A kind of lng-fuel composite bunkering pontoon

A pontoon and fuel oil technology, which is applied in the field of LNG-fuel oil filling pontoons, can solve the problems of large filling loss, no consideration of water replenishment, and weak continuous filling capacity, and achieve energy saving and emission reduction effects, energy saving and emission reduction Good performance and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better understand the present invention, the present invention is described in detail below in conjunction with specific examples. It will, however, be evident that various changes and modifications can be made to the present invention without departing from the broader spirit and scope of the invention as defined in the appended claims. Therefore, the following examples have an illustrative rather than a limiting meaning.

[0038] Example:

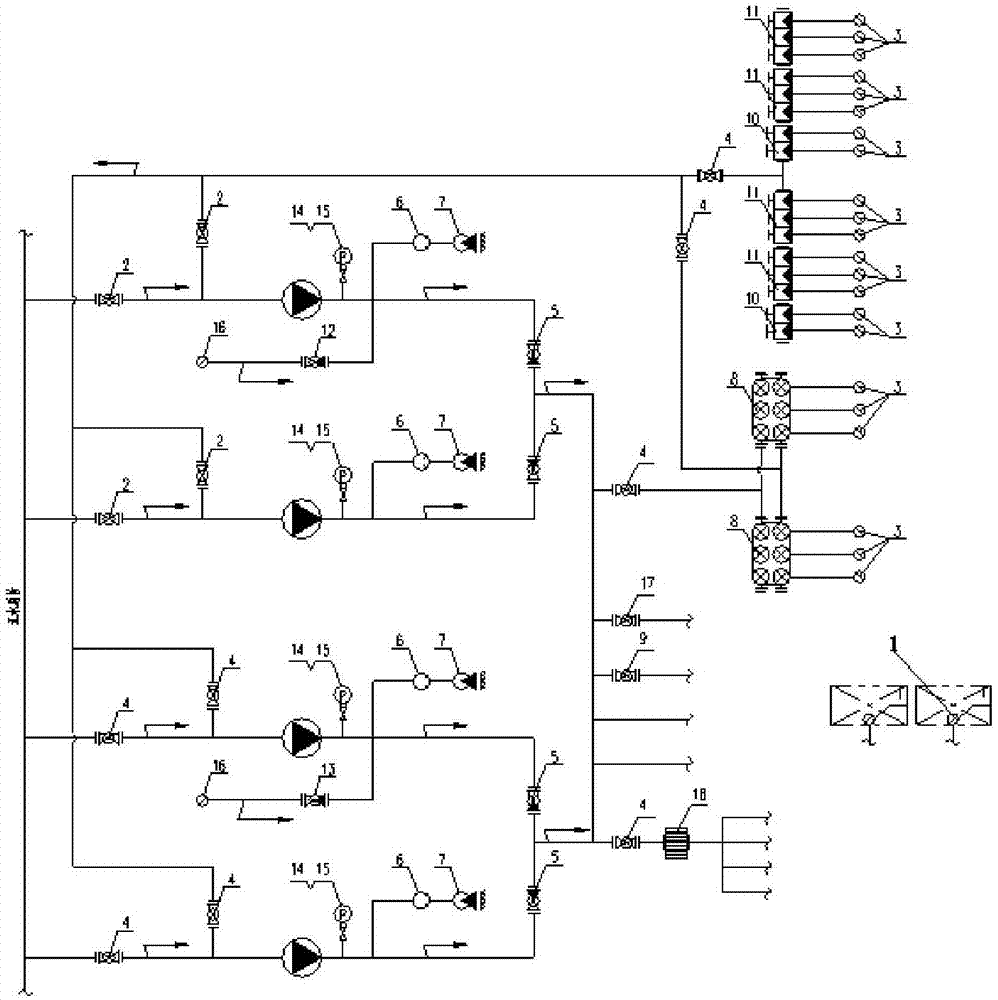

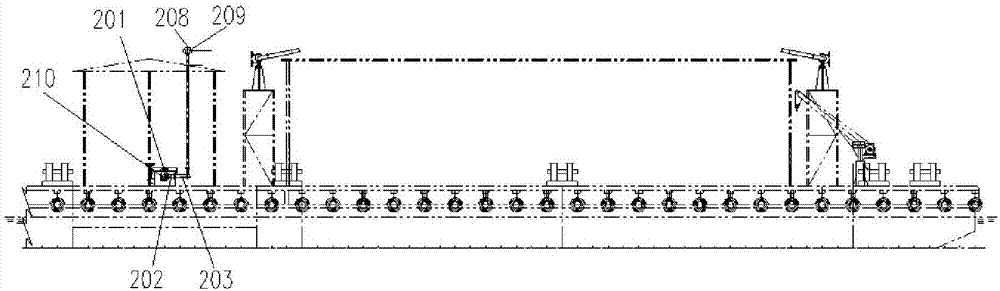

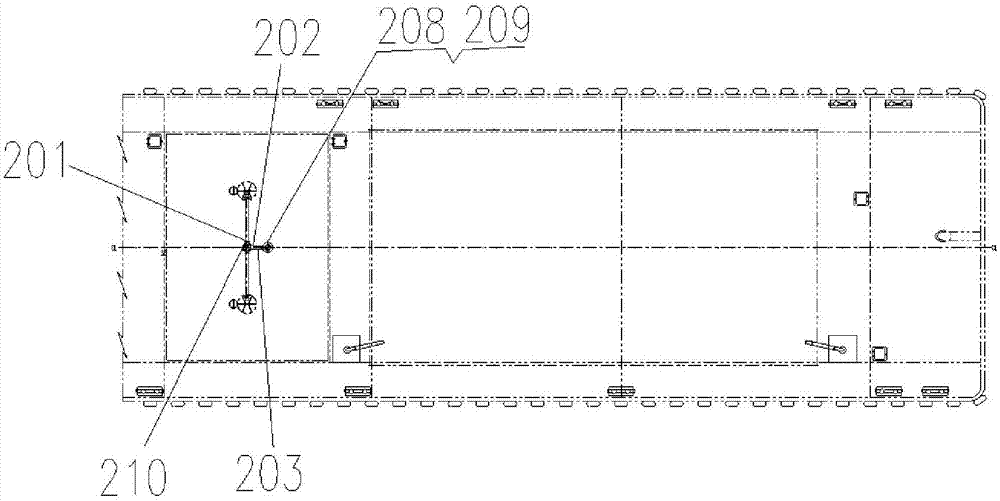

[0039] A kind of LNG-fuel oil bunkering pontoon, such as Figure 1 to Figure 20 As shown, it includes the bilge and ballast system installed in the hold, cargo oil tank ventilation system, fire-fighting water mist and water curtain system, whole ship ventilation and measurement system, and refueling system. The refueling system is provided with a refueling piping system; The bottom and ballast system includes a filter screen 1, behind the filter screen 1 there is a first stop valve 2 and a second stop valve 4, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com