Diesel pour point depressant and preparation method and application thereof

A technology of diesel pour point depressant and active agent, which is applied in the field of diesel pour point depressant and its preparation, can solve the problems of increased total cost and poor economy, and achieves poor overcoming effect, improved low-temperature fluidity, and improved pour point depressant effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A practical diesel pour point depressant containing a nonionic surfactant, comprising the following components and contents by weight:

[0030] 20 parts of fatty acid methyl ester ethoxylate,

[0031] Tween 80 20 servings,

[0032] 60 parts of tetradecyl methacrylate-glycidyl methacrylate copolymer.

[0033] Wherein, the preparation method of tetradecyl methacrylate-glycidyl methacrylate copolymer is: after the molar ratio is 3:1, tetradecyl methacrylate and glycidyl methacrylate are mixed, and then added to toluene solvent , under the condition that the total mass of the reactants is 0.9% of benzoyl peroxide as an initiator, react at 120° C. for 9 hours to obtain a tetradecyl methacrylate-glycidyl methacrylate copolymer.

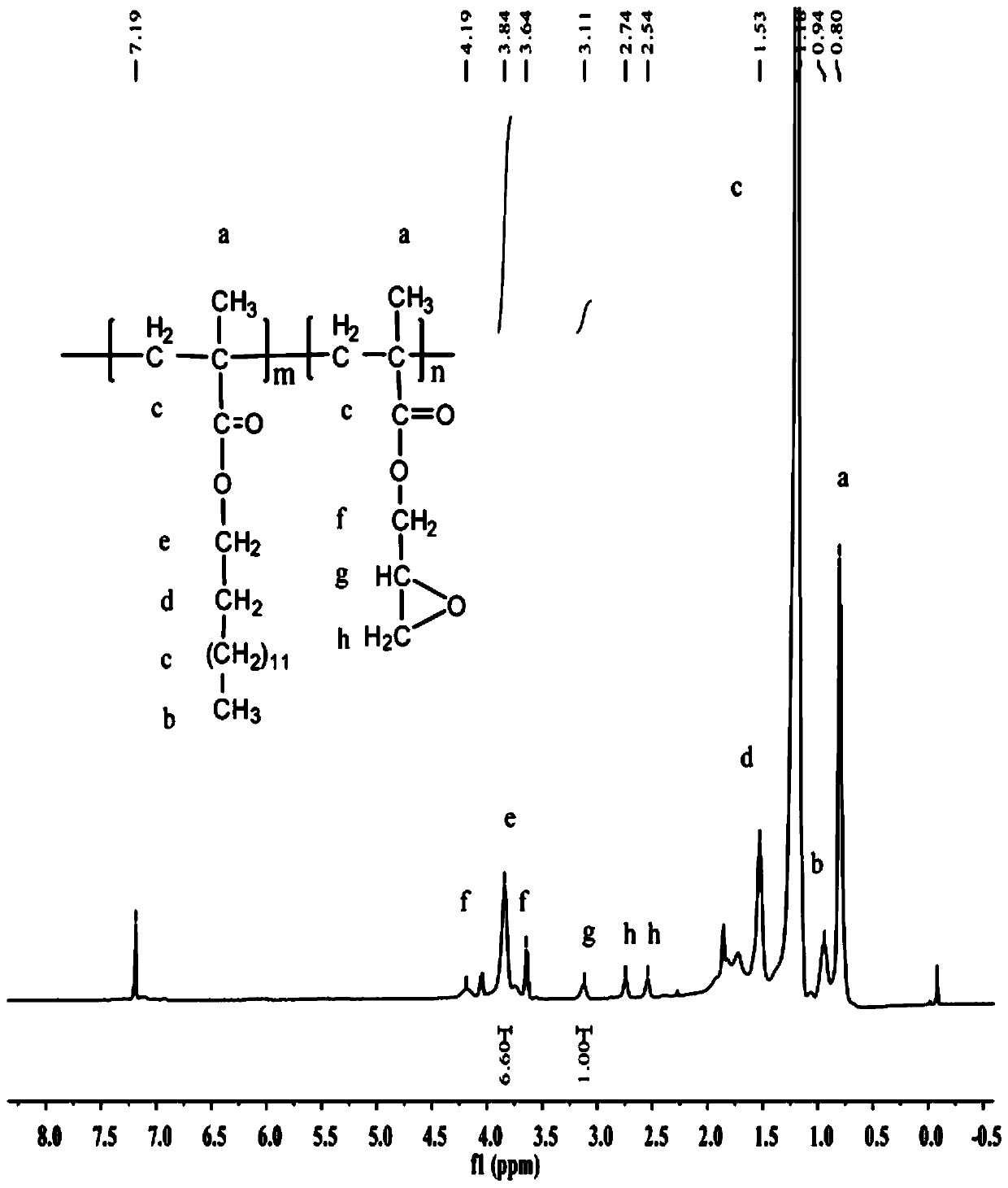

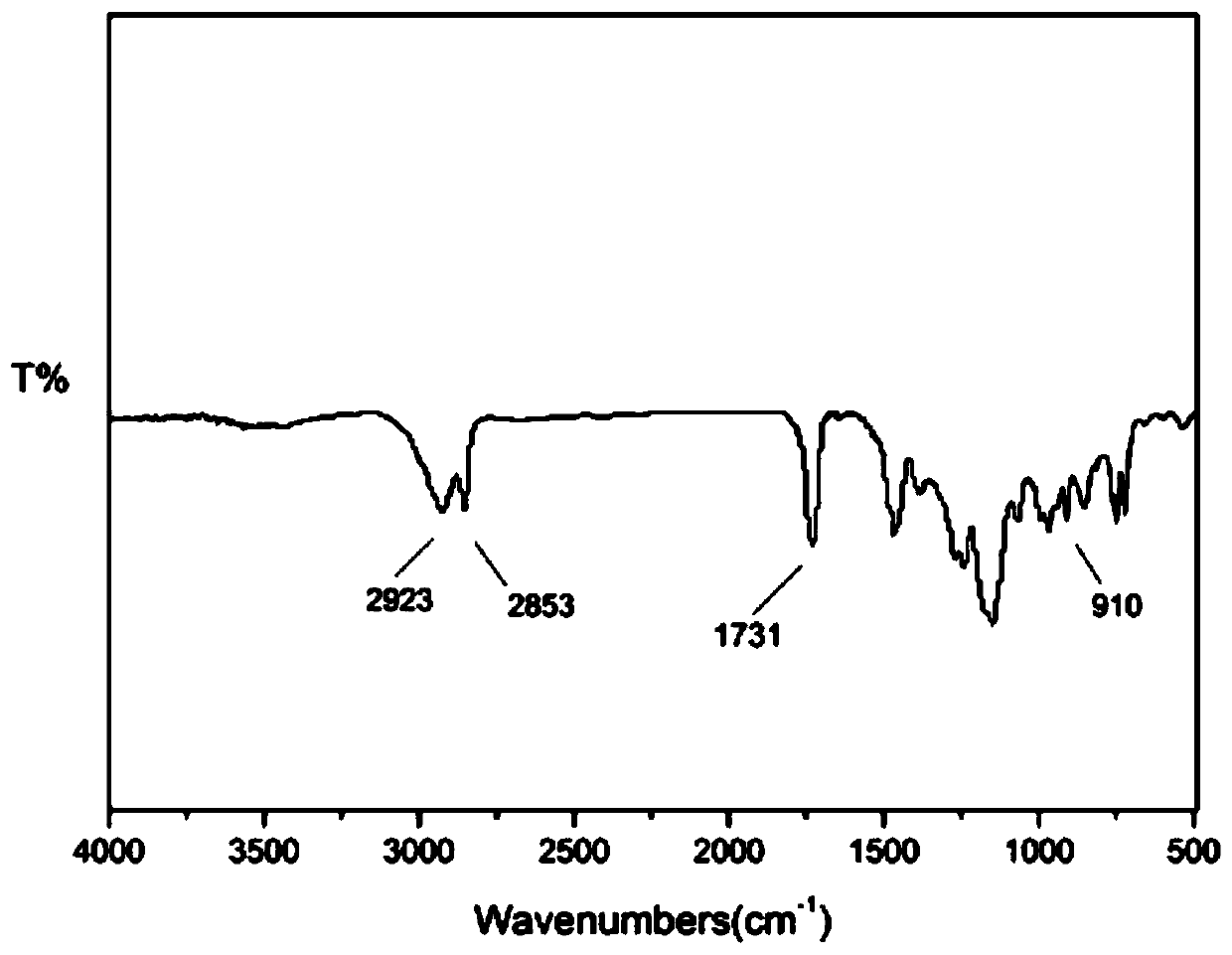

[0034] The obtained tetradecyl methacrylate-glycidyl methacrylate copolymer was characterized by nuclear magnetic and infrared, and the results were as follows: figure 1 , figure 2 shown. Depend on figure 1 It can be seen that δ at h H =2.54,...

Embodiment 2

[0046] A practical diesel pour point depressant containing a nonionic surfactant, comprising the following components and contents by weight:

[0047] 20 parts of fatty acid methyl ester ethoxylate,

[0048] Tween 80 30 servings,

[0049] 50 parts of tetradecyl methacrylate-glycidyl methacrylate copolymer.

[0050] Wherein, the preparation method of tetradecyl methacrylate-glycidyl methacrylate copolymer is: after the molar ratio is 3:1, tetradecyl methacrylate and glycidyl methacrylate are mixed, and then added to toluene solvent , under the condition that the total mass of the reactants is 0.9% of benzoyl peroxide as an initiator, react at 120° C. for 9 hours to obtain a tetradecyl methacrylate-glycidyl methacrylate copolymer.

[0051] The practical preparation method of diesel pour point depressant is as follows: directly mixing fatty acid methyl ester ethoxylate, Tween 80 and tetradecyl methacrylate-glycidyl methacrylate copolymer.

[0052] Practical diesel pour point d...

Embodiment 3

[0054] A practical diesel pour point depressant containing a nonionic surfactant, comprising the following components and contents by weight:

[0055] 10 parts of fatty acid methyl ester ethoxylate,

[0056] Tween 80 40 servings,

[0057] 50 parts of tetradecyl methacrylate-glycidyl methacrylate copolymer.

[0058] Wherein, the preparation method of tetradecyl methacrylate-glycidyl methacrylate copolymer is: after the molar ratio is 3:1, tetradecyl methacrylate and glycidyl methacrylate are mixed, and then added to toluene solvent , under the condition that the total mass of the reactants is 0.9% of benzoyl peroxide as an initiator, react at 120° C. for 9 hours to obtain a tetradecyl methacrylate-glycidyl methacrylate copolymer.

[0059] The practical preparation method of diesel pour point depressant is as follows: directly mixing fatty acid methyl ester ethoxylate, Tween 80 and tetradecyl methacrylate-glycidyl methacrylate copolymer.

[0060] Practical diesel pour point d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com