Solvent composition for disassembling flexible optical device and application

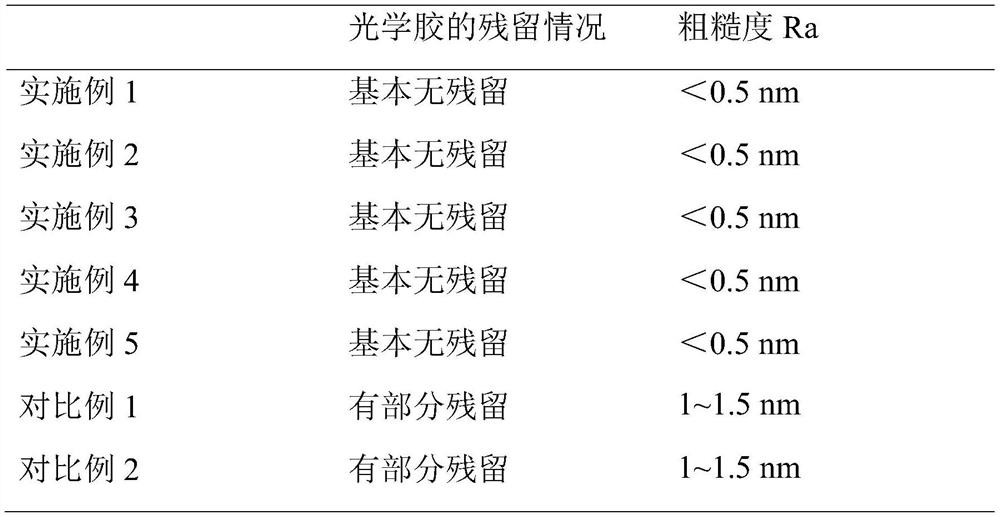

A technology of solvent composition and optical devices, which is applied in the field of optical parts processing, can solve the problems that the disassembly method is easy to damage the optical devices, etc., and achieve the effect of simple and convenient disassembly method, enhanced solvency, and no change in roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Solvent compositions and applications for dismantling flexible optical devices

[0059] A solvent composition for dismantling flexible optical devices

[0060] Based on the total mass of the solvent composition as 100%, it includes the following components in the following weight percentages:

[0061] n-heptane 45%;

[0062] Cyclohexanone 20%;

[0063] Ethyl acetate 35%.

[0064] A method of dismantling a flexible optical device

[0065] The method comprises the steps of:

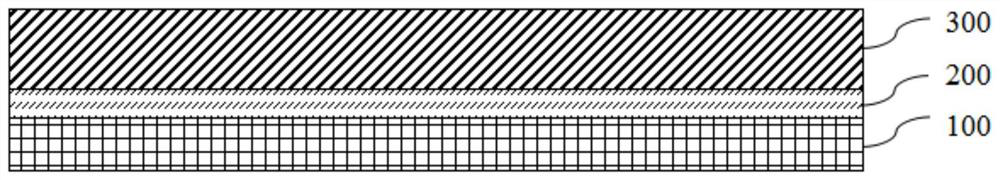

[0066] A flexible optical device is provided, the flexible optical device as attached figure 1 As shown, the flexible optical device includes a detachable substrate support 300, and the OCA optical adhesive layer 200 and the flexible OLED layer 100 are sequentially stacked on the surface of the substrate support 300, and the thickness of the OCA optical adhesive layer is 30 microns;

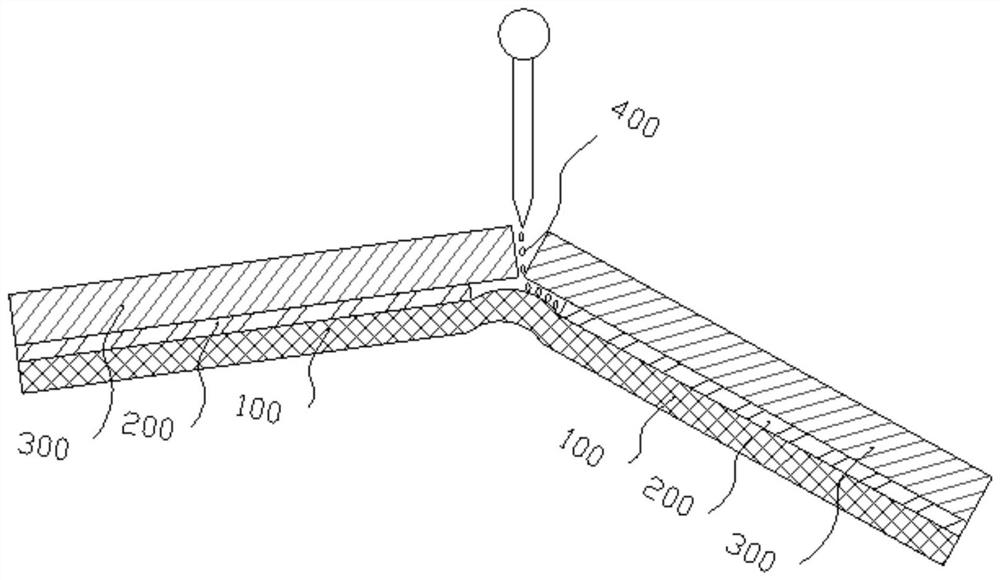

[0067] Bending the flexible optical device, so that the substrate support of the flexible optical device is...

Embodiment 2

[0070] Solvent compositions and applications for dismantling flexible optical devices

[0071] A solvent composition for dismantling flexible optical devices

[0072] Based on the total mass of the solvent composition as 100%, it includes the following components in the following weight percentages:

[0073] Hexane 43%;

[0074] Butanone 25%;

[0075] Butyl acetate 32%.

[0076] A method of dismantling a flexible optical device

[0077] The method comprises the steps of:

[0078] A flexible optical device is provided, the flexible optical device as attached figure 1 As shown, the flexible optical device includes a detachable substrate support 300, and the OCA optical adhesive layer 200 and the flexible OLED layer 100 are sequentially stacked on the surface of the substrate support 300, and the thickness of the OCA optical adhesive layer is 25 microns;

[0079]Bending the flexible optical device, so that the substrate support of the flexible optical device is separate...

Embodiment 3

[0082] Solvent compositions and applications for dismantling flexible optical devices

[0083] A solvent composition for dismantling flexible optical devices

[0084] Based on the total mass of the solvent composition as 100%, it includes the following components in the following weight percentages:

[0085] Pentane 40%;

[0086] Acetone 30%;

[0087] Amyl Acetate 30%.

[0088] A method of dismantling a flexible optical device

[0089] The method comprises the steps of:

[0090] A flexible optical device is provided, the flexible optical device as attached figure 1 As shown, the flexible optical device includes a detachable substrate support 300, and the OCA optical adhesive layer 200 and the flexible OLED layer 100 are sequentially stacked on the surface of the substrate support 300, and the thickness of the OCA optical adhesive layer is 20 microns;

[0091] Bending the flexible optical device, so that the substrate support of the flexible optical device is separate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com