Methanol diesel oil and preparation method thereof

A diesel and methanol technology, applied in the field of petrochemical industry, can solve the problems of poor mutual solubility, high cost of methanol and diesel, and poor performance, and achieve the effects of strong water phase resistance, improved mutual solubility, and improved diesel grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

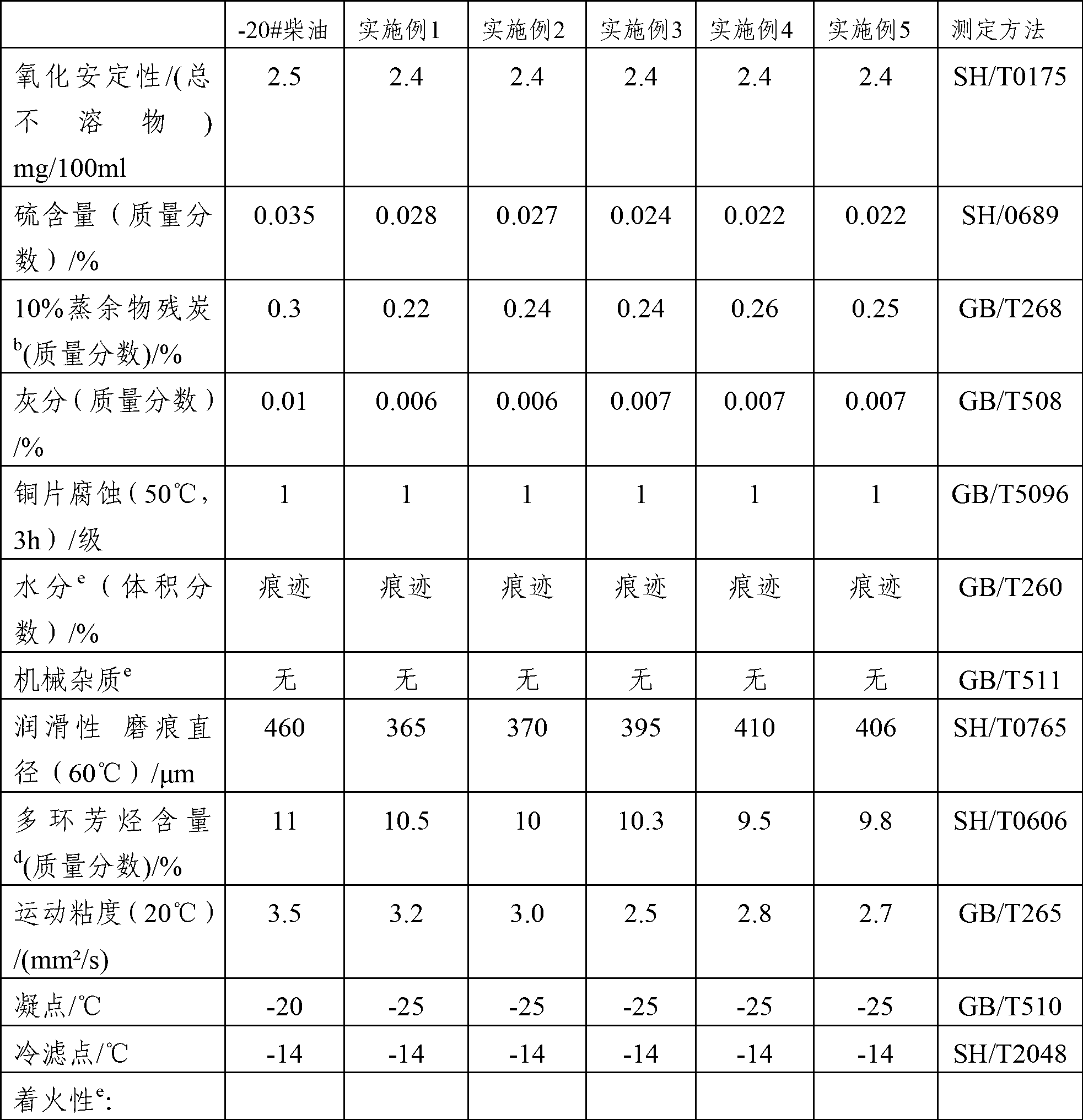

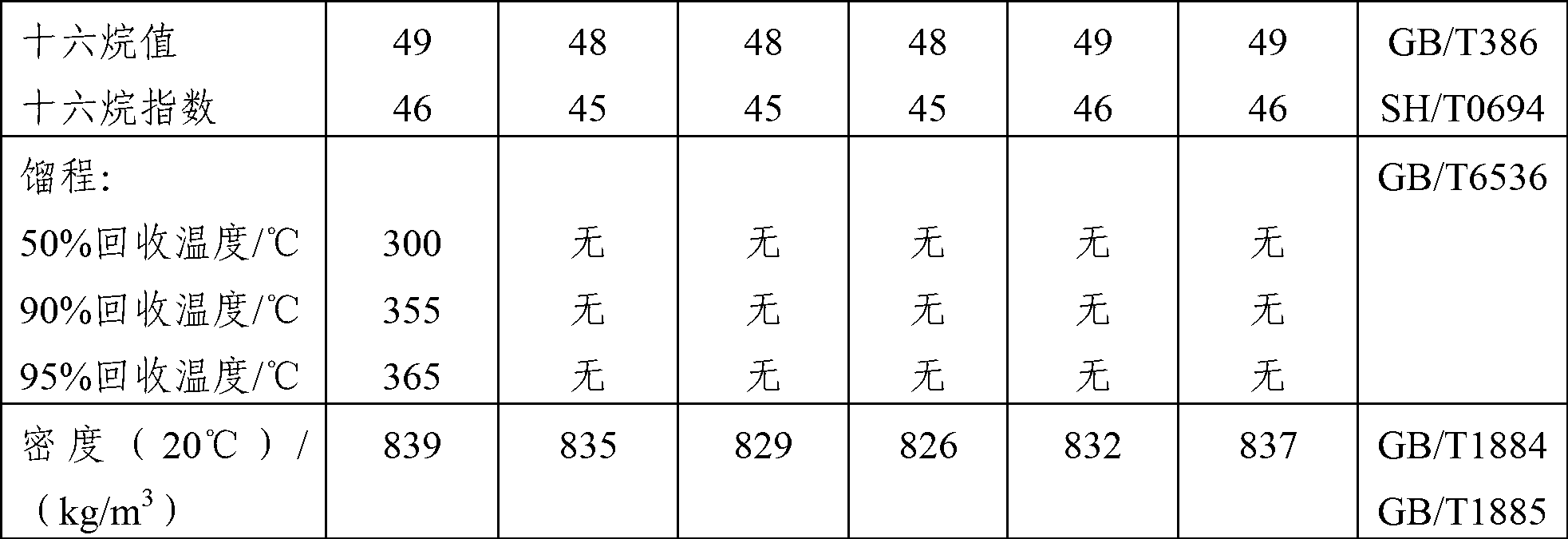

Examples

Embodiment 1

[0035] Formula (by weight): ①methanol: 150 parts; ②petroleum acid: 50 parts; ③oleic acid: 100 parts; ④BD100 biodiesel: 150 parts; ⑤0# fossil diesel: 487 parts; Isobutanol: 1.5 parts; ⑧ Isooctyl alcohol: 2 parts; ⑨ Isooctyl nitrate: 0.5 parts; ⑩ 3# aviation kerosene: 55 parts; Zinc peroxide: 2.5 parts.

[0036] Preparation Process:

[0037] (1) Mix ⑦ and ⑧ and stir for about 10 minutes to form mixture A.

[0038] (2) Mix and stir ①, ② and ③ for 15-30 minutes until uniform, forming mixture B.

[0039] (3) Combine ④, ⑤, ⑨ and Mix and stir for 15-30 minutes until homogeneous, forming Mixture C.

[0040] (4) Mix A, B, C and ⑩ and stir for 15-30 minutes to form D.

[0041] (5) Mix and stir D and ⑥ for 10-20 minutes to form methanol diesel.

Embodiment 2

[0043] Formula (by weight): ①methanol: 200 parts; ②petroleum acid: 80 parts; ③linoleic acid: 100 parts; ④BD100 biodiesel: 130 parts; ⑤0# fossil diesel: 418 parts; ⑥isopropanol: 1.5 parts; ⑦Isobutanol: 3.5 parts; ⑧Isooctyl alcohol: 3 parts; ⑨Isooctyl nitrate: 1 part; ⑩3# aviation kerosene: 60 parts; Zinc peroxide: 3 parts.

[0044] Preparation Process:

[0045] (1) Mix ⑦ and ⑧ and stir for about 10 minutes to form mixture A.

[0046] (2) Mix and stir ①, ② and ③ for 15-30 minutes until uniform, forming mixture B.

[0047] (3) Combine ④, ⑤, ⑨ and Mix and stir for 15-30 minutes until homogeneous, forming Mixture C.

[0048] (4) Mix A, B, C and ⑩ and stir for 15-30 minutes to form D.

[0049] (5) Mix and stir D and ⑥ for 10-20 minutes to form methanol diesel.

Embodiment 3

[0051]Formula (by weight): ①methanol: 250 parts; ②petroleum acid: 50 parts; ③stearic acid: 130 parts; ④BD100 biodiesel: 150 parts; ⑤0# fossil diesel: 334 parts; ⑥isopropanol: 2 parts; ⑦Isobutanol: 3.5 parts; ⑧Isooctyl alcohol: 5 parts; ⑨Isooctyl nitrate: 1.5 parts; ⑩3# aviation kerosene: 70 parts; Zinc peroxide: 4 parts.

[0052] Preparation Process:

[0053] (1) Mix ⑦ and ⑧ and stir for about 10 minutes to form mixture A.

[0054] (2) Mix and stir ①, ② and ③ for 15-30 minutes until uniform, forming mixture B.

[0055] (3) Combine ④, ⑤, ⑨ and Mix and stir for 15-30 minutes until homogeneous, forming Mixture C.

[0056] (4) Mix A, B, C and ⑩ and stir for 15-30 minutes to form D.

[0057] (5) Mix and stir D and ⑥ for 10-20 minutes to form methanol diesel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com