Patents

Literature

34results about How to "No air lock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly lead-less gasoline and its preparation method

The invention relates to a kind of environment-friendly lead-free gasoline which includes the following ingredients: 25-35wt% part of gasoline (or light oil / naphtha), 25-35wt% part of methanol, 5-10wt% of n-butanol, 13-29wt% of avantin, 4-10wt% of absolute alcohol, 1-1.5wt% of acetone, 2-2.5wt% of oil benzene, 8-23wt% of di-isobutyl ether and 0.5-1wt% of nucleus additive. The mentioned additive includes the following ingredients: 20-25wt% of acetone, 10-21wt% of isobutanol, 5-15wt% part of kerosene, 25-40wt% part of dimethyl benzene and 6-14wt% part of the gasoline quieting, anti-oxygen, anti-detonate, and anti-corrosion agent. Adding the mentioned material according to the ratio to the reactor and agitating pots, synthesizing for 15-30 minutes; agitating the material in the static admixer to get the gasoline which has good evaporating ability, anti- detonate ability, safe charactiristic, anti-corrosion ability, compatibility and environment-friendly quality.

Owner:陈志红

Automotive methanol gasoline M40-M85 and preparation method thereof

InactiveCN103695049AIncrease contentReduce pollutionLiquid carbonaceous fuelsFuel additivesIsobutanolEthylenedioxy

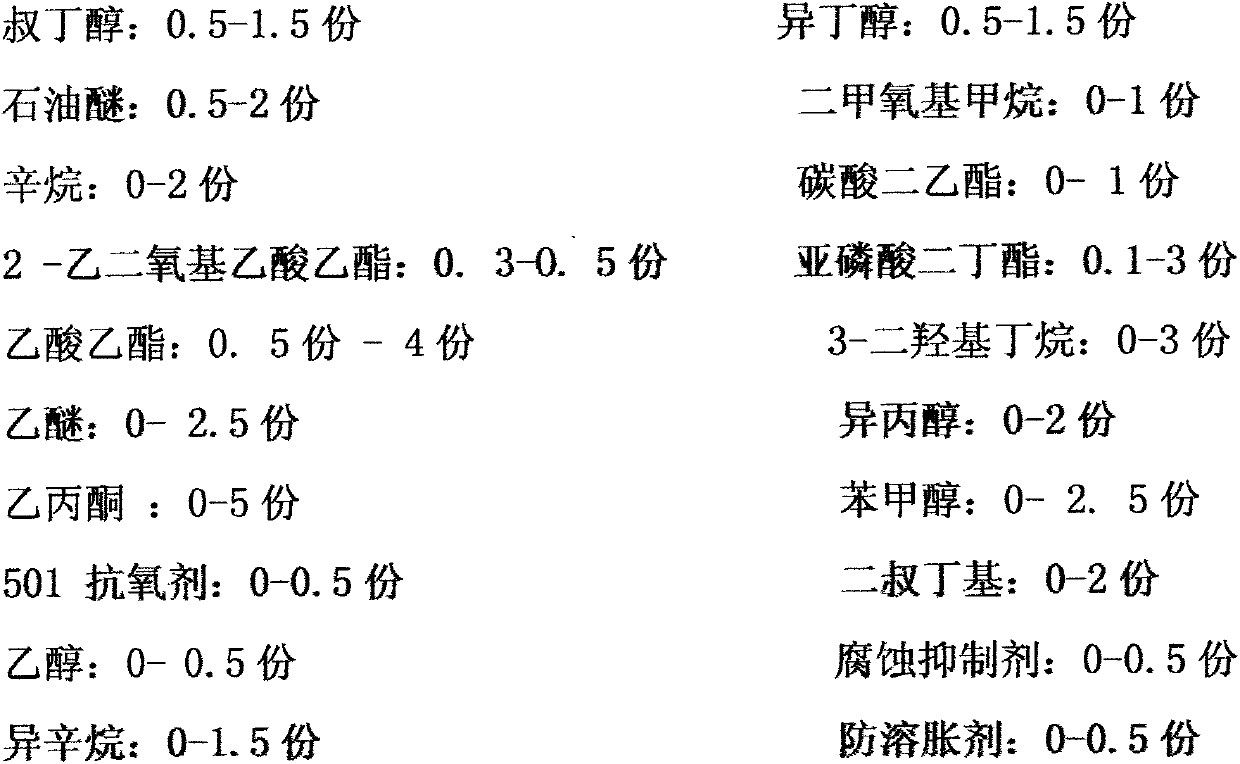

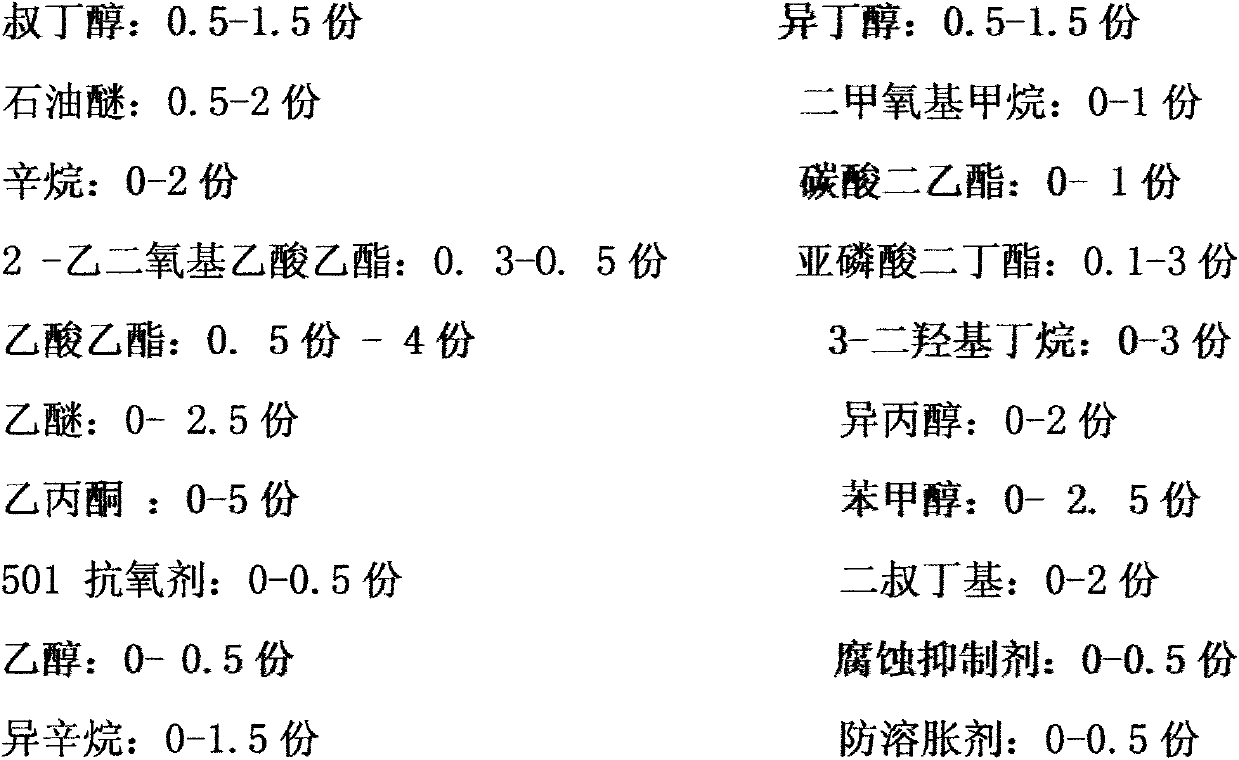

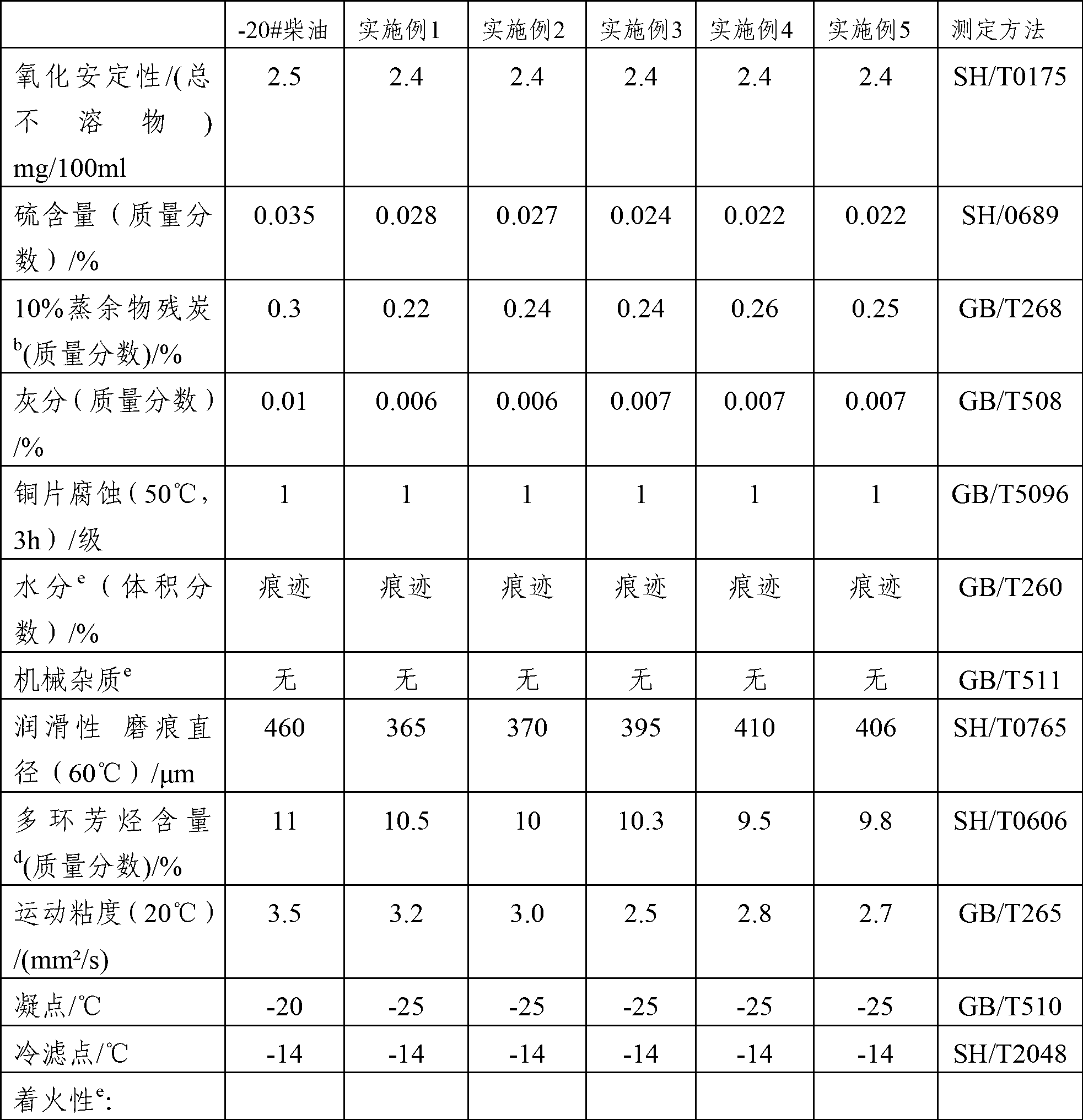

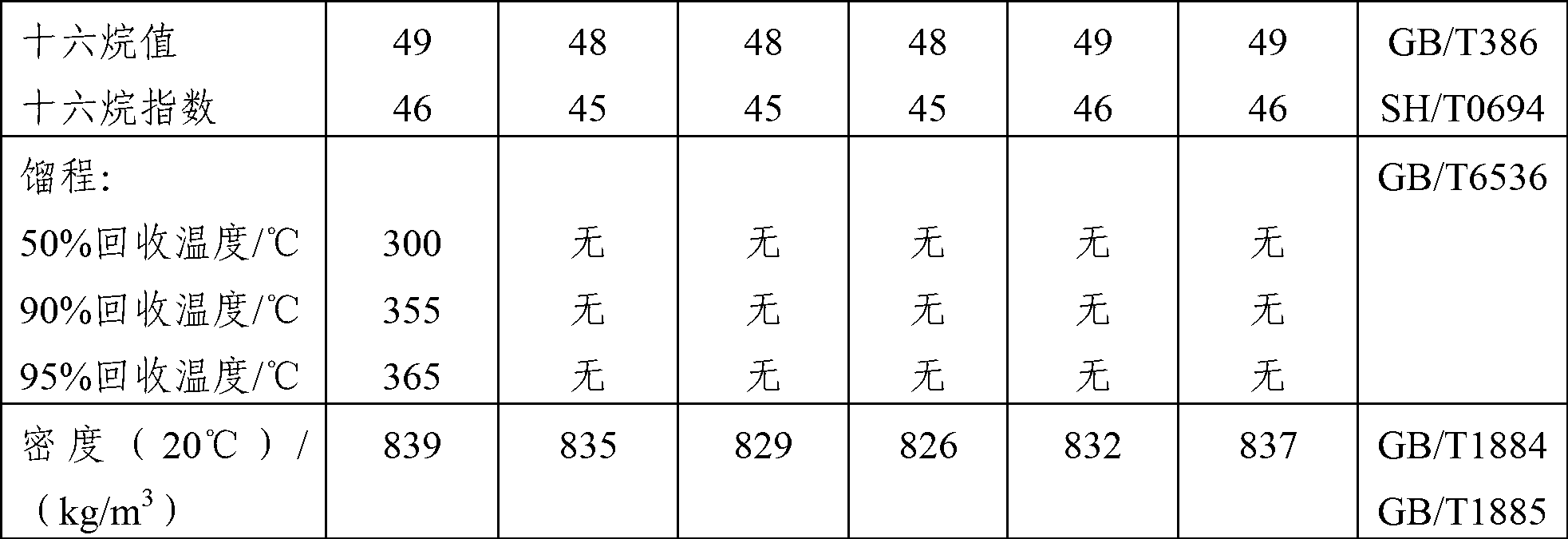

The invention relates to automotive methanol gasoline M40-M85 and a preparation method thereof. The automotive methanol gasoline M40-M85 comprises basic materials and additives, wherein the basic materials comprise gasoline and methanol; the additives comprise tertiary butanol, isobutanol, petroleum ether, dimethoxymethane, octane, diethyl carbonate, 2-ethylenedioxy acetate, dibutyl phosphite, ethyl acetate, 3-dihydroxy butane, diethyl ether, isopropanol, acetylacetone, benzyl alcohol, 501 antioxidant, di-tertiary butyl, ethanol, a corrosion inhibitor, isooctane and an anti-swelling agent. The automotive methanol gasoline M40-M85 has the advantages that the fuel performance is good, and the discharging index meets environment-friendly requirements; the automotive methanol gasoline M40-M85 can be directly used without changing the structures of existing engines and oilers.

Owner:王佐法

Methanol diesel oil and preparation method thereof

InactiveCN103013590APromote mutual solubilityEnhancement of miscible propertiesLiquid carbonaceous fuelsZinc peroxideSolvent

The invention relates to methanol diesel oil which comprises methanol, diesel oil, fatty acid, petroleum acid, cosolvent, aviation kerosene, a cetane number improver and zinc peroxide. The invention further relates to a preparation method of the methanol diesel oil. According to the methanol diesel oil, the content of methanol in a system is greater, the methanol diesel oil has better mutual solubility with fossil diesel oil, the performance of the methanol diesel oil is improved obviously, and the methanol diesel oil can serve as -20# diesel oil for use, and is safe, environment-friendly and low in raw materials cost. The preparation method is simple in step, mild in condition and suitable for large-scale industrial production.

Owner:BEIJING QINGYANLIHUA GASOLINEEUM CHEM

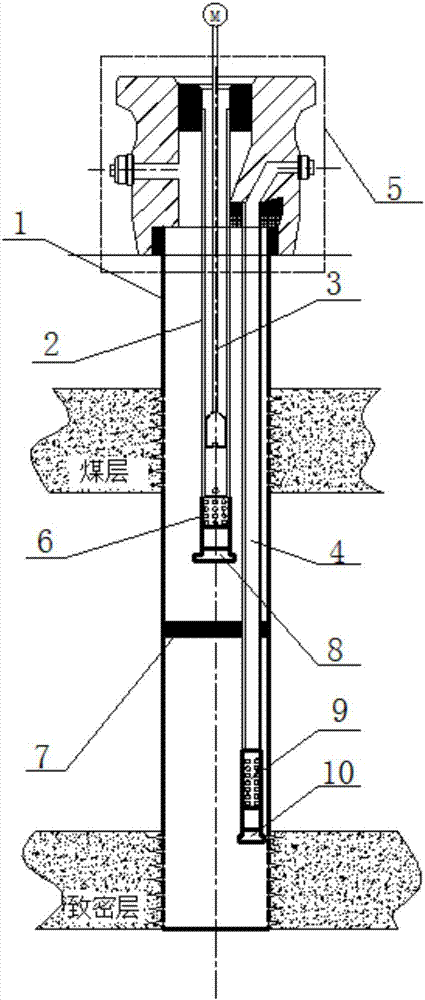

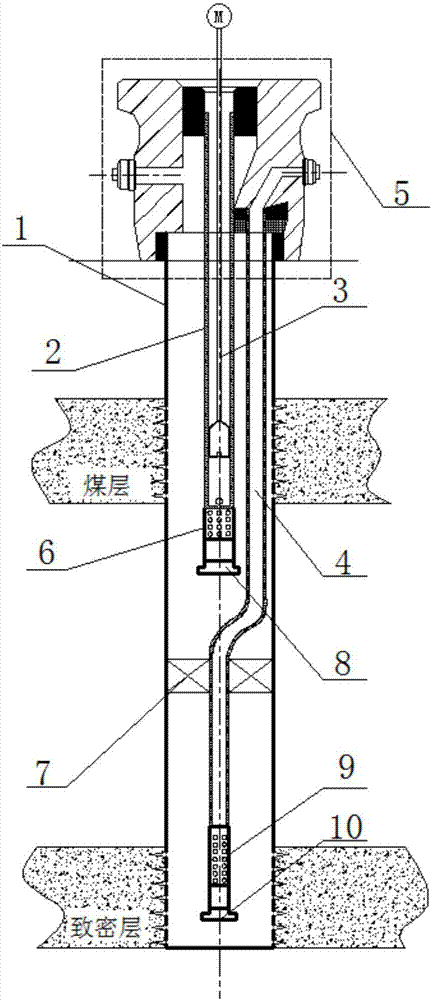

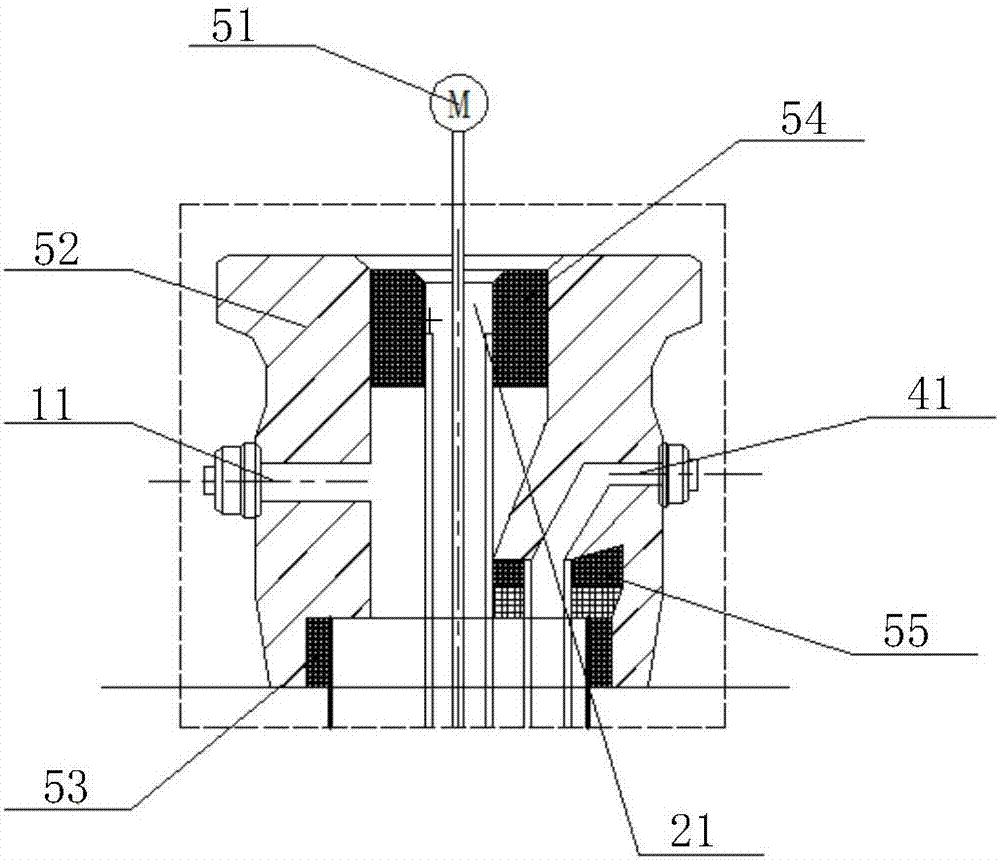

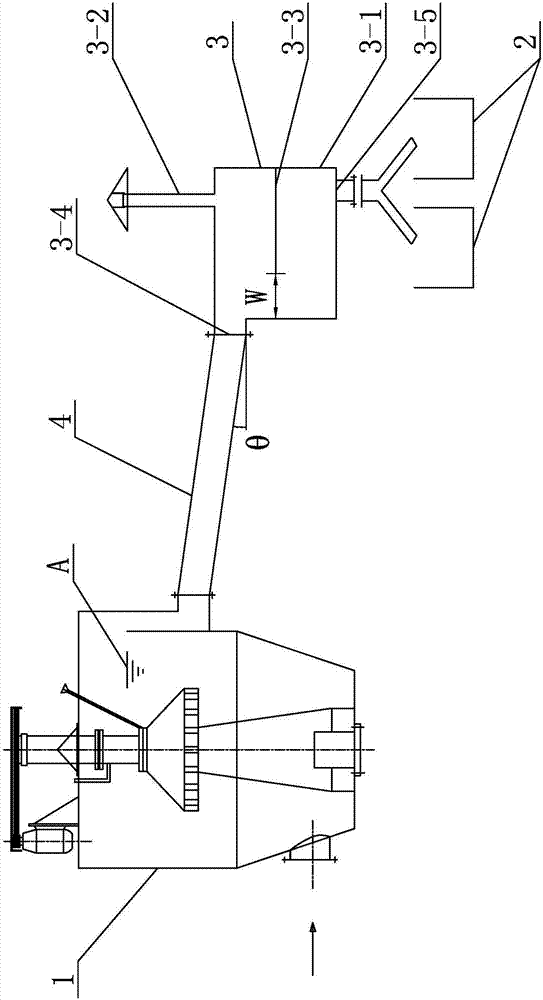

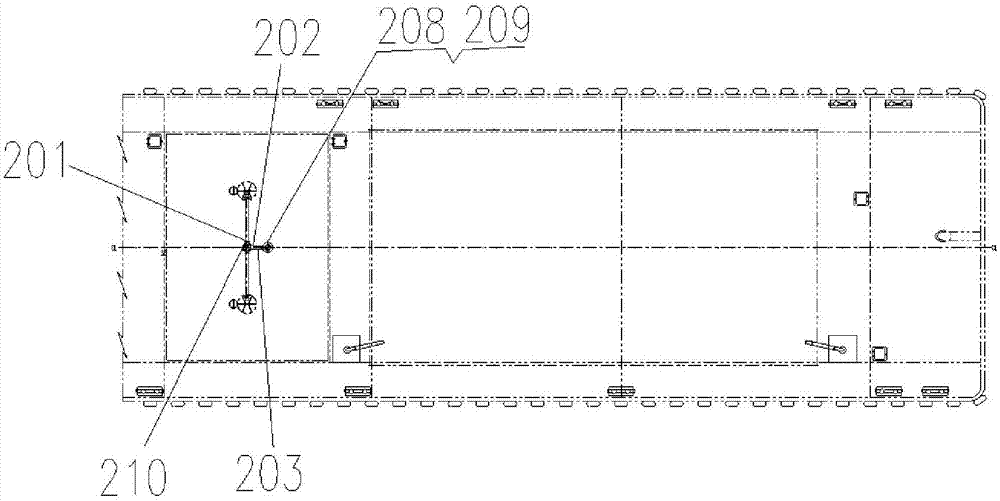

Dual-gas co-mining device

PendingCN107387020ANo streamingIncrease gas productionFluid removalSealing/packingCoal measuresDesorption

The invention discloses a dual-gas co-mining device which comprises a casing pipe, a first oil pipe, a second oil pipe and a bridge plug. During well-drain operation of a coal-bed gas well, perforation is performed on a tight sandstone layer, and the tight sandstone gas production layer or a shale gas production layer and a coal bed gas production layer is packed through the bridge plug; perforation is performed on the coal bed gas production layer; the second oil pipe and the first oil pipe with a sucker rod are sequentially placed into the casing pipe. The coal bed gas production layer is drained through a triple-extraction artificial lifting system, after a coal bed gas reservoir reaches desorption pressure, coal bed gas is annularly exhausted from the first oil pipe and the casing pipe, and gas production is achieved; the second oil pipe is used for performing tight sandstone gas exhaust and mining on the right sandstone layer or performing shale gas exhaust and mining on the shale layer. According to the dual-gas co-mining device, it is ensured that no series flow happens between different production layers, no airlocking happens during gas production, co-mining of dual gases of different buried depths and different gas production mechanisms is achieved, and the gas yield of the coal series gas well is effectively increased, and development economic benefits are increased.

Owner:CHINA UNITED COALBED METHANE +1

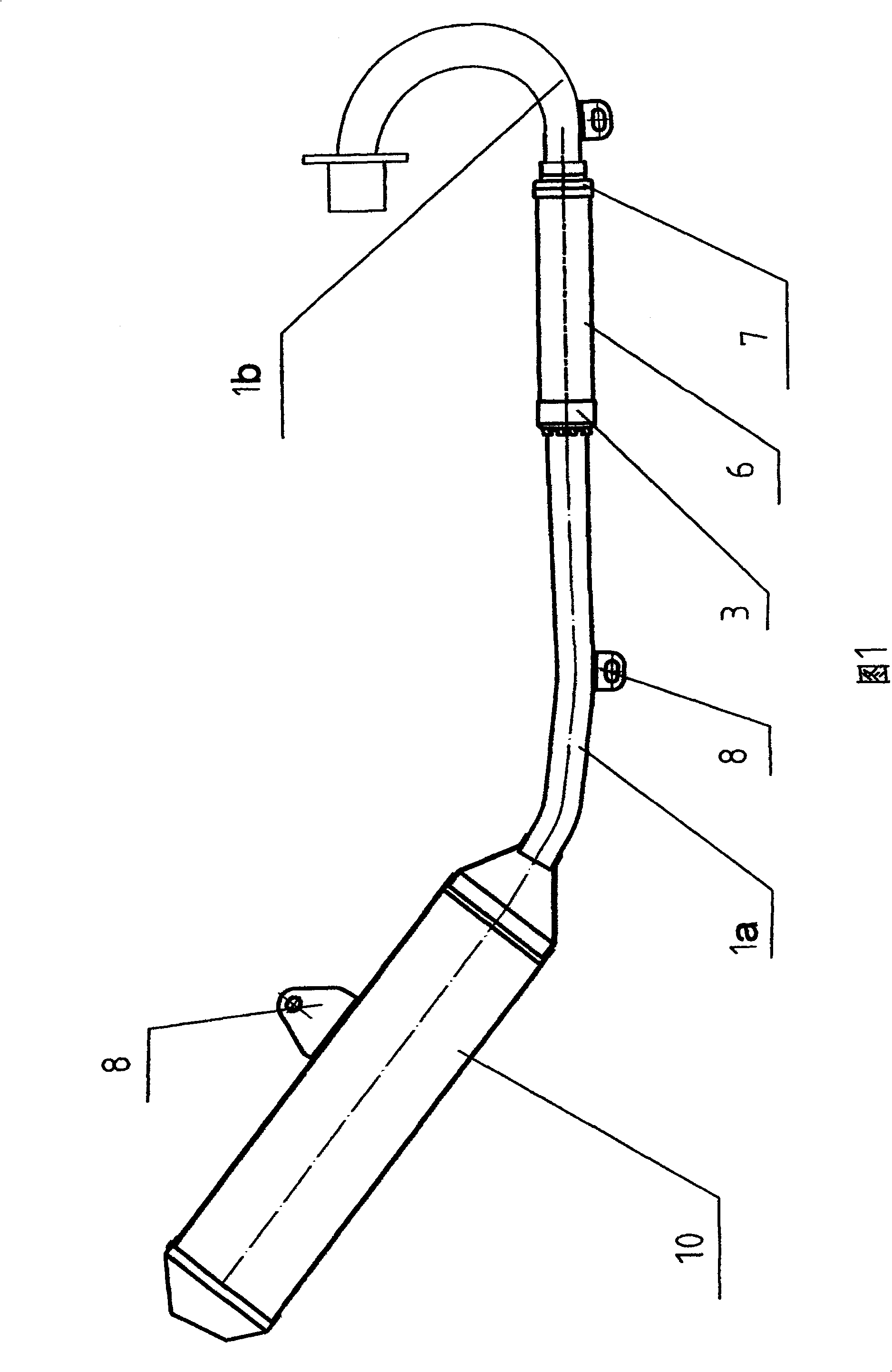

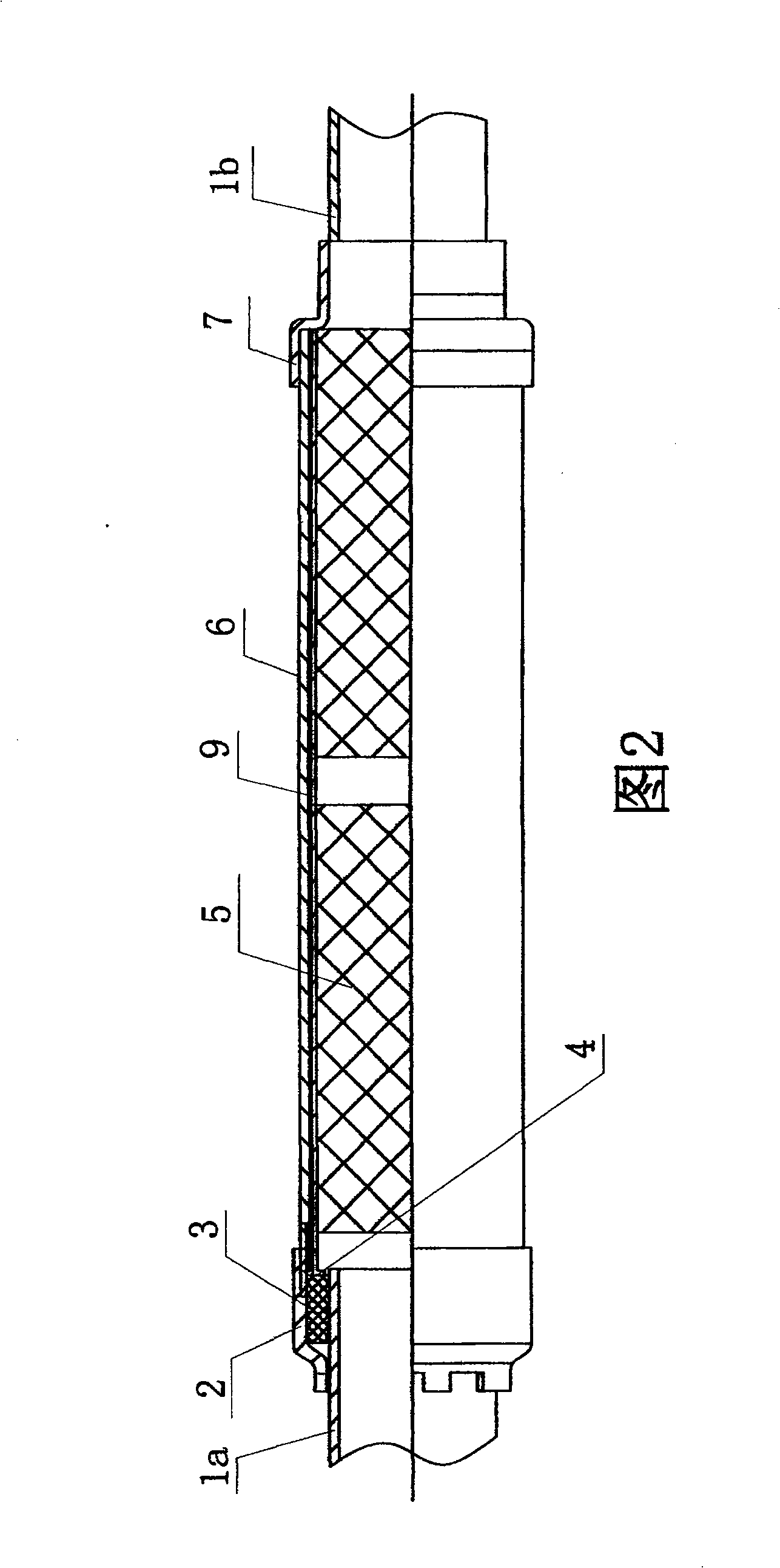

Vertical self-priming pump and vertical self-priming pump with filtration device

InactiveCN101424277AReduce constraintsEfficient deliveryPump componentsPriming pumpFiltrationEngineering

The subject of the invention is to provide a vertical self-suction pump which has low restriction in setting space and setting direction, and specifically provide a vertical self-suction pump which has easy and safe filter replacement operation, no requirement for pumping out the air in the pump or water injection before starting-up, and has low restriction in setting space and setting direction compared with the condition of adopting a horizontal pump structure, and is provided with a filtering device. The vertical self-suction pump adopts a valveless structure without a back valve. The vertical self-suction pump is characterized by comprising the following components: a pump part which is provided with a suction inlet, a suction chamber, an impeller, a self-suction chamber, a discharging opening in sequence from the upstream to the downstream of flow path, the suction inlet and the discharging opening are configured at positions above the suction chamber and the impeller, the self-suction chamber is configured at the position above the suction inlet and the discharging opening; and a driving part which is connected with the lower part of the pump body and becomes the driving source of pump body, wherein the rotation direction of impeller is an approximately horizontal direction.

Owner:WORLD CHEM CO LTD

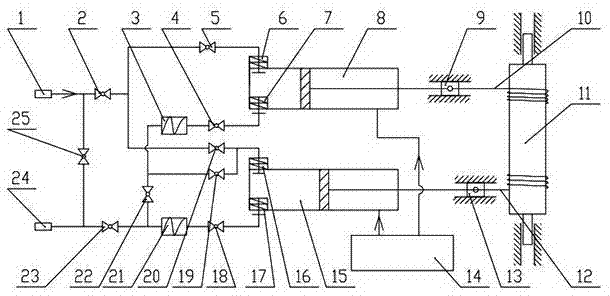

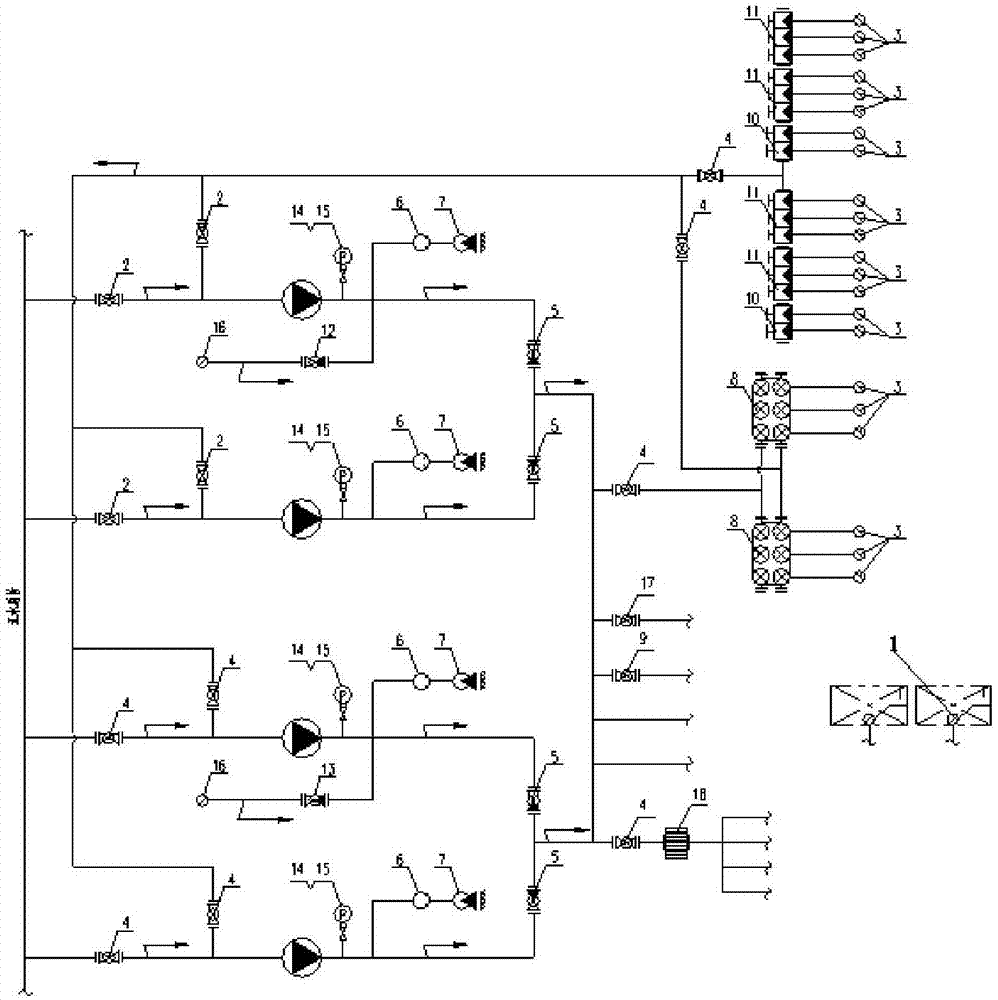

Pressurization and mixed transportation process and device of gas field well station

InactiveCN104500362ASupercharge effect is goodHigh mixing efficiencyFluid-pressure convertersPipeline systemsHydraulic cylinderReciprocating motion

The invention relates to a process and a device for performing the pressurization and the mixed transportation for natural gas in a gas field well station, and solves the problems of weak adaptability to variable working conditions, limited adjusting capacity and low mixed transportation efficiency in a traditional gas field natural gas compressor. A hydraulic cylinder A and a hydraulic cylinder B alternately pump in hydraulic oil under the control of a hydraulic working station to push a piston to move; with a steel wire rope A and a steel wire rope B, when any one of the hydraulic cylinders advances, the other one of the hydraulic cylinders can return, so that alternate reciprocating motion is realized; the hydraulic cylinder A and the hydraulic cylinder B not only can realize series connection operation, but also can realize parallel connecting operation; and the pressurization and the outward transportation of gas and liquid two-phase flows can be realized by continuous reciprocating motion of the hydraulic cylinder A and the hydraulic cylinder B under combined actions of a one-way valve A, a one-way valve B, a one-way valve C and a one-way valve D. The process and the device have strong adaptability to single wells, good pressurization effect on the gas and liquid two-phase flows and high mixed transportation efficiency, can be flexibly regulated according to the production conditions of single wells administered by a gas gathering station, and save the production cost.

Owner:CHENGDU TINGYUAN TECH

Clean gasoline fuel

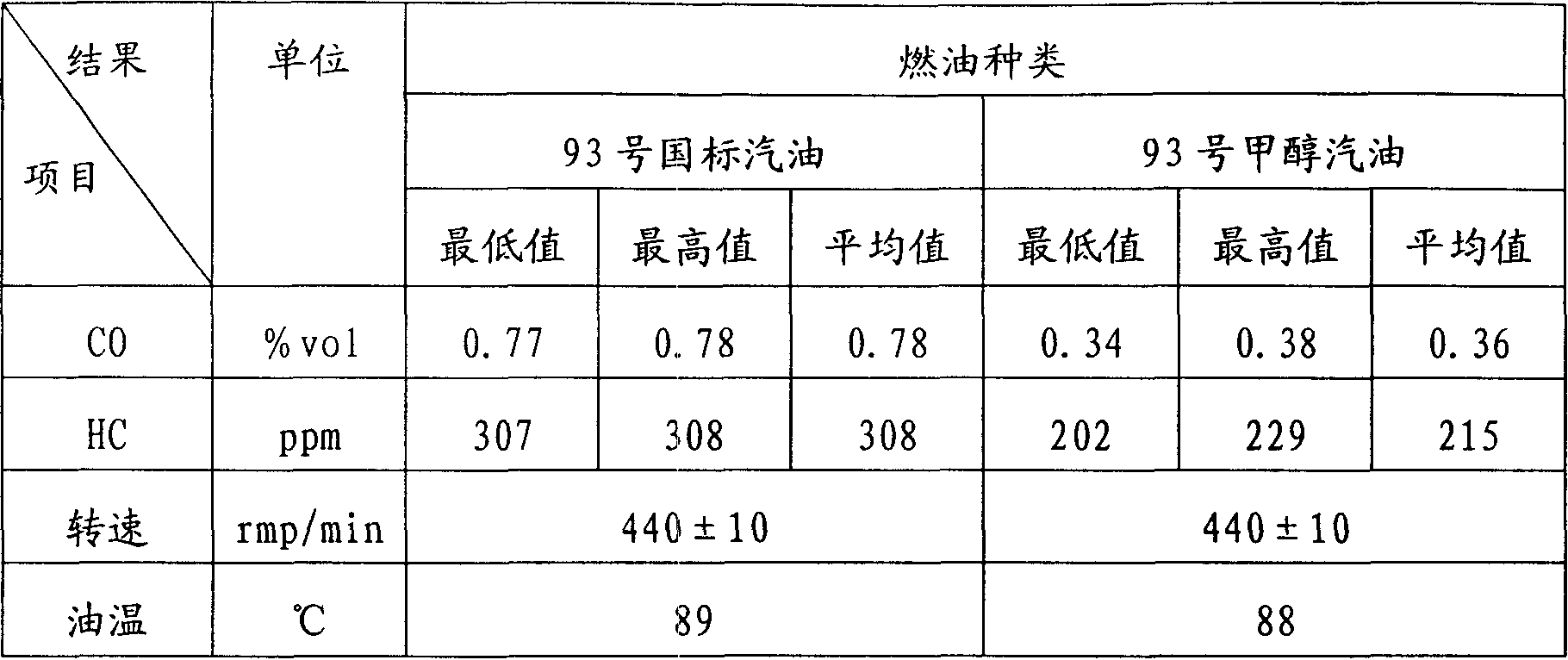

The present invention relates to vehicular fuel, and is especially one kind of clean gasoline fuel capable of replacing gasoline for use in vehicle. The clean gasoline fuel is mixture of additive 9-22 %, methanol 20-80 % and light oil, naphtha, solvent oil or gasoline 5-62 %. The clean gasoline fuel meets the standard of no-lead gasoline, has CO exhaust and hydrocarbon exhaust 46.2 % and 69.8 % lower than that of gasoline separately, and may be used in replacing vehicular gasoline.

Owner:任建伟 +1

High-cleanness methanol gasoline for vehicle

InactiveCN110885705AHigh calorific valueGood compatibilityLiquid carbonaceous fuelsMethanol fuelOil additive

Owner:中油新能源有限公司

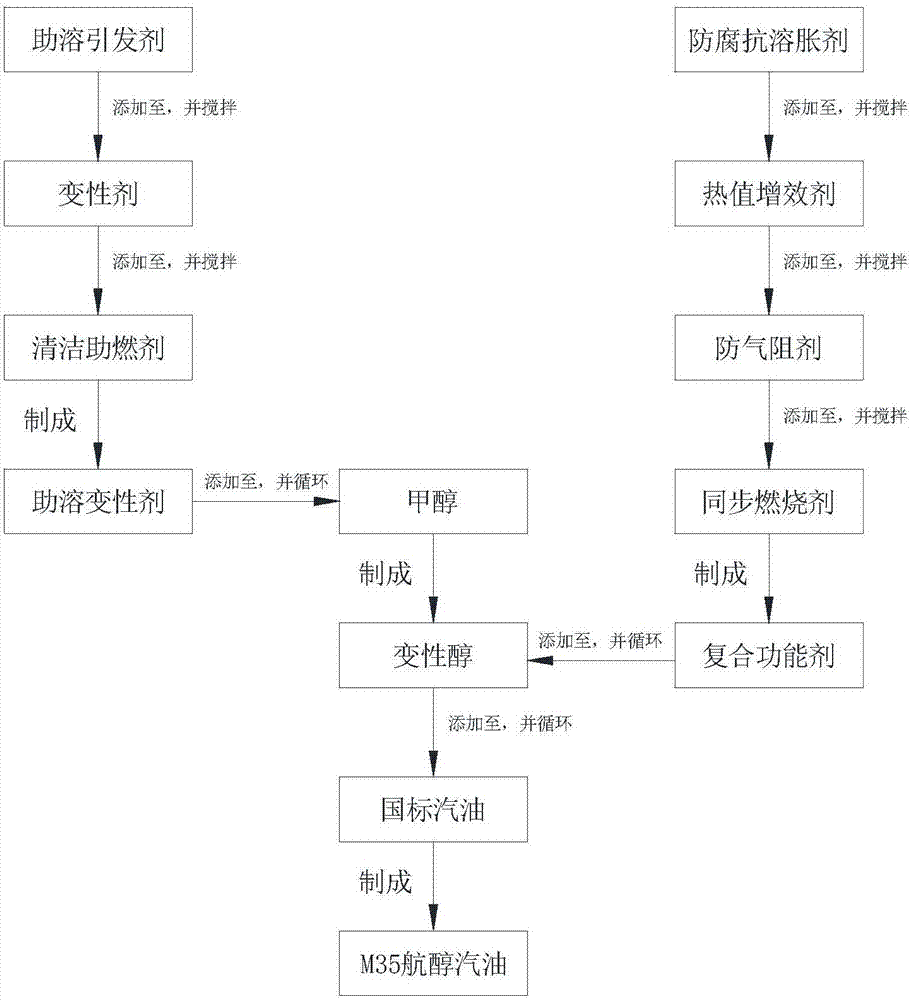

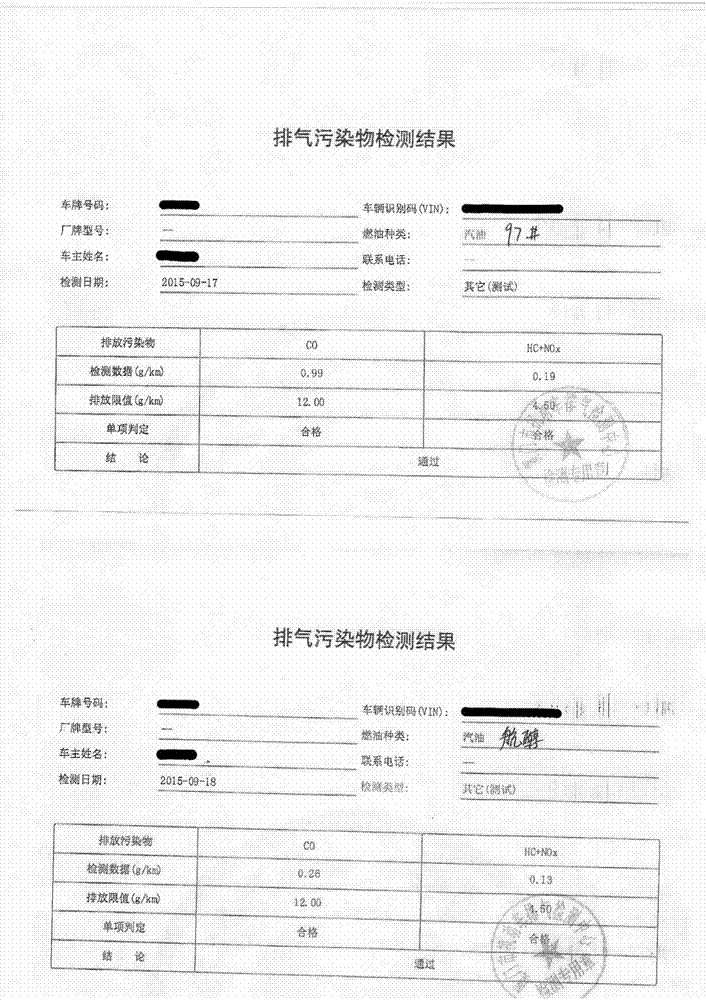

Vehicle EPM35 aerosol gasoline and production method thereof

InactiveCN107245354AReduce consumptionReduce pollutionLiquid carbonaceous fuelsFuel additivesComposite functionGasoline

The invention discloses a vehicle EPM35 aerosol gasoline. A purpose of the present invention is to solve a plurality of technical problems of storage and transportation stratification, low temperature cold starting, high temperature vapor lock, low antiknock property in the existing methanol gasoline. The aerosol gasoline comprises, by mass, 95% of a main combustion agent, 0.5-4% of a solubilizing denaturation agent, and 1-4.5% of a composite functional agent, wherein the main combustion agent comprises methanol and national standard gasoline, the methanol content is 30-40%, the national standard gasoline is 55-65%, the solubilizing denaturation agent comprises a solubilizing initiator, a denaturation agent and a cleaning combustion-supporting agent, and the composite functional agent comprises a heat value synergist, an anticorrosive anti-swelling agent, an anti-vapor lock agent and a synchronous combustion agent. The vehicle EPM35 aerosol gasoline of the present invention is not easily layered during storage and transportation, can avoid high temperature vapor lock and low temperature cold start, does not produce metal corrosion and non-metallic swelling, and further has advantages of environmental protection emission and the like.

Owner:寇延华

Novel liquid fuel and preparation method thereof

InactiveCN104611074AGood combustion continuityGood miscibilityLiquid carbonaceous fuelsLiquid fuelSolvent

The invention relates to the field of fuel preparation, particularly to a novel liquid fuel and a preparation method thereof. The novel liquid fuel provided by the invention is prepared from the compounding of a main material and three kinds of auxiliary solvents, the auxiliary solvents are successively mixed, the obtained mixed auxiliary solvent has good intersolubility, and no other impurities are generated; the mixed and dissolved auxiliary solvent is added in the main material so as to mutually dissolve with the ingredients in the main material, as a result, the ingredients can sufficiently react, the ingredients cooperate with one another, the prepared novel liquid fuel effectively solves the problem that the octane values of most standard fuels are substandard, and the anti-detonating quality enhancing effect is excellent; the problem of cold ignition boot is solved; the novel liquid fuel has the characteristics of energy conservation, emission reduction, high effects, environmental protection and easiness in use, the novel liquid fuel can be singly used in a large amount for a long time, and also can be mixed with conventional commercial gasoline, such as number 97, 93, in any proportion, bad influences cannot be generated, engines and the like do not need to be washed, and the novel liquid fuel has relieving and supplementing effects for the current domestic situation of resource shortage to some extent.

Owner:SICHUAN DIBIAO NEW ENERGY TECH CO LTD

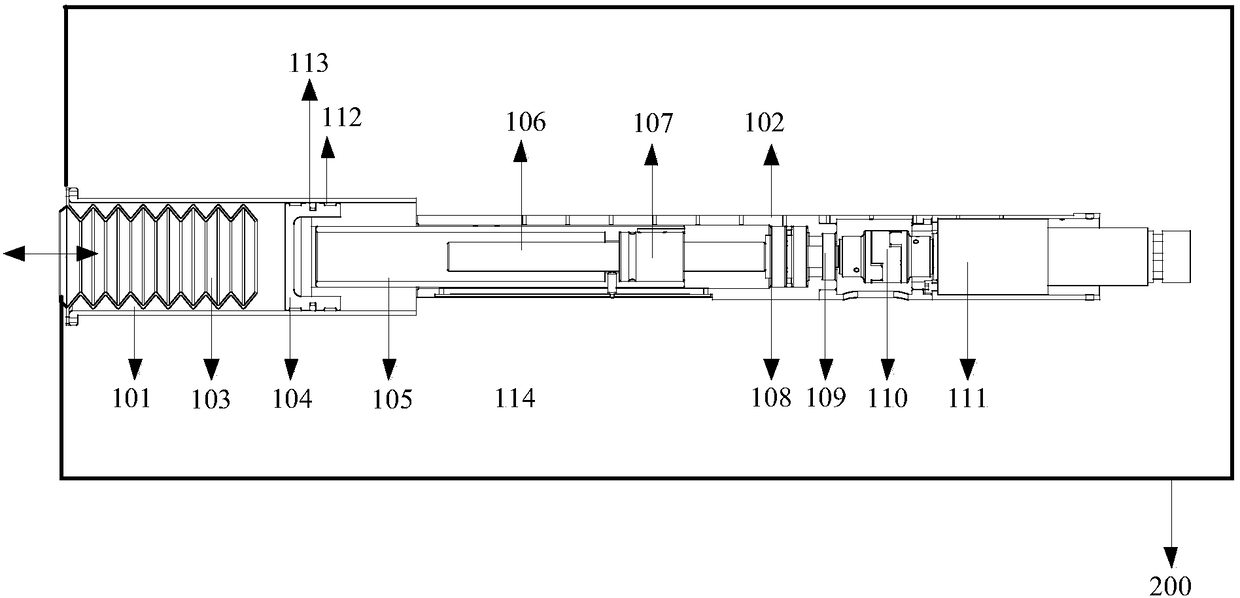

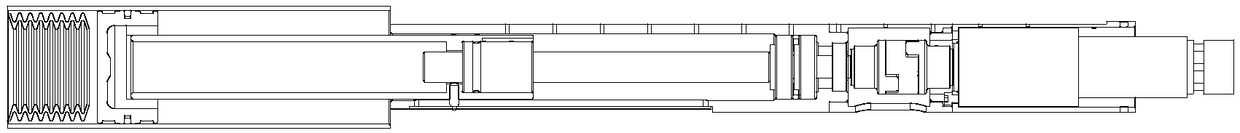

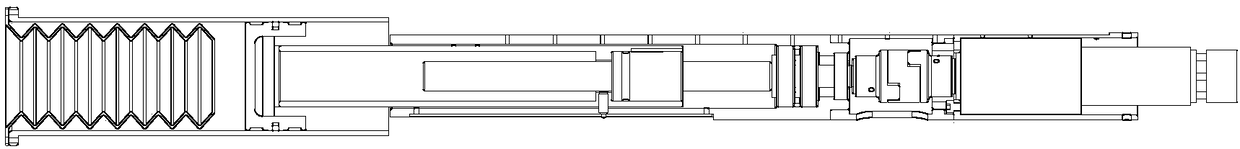

Buoyancy adjusting pump system for kilometric underwater glider

PendingCN108609144ALarge oil discharge volumeShort oil drain and oil absorption timesPiston pumpsPositive-displacement liquid enginesPistonUnderwater glider

The invention discloses a buoyancy adjusting pump system for a kilometric underwater glider. The buoyancy adjusting pump system comprises a piston cylinder and a transmission supporting cylinder whichare sequentially arranged in a cabin body from front to back in the longitudinal direction. The piston cylinder is provided with a front end opening communicating with the outside world. The rear endof the piston cylinder is fixedly connected with the transmission supporting cylinder. A corrugated expansion pipe and a piston which are coaxial with the piston cylinder are mounted in the piston cylinder. The corrugated expansion pipe is arranged in front of the piston, and the corrugated expansion pipe and the piston are arranged in an isolated mode. The corrugated expansion pipe is provided with a front end opening communicating with the outside world. The front end opening of the corrugated expansion pipe is fixed to the front end opening of the piston cylinder in a sealed mode. The rearend of the corrugated expansion pipe is provided with a back cover. A bellow-type oil bag is formed by the piston cylinder, the corrugated expansion pipe and the piston and is filled with hydraulic oil. A piston transmission mechanism is mounted in the transmission supporting cylinder. The buoyancy adjusting pump system can be suitable for the kilometric underwater glider and is large in displacement, high in speed, high in maneuverability and simple in structure.

Owner:STATE OCEAN TECH CENT

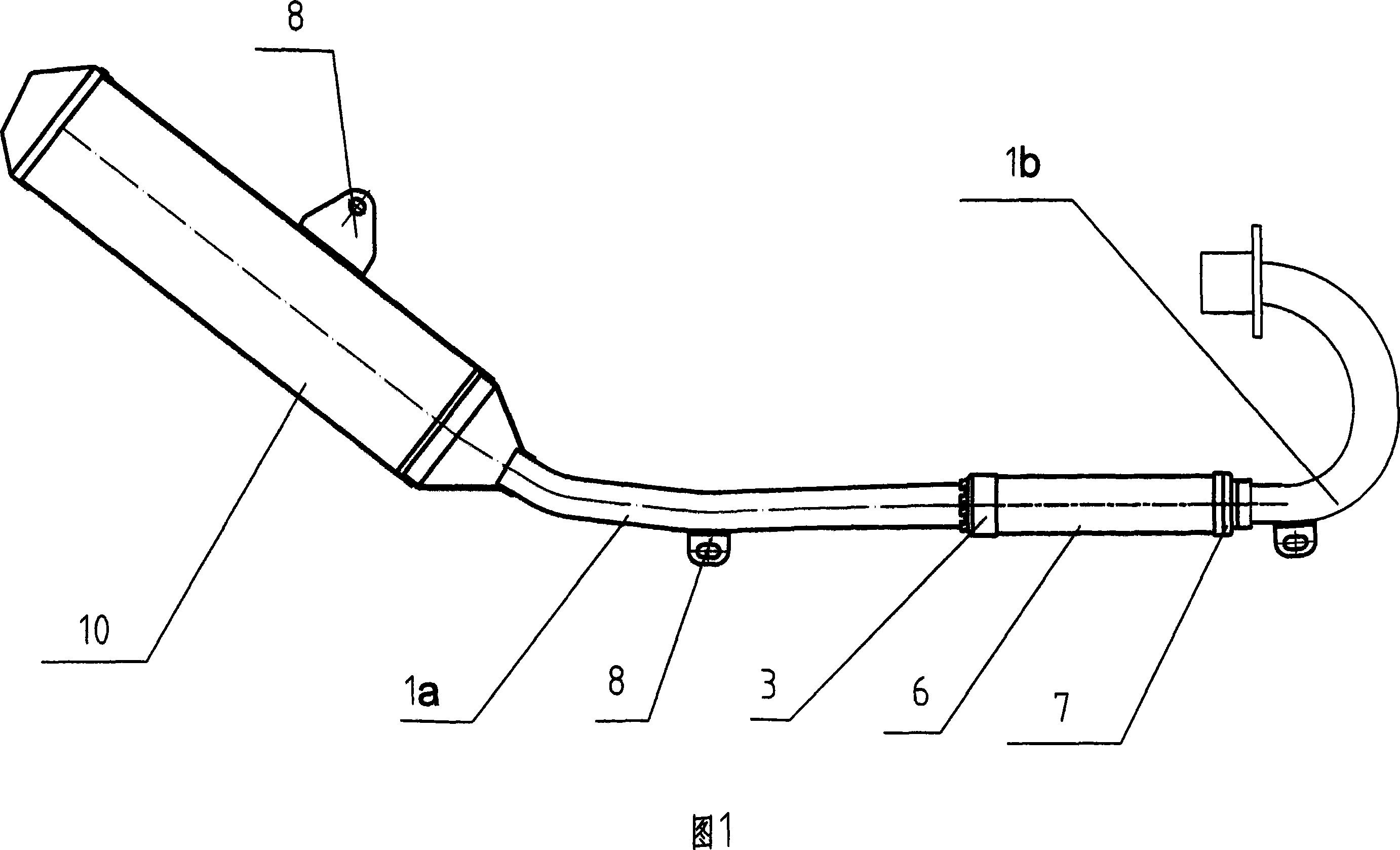

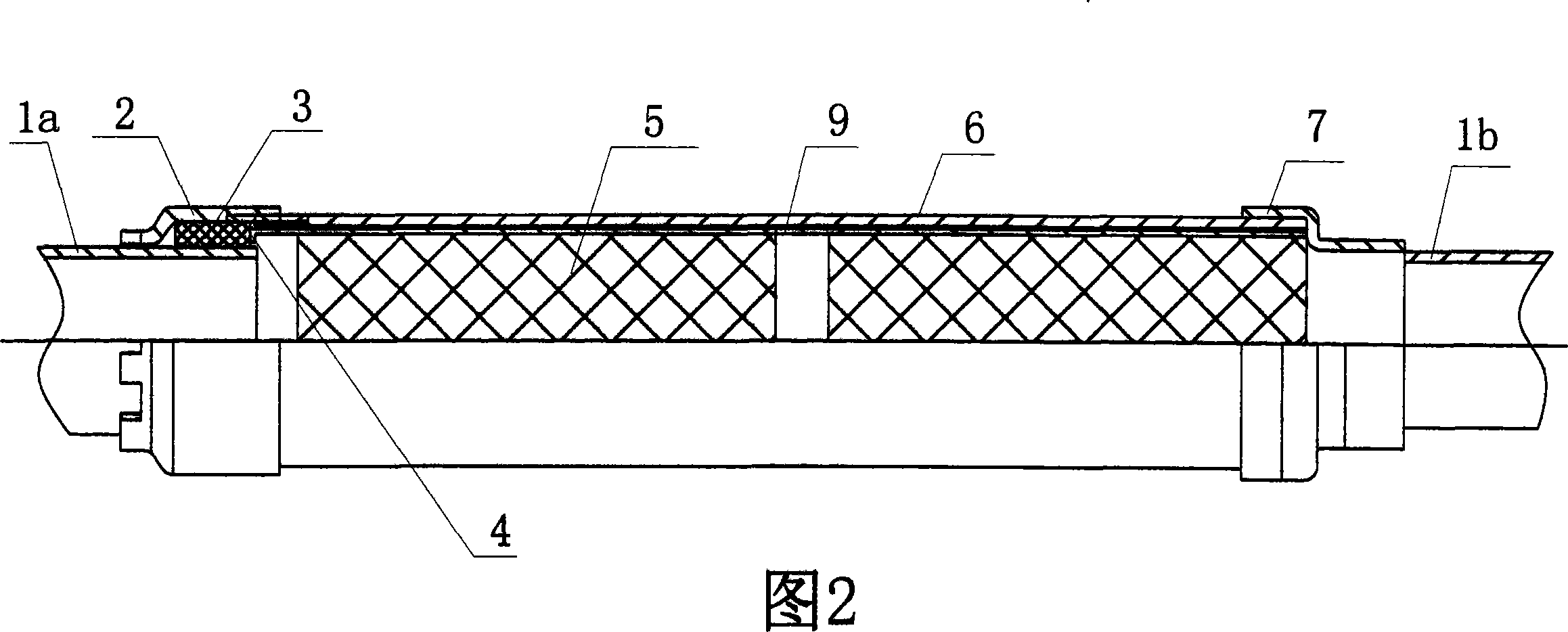

Detachable mounting structure of exhaust pipe catalytic converter

InactiveCN101070771AIncrease the cross-sectional areaImprove catalytic conversion effectExhaust apparatusSilencing apparatusVehicle frameMuffler

Owner:LONCIN MOTOR

Vehicular series methanol gasoline and preparing method thereof

The invention discloses a series of methanol gasoline for automobiles and a preparation method thereof. The methanol gasoline comprises (by weight parts) catalytic cracking gasoline 50 to 80, denatured methanol 3 to 40, and environment-protection non-benzene 120 solvent oil 5 to 20, wherein the denatured methanol comprises (by weight parts) oligomeric active polyisobutylene amine (PIBA) 70, ethyl hexa-nitroaniline (EHN) 1, water-free fusel oil 20, ethanol 9, and methanol 900. The preparation method of the methanol gasoline comprises the following steps of: (A) adding the water-free fusel oil into a mixing tank according to the ratio, sequentially adding the ethanol, the oligomeric active polyisobutylene amine, the ethyl hexa-nitroaniline and the methanol, and mixing uniformly to obtain the denatured methanol; and (B) adding the denatured methanol into the mixing tank, respectively adding the environment-protection non-benzene 120 solvent oil and the catalytic cracking gasoline, and mixing uniformly. The methanol gasoline is suitable for automobile in summer to prevent the occurrence of air lock, and has the advantages of simple preparation method and convenient popularization.

Owner:山西华顿实业有限公司

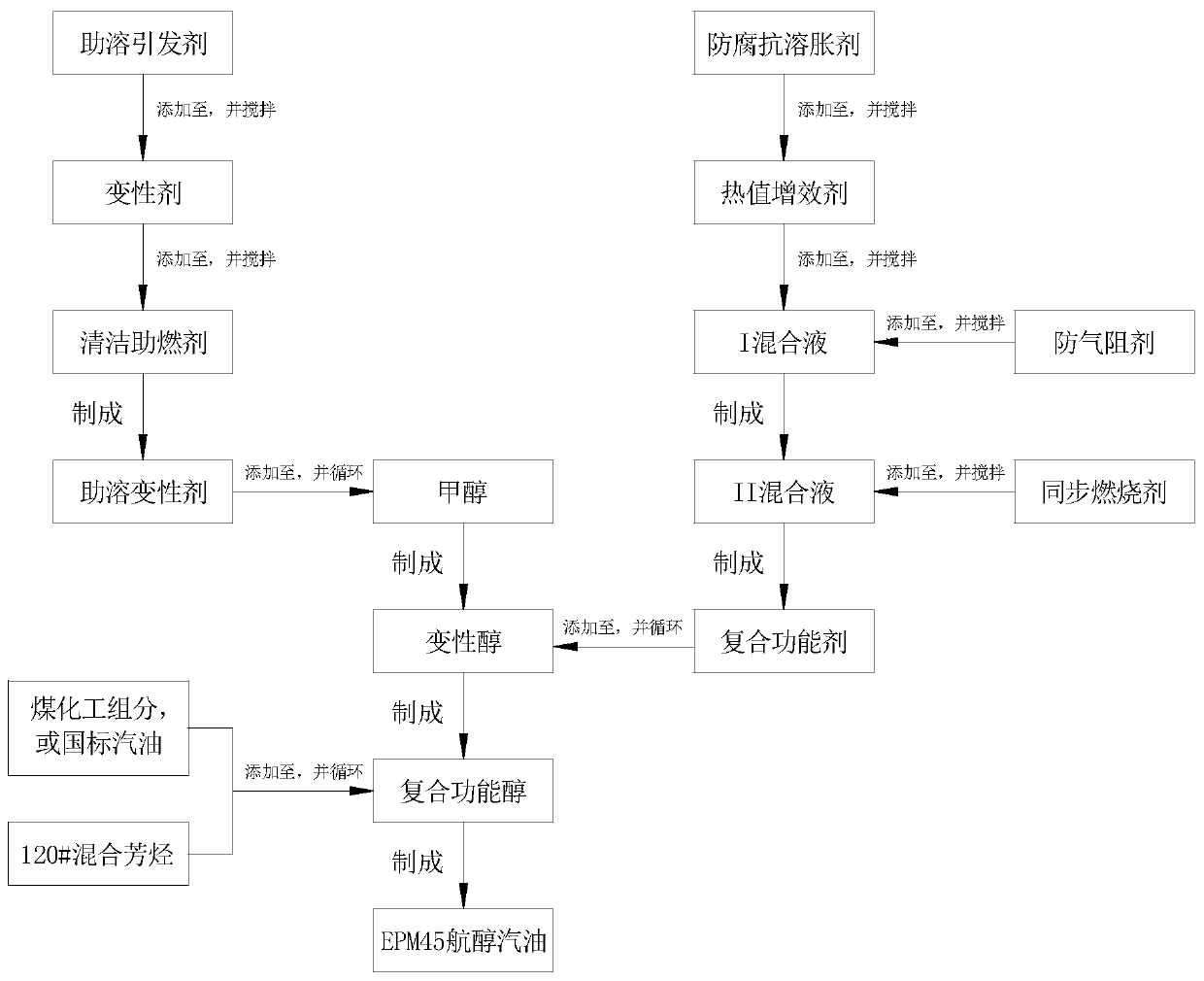

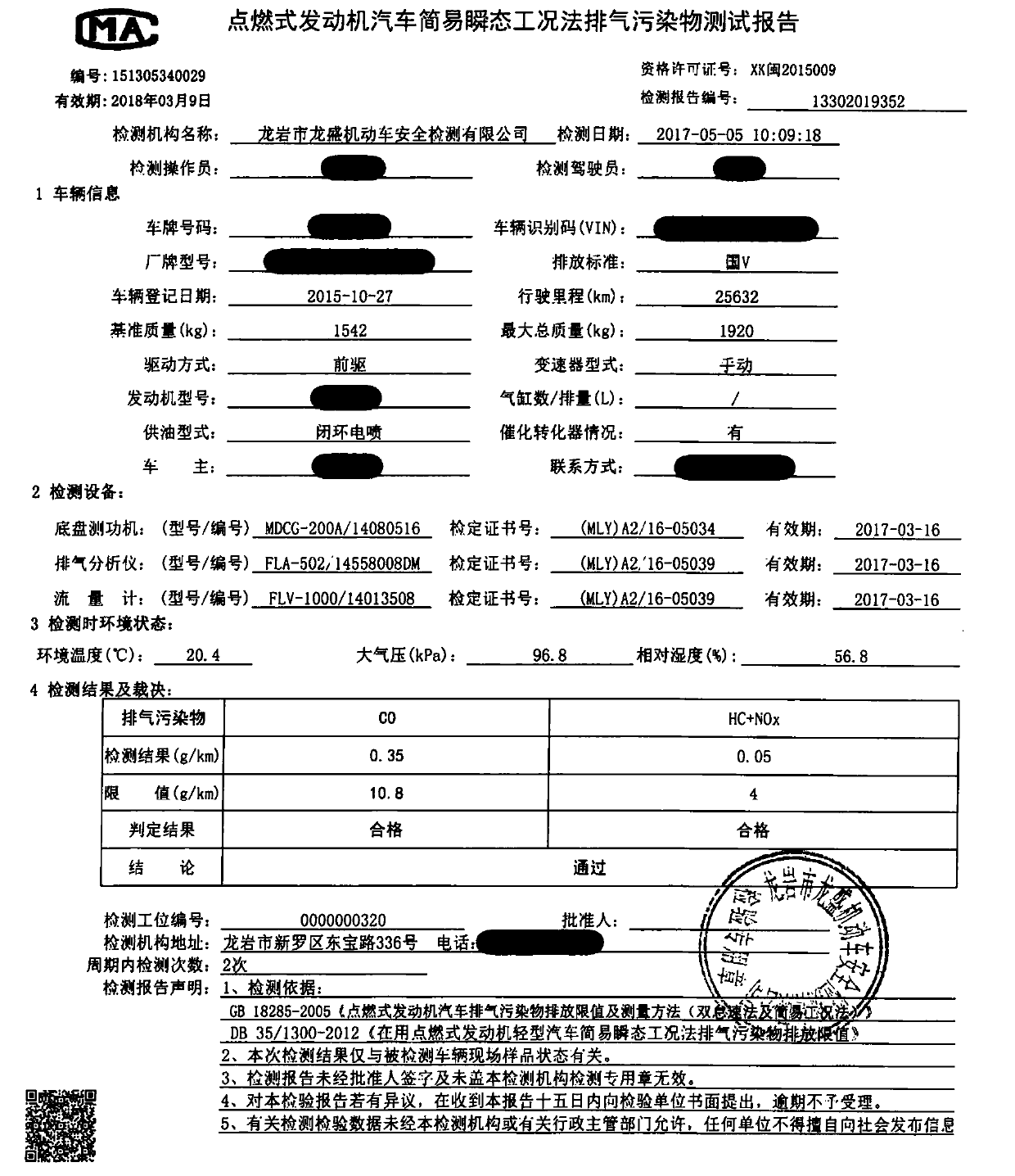

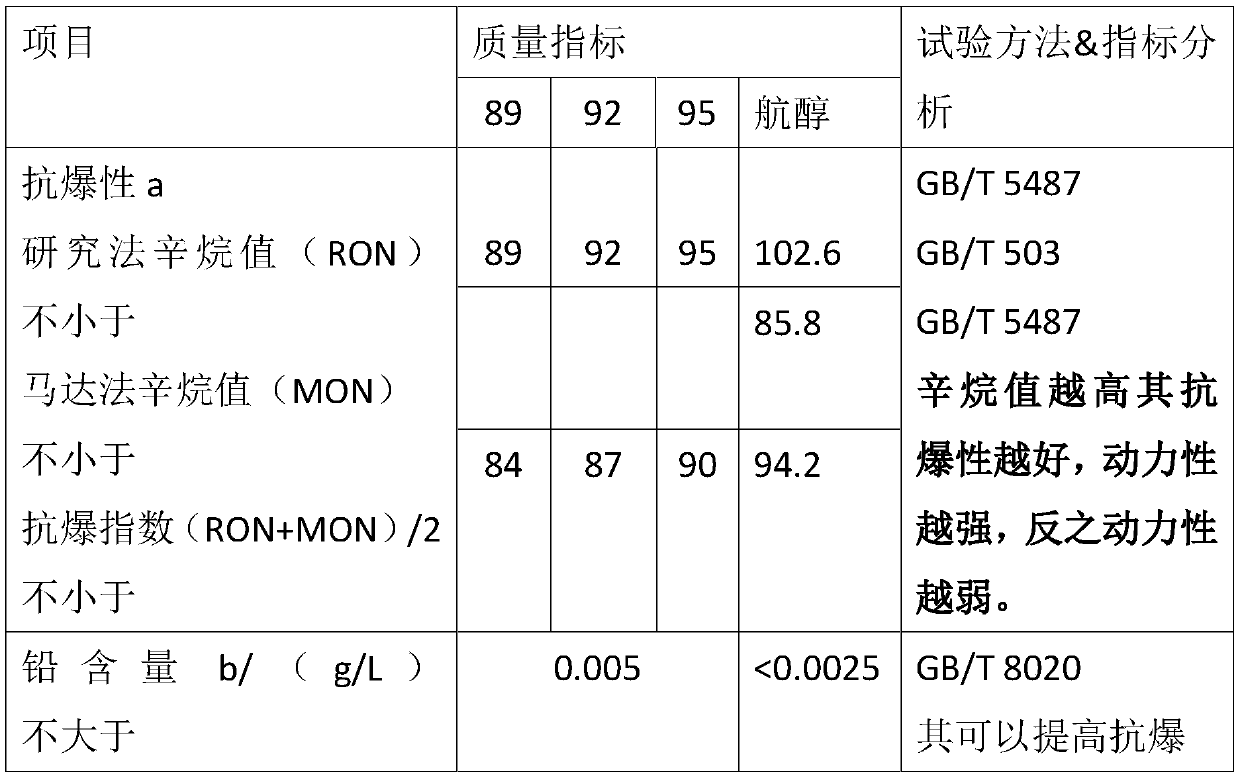

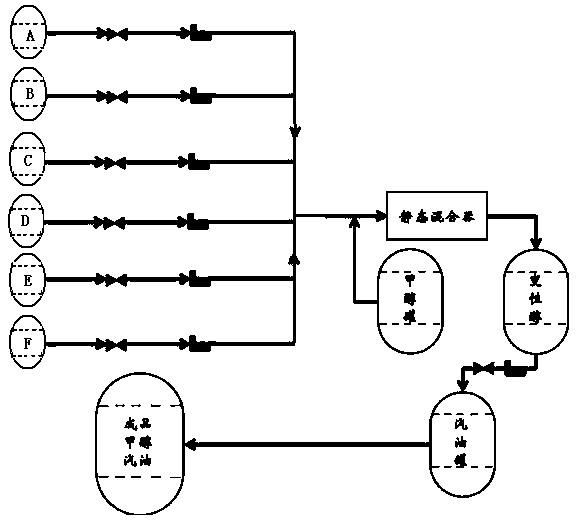

EPM45 navigation alcohol fuel for automobile and preparation method of EPM45 navigation alcohol fuel

InactiveCN110157498AReduce consumptionReduce pollutionLiquid carbonaceous fuelsEnvironmental resistanceAlcohol fuel

The invention discloses an EPM45 navigation alcohol fuel for an automobile, and solves the technical problems that current navigation alcohol fuel has a plurality of technical problems, such as stratification during storage and transportation, low-temperature cold starting, high-temperature air lock, and low explosion resistance. The navigation alcohol fuel comprises the following components, in percentages by mass: 95% of a main combustion agent, 1%-5% of a solubilization denaturing agent, and 1%-4.5% of a composite functional agent, wherein the main combustion agent includes 40-55% of methanol, 30-40% of a coal chemical component or Chinese standard gasoline and 5-20% of 120# mixed aromatic hydrocarbons; the solubilization denaturing agent includes a solubilization initiator, a denaturing agent and a clean combustion improver; and the composite functional agent includes a calorific value synergist, an antiseptic anti-swelling agent, an air lock prevention agent and a synchronous combustion agent. The EPM45 navigation alcohol fuel provided by the invention has the advantages of being not easy to stratify during storage and transportation, avoiding high-temperature air lock and low-temperature cold starting, and being free of metal corrosion and non-metal swelling, and friendly to environment during emission, and the like.

Owner:寇延华

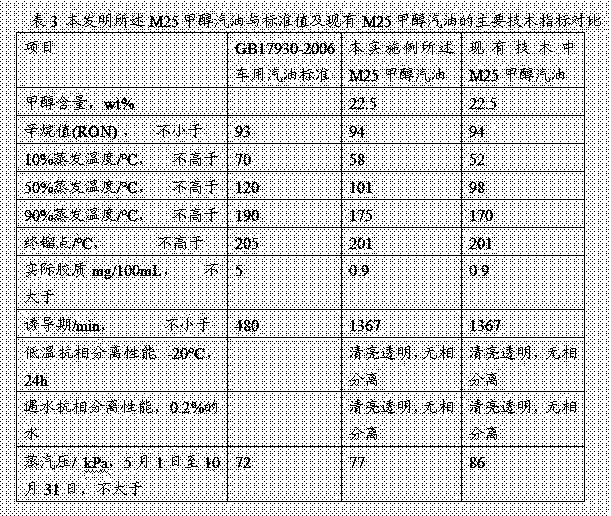

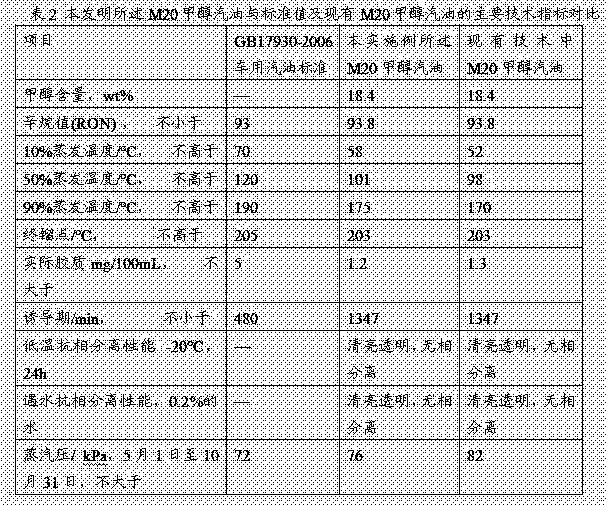

Compound additive for methanol gasoline, and preparation method and application thereof

ActiveCN102585932BLow saturated vapor pressureNo air lockLiquid carbonaceous fuelsFuel additivesGasolineMetal

The invention belongs to the field of clean fuels, and particularly relates to a compound additive for reducing saturated vapor pressure of methanol gasoline, and a preparation method for the compound additive, and application of the compound additive to preparation of M15-M25 methanol gasoline. The compound additive for the methanol gasoline consists of cosolvent, a dispersion stabilizer, a power accelerator, a vapor pressure adjustment inhibitor, a rubber swelling inhibitor, and a metal corrosion inhibitor in a selected weight part ratio. The compound additive for the methanol gasoline can effectively reduce the saturated vapor pressure of the methanol gasoline; even the compound additive is used in summer, the relative specification can also be met, the phenomenon of air resistance is avoided, and the technical problem that the methanol gasoline in a low proportion produces air resistance possibly in high-temperature summer, and cannot be supplied smoothly can be completely solved.

Owner:DONGFANG HONGSHENG NEW ENERGY APPL TECH RES INST +1

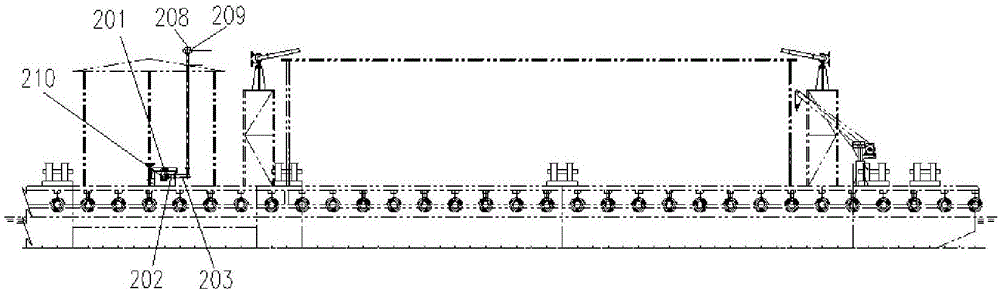

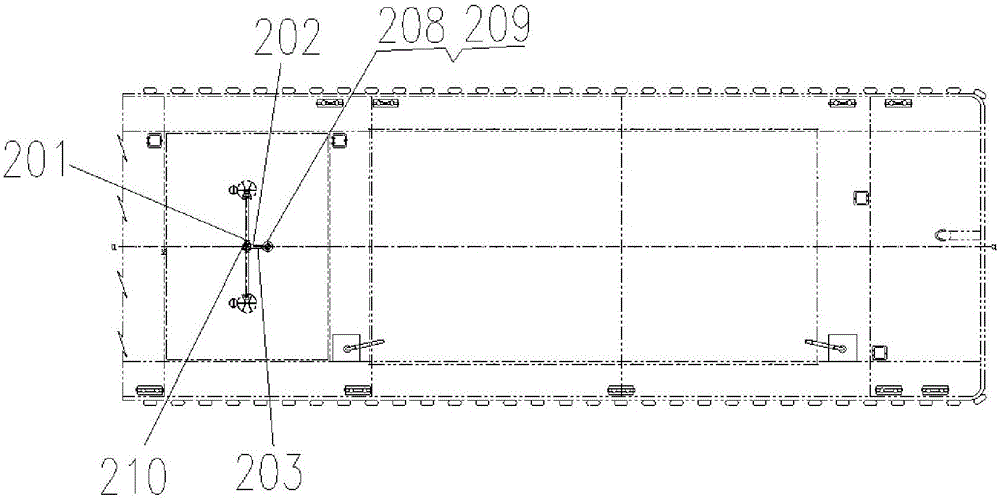

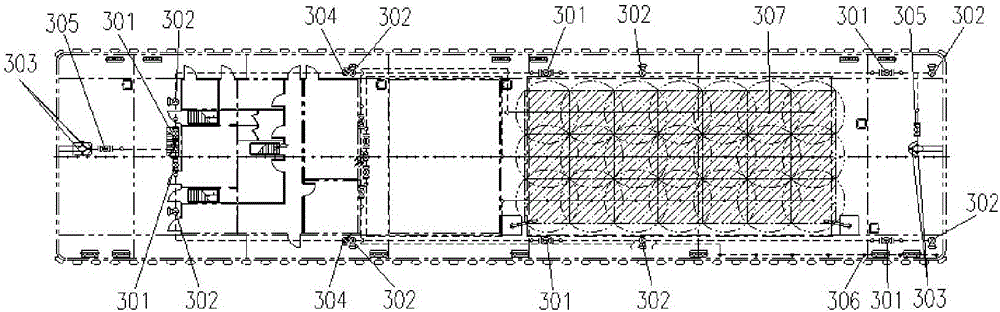

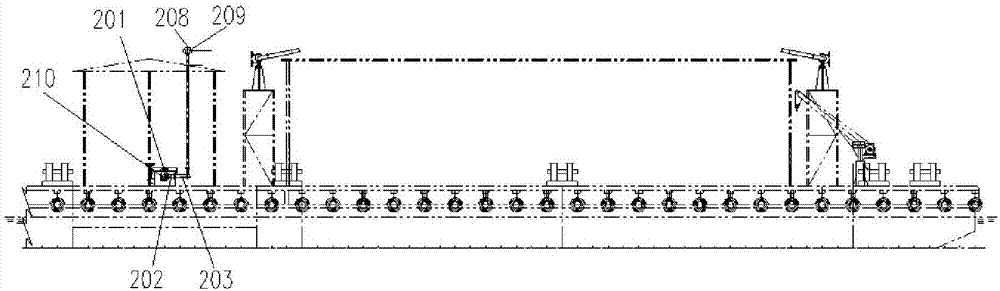

Liquefied natural gas (LNG)-fuel oil combined injection wharf boat

ActiveCN106080979AIncrease temperatureDisplay volumeCargo handling apparatusFire rescueFuel oilBallast

The invention relates to a liquefied natural gas (LNG)-fuel oil combined injection wharf boat which comprises a hold floor, a ballast system, a cargo oil tank ventilation system, a firefighting water mist and water curtain system, a whole ship ventilation and measurement system and a refueling system, wherein the hold floor is arranged in a cabin. The refueling system is provided with a refueling pipe system. According to the LNG-fuel oil combined injection wharf boat, overwater supply requirements are met, cleanliness and environment friendliness are achieved, the automation degree is high, and the energy-saving and emission reduction performance is good; and in addition, the informatization degree of the LNG-fuel oil combined injection wharf boat is higher than that of boats of the same type, the safety is good, the cost is low, the continuous injection capacity is high, and the comprehensive injection benefits are improved.

Owner:JIANGSU SHIP DESIGN & RES INST

Vehicular series methanol gasoline and preparing method thereof

The present invention discloses a series of methanol gasoline for automobiles and a preparation method thereof. The methanol gasoline comprises (by weight parts) catalytic cracking gasoline 50 to 80, denatured methanol 3 to 40, and environment-protection non-benzene 120 solvent oil 5 to 20, wherein the denatured methanol comprises (by weight parts) oligomeric active polyisobutylene amine 70, ethyl hexa-nitroaniline 1, water-free fusel oil 20, ethanol 9, and methanol 900. The preparation method of the methanol gasoline comprises the following steps of: (A) adding the water-free fusel oil into a mixing tank according to the ratio, sequentially adding the ethanol, the oligomeric active polyisobutylene amine, the ethyl hexa-nitroaniline and the methanol, and mixing uniformly to obtain the denatured methanol; and (B) adding the denatured methanol into the mixing tank, respectively adding the environment-protection non-benzene 120 solvent oil and the catalytic cracking gasoline, and mixing uniformly. The methanol gasoline is suitable for automobile in summer to prevent the occurrence of air lock, and has the advantages of simple preparation method and convenient popularization.

Owner:山西华顿实业有限公司

Production process of diesel engine M100 balance fuel product

InactiveCN109628170AIncrease motivationEnhances Non-Laying Non-EmulsifyingLiquid carbonaceous fuelsAlkaneSolvent

The invention provides a production process of a diesel engine M100 balance fuel product. The product is prepared by mixing 75-79 parts of methanol, 9-12 parts of component oil and 1%-4% of an additive, the component oil is prepared from, 10%-14% of solvent oil, 28-31 parts of saturated alkane, 0.03-0.06 part of N,N'-diisobutylphenyldiamine, 0.4-0.7 part of sodium petroleum sulfonate, 2-5 parts ofglycerol, 0.2-0.5 part of copper naphthenate, 17%-20% of a diesel and 4-7 parts of of isopentane, and the additive is prepared from, 3-6 parts of an ethylene glycol methyl ether, 0.05-0.08 part of N,N'-Eriya salicyl-1,2-propylenediamine, 2-5 parts of hydrogen peroxide and 0.07-0.10 part of alkyl nitrate. The process can be directly used on a diesel engine, enhance the power of the fuel product,do not conduct laying and emulsification to ensure normal combustion, and meet and exceed fuel environmental protection requirements required by a state by using a relatively economical use price andthe fuel product with a stable phase, and the adjusted oil product meets the various power and calorific value requirements of a gasoline engine, and achieves stronger power and better economy than agasoline.

Owner:湖南加立减新能源科技有限公司

Alcohol-based clean fuel

InactiveCN109628165AReduce solubilityBoost octaneLiquid carbonaceous fuelsFuel additivesChemistryPetroleum

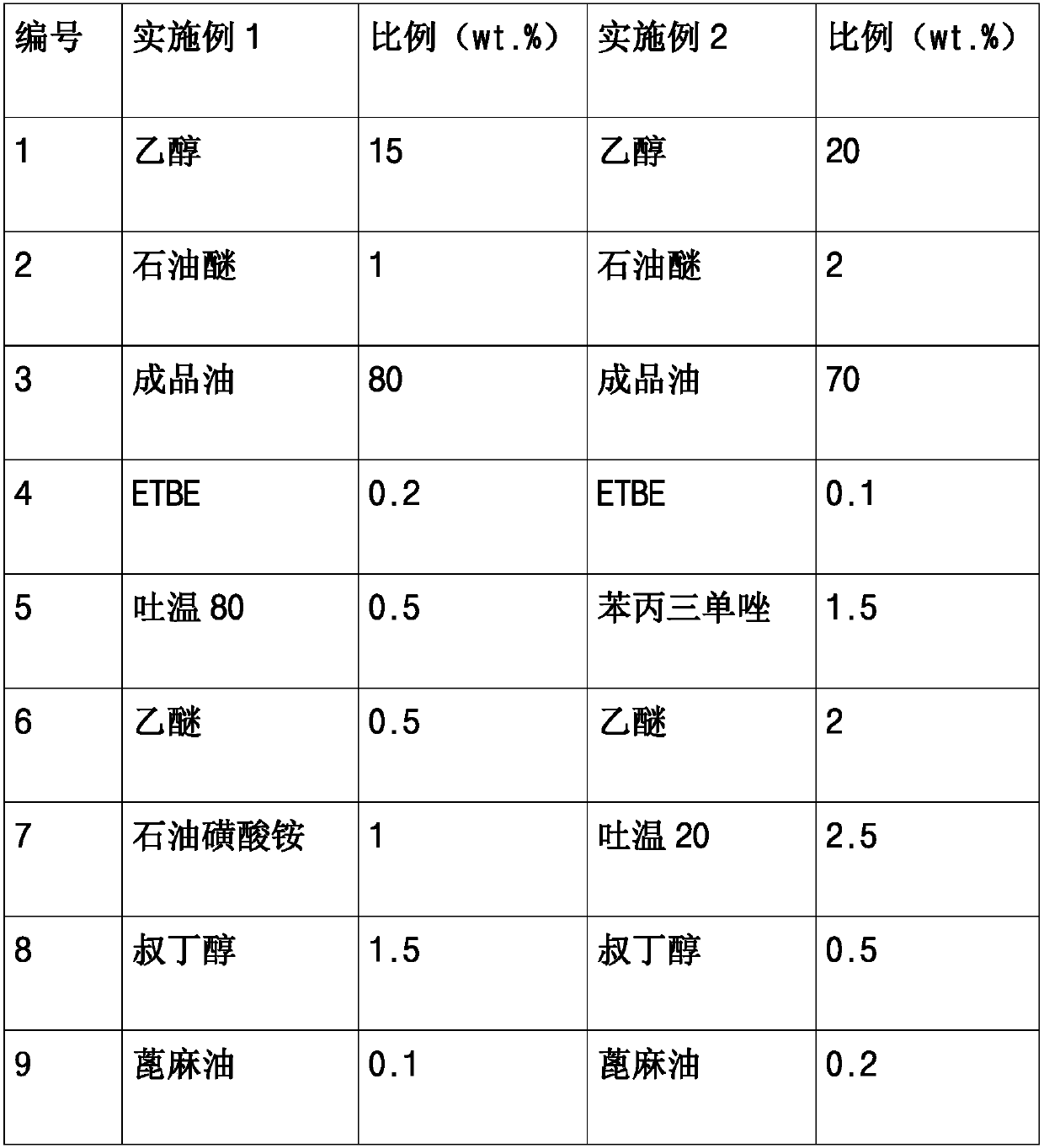

The invention relates to alcohol-based clean fuel. The alcohol-based clean fuel is prepared from 15-30% of ethyl alcohol, 1-3% of petroleum ether or naphtha, 70-85% of gasoline, 0.5-1.5% of Tween-80 or benzotriazole, 0.1-0.2% of ethyl tert butyl ether (ETBE), 0.5-2% of diethyl ether, 1-3% of petroleum ammonium sulphonate or Tween-20 or triethanolamine, 0.3-1.5% of tertiary butanol or isopropanol,0.1-1% of castor oil, 0.1-2% of cyclohexanone and 0.1-2.4% of trimethyl butane. The participation amount of the ethyl alcohol of the fuel is large, no layering is caused during use, air resistance canbe avoided, power is strong, corrosion to metal is low, the swelling property of an engine sealing ring is low, a vehicle engine does not need to be modified, and the engine is easy to start in a low-temperature state during use.

Owner:GUOHAO BEIJING NEW ENERGY TECH DEV CO LTD

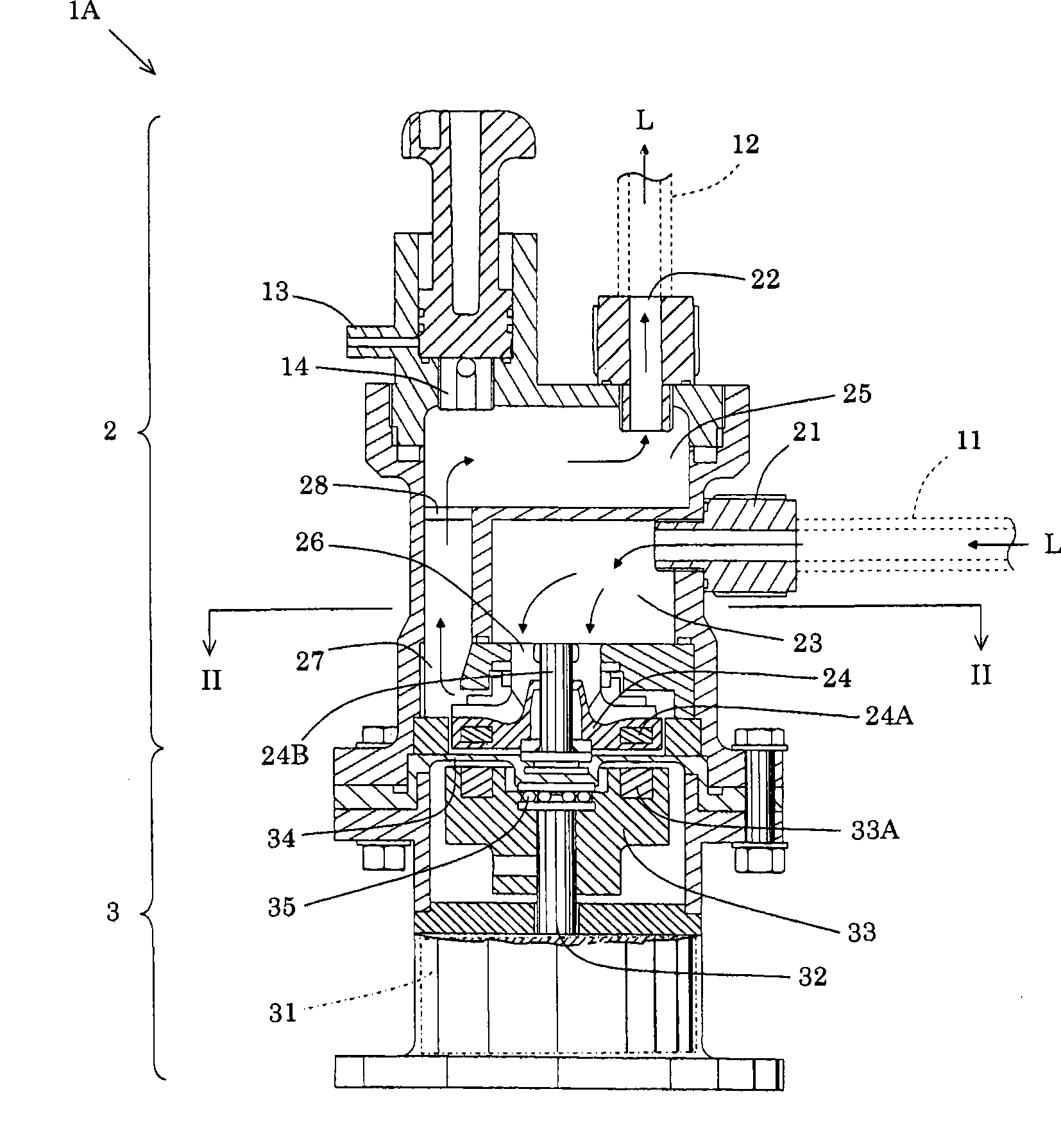

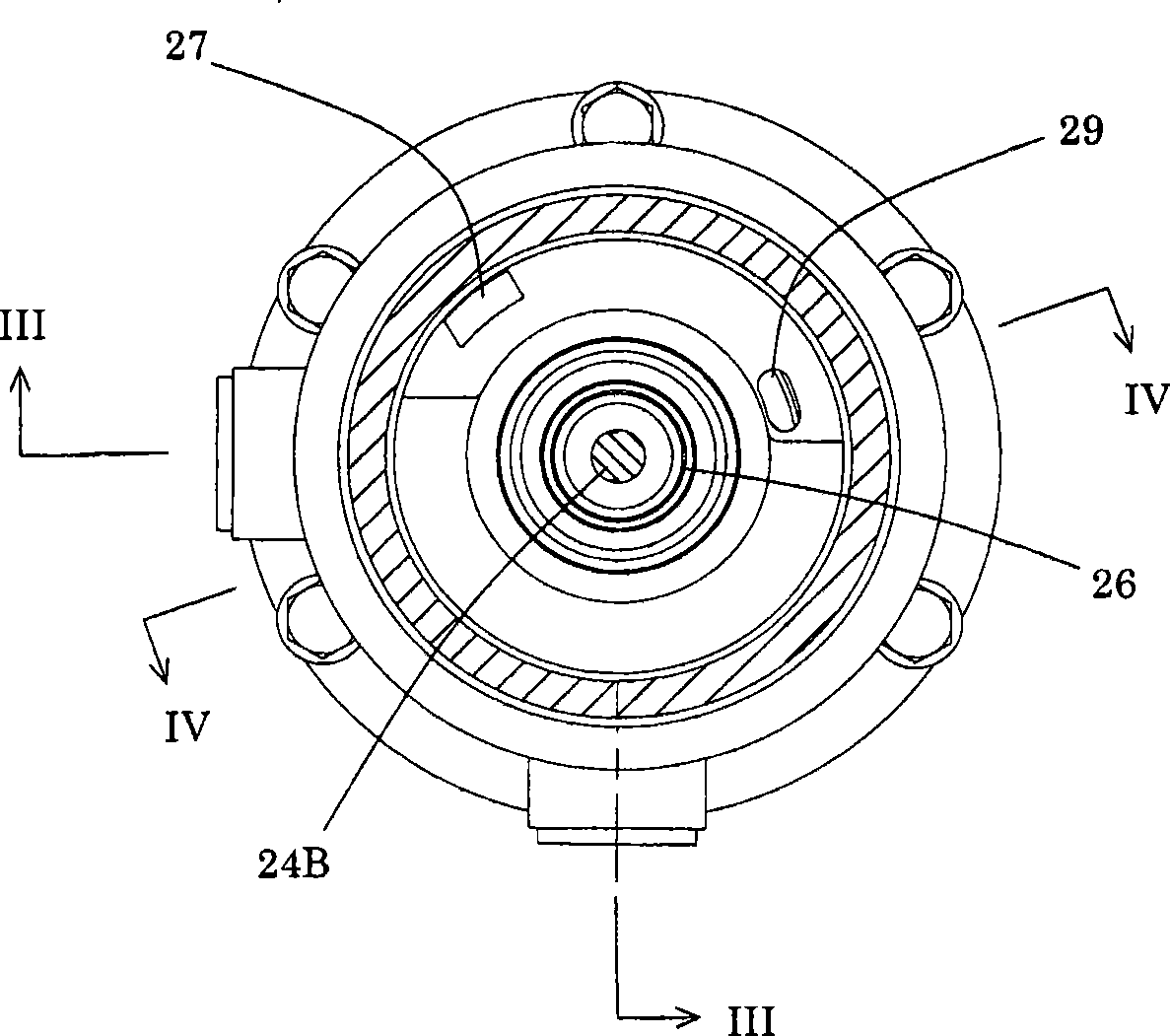

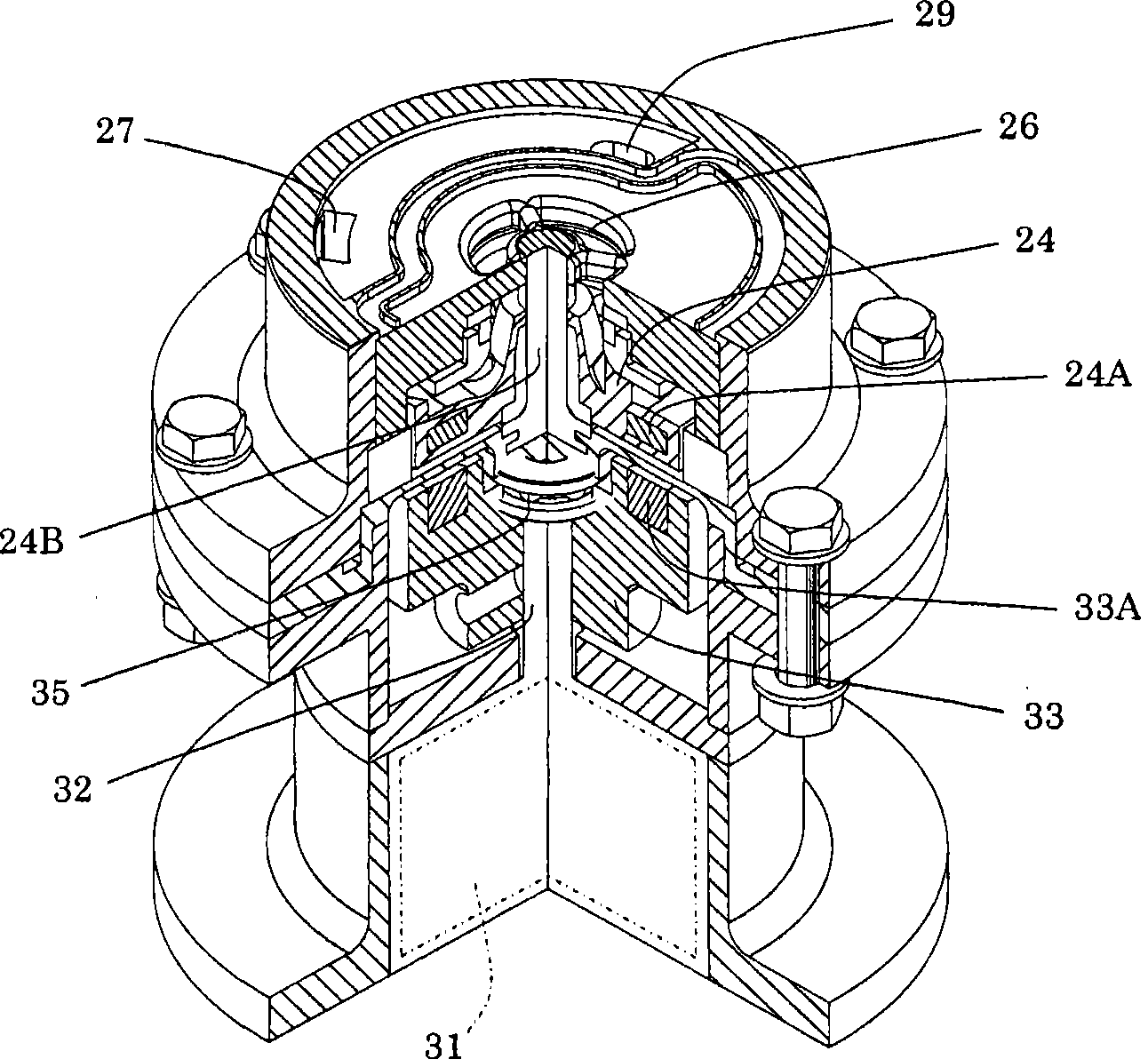

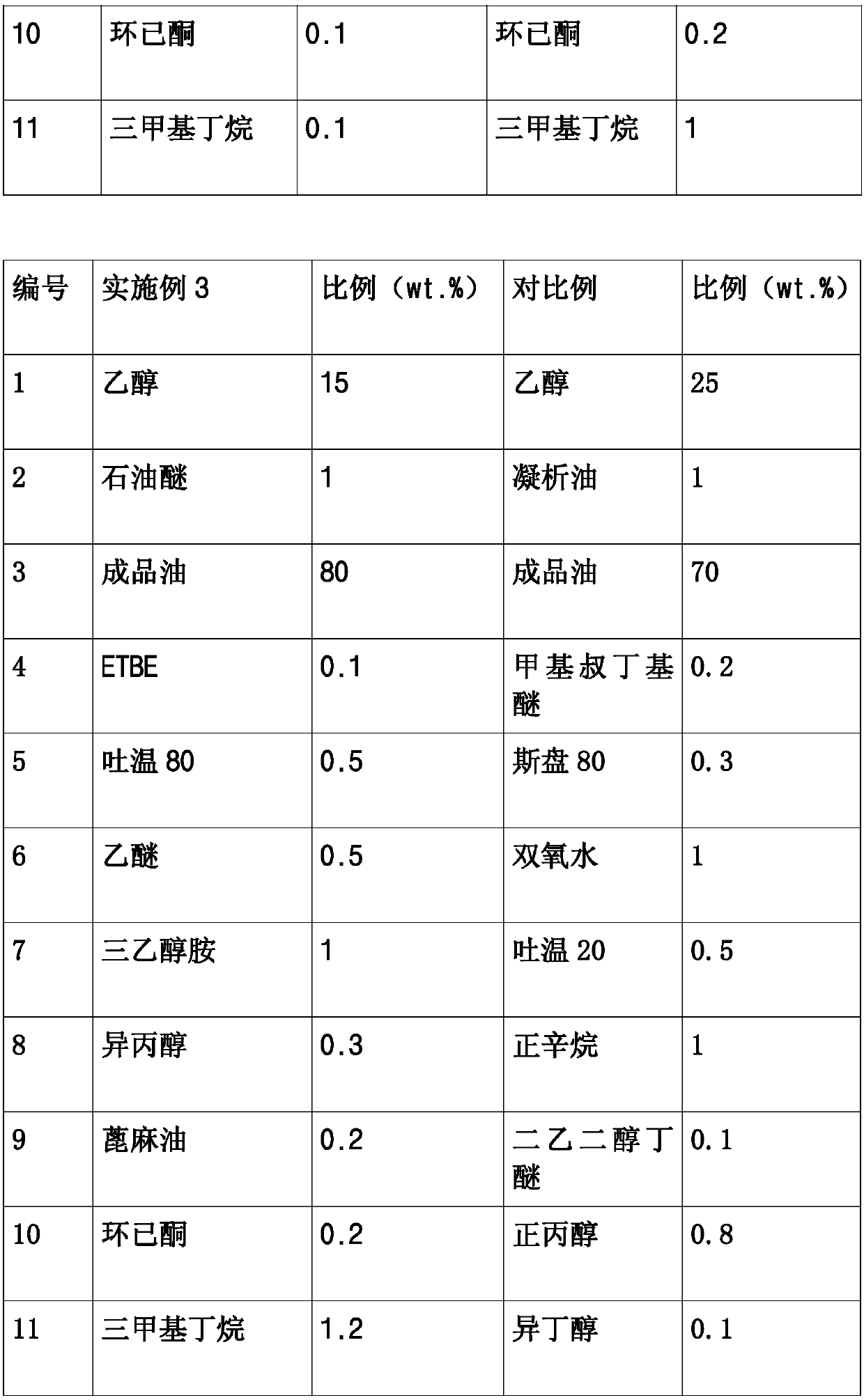

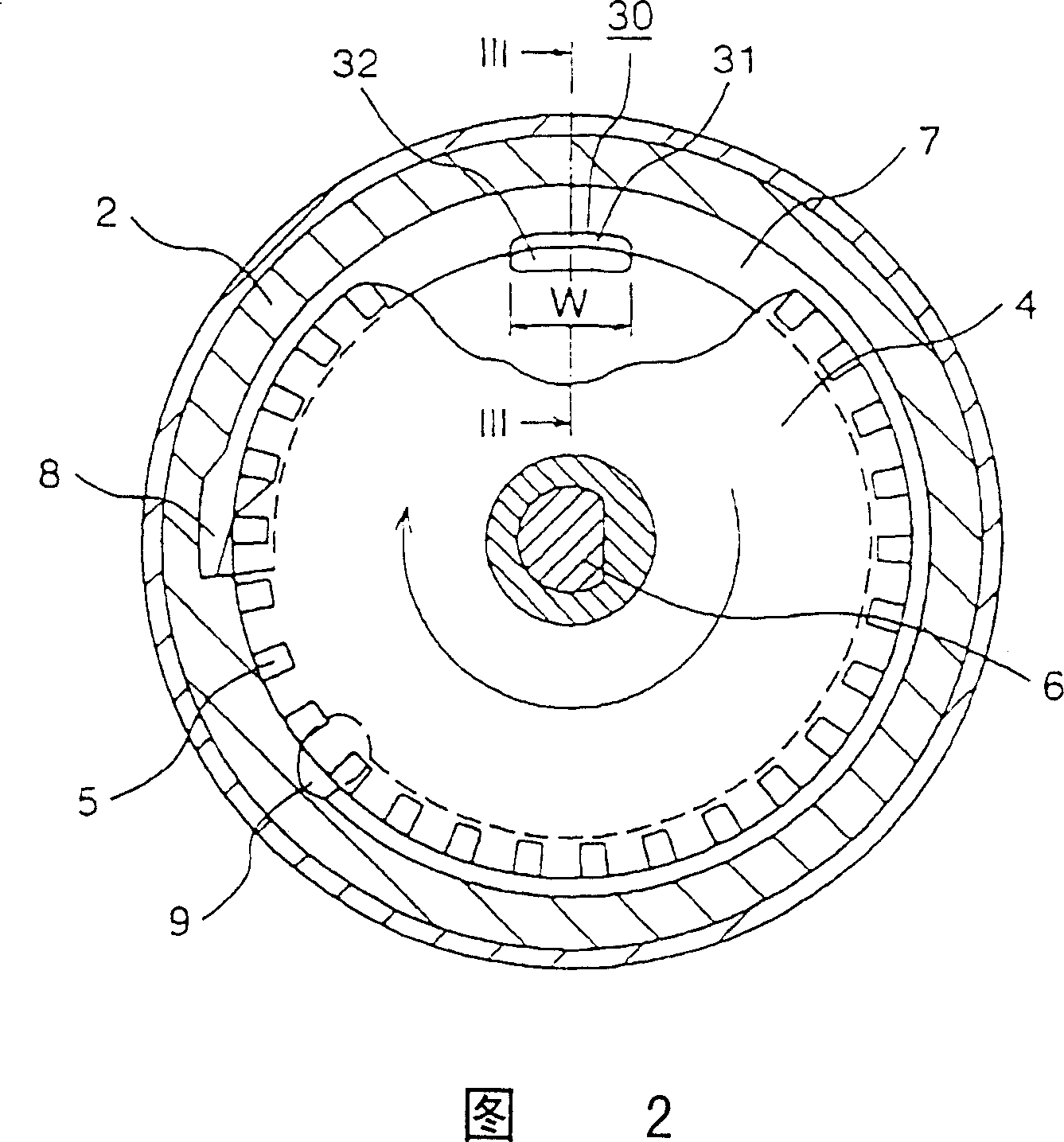

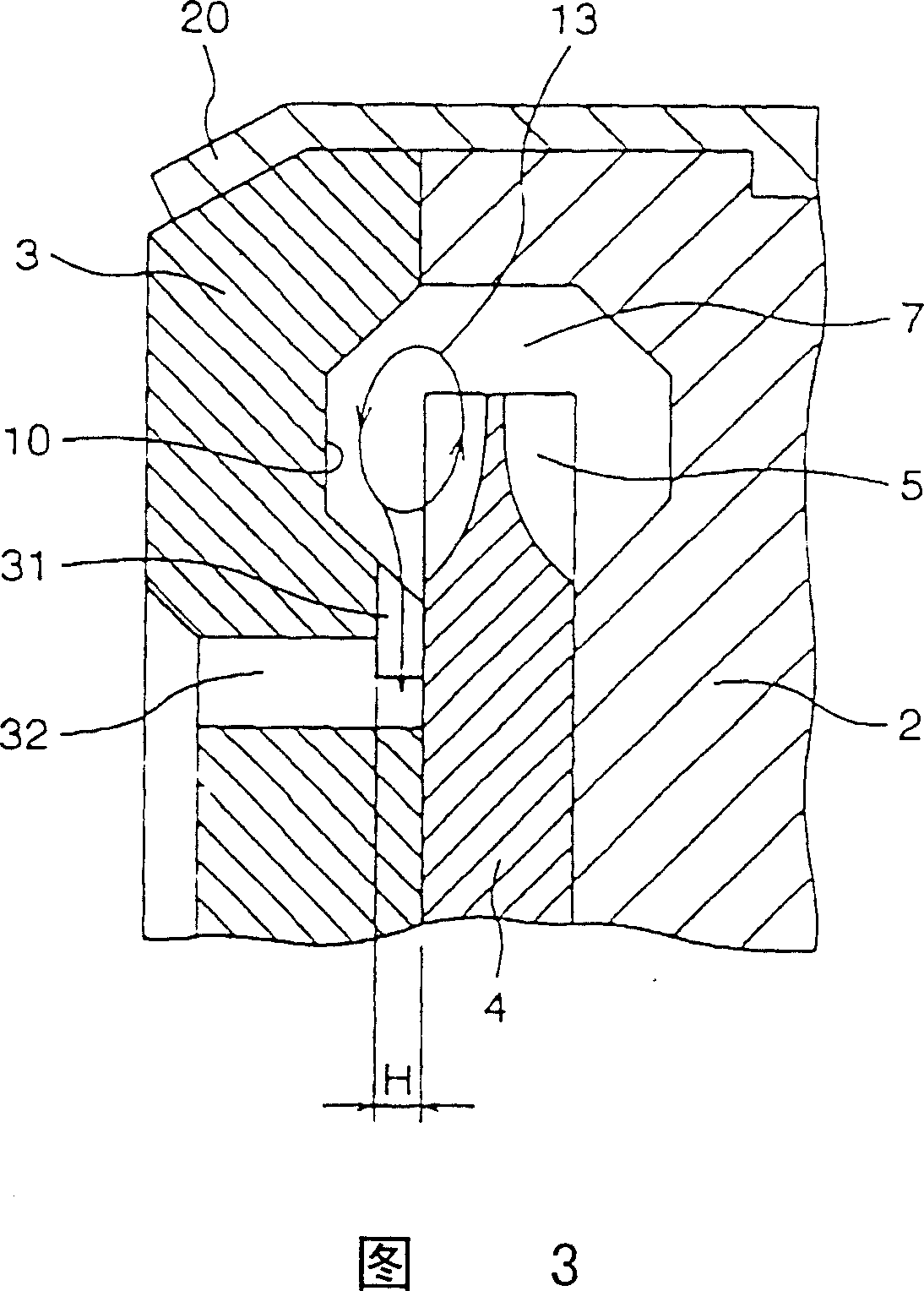

Cycular-flowing type fluid pump

A circumferential flow type liquid pump wherein a degassing passage opened in a stepped portion-carrying state in a bottom wall portion and extending radially inward is formed in the vicinity of an impeller in an inner circumferential portion of a pump flow passage, to allow communication between this degassing passage and the exterior of a pump casing assembly (1), and a cross-sectionally arcuate through port which has a cross-sectional area sufficiently larger than that of the degassing passage and which extends along the pump flow passage is provided. The through port may comprise plurality of through ports arranged in the range of the cross-sectionally arcuate area, or a through port directly communicating with the pump flow passage without the degassing passage interposed therebetween.

Owner:MITSUBISHI ELECTRIC CORP

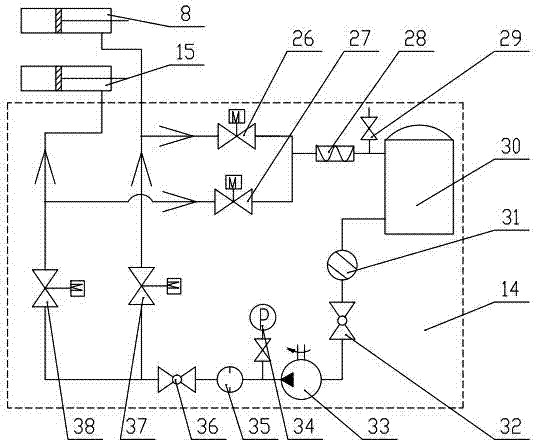

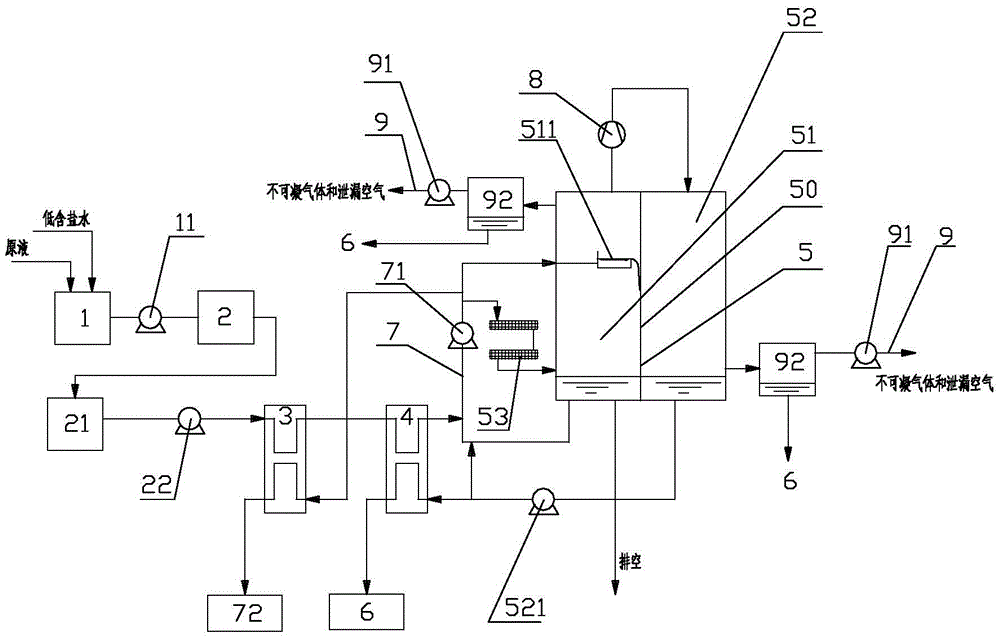

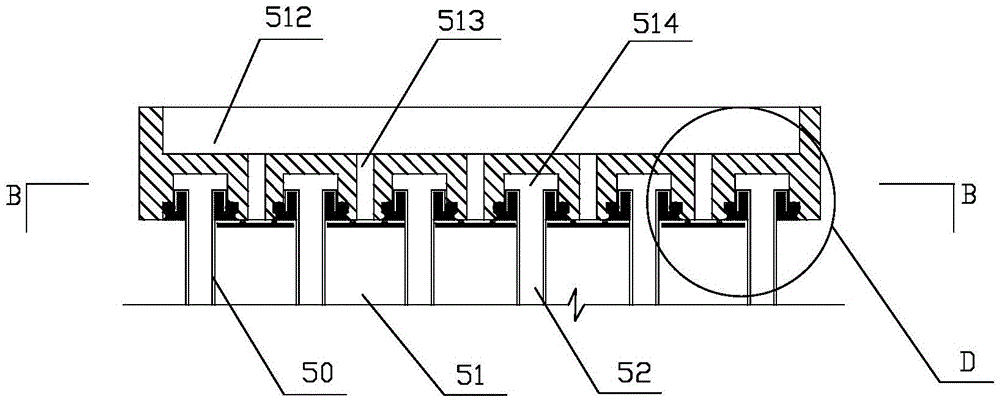

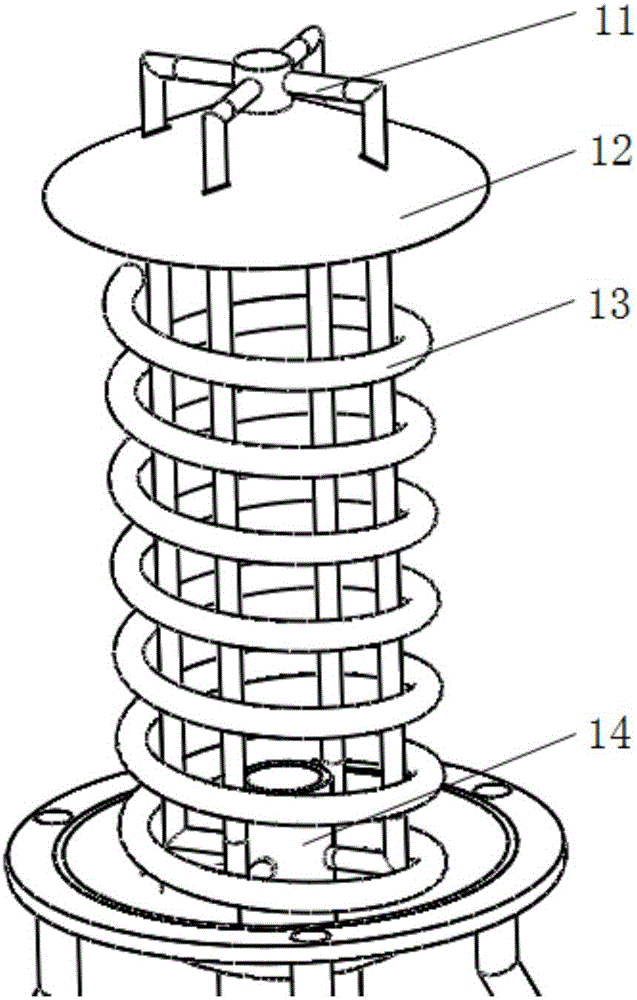

A mechanical vapor recompression evaporation system and energy-saving method

ActiveCN104027993BSolve corrosiveAvoid badEvaporation with vapour compressionEvaporator accessoriesPolymer thin filmsEngineering

The invention discloses a mechanical steam recompressing evaporation system and an energy saving method, and belongs to the technical fields of evaporation and energy conservation. The mechanical steam recompressing evaporation system is designed for solving the problems that an existing MVR system forms scales, corrodes, and is high in manufacturing cost and energy consumption in the industrial wastewater treatment and recover processes. The evaporation system comprises a stock solution storage tank, a pretreater, a heat exchange device, an evaporation and condensation device and a condensed water recovery pond, wherein the stock solution storage tank, the pretreater, the heat exchange device, the evaporation and condensation device and the condensed water recovery pond are sequentially connected in the flowing direction of liquid. The evaporation and condensation device comprises a plurality of evaporators, a plurality of condensers and an electromagnetic induction heater, the evaporators and the condensers are arranged in a separated mode through a plurality of thin polymer films; the heat exchange device is connected with the evaporators through a circulating liquid system, the evaporators are connected with the condensers through fans, and the condensers are connected with the condensed water recovery pond through the heat exchange device. The invention further provides the energy-saving method of the evaporation system. The thin polymer films are used for replacing metal films of the existing MVR system to manufacture the evaporation and condensation device, the evaporation and condensation device has the equivalent heat transfer effect as the metal-film evaporation and condensation device, and the problems of corrosion and scale forming on the surfaces of the evaporators are solved.

Owner:BEIJING OTC ENERGY & ENVIRONMENT ENGINEERING PUBLIC LIMITED COMPANY

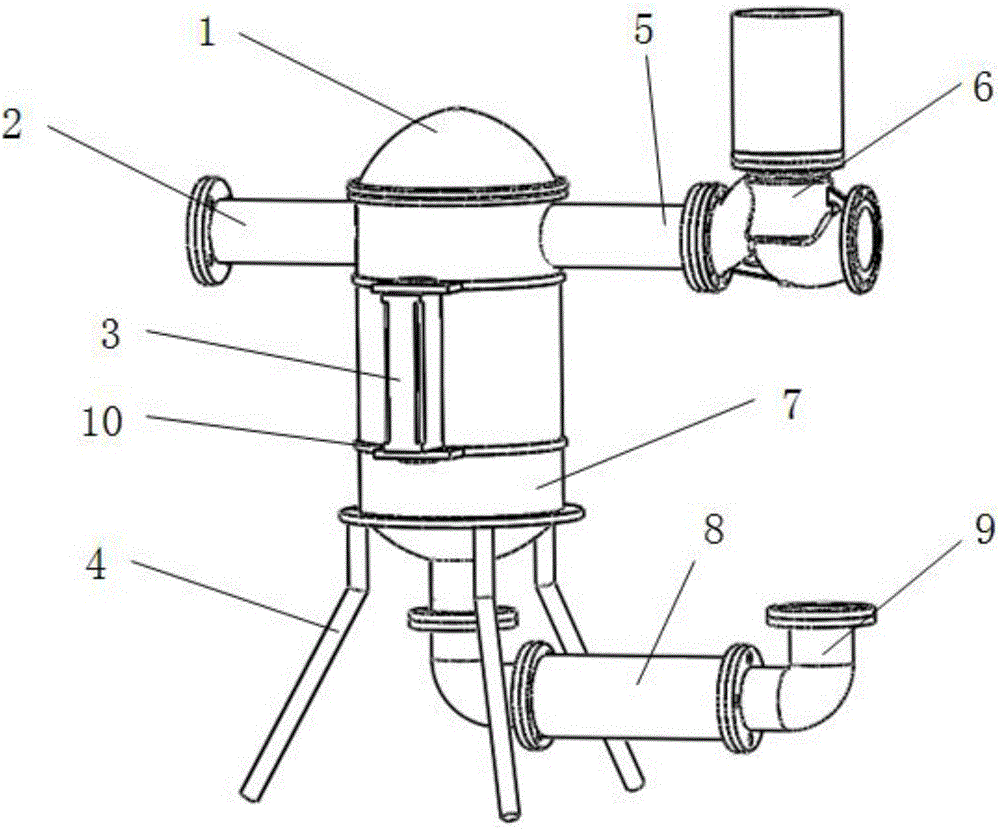

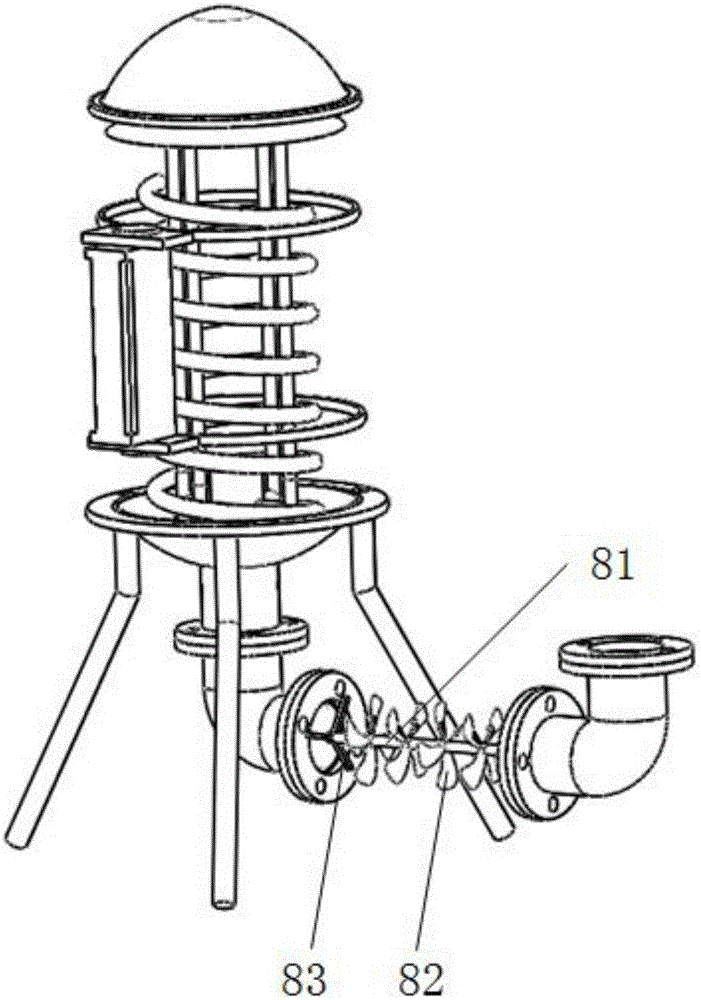

Uniform gas-liquid mixing device used before underwater mixed transportation pumping inlet

InactiveCN106807297AImprove mixing efficiencyNo air lockPump componentsFlow mixersEngineeringGuide tube

The invention relates to a uniform mixing device, in particular to a uniform gas-liquid mixing device used before an underwater mixed transportation pumping inlet. The uniform gas-liquid mixing device comprises a cylinder cover, an inlet tube, a liquid level sensor, a bracket, a backflow tube, an electromagnetic valve, a tank body, a secondary mixing cavity, a support shaft, blades, a triangular fixing rack, an outlet tube, a fixing tape, a gas guide tube, a gas collection cover, electric heating wires, a mixing cavity and a gas inlet hole, wherein the cylinder cover is fixed at the top of the tank body through a bolt and forms a sealed space with the tank body; the tank body is fixed on the bracket; the inlet tube is fixed at one end of the tank body and communicated with the sealed space inside the tank body; the backflow tube is fixed at the other end of the tank body and communicated with the sealed space inside the tank body; the electromagnetic valve is connected with the backflow tube through a flange. Due to the design idea of 'separating firstly and mixing later', gas-liquid separation of a gas-liquid mixture is carried out firstly, and mixing is carried out later, so that the gas-liquid mixing efficiency can be relatively high, moreover, air blocking can be avoided, a vapor mixture can be automatically eliminated, and the working intensity of use and maintenance can be alleviated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

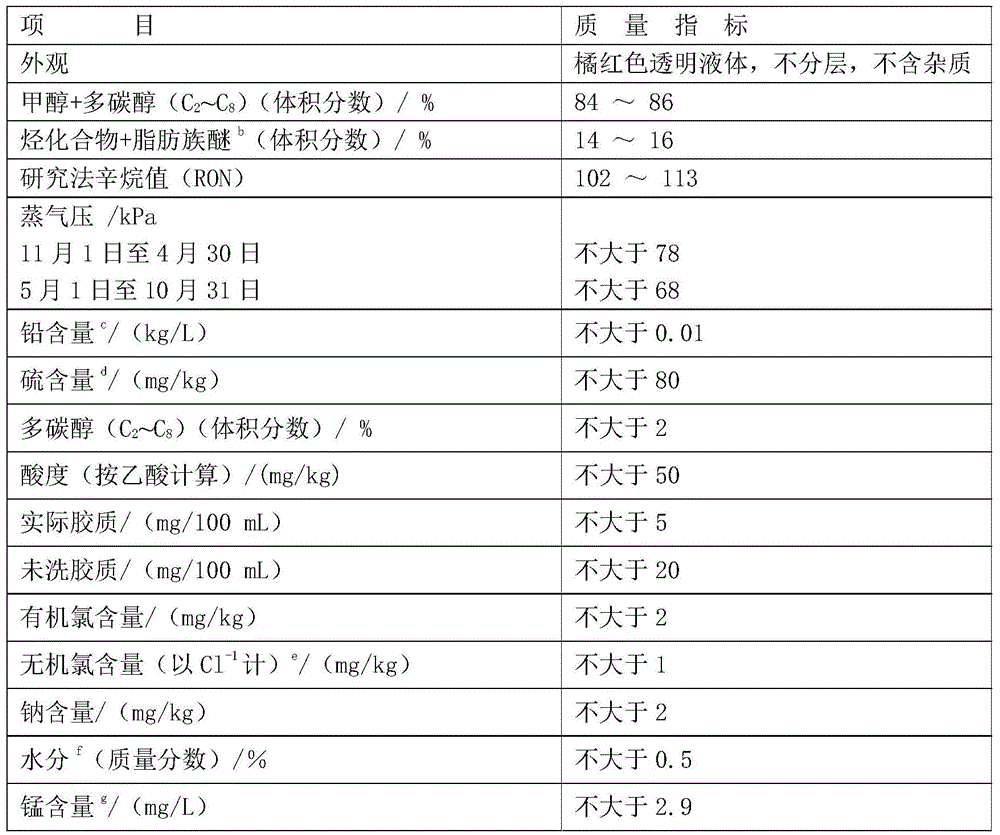

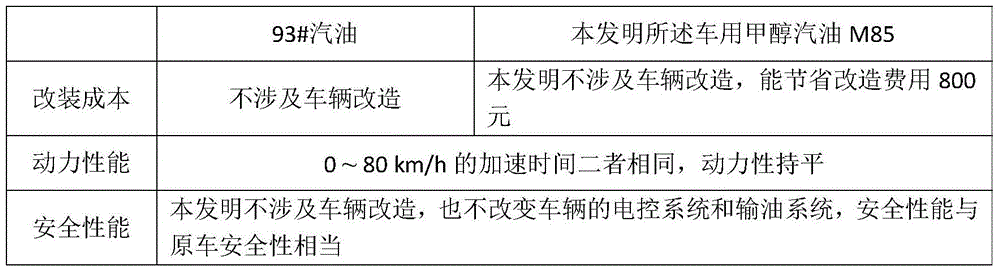

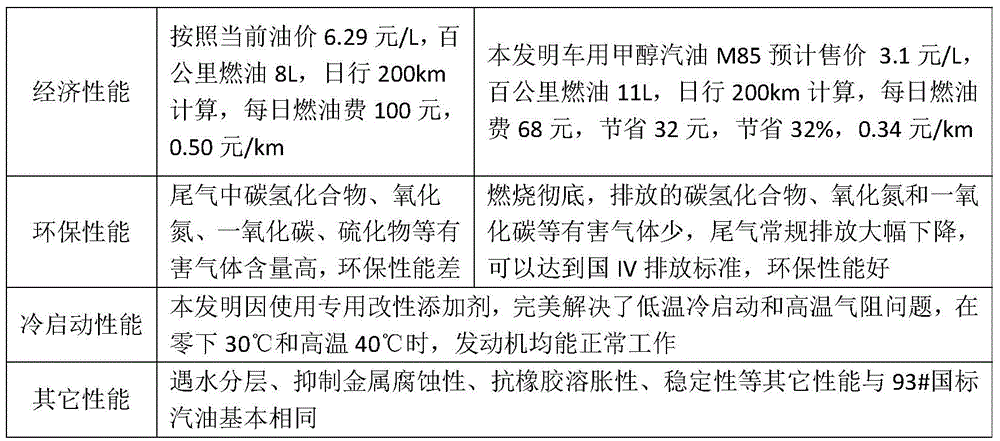

High clean new car methanol gasoline m85

The invention relates to the field of motor fuels, in particular to novel motor methanol gasoline M85 with high cleanness. The novel motor methanol gasoline M85 is prepared by mixing the following raw materials in percent by volume: 84-86 percent of methanol, 12-15 percent of motor gasoline, and 1-3 percent of a dedicated property-modifying additive for the motor methanol gasoline M85. The dedicated property-modifying additive can perfectly solve the problems that motor methanol gasoline M85 is low in low-temperature cold starting performance, high in possibility of layering when encountering a water phase, relatively low in metal corrosion inhibiting performance, low in rubber swelling resistance, low in combustion efficiency, low in dynamic property, low in stability, and low in possibility of storing for a long time, the mixed motor methanol gasoline M85 can be normally used through direct filling, without the need of refitting of an automotive engine.

Owner:山西智杰软件工程有限公司

High-energy composite alcohol-based gasoline and its preparation method

The invention discloses high-energy composite alcohol radical gasoline. The high-energy composite alcohol radical gasoline is prepared from a modified additive, methanol and gasoline, wherein the modified additive is prepared from a cosolvent, a corrosion inhibitor, a detergent dispersant, a rubber plasticizer and a vapor pressure inhibitor. The invention also discloses a preparation method of the high-energy composite alcohol radical gasoline. With the adoption of the high-energy composite alcohol radical gasoline, the formula design is unique and reasonable, the intersolubility is good, the layering problem of methanol and gasoline is effectively solved, the water resistance is improved, the low-temperature ignition startability is good, the anti-corrosion swelling property is strong, no air-lock phenomenon occurs under extreme high temperature weather, the high-temperature lubricity is good, no destructiveness exists to engine oil, and the exhaust emission is superior to that of conventional petrochemical gasoline. The preparation method is simple in preparation process, is low in production cost, is easily implemented, is high in production efficiency, and is suitable for being widely popularized and applied.

Owner:孙建国

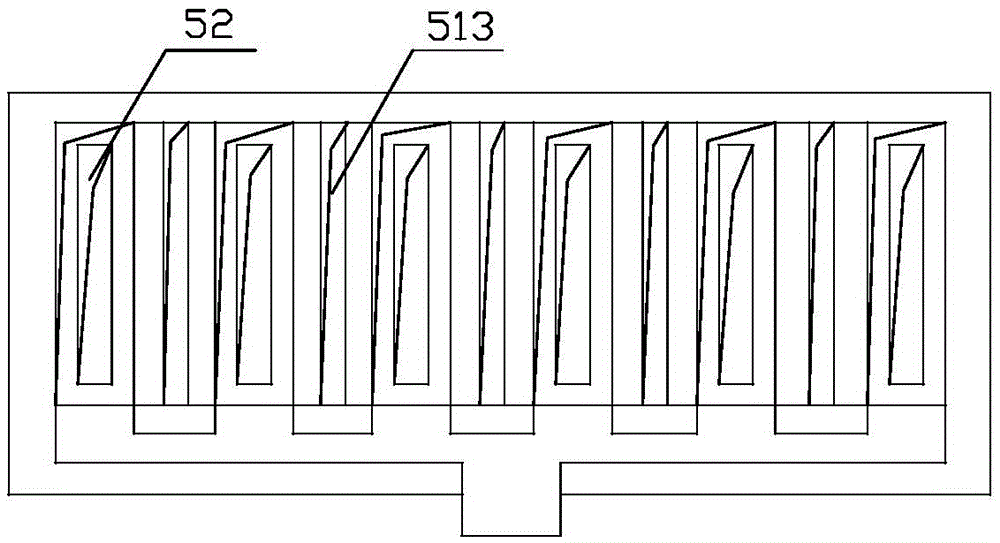

Slurry flotation system additionally provided with buffer device

The utility model relates to an ore pulp flotation system equipped with a buffer device, which relates to an ore pulp flotation system. Due to the uneven mixing of clean coal and flotation agent from the slurry preparation device and large fluctuations in the amount of material entering the flotation machine, air resistance is prone to occur during the feeding process. In addition, a large number of manual operations affect the flotation of the slurry. The effect is very disturbing. In this product, the container is set between the pulp preparer and the flotation device, and the container is processed with a feed port connected with the outlet end of the pulp preparer, and the container is also processed with an inlet port connected with the flotation device Connected to the discharge port, the outer wall of the container is provided with an exhaust device, the exhaust device is connected to the inner cavity of the container, the inner cavity of the container is provided with a baffle, and the surface of the baffle is set towards the feeding port of the container . This product is used for recovery of clean coal.

Owner:黑龙江宝泰隆新能源新材料研究院

Detachable mounting structure of exhaust pipe catalytic converter

InactiveCN100535404CEasy to installThe fixing method is simple and convenientJoints with sealing surfacesExhaust apparatusVehicle frameExhaust pipe

Owner:LONCIN MOTOR

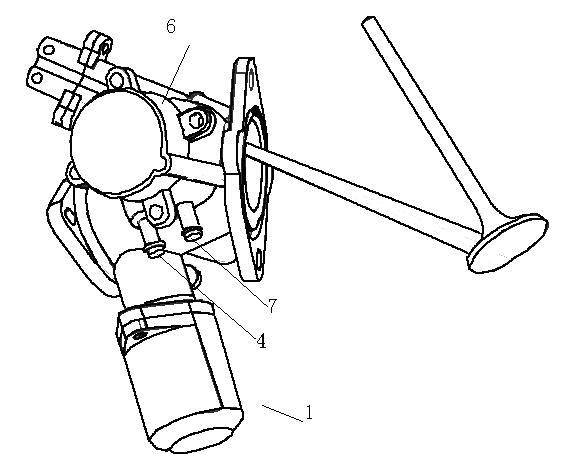

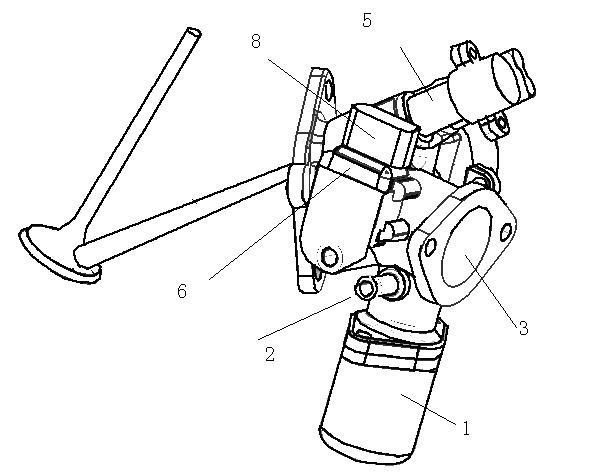

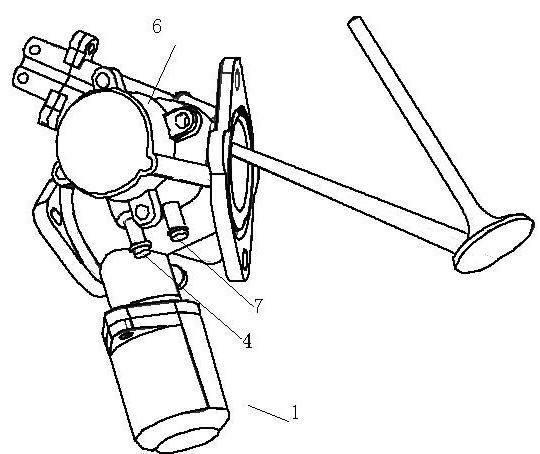

Motorcycle engine air-fuel ratio control method and device

InactiveCN102155314ASimple structureReduce manufacturing costElectrical controlMachines/enginesInlet channelSpray nozzle

The invention discloses a motorcycle engine air-fuel ratio control device which is a key part of an engine and comprises an air inlet control mechanism and a fuel control mechanism, wherein the air inlet control mechanism comprises a step motor, an air channel and an air inlet channel, the opening volume of the air channel is controlled by the step motor and the air inlet channel is communicated with the air channel; the fuel control mechanism comprises a gasoline inlet pipe, a gasoline spraying nozzle, a gasoline pressure regulating valve and a gasoline return pipe which are sequentially circularly connected; and the air inlet channel is communicated with the gasoline pressure regulating valve. The device has simple structure and low manufacture cost, can accurately control the air-fuel ratio to reach 16.7:1, has no air resistance and eliminates shortage or interruption of gasoline of the engine.

Owner:董鸿儒 +1

A kind of lng-fuel composite bunkering pontoon

ActiveCN106080979BIncrease temperatureDisplay volumeCargo handling apparatusFire rescueInformatizationFuel oil

Owner:JIANGSU SHIP DESIGN & RES INST

High-cleanness methanol fuel for vehicle

InactiveCN110885706AEasy to prepareImprove performanceLiquid carbonaceous fuelsCombustionMethanol fuel

The invention provides high-cleanness methanol fuel for a vehicle, and belongs to the technical field of methanol fuel. The high-cleanness methanol fuel for a vehicle is prepared from the following raw materials in parts by volume: 15-30 parts of methanol, 60-90 parts of gasoline and 4-8 parts of a composite additive, the composite additive is prepared from the following raw materials in parts byvolume: 3-5 parts of an auxiliary agent, 5-10 parts of a cosolvent, 10-25 parts of an energizer, 3-5 parts of an antioxidant, 5-10 parts of a metal corrosion inhibitor and 5-10 parts of a rubber swelling inhibitor. The methanol fuel disclosed by the invention is simple to prepare and good in performance, the oil consumption is equivalent to that of national standard gasoline, and the emission index meets the environmental protection requirement. In addition, the high-cleanness methanol fuel for the vehicle has good intermiscibility and strong water resistance, a vehicle is easy to start in a cold manner, the air resistance phenomenon is avoided, the heat value is high, the combustion is complete, and the corrosion of metal parts is inhibited. In addition, the methanol fuel is not layered when meeting water, and is good in stability, high in heat value and more obvious in energy-saving effect.

Owner:中油新能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com