Hydrocracking-catalytic cracking combined treatment method for coal tar and residual oil

A catalytic cracking and hydrocracking technology, applied in hydrotreating process, hydrocarbon oil treatment, petroleum industry and other directions, can solve the problems of low yield of light oil, low conversion rate, easy coking, etc. The effect of reducing coking and slowing down the rate of coke formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

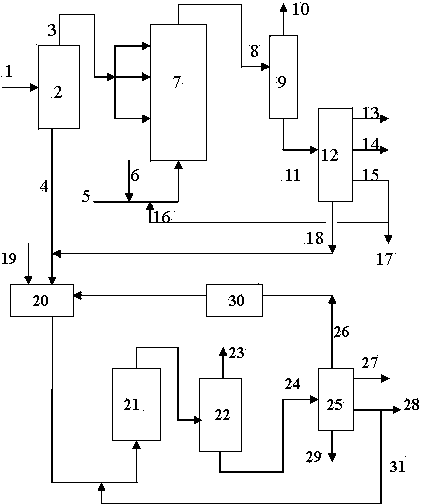

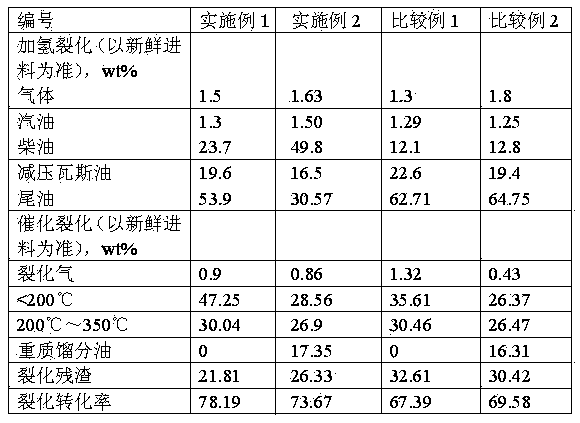

[0042] The dry point of light coal tar in the raw material used in the test is 485°C, and the weight ratio of residual oil and light coal tar in the feed to the ebullated bed reactor is 5:1. The test process is as follows: figure 1 shown. Fluidized bed reactor hydrocracking catalyst A tungsten-nickel catalyst supported by alumina, wherein the catalyst contains 6wt% nickel (calculated as NiO) and 12wt% tungsten (calculated as WO 3 calculate). Catalyst particle diameter is 0.5mm, bulk density is 0.79g / cm 3 , the specific surface area is 260m 2 / g. The catalytic cracking catalyst is a catalytic cracking catalyst containing 10w% zeolite molecular sieve, the rest is an aluminum silicate carrier, and the supercritical solvent is gasoline distillate. The reaction conditions, product distribution and product properties are shown in Table 2-Table 5. Part of the vacuum gas oil is recycled back to the ebullating bed reactor, and the weight ratio of vacuum gas oil and residual oil re...

Embodiment 2

[0044] The dry point of light coal tar in the raw material used in the test is 485°C, and the weight ratio of residual oil and light coal tar in the feed to the ebullated bed reactor is 1:1. The test process is as follows: figure 1 shown. Fluidized bed reactor hydrocracking catalyst A tungsten-nickel catalyst supported by alumina, wherein the catalyst contains 6wt% nickel (calculated as NiO) and 12wt% tungsten (calculated as WO 3 calculate). Catalyst particle diameter is 0.5mm, bulk density is 0.79g / cm 3 , the specific surface area is 260m 2 / g. The catalytic cracking catalyst is a catalytic cracking catalyst containing 10w% zeolite molecular sieve, the rest is an aluminum silicate carrier, and the supercritical solvent is a diesel fraction. The reaction conditions, product distribution and product properties are shown in Table 2-Table 5. Part of the vacuum gas oil is recycled back to the ebullating bed reactor, and the weight ratio of vacuum gas oil and residual oil recy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com