Composite nano diesel oil pour point depressant as well as preparation method and application thereof

A diesel pour point depressant and composite technology, applied in the field of composite nano diesel pour point depressant and its preparation, can solve problems such as single type, and achieve the effects of lowering the condensation point and cold filter point, stable performance and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of composite nano-diesel pour point depressant, comprising the following steps:

[0027] 1) Add silane coupling agent and nano silicon dioxide with aminopropyl group into solvent A, heat and stir, and obtain nanomaterials through post-treatment, such as figure 1 shown;

[0028] 2) adding the nano material and polyethylene-vinyl acetate into the solvent B, performing melt blending, and separating to obtain a composite nano diesel pour point depressant.

[0029] In step 1), the silane coupling agent is aminopropyl-triethoxysilane, and the solvent A is formed by mixing ethanol and water in a volume ratio (8-10):1. The mass ratio of silane coupling agent to nano silicon dioxide is 1:(2.5-3.5). The temperature of heating and stirring is 70-80° C., and the time is 2.5-3.5 hours; post-treatment includes centrifugation, washing, drying and grinding. The centrifugation temperature is 50-70° C., and the time is 8-12 minutes; ...

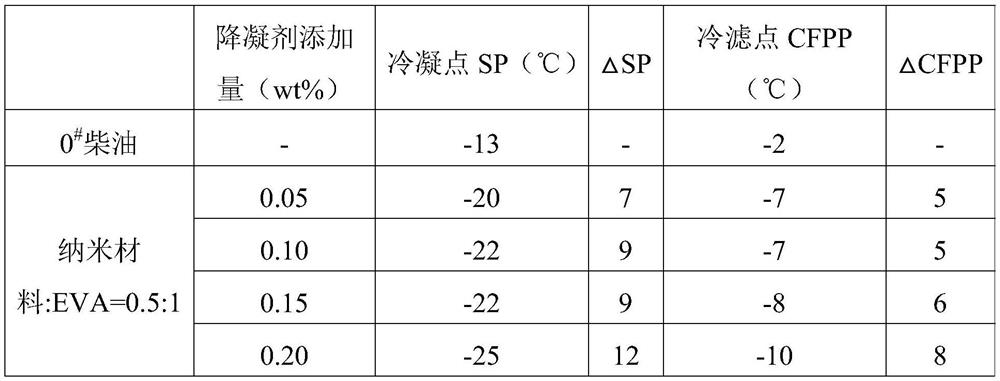

Embodiment 1

[0035] A composite nano-diesel pour point depressant for lowering the cold filter point and condensation point of diesel oil, which is made by mixing aminopropyl-triethoxysilane and nano-silica, and then combined with polyethylene vinyl acetate after separation and purification Ester (EVA) copolymer melt blending obtains, and concrete preparation process is as follows:

[0036] 1) Put the single-necked flask into a constant temperature magnetic stirrer, add 45ml of ethanol and 5ml of deionized water into the single-necked flask, mix and stir at room temperature for 1h;

[0037] After the stirring was completed, 2.0 g of aminopropyl-triethoxysilane and 6.0 g of nano-silicon dioxide were put into the ethanol solution, and stirred at 75° C. for 3 h.

[0038] After the reaction, centrifuge the product at 60°C for 10 minutes to completely separate the solution from the nanomaterials, put it in a vacuum oven and dry it at 60°C for 12 hours to remove the remaining small amount of eth...

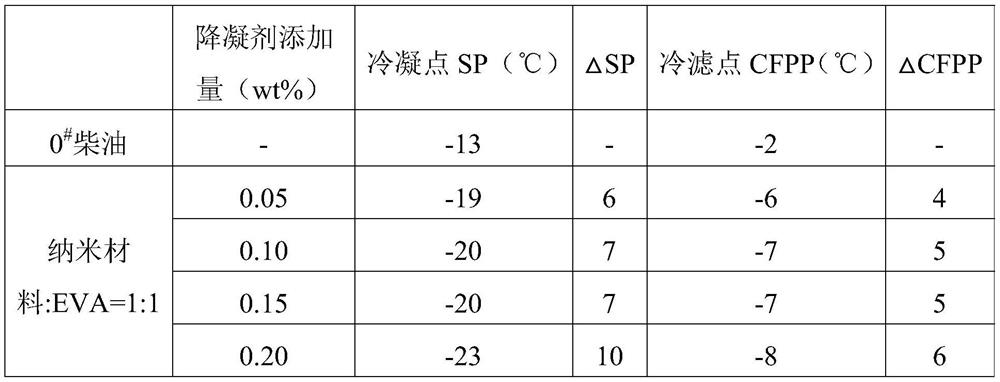

Embodiment 2

[0046] A composite nano-diesel pour point depressant for lowering the cold filter point and condensation point of diesel oil, which is made by mixing aminopropyl-triethoxysilane and nano-silica, and then combined with polyethylene vinyl acetate after separation and purification Ester (EVA) copolymer melt blending obtains, and concrete preparation process is as follows:

[0047] 1) Put the single-necked flask into a constant temperature magnetic stirrer, add 45ml of ethanol and 5ml of deionized water into the single-necked flask, mix and stir at room temperature for 1h;

[0048] After the stirring was completed, 2.0 g of aminopropyl-triethoxysilane and 6.0 g of nano-silicon dioxide were put into the ethanol solution, and stirred at 75° C. for 3 h.

[0049] After the reaction, centrifuge the product at 60°C for 10 minutes to completely separate the solution from the nanomaterials, put it in a vacuum oven and dry it at 60°C for 12 hours to remove the remaining small amount of eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com