Detachable mounting structure of exhaust pipe catalytic converter

A technology of catalytic converter and installation structure, applied in the direction of exhaust device, muffler device, machine/engine, etc., can solve the problems of complex exhaust pipe structure, leakage of exhaust pipe, small space, etc., to improve catalytic conversion effect , the effect of increased cross-sectional area and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

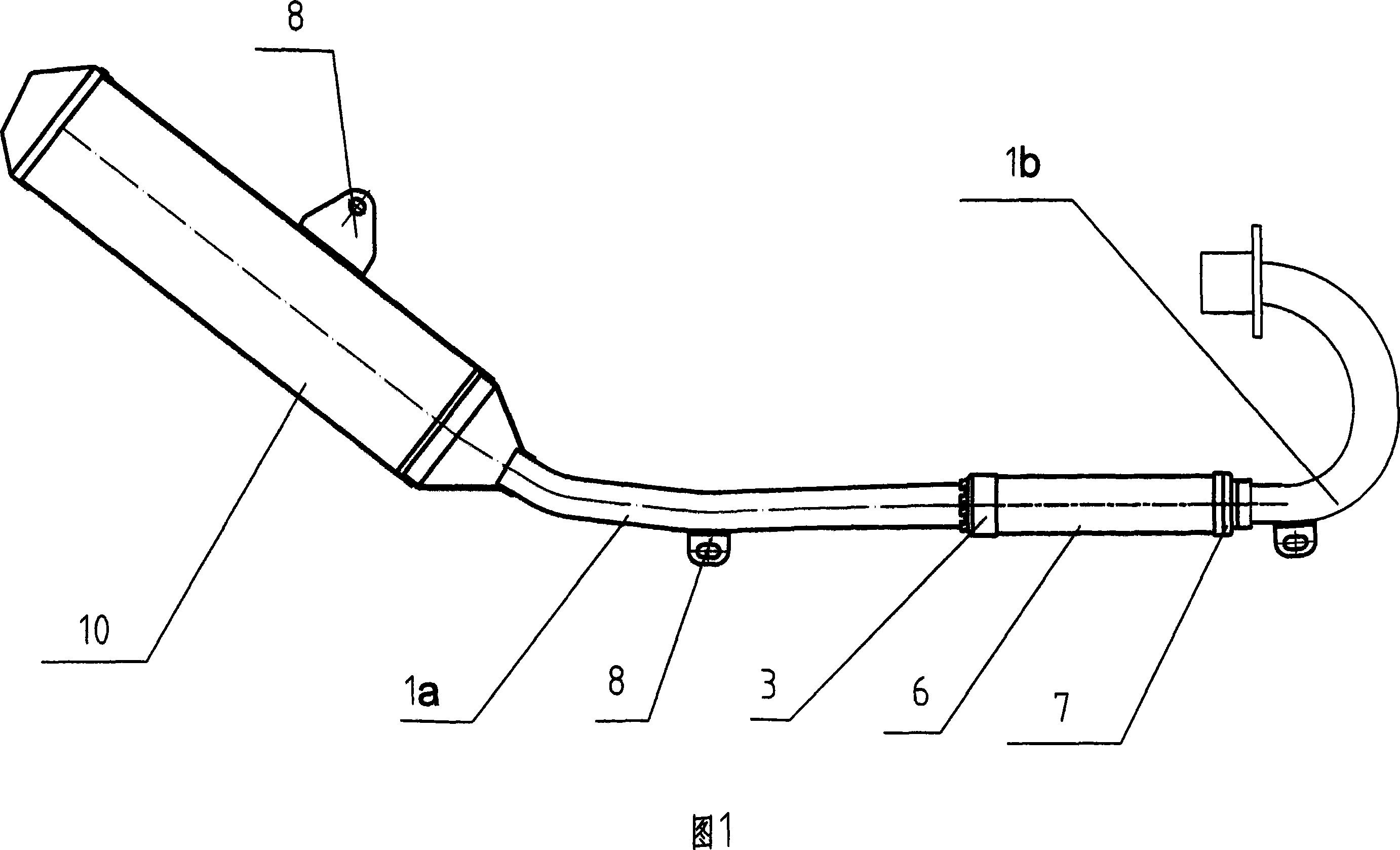

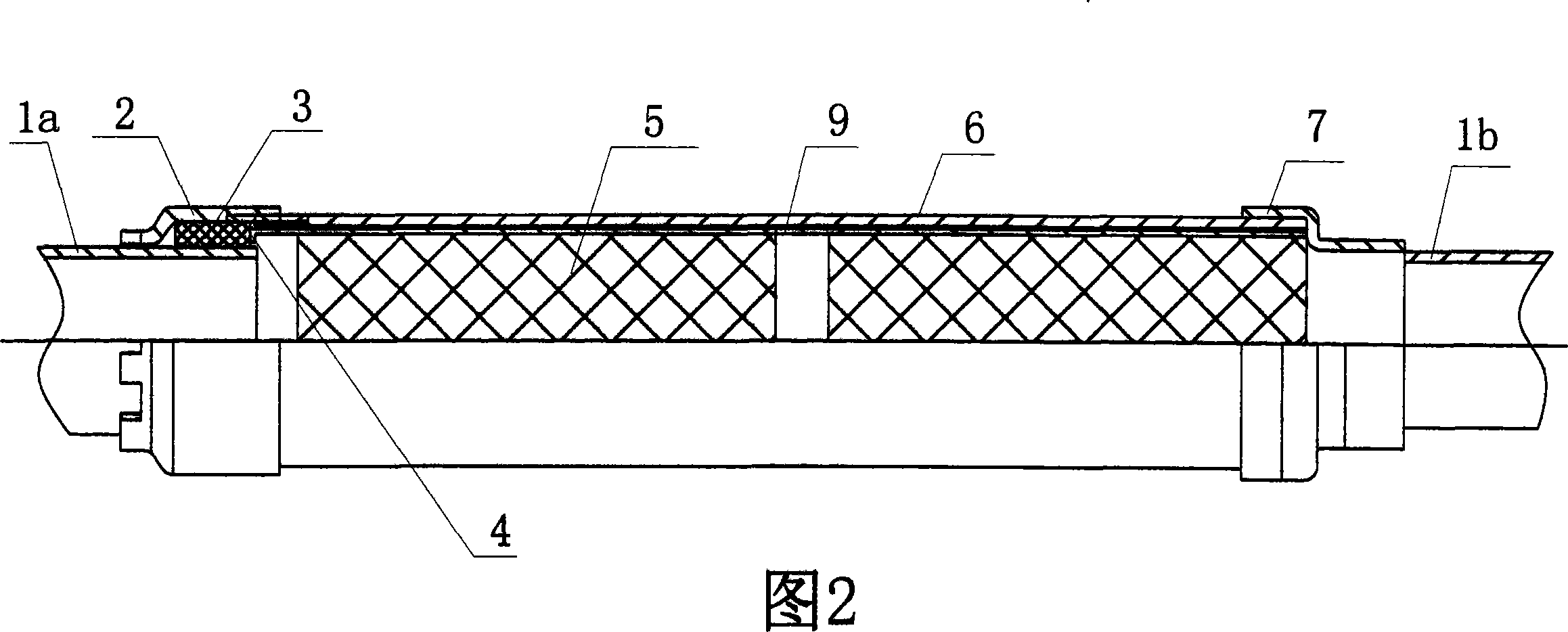

[0013] See Figures 1 and 2. The detachable installation structure of the exhaust pipe catalytic converter of the present invention comprises a catalytic converter and an exhaust pipe. The exhaust pipe is divided into two sections, one exhaust pipe 1b is fixedly connected with the engine exhaust hole through a flange, the other exhaust pipe 1a is welded and fixedly connected with the muffler 10, and the two exhaust pipes 1a, 1b and The mufflers 10 are respectively provided with lugs 8 and fixed on the vehicle frame by bolts. The adjacent ends of the two exhaust pipes 1a, 1b are respectively provided with connectors for fixing the catalytic converter, one of the connectors is a connecting sleeve 7 with stepped holes, and the small diameter end of the connecting sleeve 7 is welded and fixed on the At the end of a section of the exhaust pipe 1b, a casing 6 is welded and fixed in the large-diameter end of the step hole, and a cylindrical catalytic converter is installed in the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com