Vertical self-priming pump and vertical self-priming pump with filtration device

A filtering device, self-priming technology, applied to pump devices, components of pumping devices for elastic fluids, non-displacement pumps, etc., can solve the problem of time-consuming and labor-intensive, dangerous, polluting operators or surrounding equipment and other problems, to achieve the effect of suppressing height and setting small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] The present invention will be described in detail below based on the accompanying drawings.

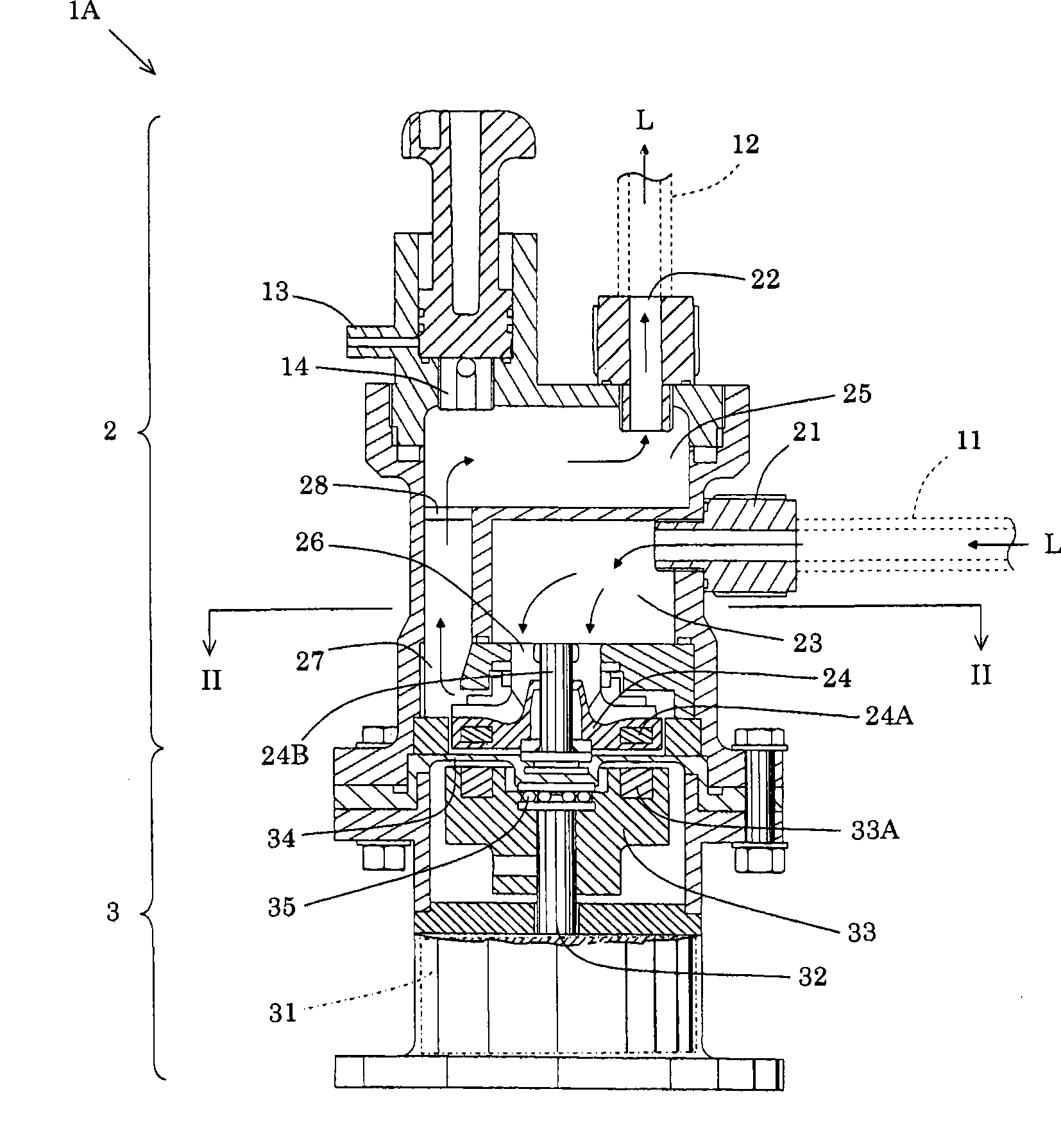

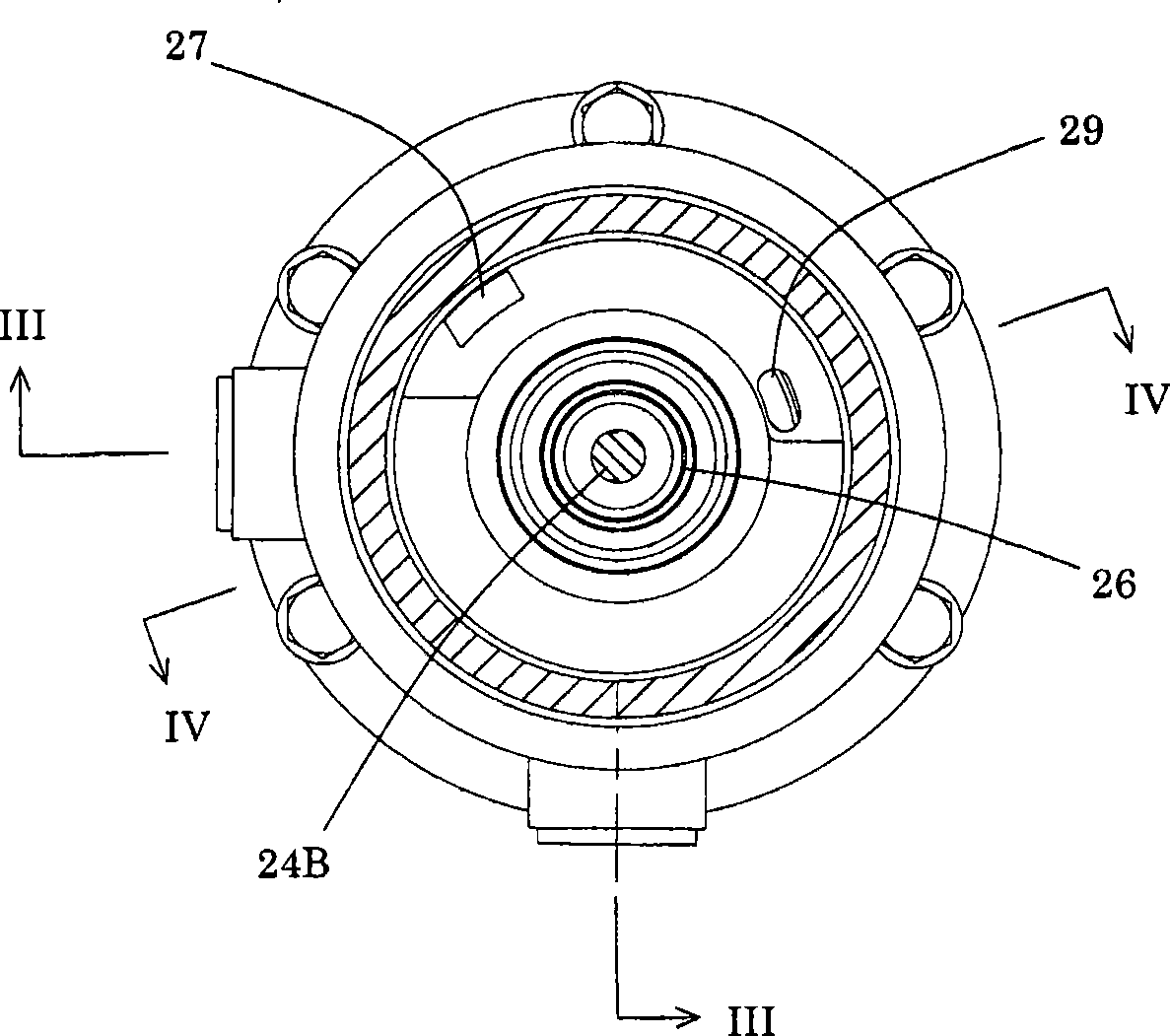

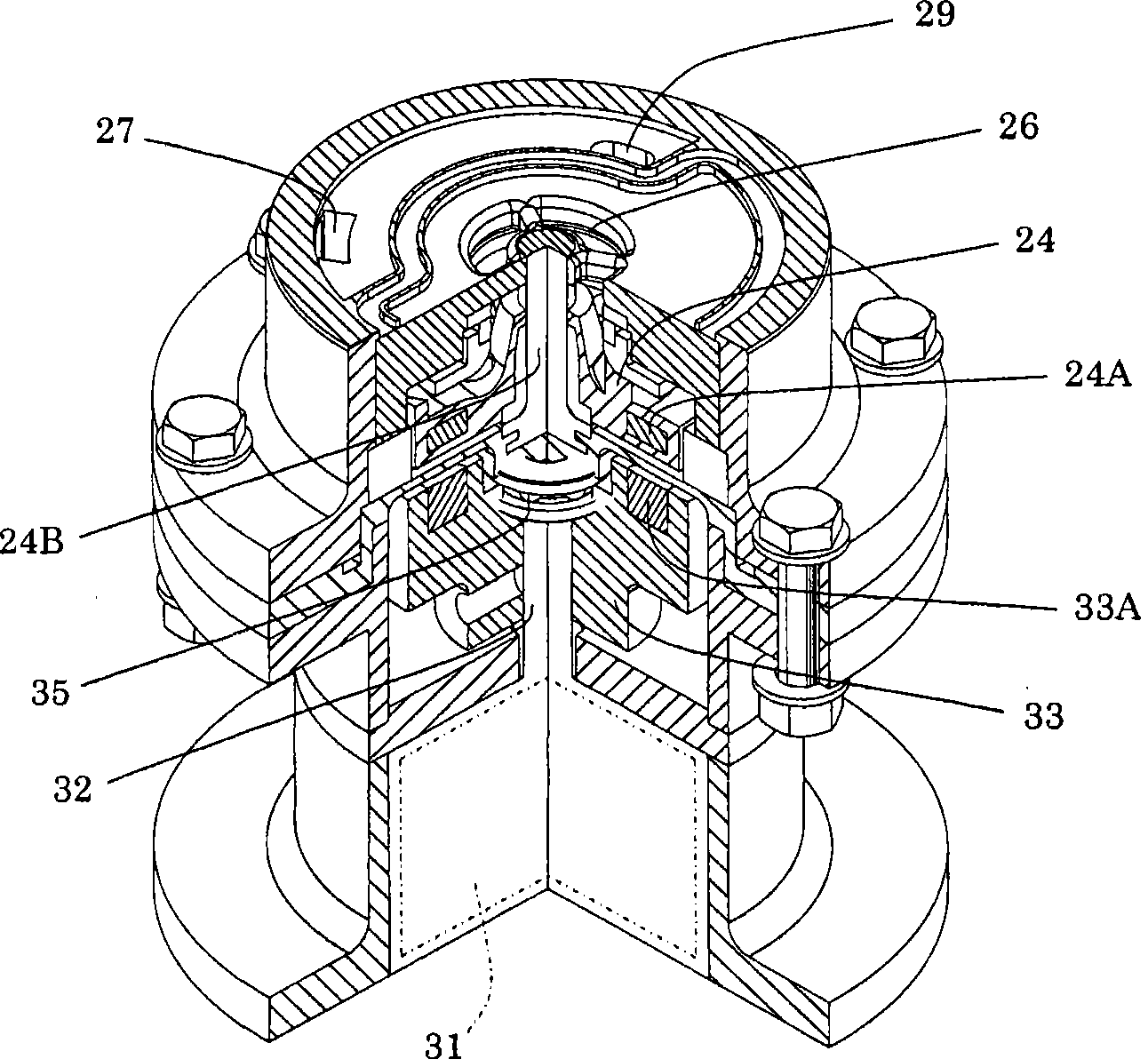

[0103] figure 1 It is a schematic sectional view showing an embodiment of a vertical self-priming pump according to the present invention, figure 2 Yes figure 1 A schematic enlarged cross-sectional view of the II-II line, image 3 is expressed in the ratio figure 1 In the structure of the lower part of the II-II line, in figure 2 A schematic enlarged cross-sectional view of the state where the III-III line is partially cut, Figure 4 is comparing figure 1 The II-II line is more of the lower part of the figure 2 A schematic enlarged cross-sectional view of line IV-IV, Figure 5 It is a schematic sectional view showing an embodiment of a vertical self-priming pump with a filter device according to the present invention, Image 6 Indicates the direction of liquid penetration relative to the filter Figure 5 The schematic enlarged end view of the VI-VI line. in additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com