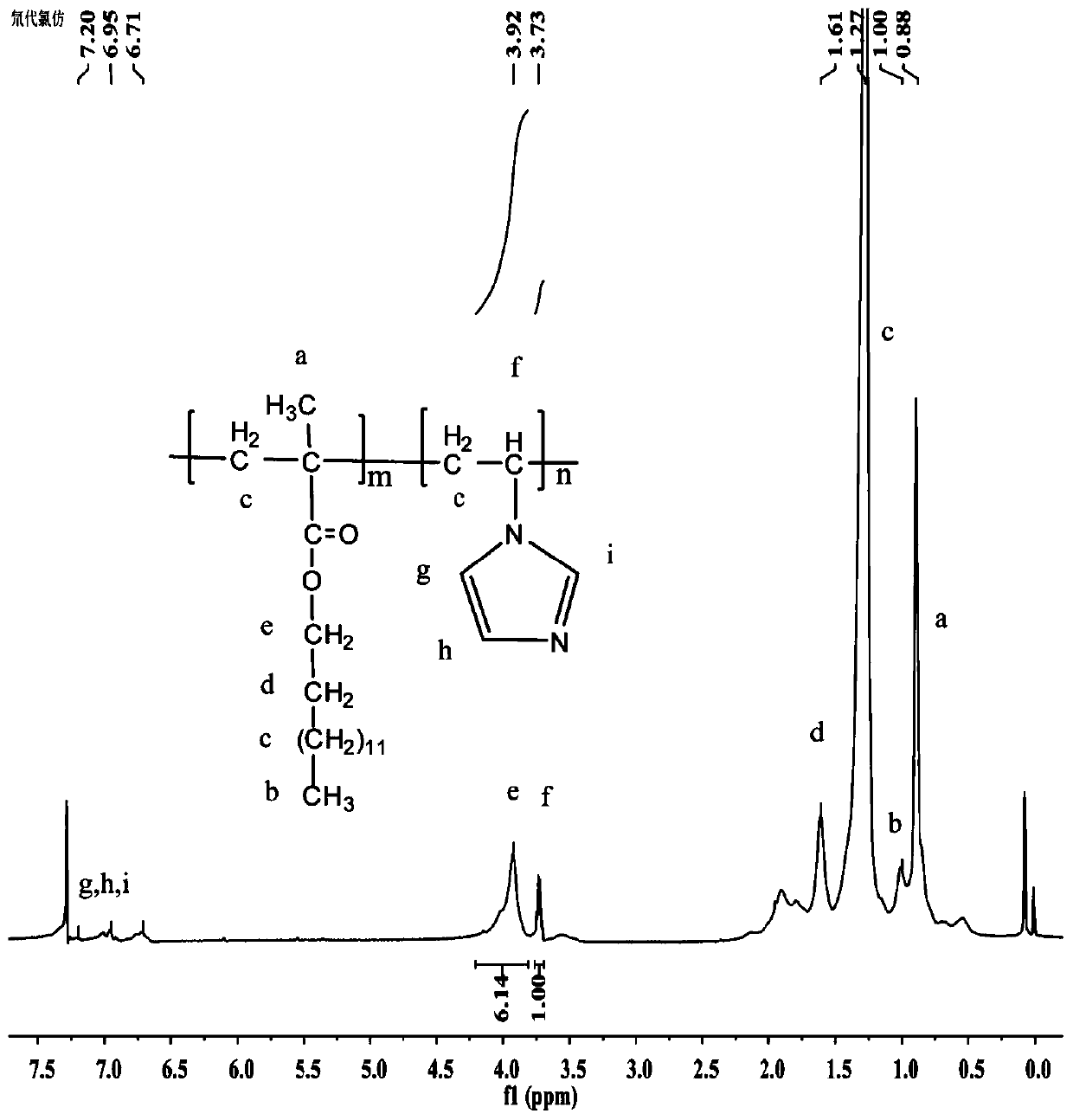

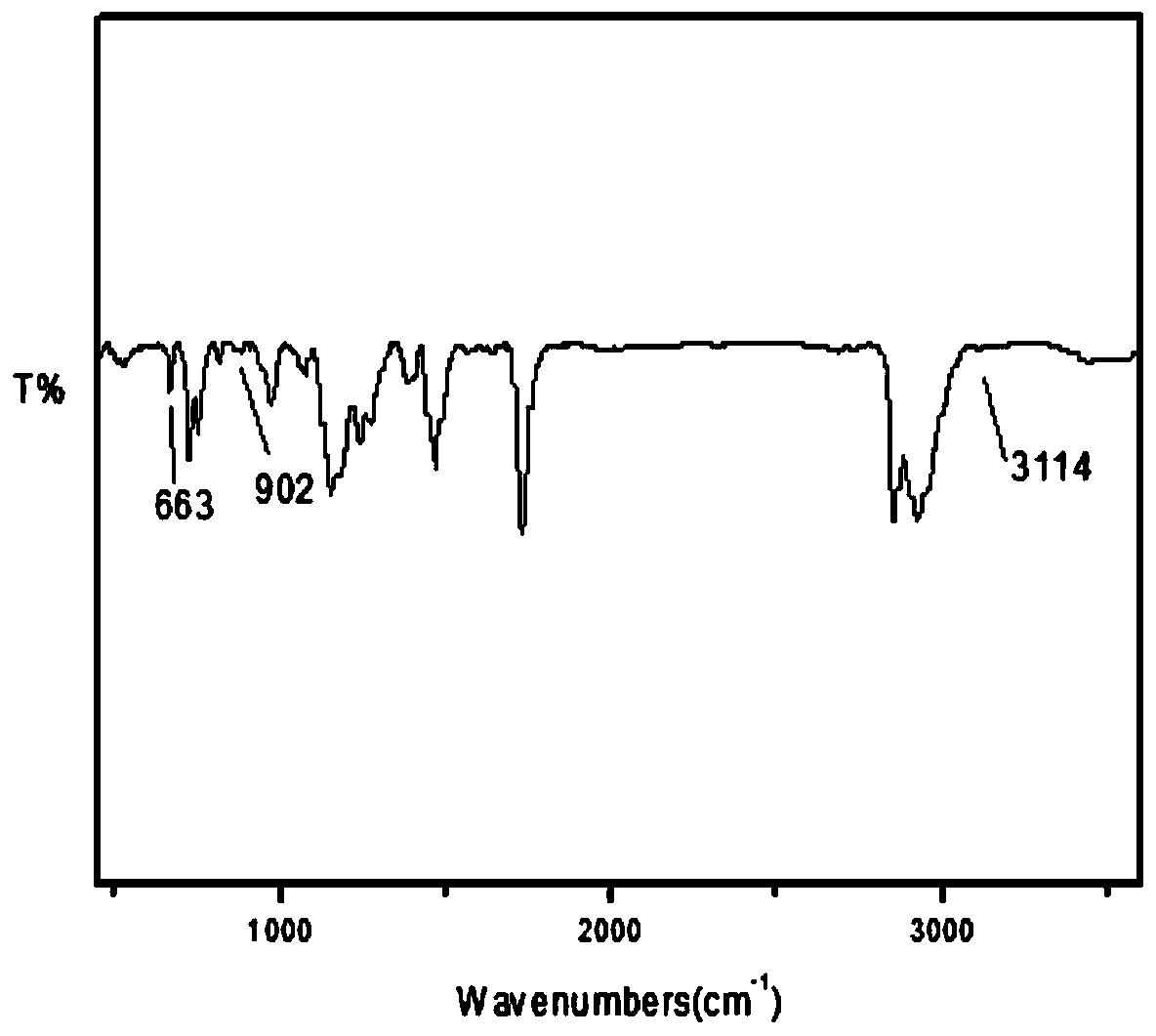

Reagent for reducing condensation point of diesel, and preparation method and application thereof

ActiveCN110093195AChanged crystallization behaviorChange crystal shapeLiquid carbonaceous fuelsFuel additivesSynthesis methodsCold filter plugging point

The invention provides a reagent for reducing the condensation point of diesel, and a preparation method and an application thereof. The reagent for reducing the condensation point of diesel comprisesa tetradecyl methacrylate-N-vinylpyrrolidone copolymer, or comprises the tetradecyl methacrylate-N-vinylpyrrolidone copolymer and a tetradecyl methacrylat-N-vinylimidazole copolymer. The above polymer diesel pour point depressant can further improve the low-temperature fluidity of the diesel, and has the advantages of simple synthesis method, small dosage, and small use amount of raw materials. The condensation point of diesel containing the reagent is 24-26 DEG C less than that of diesel free from the pour point depressant, and the cold filter plugging point of the diesel containing the reagent is 9-11 DEG C less than that of the diesel free from the pour point depressant, so that the diesel has a good fluidity at a low temperature.

Owner:SHANGHAI INST OF TECH

Surfactant compounded pour point depressant and preparation method and application thereof

InactiveCN110437900ALower freezing point and cold filter pointImprove pour point depressing effectLiquid carbonaceous fuelsFuel additivesMaleic anhydrideCold filter plugging point

The invention relates to a surfactant compounded pour point depressant. The surfactant compounded pour point depressant is prepared from the following components in percentage by mass: 40-60% of tetradecyl methacrylate-maleic anhydride-aniline, 10-30% of arlacel, 15-20% of tween and 10-20% of 1-methylnaphthalene. A preparation method of the surfactant compounded pour point depressant comprises thesteps: S1, all the components are mixed according to the proportion and evenly stirred, and thus a primary mixed solution is obtained; and S2, the primary mixed solution is dispersed again through anultrasonic generator, and thus the surfactant compounded pour point depressant is obtained. Compared with the prior art, the pour point depressant composition of diesel oil is wide in application range and can be suitable for all diesel oil in the current market, the dispersity of the pour point depressant in the 0# diesel oil available in the market can be improved, the condensation point of thediesel oil can be decreased by 20-26 DEG C, and the cold filter plugging point of the diesel oil can be decreased by 5-9 DEG C.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

Application method of benzene ring-containing binary copolymer

ActiveCN110283272AImprove low temperature fluidityIncrease polarityLiquid carbonaceous fuelsFuel additivesSolubilityFatty amine

The invention provides an application method of a benzene ring-containing binary copolymer. The preparation method of the benzene ring-containing binary copolymer comprises: dissolving a benzyl methacrylate-maleic anhydride binary copolymer in a toluene solvent, adding higher fatty amine or aromatic amine and a p-toluenesulfonic acid catalyst, carrying out an amination reaction, and purifying to obtain a benzyl methacrylate-maleic anhydride binary copolymer. The product has strong solubility, and also can effectively improve the low temperature fluidity of diesel oil. By adding a diesel oil pour point depressant of the obtained benzene ring-containing binary copolymer into Songjiang No. 0 diesel oil, condensation point and cold filter plugging point of the diesel oil can be lowered by 6-19 DEG C and 0-7 DEG C respectively.

Owner:SHANGHAI INST OF TECH

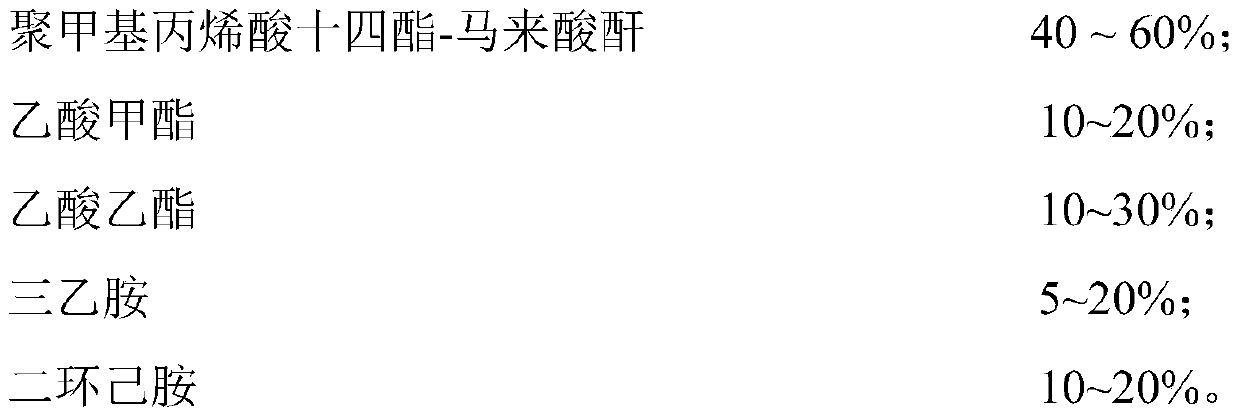

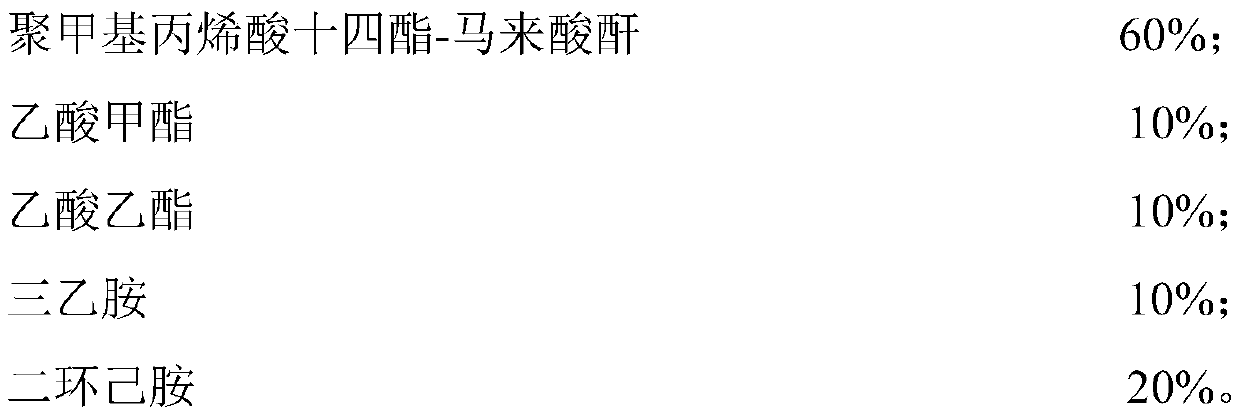

Compound diesel oil pour point depressant and preparation method and application thereof

InactiveCN110437897ALowering the freezing pointLower cold filter pointLiquid carbonaceous fuelsFuel additivesDispersityEthyl acetate

The invention relates to a compound diesel oil pour point depressant. The compound diesel oil pour point depressant is prepared from the following components in percentage by mass: 40-60% of polytetradecyl methacrylate-maleic anhydride, 10-20% of methyl acetate, 10-30% of ethyl acetate, 5-20% of triethylamine, and 10-20% of dicyclohexylamine. A preparation method comprises the steps that S1, all the components are mixed according to the proportion and evenly stirred, and thus a primary mixed solution is obtained; and S2, the primary mixed solution is dispersed again through an ultrasonic generator, and thus the compound diesel oil pour point depressant is obtained. Compared with the prior art, the diesel oil pour point depressant composition is wide in application range and can be suitablefor all diesel oil in the current market, the dispersity of the pour point depressant in the 0# diesel oil available in the market can be improved, the condensation point of the diesel oil can be decreased by 15-20 DEG C, and the cold filter plugging point of the diesel oil can be decreased by 4-9 DEG C.

Owner:SHANGHAI INST OF TECH

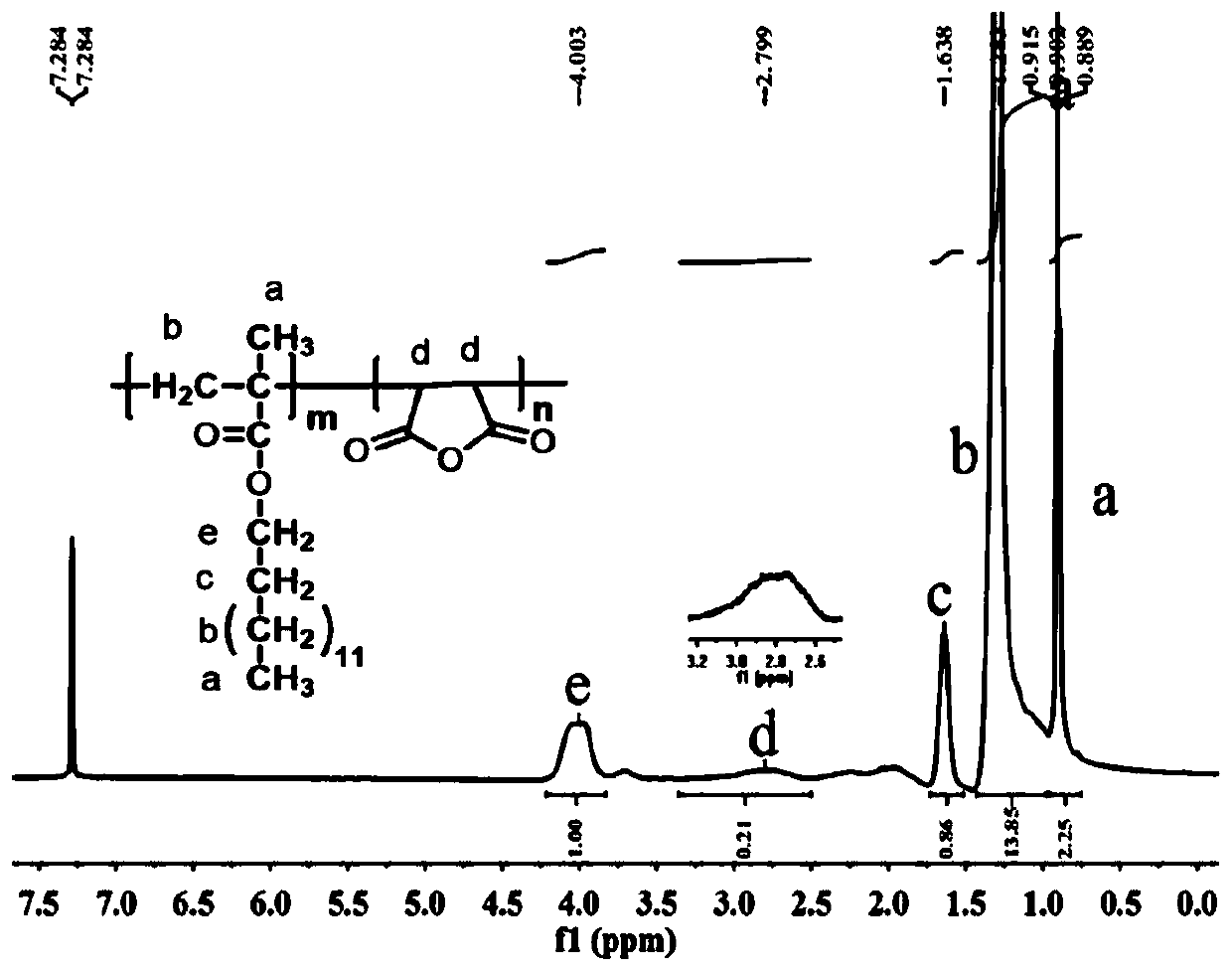

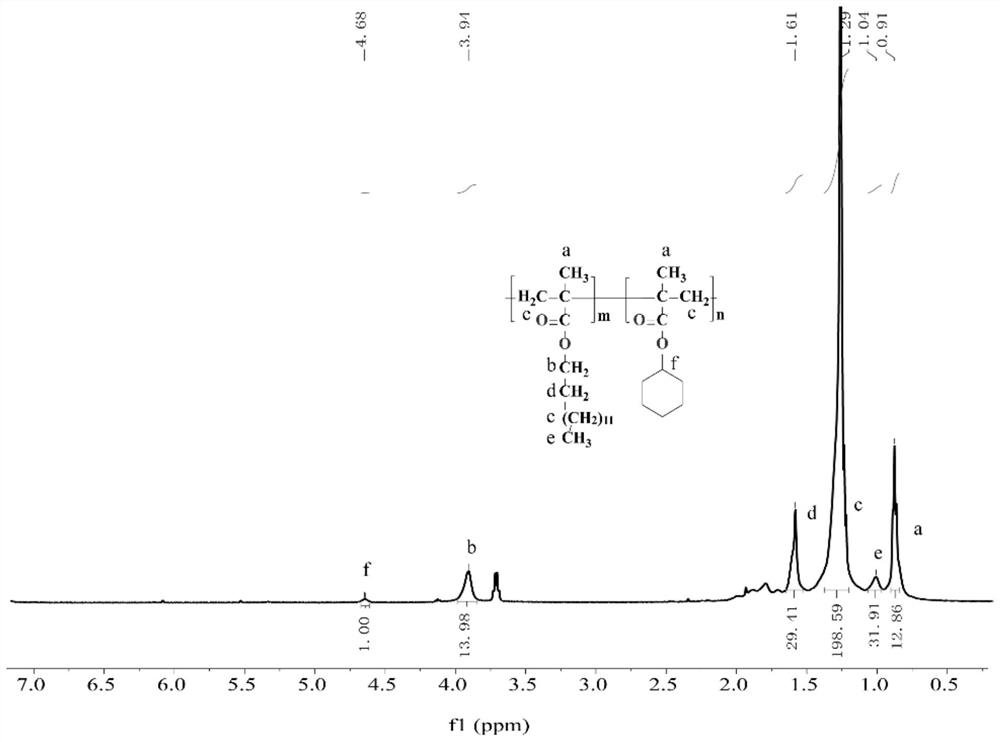

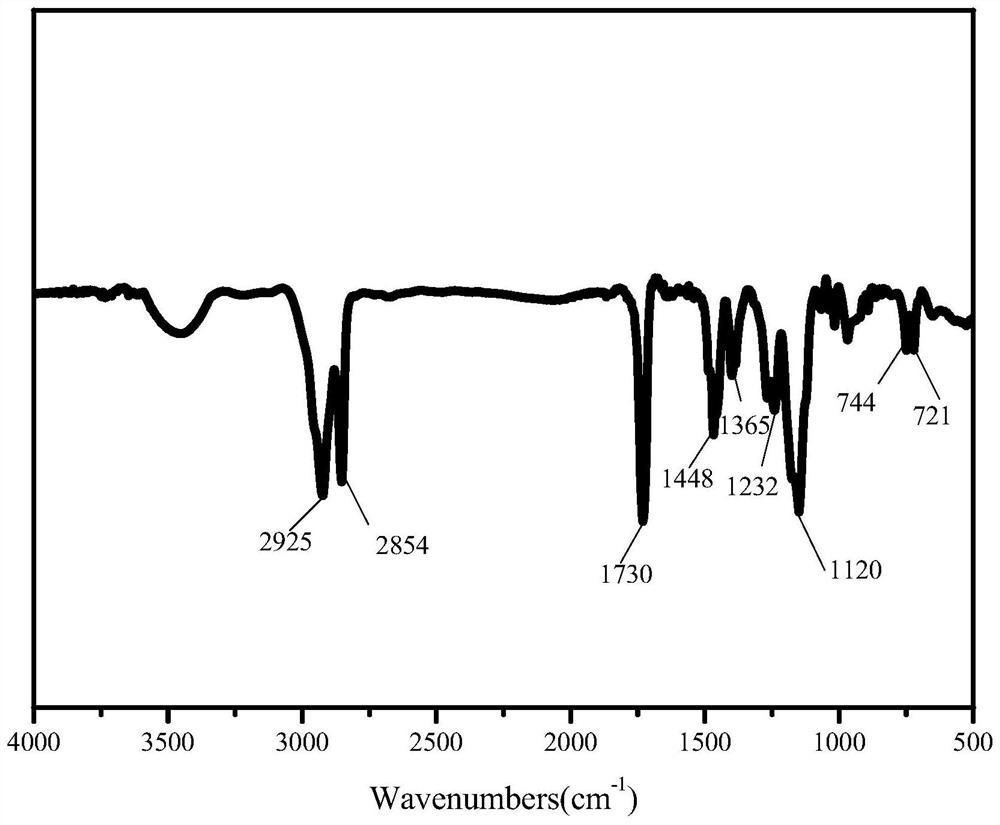

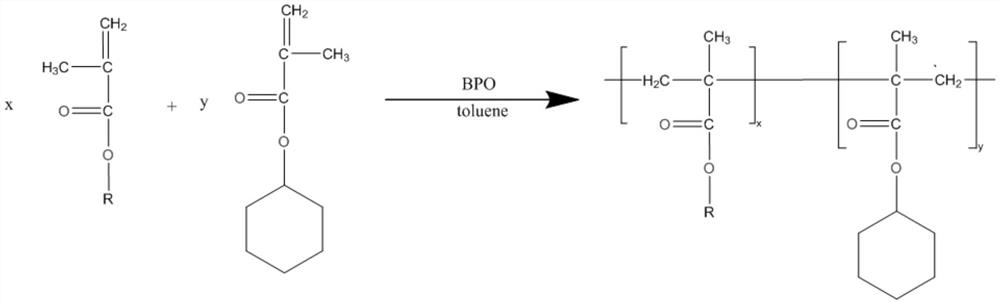

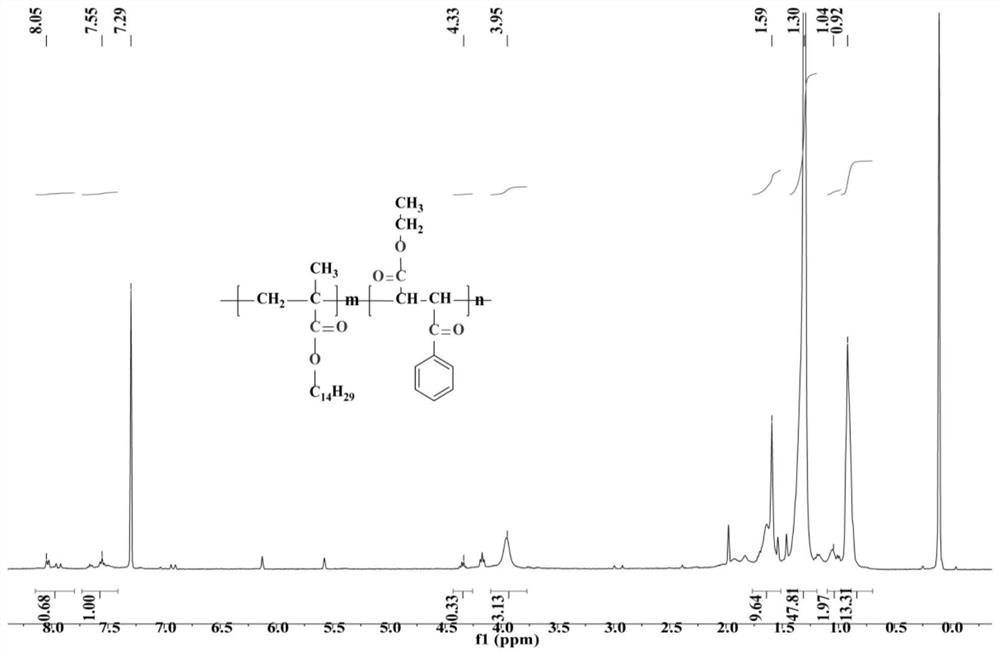

Binary polymer biodiesel pour point depressant as well as preparation method and application thereof

PendingCN112898476AImprove low temperature fluidityLower condensation pointLiquid carbonaceous fuelsFuel additivesPolymer scienceBiodiesel

The invention relates to a binary polymer biodiesel pour point depressant and a preparation method and application thereof.The preparation method comprises the steps that firstly, a mixed solution of methacrylic acid and higher alcohol is prepared, heated to 50-70 DEG C and evenly mixed, then a catalyst is added, heated to 110-120 DEG C and subjected to a constant-temperature reaction for 5-6 h, and a methacrylic acid high-carbon ester is obtained; and the methacrylic acid high-carbon ester and a methacrylic acid cyclic ester are prepared into a mixed solution, and polymerization reaction is carried out under the action of an initiator to obtain the binary polymer biodiesel pour point depressant. Compared with the prior art, the preparation method has the advantages that the preparation process is simple, the operation is convenient, the pour point depressing effect is effectively improved by introducing cyclohexyl methacrylate as a pour point depressant modification functional component, and the condensation point and the cold filter plugging point of the biodiesel are respectively reduced by 2-8 DEG C and 1-8 DEG C, so that the applicable temperature range of the biodiesel is expanded.

Owner:SHANGHAI INST OF TECH

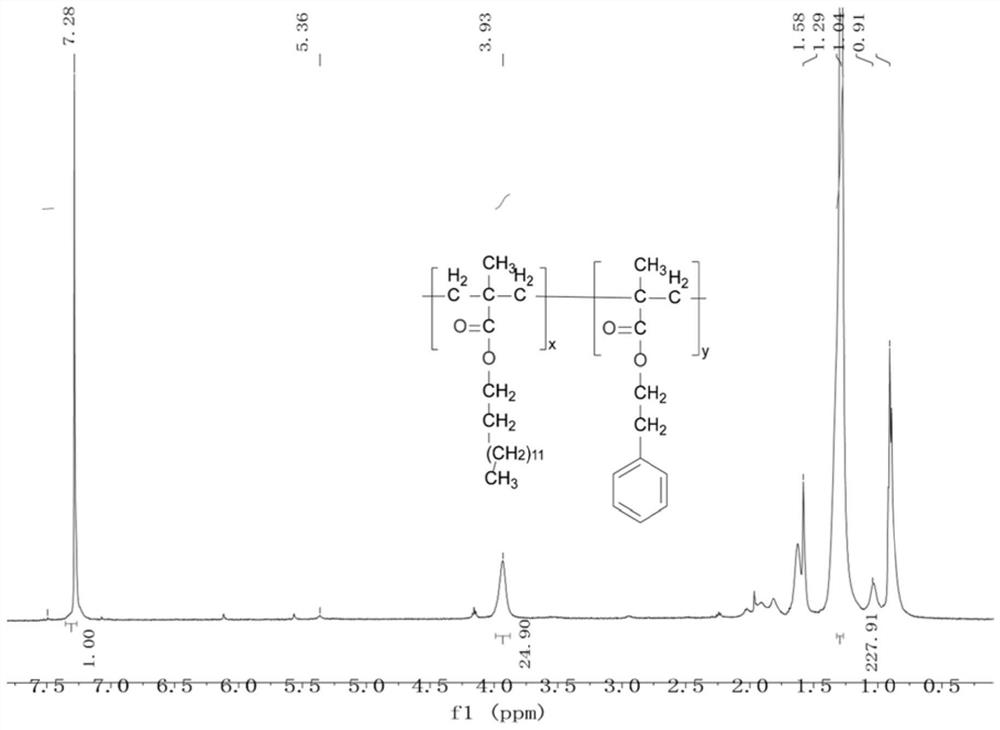

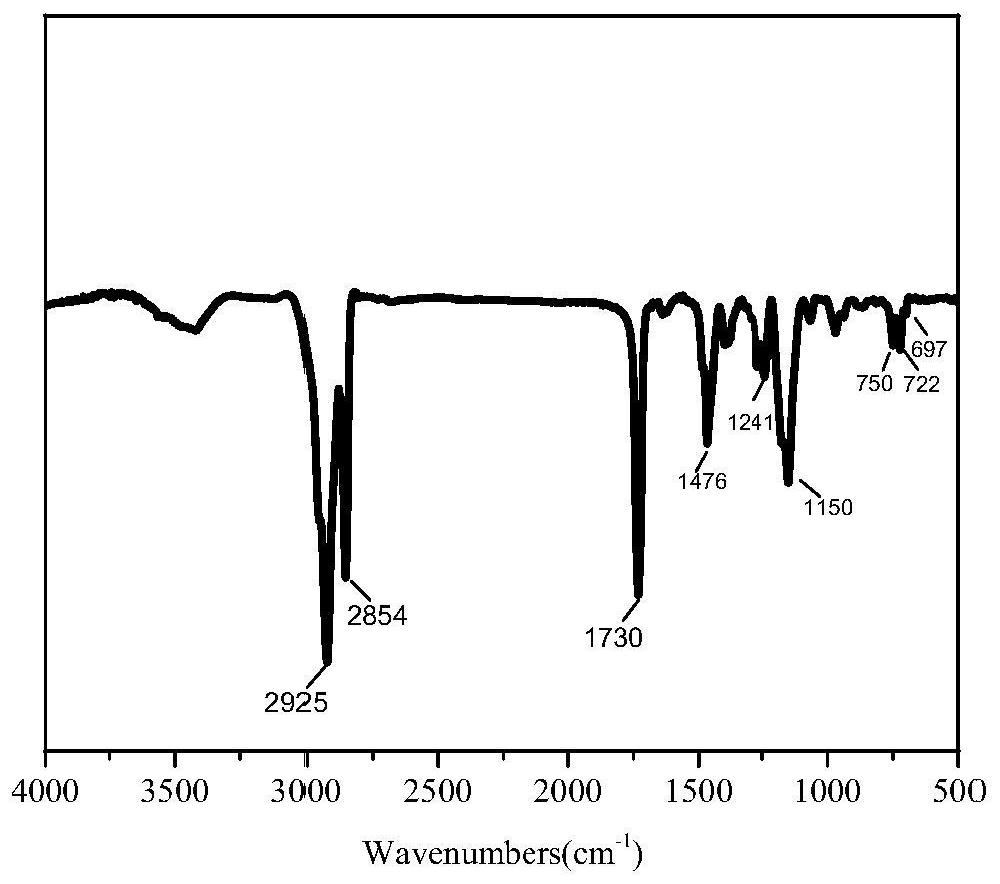

Benzene ring-containing biodiesel pour point depressant composition as well as preparation and application thereof

PendingCN113150848AImprove low temperature fluidityLowering the freezing pointBiofuelsLiquid carbonaceous fuelsMethacrylateBiodiesel

The invention relates to a benzene ring-containing biodiesel pour point depressant composition as well as preparation and an application of the biodiesel pour point depressant composition. The pour point depressant composition is prepared from the following components in percentage by weight: 20 to 60 percent of polytetradecyl methacrylate-styrene methacrylate, 10 to 20 percent of span 80, 10 to 20 percent of ethanolamine and 20 to 40 percent of fatty alcohol-polyoxyethylene ether. Compared with the prior art, the biodiesel pour point depressant composition has the advantages that growth and aggregation of crystals can be effectively inhibited by changing the crystallization behavior of biodiesel, and the low-temperature performance of the biodiesel is effectively improved.

Owner:SHANGHAI INST OF TECH

3-benzoyl ethyl acrylate diesel oil pour point depressant, diesel oil pour point depressant composition as well as preparation and application of 3-benzoyl ethyl acrylate diesel oil pour point depressant composition

ActiveCN114369198AWell mixedImprove low temperature fluidityLiquid carbonaceous fuelsFuel additivesMethacrylateParaffin wax

The invention relates to a 3-benzoyl ethyl acrylate diesel oil pour point depressant, a diesel oil pour point depressant composition as well as preparation and application of the 3-benzoyl ethyl acrylate diesel oil pour point depressant, namely a preparation method of poly (tetradecyl methacrylate)-3-benzoyl ethyl acrylate. The preparation method comprises the following steps: mixing tetradecyl methacrylate and 3-benzoyl ethyl acrylate in an organic solvent; adding a polymerization initiator, and stirring and reacting at 110 DEG C for 8 hours to obtain the product, the diesel oil pour point depressant composition comprises the following components in percentage by weight: 20-40% of PAO; 0-20% of polyethylene glycol; 30 to 50% of poly (tetradecyl methacrylate)-3-benzoyl ethyl acrylate; and 10 to 20% of isooctyl palmitate. Compared with the prior art, the diesel oil pour point depressant composition provided by the invention can hinder mutual crosslinking among wax crystals by changing the crystallization behavior of paraffin crystals, changing the growth direction of the crystals and inhibiting the generation of large wax crystals, so that a compact three-dimensional network structure cannot be formed, and the low-temperature fluidity of diesel oil is improved.

Owner:SHANGHAI INST OF TECH

Low-sulfur diesel oil additive composition, and preparation method and application of same

InactiveCN103450955BImprove the lubrication effectAvoid harmLiquid carbonaceous fuelsFuel additivesParticulatesOil additive

The invention provides a low-sulfur diesel additive composition, comprising dispersant: diesel lubricity improver: pour point depressant: cetane number improver: low-sulfur solvent in the ratio by weight of 1: 0.5-10: 0.5-50: 0.5-100: 0.5-200 composition. As an additive for low-sulfur diesel oil, the low-sulfur diesel additive composition of the present invention does not introduce new sulfur elements and can meet environmental protection regulations. It can not only avoid the harm caused to vehicles by introducing new sulfur elements in ordinary low-sulfur diesel oil additives, but also Significantly improve the lubricating performance of diesel, reduce the wear of the fuel injection system, increase the service life of the engine, increase the cetane number of diesel, enhance its combustion performance, and reduce pollution such as coke, particulate matter, incomplete combustion emissions, and CO Reduce the emission of pollutants, reduce carbon deposits in the engine, prolong the life of the engine, improve the thermal efficiency of the engine, and reduce fuel consumption.

Owner:英杰惠能(北京)能源新技术有限公司

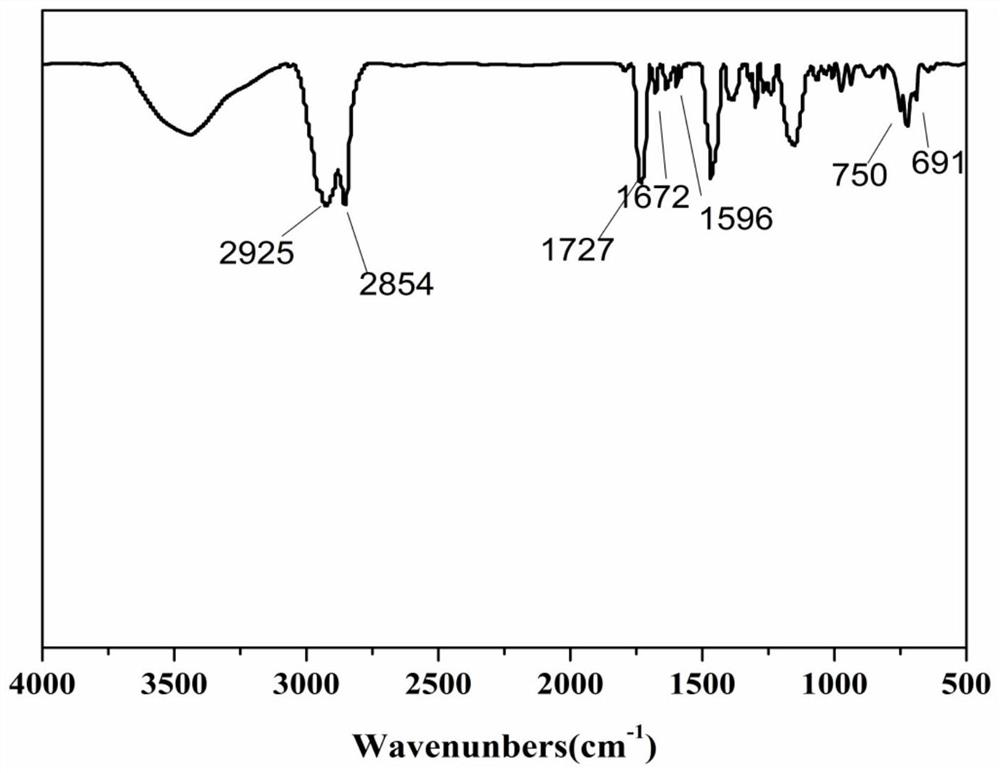

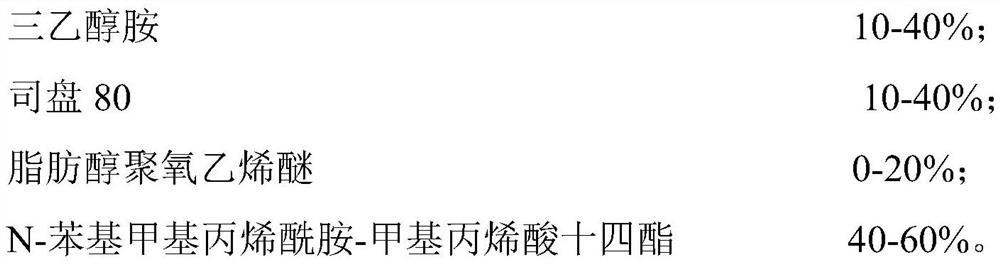

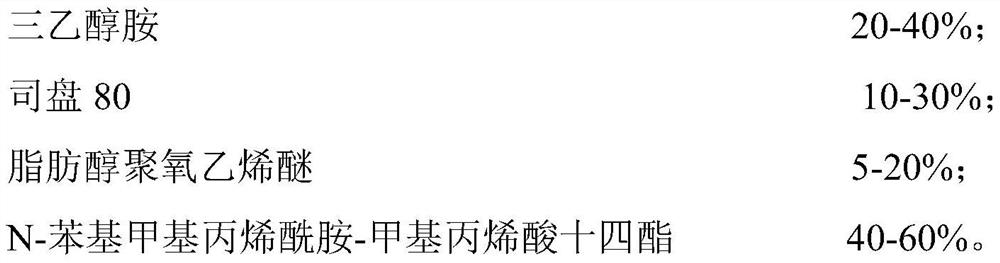

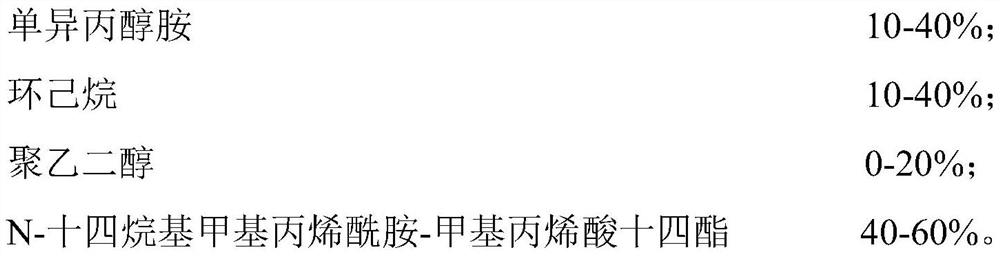

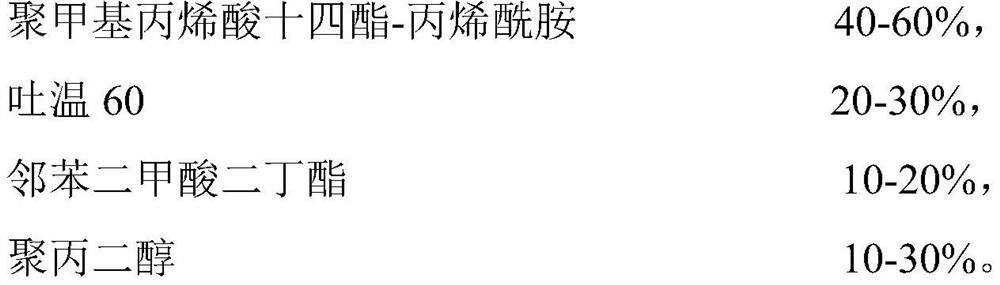

Polar nitrogen-containing diesel pour point depressant composition as well as preparation and application thereof

ActiveCN111718768ALower cold filter pointGood effectLiquid carbonaceous fuelsFuel additivesMethacrylateDioxyethylene Ether

The invention relates to a polar nitrogen-containing diesel oil pour point depressant composition as well as preparation and application thereof. The diesel oil pour point depressant composition is prepared from the following components in percentage by weight: 10-40% of triethanolamine; 10 to 40 percent of span 80; 0 to 20 percent of fatty alcohol-polyoxyethylene ether; and 40 to 60% of N,N-phenyl methacrylamide-tetradecyl methacrylate. Compared with the prior art, the dispersity of the pour point depressant in 0 # diesel oil sold in the market can be improved, the condensation point of the pour point depressant can be reduced by 22-26 DEG C, and the cold filter plugging point of the pour point depressant can be reduced by 8-12 DEG C.

Owner:SHANGHAI INST OF TECH

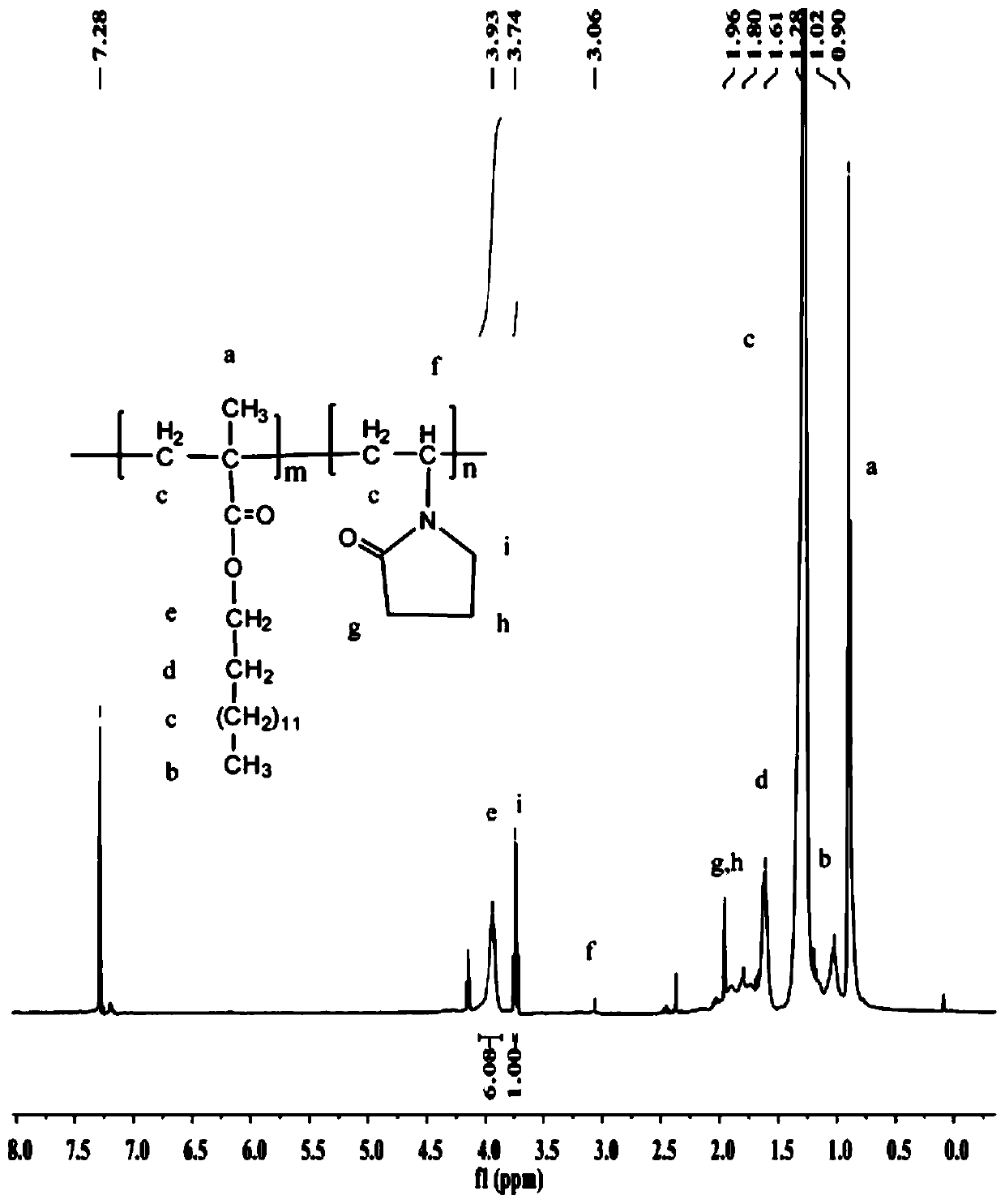

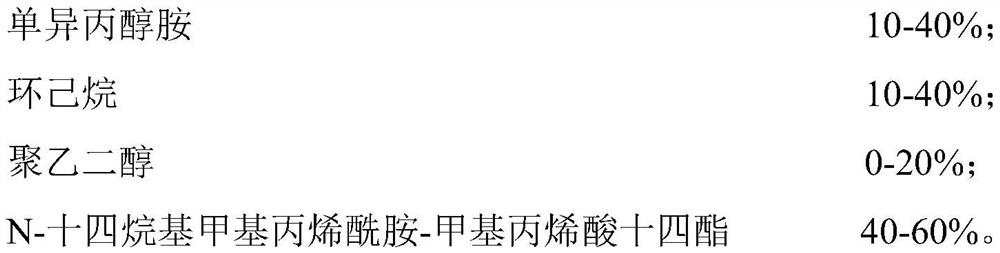

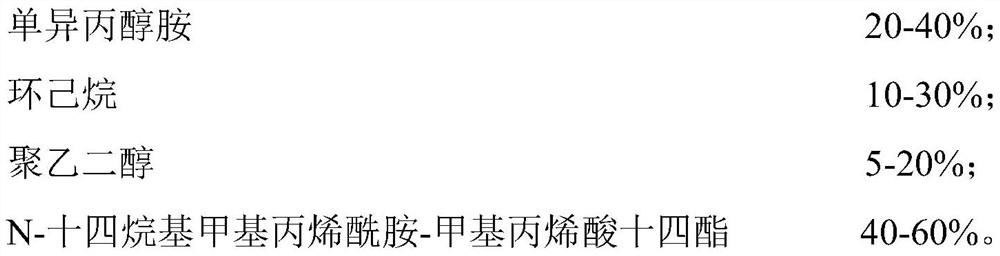

Nitrogen-containing diesel pour point depressant composition as well as preparation and application thereof

InactiveCN111676074AImprove low temperature fluidityEvenly dispersedLiquid carbonaceous fuelsFuel additivesMethacrylateMeth-

The invention relates to a nitrogen-containing diesel oil pour point depressant composition as well as preparation and application thereof. The nitrogen-containing diesel oil pour point depressant composition is prepared from the following components in percentage by weight: 10-40% of mono-isopropanol amine, 10 to 40% of cyclohexane; 0-20% of polyethylene glycol; and 40 to 60% of N,N-tetradecyl methacrylamide-tetradecyl methacrylate. The obtained diesel oil pour point depressant composition is added into No.0 diesel oil sold in the market, and the condensation point and the cold filter plugging point of the diesel are reduced by 21-25 DEG C and 9-13 DEG C respectively.

Owner:SHANGHAI INST OF TECH

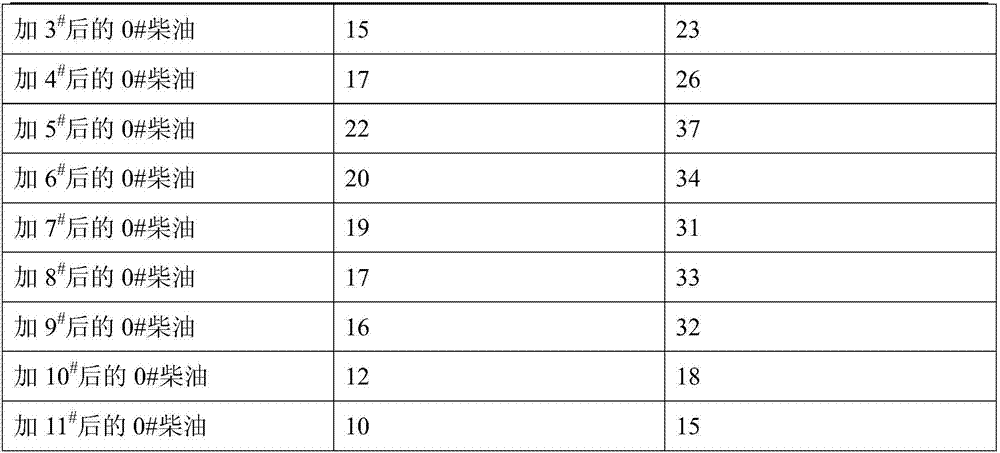

Nano composite ternary polymer pour point reducer and preparation method thereof

ActiveCN107163997AGood effectGood oil solubilityLiquid carbonaceous fuelsFuel additivesDispersityHigh carbon

The invention discloses a nano composite ternary polymer pour point reducer and a preparation method thereof. Modified nano montmorillonite and a ternary polymer according to a mass ratio of 1:1 to 1:8 are taken as raw materials, and the nano composite ternary polymer pour point reducer is prepared through a solvent blending method. The nano composite ternary polymer pour point reducer is prepared by the steps: taking fumaric acid high-carbon mixed alcohol ester, styrene and methyl methacrylate as monomers, and carrying out a polymerization reaction under the action of an initiator, thereby obtaining the pour point reducer, wherein the fumaric acid high-carbon mixed alcohol ester is an ester formed by fumaric acid and several alcohols selected from C14-C25 alcohols. The preparation method is simple, the raw materials are cheap and readily available, and the nano composite ternary polymer pour point reducer with high dispersity and excellent effects is provided. When the nano composite ternary polymer pour point reducer is applied to 0# diesel oil, the pour point depression effect is superior to that of a ternary polymer pour point reducer, so that the cold filter plugging point and condensation point of gasoline are respectively reduced by 14-22 DEG C and 18-37 DEG C.

Owner:SHANGHAI INST OF TECH

Preparation method of blend biodiesel suitable for use in high and cold areas

The invention relates to a preparation method of blend biodiesel, in particular relates to a blend biodiesel suitable for use in high and cold areas, and belongs to the technical field of fuels. The preparation method comprises the following steps: uniformly mixing fatty alcohol polyoxypropylene ether, rosin, lead-free gasoline, fatty acid ammonium, tert-butyl peroxyacetate, phenylpropanol, oleic acid and paraffin, then heating for dissolution, stirring uniformly, and cooling to room temperature to obtain an additive; and uniformly mixing diesel oil, cracked kerosene, 70# gasoline, biodiesel, a cosolvent, a stabilizer and the additive, then heating, keeping the temperature while stirring, and then cooling, wherein the diesel oil refers to 0#, 10# or 20# diesel oil. The condensation point of the biodiesel prepared by the method provided by the invention, compared with that of common biodiesel, is greatly reduced and can reach less than -10 DEG C, so that the biodiesel is suitable for use in the high and cold areas.

Owner:杨金伟

Marine biofuel oil and preparation method thereof

InactiveCN104789276BHigh calorific valueIncrease oxygen contentLiquid carbonaceous fuelsExhaust gas emissionsFuel oil

The invention discloses marine biological fuel oil which is prepared from the following ingredients in percentage by weight: 30-50 percent of waste plant oil residue, 5-10 percent of waste fusel, 30-50 percent of absorber oil, 15-30 percent of waste oil and 0.5-2 percent of an additive. The marine biological fuel oil makes full use of parts of waste resources and renewable energy sources, can remit the exploitation and consumption of oil resources, and is wide in raw material source, low in cost and good in economic benefit. The marine biological fuel oil is rich in oxygen, good in combustion performance, complete in combustion, high in thermal efficiency, less in exhaust gas emission pollutant and low in sulfur content, reduces mechanical corrosivity and sulfide emission, can be widely applied to the application fields of boilers and ships using petrochemical heavy oil burners, remits the shortage of oil resource, and reduces the pollution of waste oil on social environment.

Owner:舟山冉升能源科技有限公司

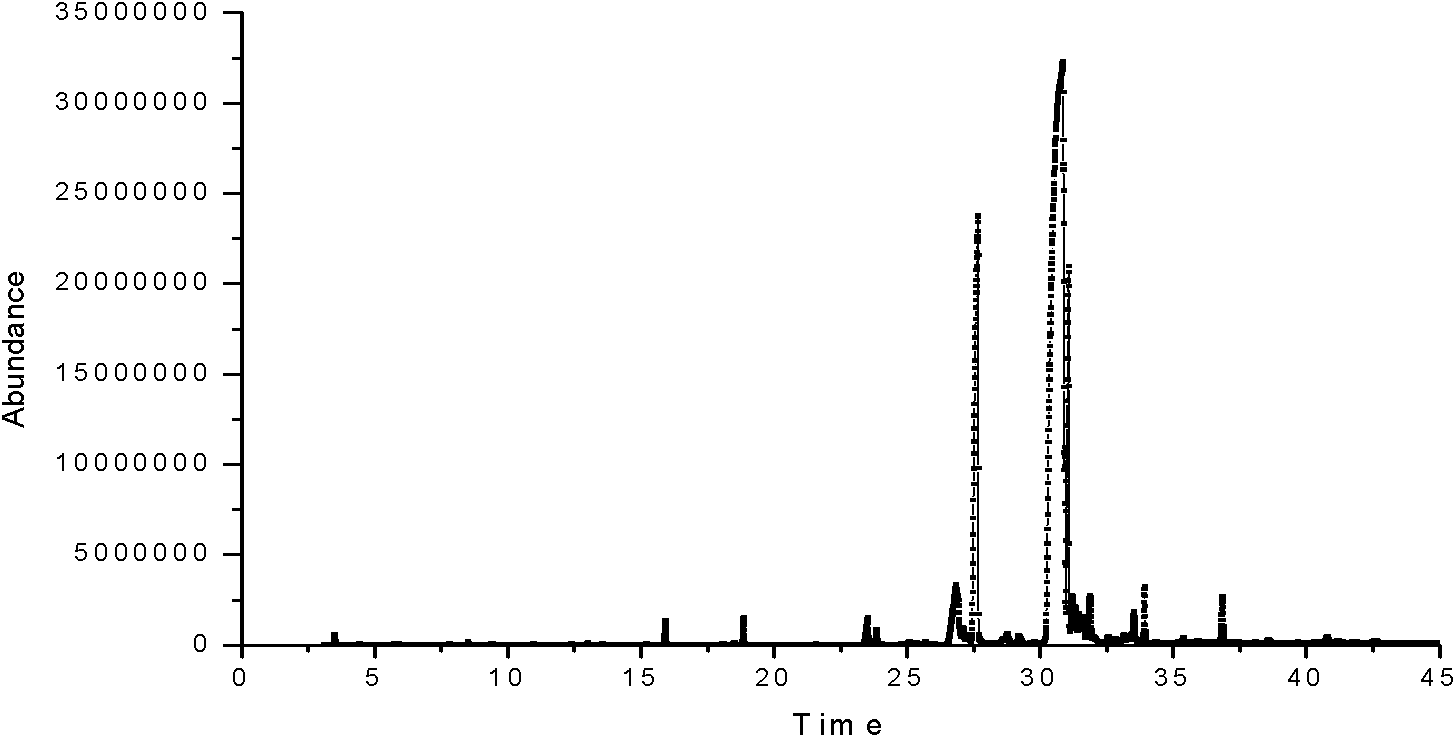

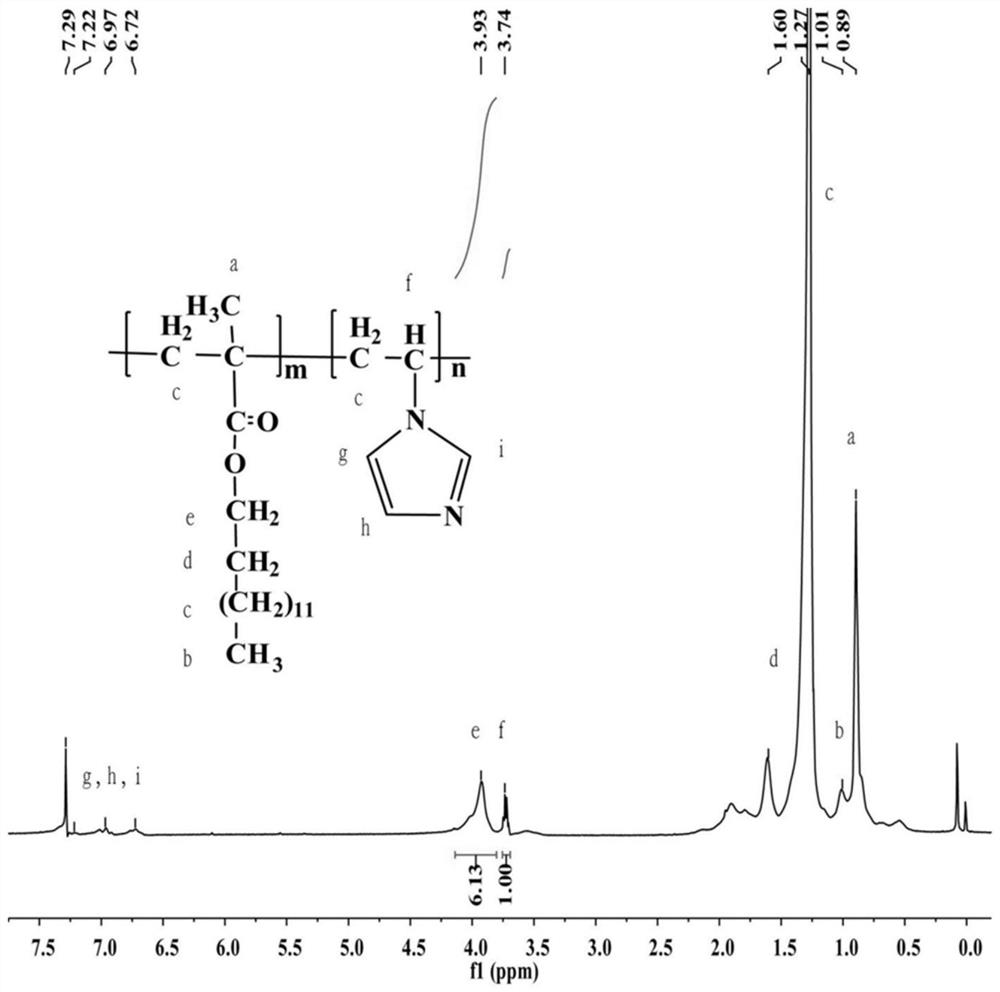

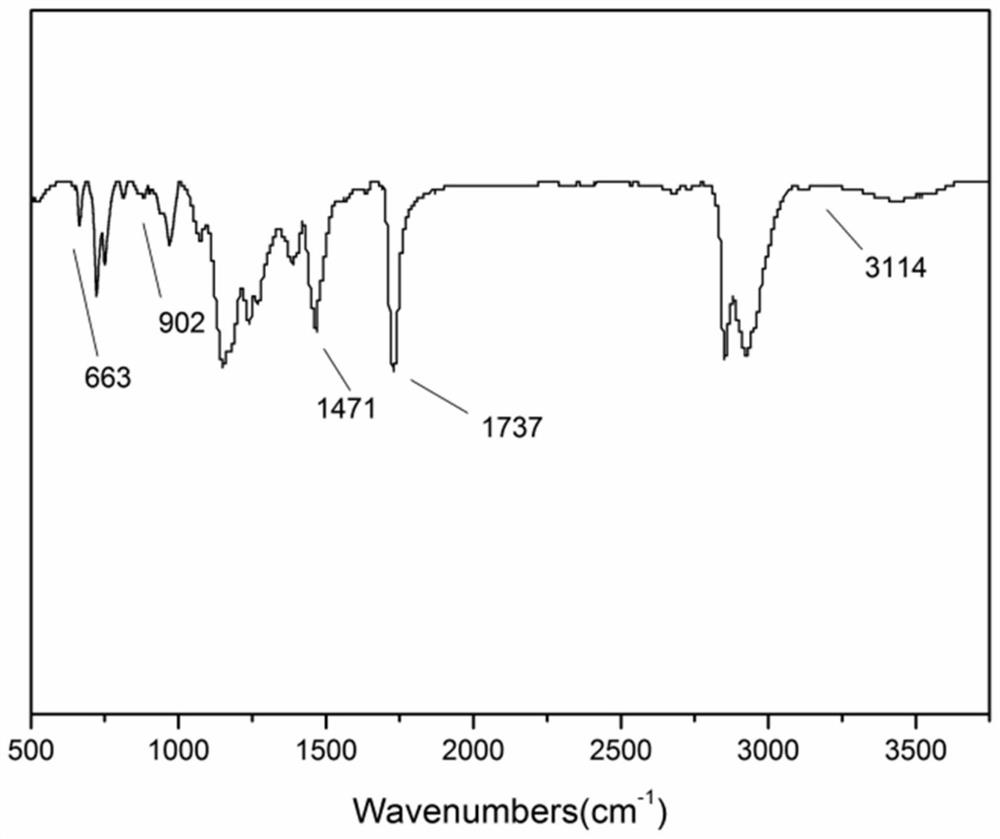

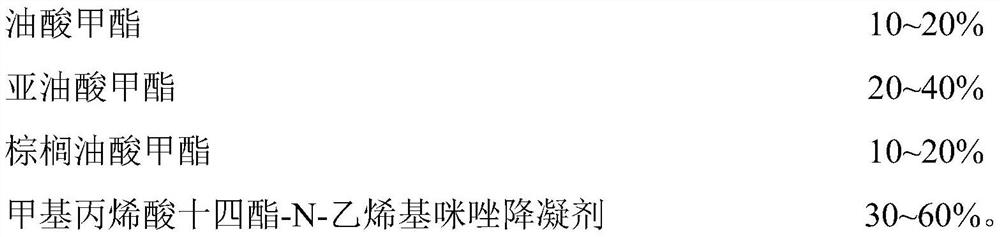

A kind of pour point depressant composition for diesel oil and its preparation method and application

ActiveCN110184101BImprove solubilityChange sizeLiquid carbonaceous fuelsFuel additivesOrganosolvMethyl oleate

The present invention relates to a kind of pour point depressant composition for diesel oil and its preparation method and application, the pour point depressant composition is obtained by mixing methyl ester organic solvent and myristyl methacrylate-N-vinylimidazole pour point depressant, comprising The following components and weight percentage content: methyl oleate 10~20%, methyl linoleate 20~40%, methyl palmitoleate 10~20%, tetradecyl methacrylate-N-vinylimidazolium The coagulant is 30-60%, and the above raw materials are directly mixed according to the mass ratio to obtain the diesel pour point depressant composition. Add the composition to Songjiang 0# diesel oil at a mass content of 0.15%, and ultrasonically disperse at 40°C for 30 minutes. After testing, the condensation point of diesel oil can be reduced by 13-18°C, and the cold filter point can be reduced by 5-8°C.

Owner:SHANGHAI INST OF TECH

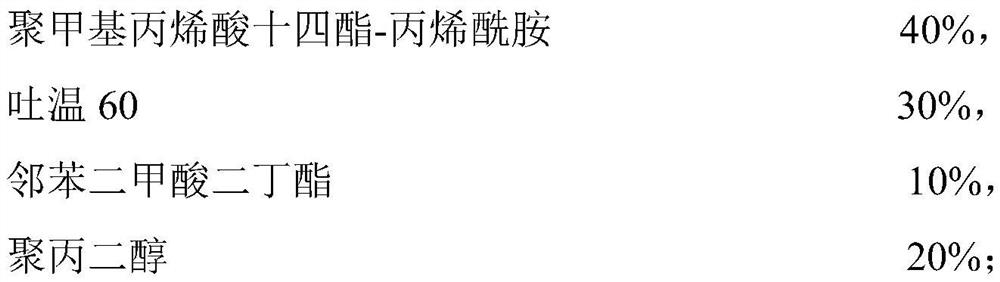

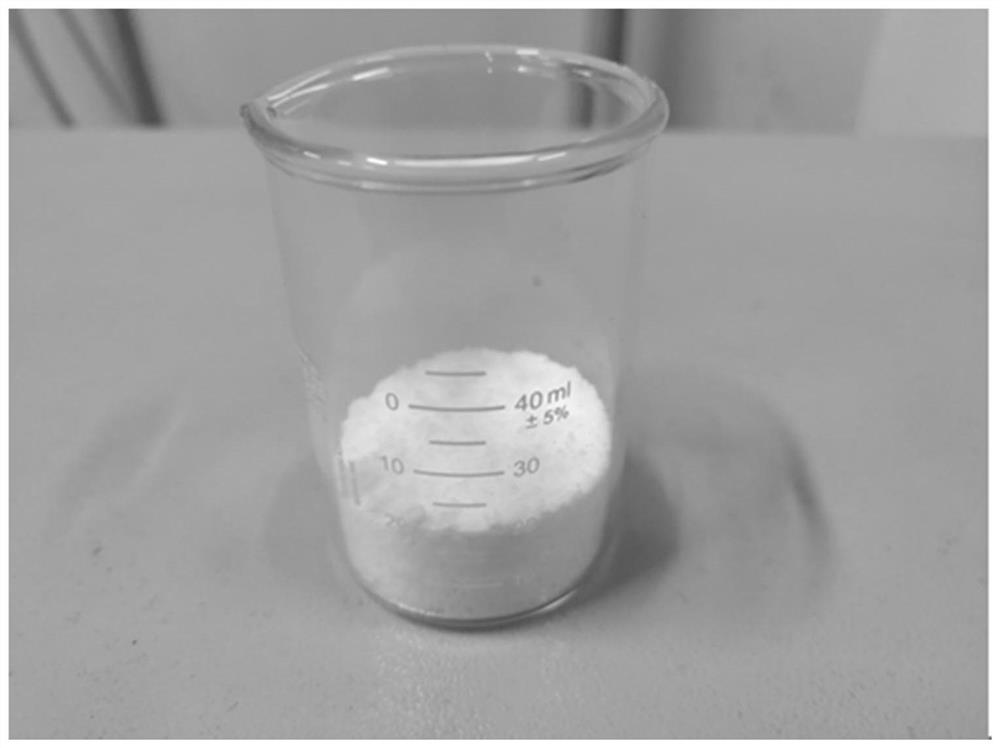

Biodiesel pour point depressant composition as well as preparation and application thereof

ActiveCN111676072AImprove cold flow propertiesIncrease exposureLiquid carbonaceous fuelsFuel additivesChemistryDi n butyl phthalate

The invention relates to a biodiesel pour point depressant composition as well as preparation and application thereof. The pour point depressant composition is prepared from the following components in percentage by weight: 40 to 60% of polytetradecyl methacrylate-acrylamide, 10 to 30% of Tween 60, 10 to 20% of dibutyl phthalate and 10 to 30 percent of polypropylene glycol. The growth and aggregation of crystals can be effectively inhibited by changing the crystallization behavior of biodiesel by the biodiesel pour point depressant composition, and the low-temperature performance of the biodiesel is effectively improved.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

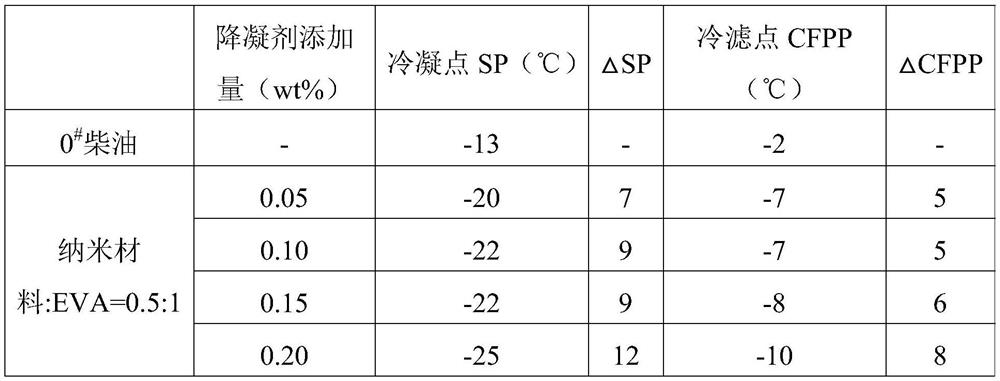

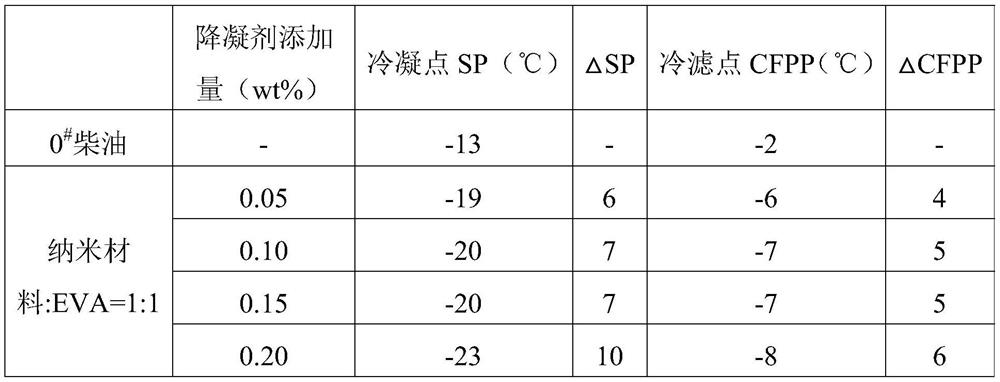

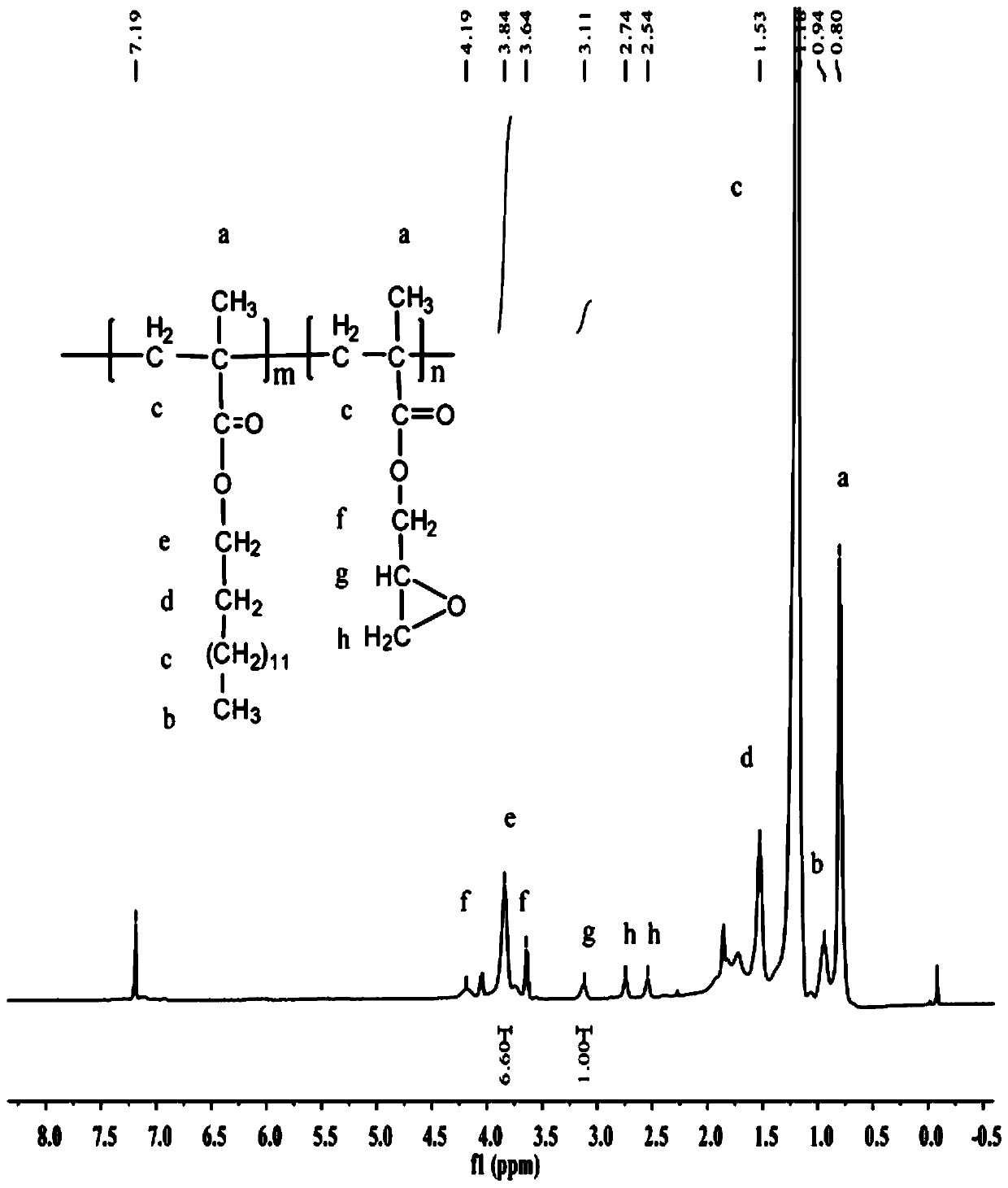

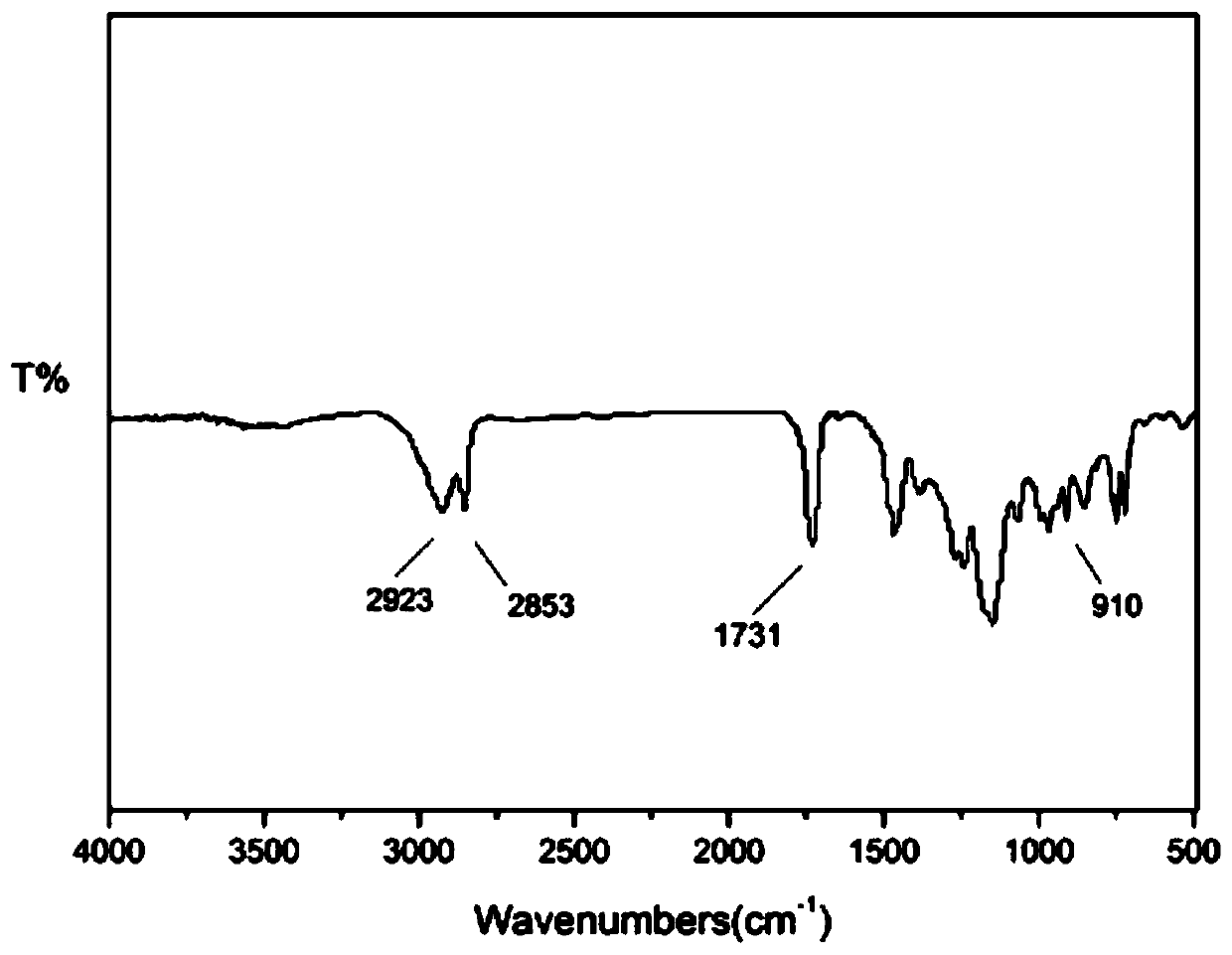

Composite nano diesel oil pour point depressant as well as preparation method and application thereof

PendingCN114479965AIncrease polarityImprove solubilityLiquid carbonaceous fuelsSilanesCarvacryl acetate

The invention relates to a composite nanometer diesel oil pour point depressant and a preparation method and application thereof.The preparation method comprises the following steps that 1, a silane coupling agent with aminopropyl and nanometer silicon dioxide are added into a solvent A, heating and stirring are conducted, and a nanometer material is obtained after aftertreatment; and 2) adding the nano material and polyethylene-vinyl acetate into a solvent B, carrying out melt blending, and separating to obtain the composite nano diesel oil pour point depressant. Compared with the prior art, the nano silicon dioxide material treated by the silane coupling agent has organic compatibility, and is compounded with the oil-soluble polymer to prepare the composite nano diesel oil pour point depressant, so that the pour point depression effect is effectively enhanced, the low-temperature flowing property of diesel oil is improved, and the application prospect of a nano material in the field of diesel oil pour point depressants is expanded.

Owner:SHANGHAI INST OF TECH

Diesel pour point depressant and preparation method and application thereof

ActiveCN110564465ALower condensation pointImprove low temperature fluidityLiquid carbonaceous fuelsFuel additivesGlycidyl methacrylateDepressant

The invention relates to a diesel pour point depressant and a preparation method and application thereof. The diesel pour point depressant comprises the following components in parts by weight: 40-60parts of a nonionic surfactant and 40-60 parts of tetradecyl methacrylate-glycidyl methacrylate copolymer. Compared with the prior art, the diesel pour point depressant contains the nonionic surfactant; after the diesel pour point depressant is added into diesel, the condensation point of the diesel can be reduced by 16-19 DEG C and the cold filter plugging point is reduced by 6-9 DEG C through tests, the problem of poor low-temperature fluidity of the diesel is further solved, and a direction is provided for further popularization and application.

Owner:SHANGHAI INST OF TECH

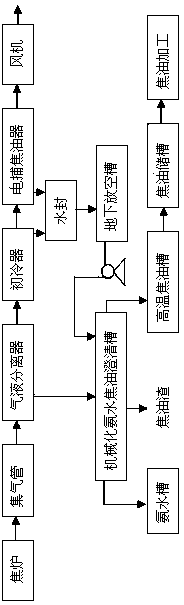

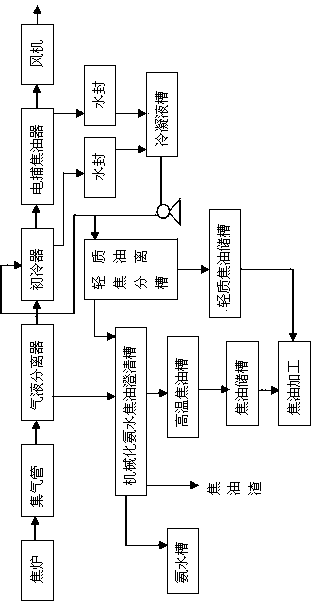

Equipment and process for producing light tar by controlling QI (Quality Index) value of tar

ActiveCN102504851BLower condensation pointSave raw materialsWorking-up tarGas purification by non-gaseous materials condensationElectricityWater flow

The invention relates to equipment and a process for producing light tar by controlling the primary QI (Quality Index) value of tar. The process comprises the following steps of: making coal gas which is primarily cooled by using a primary cooler and a condensate produced in the electric catching tar removing process of an electric tar catching device flow into a condensate groove through a water seal; conveying one path of condensate in the condensate groove to the upper and lower sections of the primary cooler by using a condensate pump for spraying; conveying the other path of condensate to a light tar separating groove; feeding the condensate from a position which is a half of the height of one side of the separating groove; making a supernate over three quarters of the height of the separating groove overflow; separating primary low-QI-value light coal tar and ammonia water out with a plug flow standing method for continuously standing and separating light tar according to the specific weight difference between light tar and water, and a medicament demulsification method for demulsifying and separating a part of emulsifying oil by adding a polyacrylamide demulsifying agent; making ammonia water flow into a mechanical ammonia water tar settling tank; feeding light tar into a light tar storage groove; and processing and treating.

Owner:HENAN ZHONGHONG GRP COAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com