Slurry flotation system additionally provided with buffer device

A buffer device and pulp technology, applied in flotation, solid separation and other directions, can solve the problem of easy occurrence of air resistance, large fluctuation of the amount of clean coal and flotation agent mixed into the flotation machine, and large interference of pulp flotation effect, etc. problem, to achieve the effect of reducing volatility, suitable for promotion, and convenient and simple transformation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

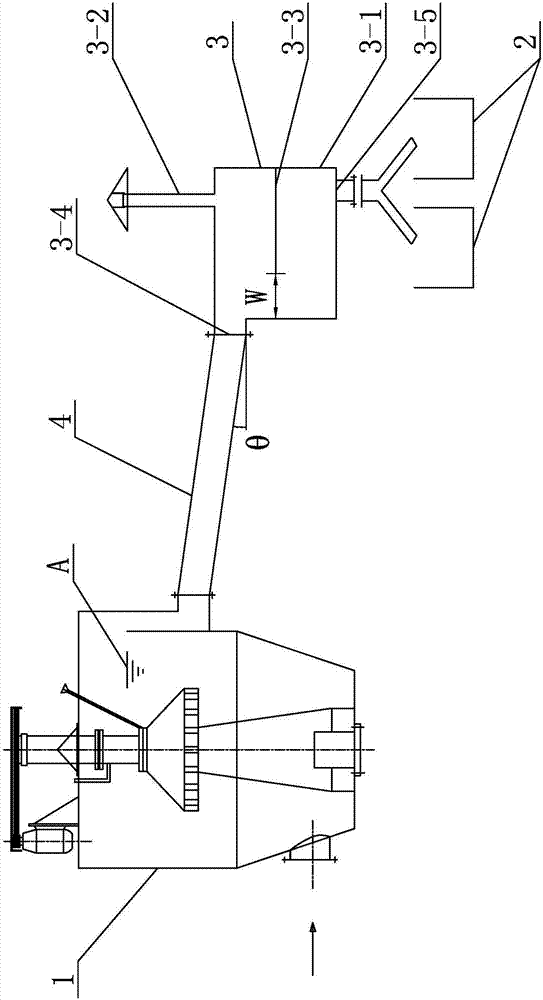

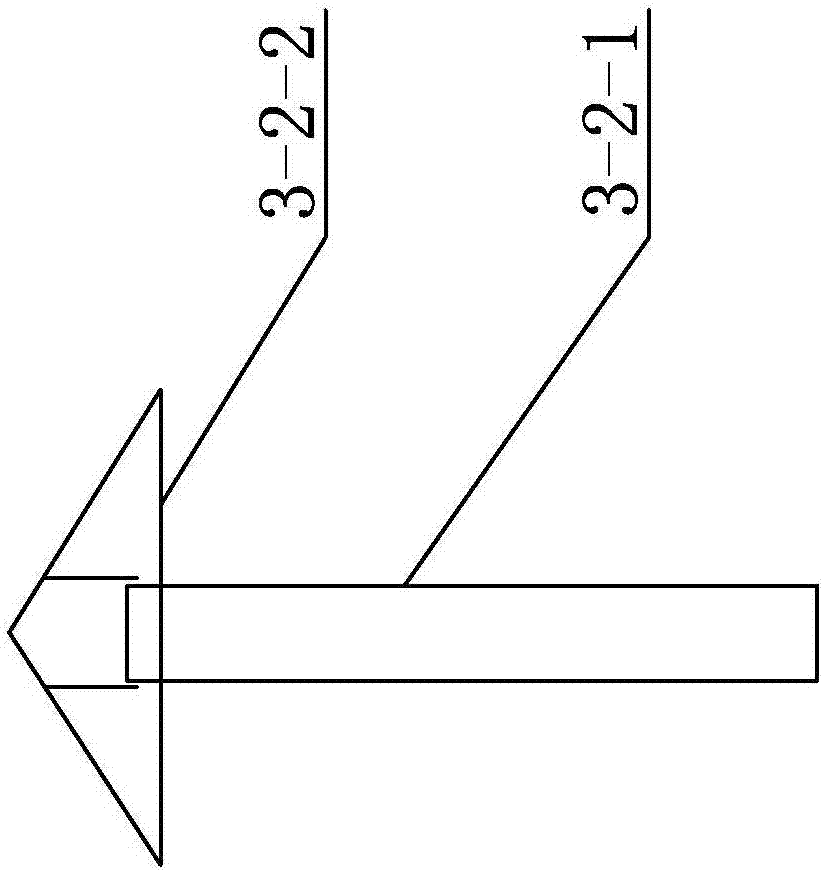

[0013] Example 1: Combining Figure 1 to Figure 2 Illustrate present embodiment, present embodiment comprises pulp preparer 1 and flotation device 2, and the outlet end of described pulp preparer 1 is arranged near the inlet end of flotation device 2, and it also comprises buffer device 3, and buffer device 3 comprises container 3-1. Exhaust device 3-2 and baffle plate 3-3. The container 3-1 is arranged between the pulp preparer 1 and the flotation device 2. The container 3-1 is processed with the pulp preparer 1 The feed port 3-4 connected to the outlet end of the container 3-1 is also processed with a discharge port 3-5 connected to the inlet end of the flotation device 2, and the outer wall of the container 3-1 is provided with The exhaust device 3-2, the exhaust device 3-2 communicates with the inner cavity of the container 3-1, the inner cavity of the container 3-1 is provided with a baffle 3-3, and the surface of the baffle 3-3 faces the container 3-1 feed port 3-4 sett...

Embodiment 2

[0017] Embodiment 2: Combination figure 1 Describe this embodiment, in this embodiment, the baffle 3-3 is a straight plate, and the baffle 3-3 is arranged horizontally, and one end of the baffle 3-3 is fixedly connected with the side inner wall of the container 3-1, and the baffle The other end of 3-3 is provided with a gap with the inner wall of the other side of container 3-1.

Embodiment 3

[0018] Example Three: Combining figure 1 To illustrate this embodiment, in this embodiment, the gap between the baffle plate 3-3 and the inner wall of the container 3-1 is a material channel, the width of the material channel is W, and the value of W ranges from 30 to 60 cm. Within this width range, the ore pulp can be guaranteed to flow down smoothly, and the next step of flotation processing can be realized smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com