Low-dielectric rare earth doped aluminoborosilicate glass powder and preparation method thereof

A doping technology of aluminoborosilicate and rare earth, which is applied in the field of glass powder processing, can solve problems not related to dielectric properties, and achieve the effects of improving solubility, reducing dielectric constant, and improving dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

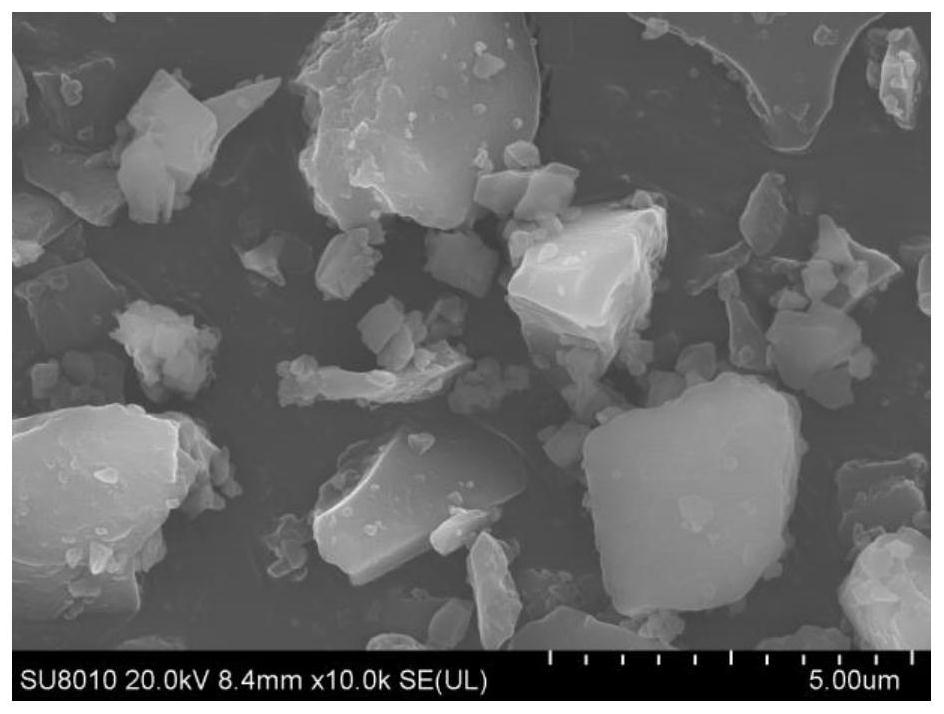

Image

Examples

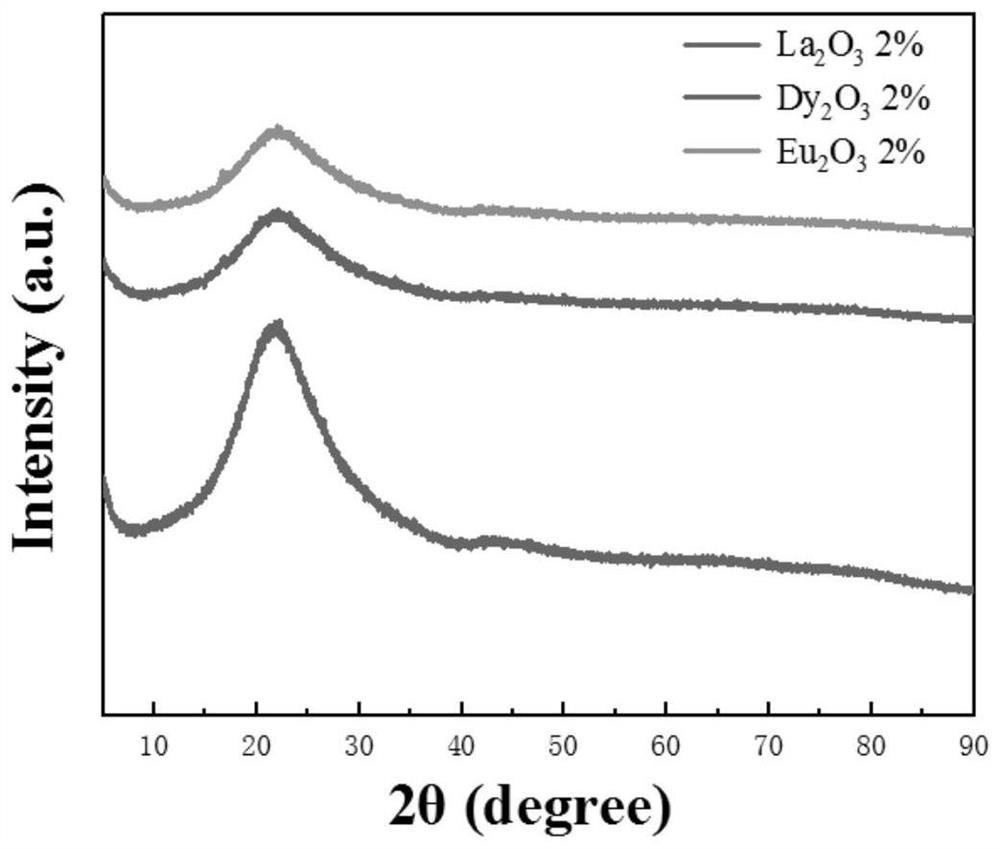

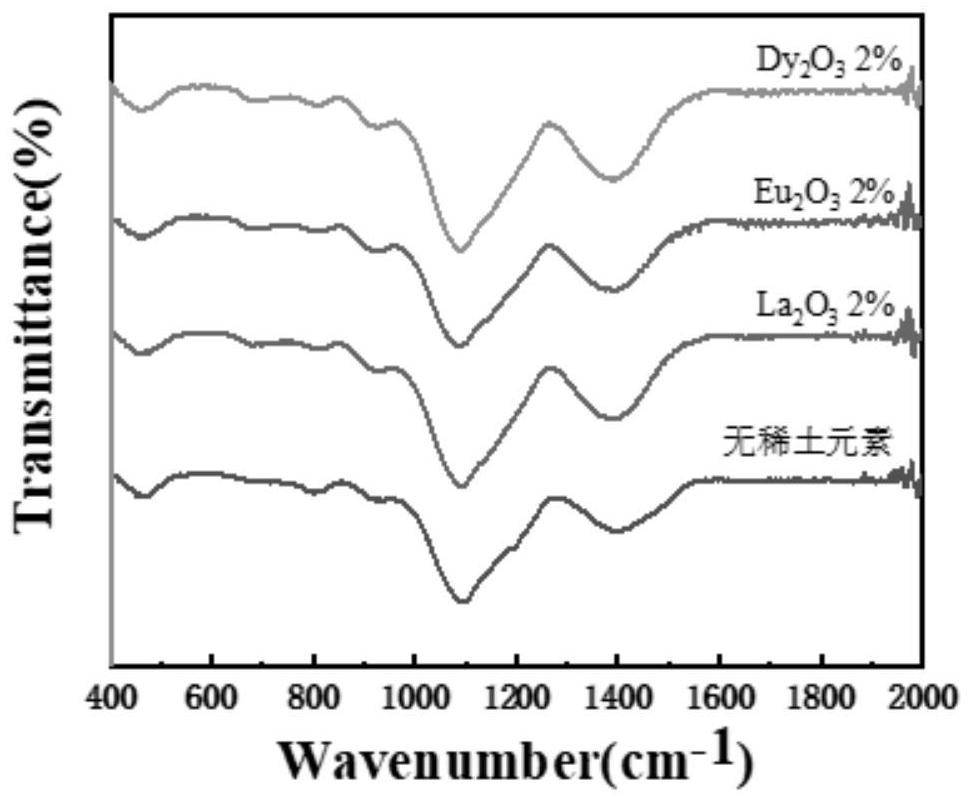

Embodiment 1

[0035] A kind of low dielectric rare earth doped aluminoborosilicate glass powder, wherein contains the composition of following mass percent:

[0036] SiO 2 : 58%; Al 2 o 3 : 10%; B 2 o 3 : 20%; CaO: 2%; MgO: 8%; La 2 o 3 Material: 2%.

[0037] The preparation method of the low dielectric rare earth doped aluminoborosilicate glass powder of the present invention is as follows:

[0038] (1) Weigh the corresponding (C 2 h 5 O) 4 Si, H 3 BO 3 , Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O, Ca(NO 3 ) 2 4H 2 O and La(NO 3 ) 3 ·6H2 O;

[0039] (2) will (C 2 h 5 O) 4 Si and C 2 h 5 o 5 Mix at a volume ratio of 1:1, add water, adjust the molar ratio of water to silicon in the solution to 10:1, add nitric acid solution dropwise to adjust the pH of the solution to 1.5, and then stir at 50°C until clear to obtain a mixed solution 1;

[0040] (3) H to be weighed 3 BO 3 Add to mixed solution 1, then stir at 50°C until clear to obtain mixed solution 2;

[0041] ...

Embodiment 2

[0048] A kind of low dielectric rare earth doped aluminoborosilicate glass powder, wherein contains the composition of following mass percent:

[0049] SiO 2 : 58%; Al 2 o 3 : 10%; B 2 o 3 : 20%; CaO: 2%; MgO: 8%; Eu 2 o 3 Material: 2%.

[0050] The preparation method of the low dielectric rare earth doped aluminoborosilicate glass powder of the present invention is as follows:

[0051] (1) Weigh the corresponding (C 2 h 5 O) 4 Si, H 3 BO 3 , Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O, Ca(NO 3 ) 2 4H 2 O and Eu(NO 3 ) 3 ·6H 2 O;

[0052] (2) will (C 2 h 5 O) 4 Si and C 2 h 5 o 5 Mix at a volume ratio of 1:1, add water, adjust the molar ratio of water to silicon in the solution to 10:1, add nitric acid solution dropwise to adjust the pH of the solution to 1.8, and then stir at 55°C until clear to obtain a mixed solution 1;

[0053] (3) H to be weighed 3 BO 3 Added to mixed solution 1, then stirred at 55°C until clear to obtain mixed solution 2;

...

Embodiment 3

[0061] A kind of low dielectric rare earth doped aluminoborosilicate glass powder, wherein contains the composition of following mass percent:

[0062] SiO 2 : 58%; Al 2 o 3 : 10%; B 2 o 3 : 20%; CaO: 2%; MgO: 8%; Dy 2 o 3 Material: 2%.

[0063] The preparation method of the low dielectric rare earth doped aluminoborosilicate glass powder of the present invention is as follows:

[0064] (1) Weigh the corresponding (C 2 h 5 O) 4 Si, H 3 BO 3 , Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O, Ca(NO 3 ) 2 4H 2 O and Dy(NO 3 ) 3 ·6H 2 O;

[0065] (2) will (C 2 h 5 O) 4 Si and C 2 h 5 o 5 Mix at a volume ratio of 1:1, add water, adjust the molar ratio of water to silicon in the solution to 10:1, add nitric acid solution dropwise to adjust the pH value of the solution to 2, and then stir at 60°C until clear to obtain a mixed solution- ;

[0066] (3) H to be weighed 3 BO 3 Add to mixed solution 1, then stir at 60°C until clear to obtain mixed solution 2;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com