Cycular-flowing type fluid pump

A liquid pump, flow-type technology, applied in the field of circumferential flow liquid pumps, can solve problems such as unreliable avoidance of air locks, lengthening of side walls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

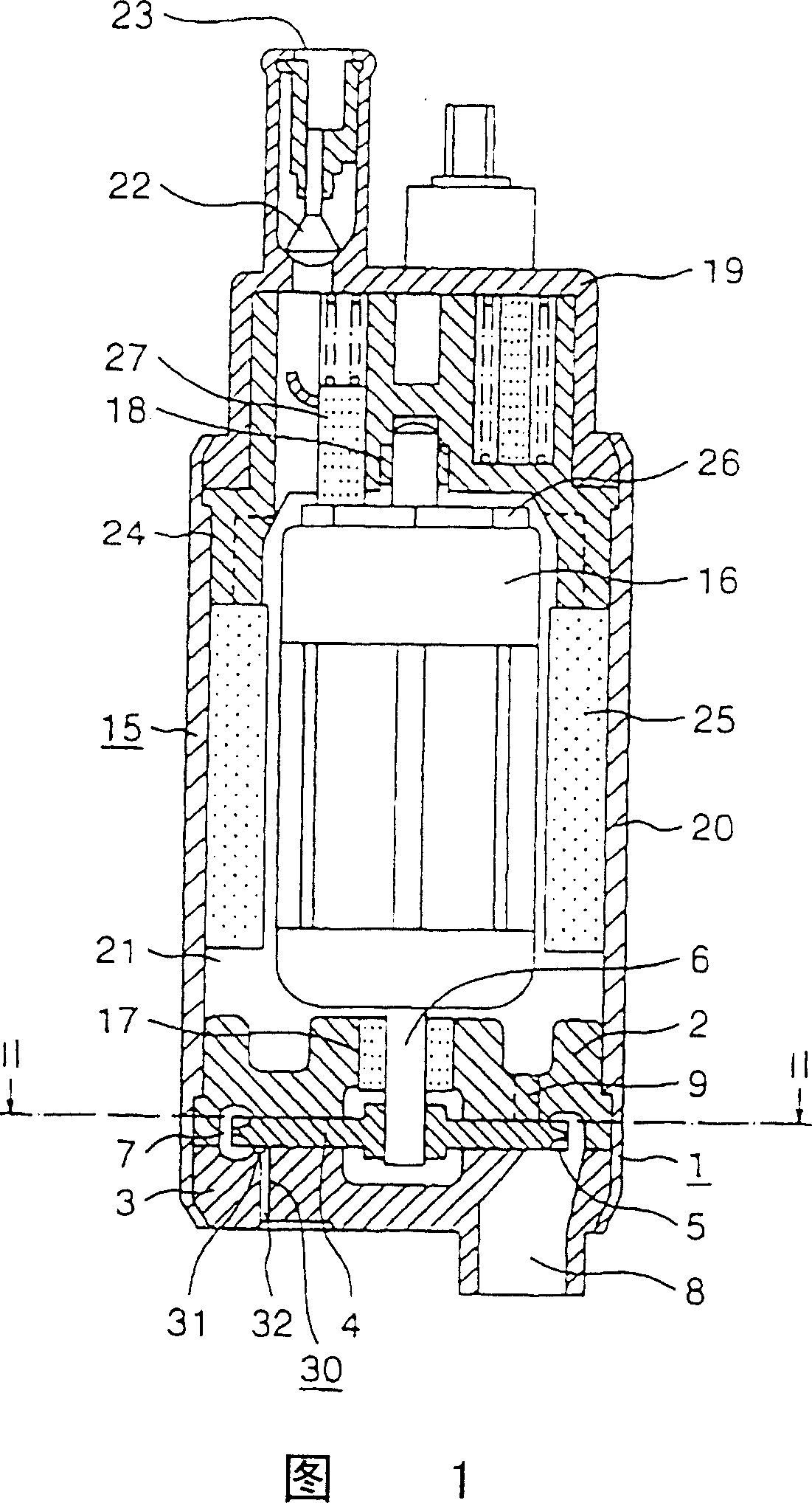

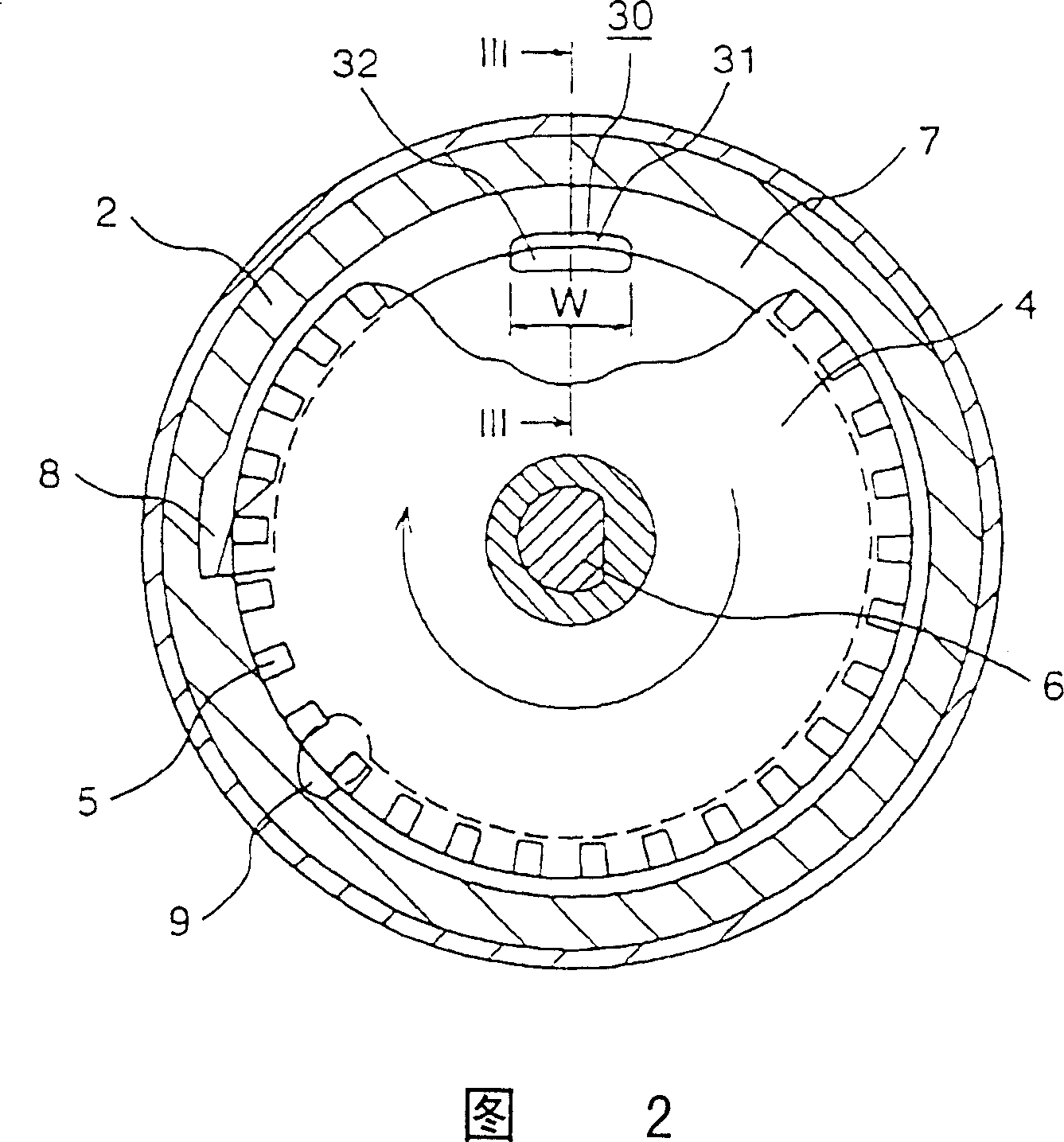

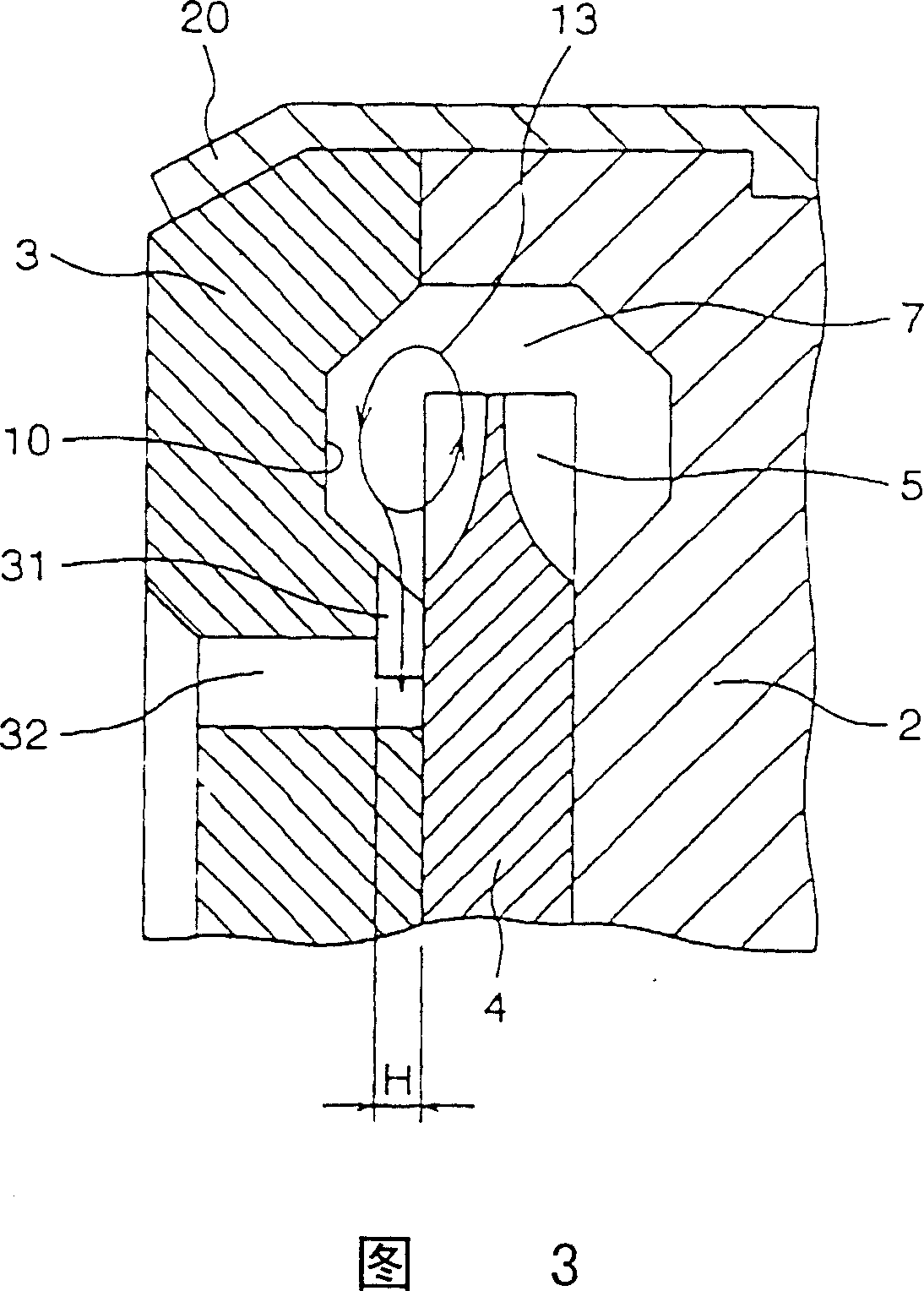

[0026] 1 is a longitudinal cross-sectional view of a circular flow type liquid pump according to an embodiment of the present invention, FIG. 2 is an enlarged cross-sectional view taken along line II-II in FIG. 1 , and FIG. 3 is an enlarged cross-sectional view taken along line III-III in FIG. 2 . In the figure, 1 to 10, 13, 15 to 27 have the same structure as the above-mentioned conventional device, and the description thereof is omitted.

[0027] In the drawing, on the cover 3 of the pump casing assembly 1, as shown in FIG. 3, the air release passage 31 is provided near the impeller 4 in the inner peripheral portion of the pump flow path 7, and the air release passage 31 is different in height. It opens at the position of the bottom surface portion 10 of the pump flow path 7 (a position located on the inner side in the circumferential direction of the bottom surface portion 10 from the bottom surface portion 10 and close to the impeller 4 ) and extends in the radial direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com